Abstract

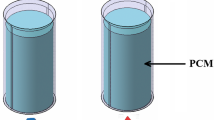

The use of latent heat energy storage can minimize the consumption of conventional fuels. The application of latent heat energy storage using phase-change materials (PCMs) can contribute to domestic energy demand without polluting the environment. This study is planned to provide more information to design latent heat energy storage systems for industrial and domestic applications. The study includes the comparison of the latent heat storage or melting of PCM in concentric and hairpin heat exchangers. The study also includes the effect of PCM type on the melting process. The numerical results obtained show an increase in heat transfer which is achieved by decreasing the diameter and increasing the length of the high-temperature fluid (HTF). The rate and the amount of energy stored are also found to be improved. The melting time is inversely proportional to thermal diffusivity. In this study, the thermal diffusivity is the highest for RT 50 (1.2 × 10–7 m2 s−1); hence, the melting time for RT 50 is the lowest (86 min for Stefan number 0.35). Also, the melting time is directly proportional to viscosity. For RT 35, the viscosity is the highest (0.023 kg m−1. sec), and the rate of melting is the lowest (146 min for Stefan number 0.35). The evaluated energy storage capacity of hairpin and concentric heat exchangers is 455 and 140 W, respectively. Hence, the storage capacity is 3.25 times higher for the hairpin heat exchanger compared to the concentric heat exchanger. On the other hand, phase-change materials with a sizeable latent heat value can store more energy but the rate of energy stored depends on the temperature difference between high-temperature fluid and the initial temperature of phase-change materials. Therefore, an effective energy storage system can be proposed through numerical analysis.

Similar content being viewed by others

Abbreviations

- PCM:

-

Phase-change material

- HEX:

-

Heat exchanger

- LHTES:

-

Latent heat thermal energy storage

- HTF:

-

High-temperature fluid

- C mushy :

-

Mushy zone constant

- SIMPLE:

-

Semi-implicit method for pressure-linked equations

- H :

-

Enthalpy (kJ kg−1)

- β :

-

Thermal expansion coefficient (1/K)

- ρ :

-

Density (kg m−3)

- γ :

-

Liquid fraction

- v :

-

Velocity component in y direction (m s−1)

- T s :

-

Solidus temperature (K)

- T l :

-

Liquids temperature (K)

- T m :

-

Mean melting temperature (K)

- T ref :

-

Reference temperature (K)

- T :

-

Temperature (K)

- \({\Delta T}_{\mathrm{Dr}}\) :

-

Temperature difference between HTF at inlet and initial temperature of PCM

- S :

-

Momentum source (kg m−2 s2)

- k :

-

Thermal conductivity (W m−1 K)

- L :

-

Latent heat of solid/liquid phase-change (kJ kg−1)

- \({\mathrm{L}}_{c}\) :

-

Characteristic length of HEX

- g :

-

Gravitational force (m s−2)

- St:

-

Stefan number

- Grm:

-

Modified Grashof number

References

Chastas P, Theodosiou T, Kontoleon KJ, Bikas D. Normalising and assessing carbon emissions in the building sector: a review on the embodied CO2 emissions of residential buildings. Build Environ. 2018;130:212–26. https://doi.org/10.1016/j.buildenv.2017.12.032.

Alazwari MA, Abu-Hamdeh NH, Khoshaim A, Almitani KH, Karimipour A. Using phase change material as an energy-efficient technique to reduce energy demand in air handling unit integrated with absorption chiller and recovery unit—applicable for high solar-irradiance regions. J Energy Storage. 2021;42:103080. https://doi.org/10.1016/j.est.2021.103080.

Sohani A, et al. Selecting the best nanofluid type for A photovoltaic thermal (PV/T) system based on reliability, efficiency, energy, economic, and environmental criteria. J Taiwan Inst Chem Eng. 2021;124:351–8. https://doi.org/10.1016/j.jtice.2021.02.027.

Farouk N, El-Rahman MA, Sharifpur M, Guo W. Assessment of CO2 emissions associated with HVAC system in buildings equipped with phase change materials. J Build Eng. 2022;51:104236. https://doi.org/10.1016/j.jobe.2022.104236.

Ürge-Vorsatz D, Cabeza LF, Serrano S, Barreneche C, Petrichenko K. Heating and cooling energy trends and drivers in buildings. Renew Sustain Energy Rev. 2015;41:85–98. https://doi.org/10.1016/j.rser.2014.08.039.

Isaac M, van Vuuren DP. Modeling global residential sector energy demand for heating and air conditioning in the context of climate change. Energy Policy. 2009;37(2):507–21. https://doi.org/10.1016/j.enpol.2008.09.051.

