Abstract

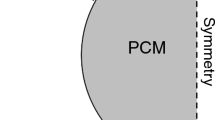

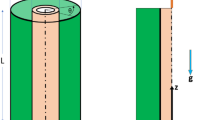

The objective of this paper is to develop the influences of channel waviness on the performance of a latent heat storage system during phase change mechanism. The heat exchanger is a vertically oriented double pipe where the heat transfers to/from the PCM in the annulus by moving the water in the inner tube. Various wavelengths, as well as wave amplitudes, are examined at various fluid Re and water temperatures (Tin) to find the effects of channel waviness on different aspects of melting/solidification time, pressure drop, pum** power and exchanged heat rate. Increasing Re, Tin and amplitude of wavy wall improves the system performance during melting and solidification mechanisms. Besides, it is found that there is an optimum dimensionless wavelength of 0.2 for achieving the minimum melting and solidification times as a result of maximum heat exchanged between the water and PCM. Furthermore, the waviness has an almost negligible effect on the pum** power which is reduced for the dimensionless wavelengths higher than 2.0. In the best scenario, the required time to melt and solidify the PCM reduces by almost 28.6% and 57.63%, respectively, using wavy channels compared with the smooth wall case.

Similar content being viewed by others

Abbreviations

- \( a_{\text{w}} \)/m:

-

Wave amplitude

- \( A_{\text{m}} \) :

-

Mushy zone constant

- \( C_{\text{p}} \)/J kg−1 K−1 :

-

Specific heat transfer coefficient

- g/m s−2 :

-

Gravity

- \( k \)/W m−1 K−1 :

-

Thermal conductivity

- \( L_{\text{w}} \)/m:

-

Wave-length

- \( L_{\text{f}} \)/J kg−1 :

-

Latent heat of fusion

- m/kg:

-

PCM mass

- P/Pa:

-

Pressure

- \( t_{\text{m}} \)/s:

-

Melting/solidification time

- T/K:

-

Temperature

- \( T_{\text{i}} \)/K:

-

Inlet temperature

- \( T_{\text{m}} \)/K:

-

Melting temperature

- \( T_{\text{e}} \)/K:

-

End temperature

- \( \vec{V} \)/m s−1 :

-

Velocity

- /m s−1 :

-

Velocity in x-direction

- \( v \)/m s−1 :

-

Velocity in y-direction

- \( \beta \)/K−1 :

-

Expansion coefficient

- \( \lambda \) :

-

Liquid fraction

- \( \mu \)/kg m−1 s−1 :

-

Viscosity

- \( \rho \)/kg m−3 :

-

PCM density

- \( \Delta H \)/J kg−1 :

-

PCM latent heat

References

Palomba V, Brancato V, Palomba G, Borsacchi S, Forte C, Freni A, et al. Latent thermal storage for solar cooling applications: materials characterization and numerical optimization of finned storage configurations. Heat Transf Eng. 2019;40(12):1033–48. https://doi.org/10.1080/01457632.2018.1451236.

Sardari PT, Babaei-Mahani R, Giddings D, Yasseri S, Moghimi M, Bahai H. Energy recovery from domestic radiators using a compact composite metal Foam/PCM latent heat storage. J Clean Prod. 2020;257:120504.

Li ZX, Al-Rashed AAAA, Rostamzadeh M, Kalbasi R, Shahsavar A, Afrand M. Heat transfer reduction in buildings by embedding phase change material in multi-layer walls: effects of repositioning, thermophysical properties and thickness of PCM. Energy Convers Manag. 2019;195:43–56. https://doi.org/10.1016/j.enconman.2019.04.075.

Ren N, Wu Y-T, Wang T, Ma C-F. Experimental study on optimized composition of mixed carbonate for phase change thermal storage in solar thermal power plant. J Therm Anal Calorim. 2011;104(3):1201–8. https://doi.org/10.1007/s10973-011-1364-5.

Siavashi M, Rasam H, Izadi A. Similarity solution of air and nanofluid im**ement cooling of a cylindrical porous heat sink. J Therm Anal Calorim. 2019;135(2):1399–415. https://doi.org/10.1007/s10973-018-7540-0.

Zhou D, Zhao CY, Tian Y. Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl Energy. 2012;92:593–605. https://doi.org/10.1016/j.apenergy.2011.08.025.