Akhtari MR, Shayegh I, Karimi N. Techno-economic assessment and optimization of a hybrid renewable earth—air heat exchanger coupled with electric boiler, hydrogen, wind and PV configurations. Renew Energy. 2020;148:839–51. https://doi.org/10.1016/j.renene.2019.10.169.

Zhao J, Li S. Life cycle cost assessment and multi-criteria decision analysis of environment-friendly building insulation materials—a review. Energy Build. 2022;254:111582. https://doi.org/10.1016/j.enbuild.2021.111582.

Karami R, Kamkari B. Experimental investigation of the effect of perforated fins on thermal performance enhancement of vertical shell and tube latent heat energy storage systems. Energy Convers Manag. 2020;210:112679. https://doi.org/10.1016/j.enconman.2020.112679.

Qu Y, Zhou D, Xue F, Cui L. Multi-factor analysis on thermal comfort and energy saving potential for PCM-integrated buildings in summer. Energy Build. 2021;241:110966. https://doi.org/10.1016/j.enbuild.2021.110966.

Barghi Jahromi MS, Kalantar V, Samimi Akhijahani H, Kargarsharifabad H. Recent progress on solar cabinet dryers for agricultural products equipped with energy storage using phase change materials. J Energy Storage. 2022;51:104434. https://doi.org/10.1016/j.est.2022.104434.

Huang Y, Yang S, Aadmi M, Wang Y, Karkri M, Zhang Z. Numerical analysis on phase change progress and thermal performance of different roofs integrated with phase change material (PCM) in Moroccan semi-arid and Mediterranean climates. Build Simul. 2023;16(1):69–85. https://doi.org/10.1007/s12273-022-0922-z.

Shabgard H, Song L, Zhu W. Heat transfer and exergy analysis of a novel solar-powered integrated heating, cooling, and hot water system with latent heat thermal energy storage. Energy Convers Manag. 2018;175:121–31. https://doi.org/10.1016/j.enconman.2018.08.105.

Cao X, Zhang N, Yuan Y, Luo X. Thermal performance of triplex-tube latent heat storage exchanger: simultaneous heat storage and hot water supply via condensation heat recovery. Renew Energy. 2020;157:616–25. https://doi.org/10.1016/j.renene.2020.05.059.

Solomon J, Kugarajah V, Ganesan P, Dharmalingam S. Enhancing power generation by maintaining operating temperature using phase change material for microbial fuel cell application. J Environ Chem Eng. 2022;10(1):107057. https://doi.org/10.1016/j.jece.2021.107057.

Ghosh D, Ghose J, Kumari P, Paul S, Datta P. Strategies for phase change material application in latent heat thermal energy storage enhancement: Status and prospect. J Energy Storage. 2022. https://doi.org/10.1016/j.est.2022.105179.

Sathishkumar A, Cheralathan M. Influence of thermal transport properties of NEPCM for cool thermal energy storage system. J Therm Anal Calorim. 2022;147(1):367–78. https://doi.org/10.1007/s10973-020-10339-0.

Wang Y, Liu Z, Zhang T, Zhang Z. Preparation and characterization of graphene oxide-grafted hexadecanol composite phase-change material for thermal energy storage. Energy Technol. 2017;5(11):2005–14. https://doi.org/10.1002/ente.201700148.

**e S, et al. Thermally stable phase change material with high latent heat and low cost based on an adipic acid/boric acid binary eutectic system. Energy Technol. 2017;5(8):1322–7. https://doi.org/10.1002/ente.201600650.

Ma G, et al. Preparation and properties of stearic acid-acetanilide eutectic mixture/expanded graphite composite phase-change material for thermal energy storage. Energy Technol. 2018;6(1):153–60. https://doi.org/10.1002/ente.201700352.

Atinafu DG, Ok YS, Kua HW, Kim S. Thermal properties of composite organic phase change materials (PCMs): a critical review on their engineering chemistry. Appl Therm Eng. 2020;181:115960. https://doi.org/10.1016/j.applthermaleng.2020.115960.

Ashagre TB, Rakshit D. Study on flow and heat transfer characteristics of encapsulated phase change material (EPCM) slurry in double-pipe heat exchanger. J Energy Storage. 2022;46:103931. https://doi.org/10.1016/j.est.2021.103931.

Chibani A, et al. A strategy for enhancing heat transfer in phase change material-based latent thermal energy storage unit via nano-oxides addition: a study applied to a shell-and-tube heat exchanger. J Environ Chem Eng. 2021;9(6):106744. https://doi.org/10.1016/j.jece.2021.106744.

Huang X, Zhu C, Lin Y, Fang G. Thermal properties and applications of microencapsulated PCM for thermal energy storage: A review. Appl Therm Eng. 2019;147:841–55. https://doi.org/10.1016/j.applthermaleng.2018.11.007.

Liu H, Wang X, Wu D. Innovative design of microencapsulated phase change materials for thermal energy storage and versatile applications: a review. Sustain Energy Fuels. 2019;3(5):1091–149. https://doi.org/10.1039/C9SE00019D.

Tofani K, Tiari S. Nano-enhanced phase change materials in latent heat thermal energy storage systems: a review. Energies. 2021. https://doi.org/10.3390/en14133821.

Arshad A, Jabbal M, Yan Y, Darkwa J. The micro-/nano-PCMs for thermal energy storage systems: a state of art review. Int J Energy Res. 2019;43(11):5572–620. https://doi.org/10.1002/er.4550.

Jouhara H, Żabnieńska-Góra A, Khordehgah N, Ahmad D, Lipinski T. Latent thermal energy storage technologies and applications: a review. Int J Thermofluids. 2020;5–6:100039. https://doi.org/10.1016/j.ijft.2020.100039.

Qureshi ZA, Ali HM, Khushnood S. Recent advances on thermal conductivity enhancement of phase change materials for energy storage system: a review. Int J Heat Mass Transf. 2018;127:838–56. https://doi.org/10.1016/j.ijheatmasstransfer.2018.08.049.

Fallah Najafabadi M, Talebi Rostami H, Farhadi M. Analysis of a twisted double-pipe heat exchanger with lobed cross-section as a novel heat storage unit for solar collectors using phase-change material. Int Commun Heat Mass Transf. 2021;128:105598. https://doi.org/10.1016/j.icheatmasstransfer.2021.105598.

Ouzzane M, Bady M. Investigation of an innovative Canadian well system combined with a frozen water/PCM heat exchanger for air-cooling in hot climate. Appl Therm Eng. 2022;213:118737. https://doi.org/10.1016/j.applthermaleng.2022.118737.

Shinde TU, Dalvi VH, Mathpati CS, Shenoy N, Panse SV, Joshi JB. Heat transfer investigation of PCM pipe bank thermal storage for space heating application. Chem Eng Process Process Intensif. 2022. https://doi.org/10.1016/j.cep.2022.108791.

Kadivar MR, Moghimi MA, Sapin P, Markides CN. Annulus eccentricity optimisation of a phase-change material (PCM) horizontal double-pipe thermal energy store. J Energy Storage. 2019;26:101030. https://doi.org/10.1016/j.est.2019.101030.

Li H, et al. A comprehensive review of heat transfer enhancement and flow characteristics in the concentric pipe heat exchanger. Powder Technol. 2022;397:117037. https://doi.org/10.1016/j.powtec.2021.117037.

Alaraji A, Alhussein H, Asadi Z, Ganji DD. Investigation of heat energy storage of RT26 organic materials in circular and elliptical heat exchangers in melting and solidification process. Case Stud Therm Eng. 2021;28:101432. https://doi.org/10.1016/j.csite.2021.101432.

Soltani H, Soltani M, Karimi H, Nathwani J. Heat transfer enhancement in latent heat thermal energy storage unit using a combination of fins and rotational mechanisms. Int J Heat Mass Transf. 2021;179:121667. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121667.

Gholaminia V, Rahimi M, Ghaebi H. Heat storage process analysis in a heat exchanger containing phase change materials. J Energy Storage. 2020;32:101875. https://doi.org/10.1016/j.est.2020.101875.

Shahsavar A, Ali HM, Mahani RB, Talebizadehsardari P. Numerical study of melting and solidification in a wavy double-pipe latent heat thermal energy storage system. J Therm Anal Calorim. 2020;141(5):1785–99. https://doi.org/10.1007/s10973-020-09864-9.

Moon H, Miljkovic N, King WP. High power density thermal energy storage using additively manufactured heat exchangers and phase change material. Int J Heat Mass Transf. 2020;153:119591. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119591.

Aljabr A, Chiasson A. Numerical modeling of the effects of the radial and axial location of added micro-encapsulated phase change materials in vertical borehole heat exchangers. Geothermics. 2023;110:102684. https://doi.org/10.1016/j.geothermics.2023.102684.

Chopra K, et al. Thermal and chemical reliability of paraffin wax and its impact on thermal performance and economic analysis of solar water heater. Energy Sustain Dev. 2023;73:39–53. https://doi.org/10.1016/j.esd.2023.01.004.

Choure BK, Alam T, Kumar R. A review on heat transfer enhancement techniques for PCM based thermal energy storage system. J Energy Storage. 2023;72:108161. https://doi.org/10.1016/j.est.2023.108161.

Zhu Y, Yu Y, Qiu Y. Effect of fins with unequal length on the performance of cylindrical latent heat storage system. J Energy Storage. 2021;35:102224. https://doi.org/10.1016/j.est.2020.102224.

Nie C, Liu J, Deng S. Effect of geometric parameter and nanoparticles on PCM melting in a vertical shell-tube system. Appl Therm Eng. 2021;184:116290. https://doi.org/10.1016/j.applthermaleng.2020.116290.

Mozafari M, Lee A, Cheng S. A novel dual-PCM configuration to improve simultaneous energy storage and recovery in triplex-tube heat exchanger. Int J Heat Mass Transf. 2022;186:122420. https://doi.org/10.1016/j.ijheatmasstransfer.2021.122420.

Gorzin M, Hosseini MJ, Rahimi M, Bahrampoury R. Nano-enhancement of phase change material in a shell and multi-PCM-tube heat exchanger. J Energy Storage. 2019;22:88–97. https://doi.org/10.1016/j.est.2018.12.023.

NematpourKeshteli A, Iasiello M, Langella G, Bianco N. Enhancing PCMs thermal conductivity: a comparison among porous metal foams, nanoparticles and finned surfaces in triplex tube heat exchangers. Appl Therm Eng. 2022;212:118623. https://doi.org/10.1016/j.applthermaleng.2022.118623.

Ghosh D, Guha C, Ghose J. Numerical investigation of paraffin wax solidification in spherical and rectangular cavity. Heat Mass Transf und Stoffuebertragung. 2019;55(12):3547–59. https://doi.org/10.1007/s00231-019-02680-4.

Ghosh D, Guha C. Numerical and experimental investigation of paraffin wax melting in spherical cavity. Heat Mass Transf und Stoffuebertragung. 2019;55(5):1427–37. https://doi.org/10.1007/s00231-018-2522-0.

Ghosh D, Guha C. Numerical simulation of paraffin wax melting in a rectangular cavity using CFD. Indian Chem Eng. 2020;62(3):314–28. https://doi.org/10.1080/00194506.2019.1689183.

Ghosh D, Kumar P, Sharma S, Guha C, Ghose J. Numerical investigation on latent heat thermal energy storage in a phase change material using a heat exchanger. Heat Transf. 2021;50(5):4289–308. https://doi.org/10.1002/htj.22075.

Brent AD, Voller VR, Reid KJ. Enthalpy-porosity technique for modeling convection-diffusion phase change: application to the melting of a pure metal. Numer Heat Transf. 1988;13(3):297–318. https://doi.org/10.1080/10407788808913615.

Rahimi M, Ranjbar AA, Ganji DD, Sedighi K, Hosseini MJ, Bahrampoury R. Analysis of geometrical and operational parameters of PCM in a fin and tube heat exchanger. Int Commun Heat Mass Transf. 2014;53:109–15. https://doi.org/10.1016/j.icheatmasstransfer.2014.02.025.

Gorzin M, Hosseini MJ, Ranjbar AA, Bahrampoury R. Investigation of PCM charging for the energy saving of domestic hot water system. Appl Therm Eng. 2018;137:659–68. https://doi.org/10.1016/j.applthermaleng.2018.04.016.

Sathishkumar A, Cheralathan M. “Influence of functionalized graphene nanoplatelets on the phase transition performance of DI water-based NEPCMs for cool thermal storage systems”, Energy Sources. Part A Recover Util Environ Eff. 2023;45(1):1187–203. https://doi.org/10.1080/15567036.2021.2007312.

Peng B, Qiu M, Xu N, Zhou Y, Sheng W, Su F. Optimum orthogonally structured fins in charging enhancement of phase change materials (PCMs): PCMs’ thermophysical properties effects. Int J Therm Sci. 2023;184:108005. https://doi.org/10.1016/j.ijthermalsci.2022.108005.

Peng B, et al. Impacts of the thermophysical properties of the phase change materials (PCMs) on the melting performance and optimum dimensions of fins. Comput Chem Eng. 2022;165:107929. https://doi.org/10.1016/j.compchemeng.2022.107929.

Narasimha Siva Teja P, Gugulothu SK, Dinesh Sankar Reddy P, Deepanraj B, Syam Sundar L. Computational investigation of the influencing parameters on the melting of phase change material in a square enclosure with built in fin and Al2O3 nanoparticles. Appl Therm Eng. 2023;232:120942. https://doi.org/10.1016/j.applthermaleng.2023.120942.

Acknowledgements

The authors are grateful for the financial support of the Science and Engineering Research Board (SERB) of India (file No. SPG/2021/004530).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumari, P., Ghosh, D. A comparative numerical analysis of concentric and hairpin heat exchanger for efficient energy storage using phase-change material. J Therm Anal Calorim 148, 12211–12224 (2023). https://doi.org/10.1007/s10973-023-12501-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12501-w