Merlin K, Delaunay D, Soto J, Traonvouez L. Heat transfer enhancement in latent heat thermal storage systems: comparative study of different solutions and thermal contact investigation between the exchanger and the PCM. Appl Energy. 2016;166:107–16. https://doi.org/10.1016/j.apenergy.2016.01.012.

Esapour M, Hosseini MJ, Ranjbar AA, Bahrampoury R. Numerical study on geometrical specifications and operational parameters of multi-tube heat storage systems. Appl Therm Eng. 2016;109:351–63. https://doi.org/10.1016/j.applthermaleng.2016.08.083.

Arshad A, Ali HM, Khushnood S, Jabbal M. Experimental investigation of PCM based round pin-fin heat sinks for thermal management of electronics: effect of pin-fin diameter. Int J Heat Mass Transf. 2018;117:861–72. https://doi.org/10.1016/j.ijheatmasstransfer.2017.10.008.

Tiari S, Qiu S, Mahdavi M. Numerical study of finned heat pipe-assisted thermal energy storage system with high temperature phase change material. Energy Convers Manag. 2015;89:833–42. https://doi.org/10.1016/j.enconman.2014.10.053.

Ghalambaz M, Mehryan S, Hajjar A, Veisimoradi A. Unsteady natural convection flow of a suspension comprising nano-encapsulated phase change materials (NEPCMs) in a porous medium. Adv Powder Technol. 2019;31(3):954–66. https://doi.org/10.1016/j.apt.2019.12.010.

Ali HM, Arshad W. Thermal performance investigation of staggered and inline pin fin heat sinks using water based rutile and anatase TiO2 nanofluids. Energy Convers Manag. 2015;106:793–803. https://doi.org/10.1016/j.enconman.2015.10.015.

Jegadheeswaran S, Sundaramahalingam A, Pohekar SD. High-conductivity nanomaterials for enhancing thermal performance of latent heat thermal energy storage systems. J Therm Anal Calorim. 2019;138(2):1137–66. https://doi.org/10.1007/s10973-019-08297-3.

Tiari S, Mahdavi M. Computational study of a latent heat thermal energy storage system enhanced by highly conductive metal foams and heat pipes. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09357-9.

Tiari S, Qiu S. Three-dimensional simulation of high temperature latent heat thermal energy storage system assisted by finned heat pipes. Energy Convers Manag. 2015;105:260–71. https://doi.org/10.1016/j.enconman.2015.08.004.

Talebizadeh Sardari P, Walker GS, Gillott M, Grant D, Giddings D. Numerical modelling of phase change material melting process embedded in porous media: effect of heat storage size. Proc Inst Mech Eng A J Power Energy. 2019:0957650919862974.

Buonomo B, Ercole D, Manca O, Nardini S. Numerical analysis on a latent thermal energy storage system with phase change materials and aluminum foam. Heat Transf Eng. 2019. https://doi.org/10.1080/01457632.2019.1600875.

Heyhat MM, Mousavi S, Siavashi M. Battery thermal management with thermal energy storage composites of PCM, metal foam, fin and nanoparticle. J Energy Storage. 2020;28:101235. https://doi.org/10.1016/j.est.2020.101235.

Mousavi S, Siavashi M, Heyhat MM. Numerical melting performance analysis of a cylindrical thermal energy storage unit using nano-enhanced PCM and multiple horizontal fins. Numer Heat Transf A Appl. 2019;75(8):560–77. https://doi.org/10.1080/10407782.2019.1606634.

Guo C, Zhang W. Numerical simulation and parametric study on new type of high temperature latent heat thermal energy storage system. Energy Convers Manag. 2008;49(5):919–27. https://doi.org/10.1016/j.enconman.2007.10.025.

Al-abidi AA, Bin Mat S, Sopian K, Sulaiman MY, Mohammed AT. CFD applications for latent heat thermal energy storage: a review. Renew Sustain Energy Rev. 2013;20:353–63. https://doi.org/10.1016/j.rser.2012.11.079.

Mahdi JM, Mohammed HI, Hashim ET, Talebizadehsardari P, Nsofor EC. Solidification enhancement with multiple PCMs, cascaded metal foam and nanoparticles in the shell-and-tube energy storage system. Appl Energy. 2020;257:113993.

Mahdi MS, Mahood HB, Campbell AN, Khadom AA. Experimental study on the melting behavior of a phase change material in a conical coil latent heat thermal energy storage unit. Appl Therm Eng. 2019. https://doi.org/10.1016/j.applthermaleng.2019.114684.

Fornarelli F, Camporeale SM, Fortunato B. Convective effects in a latent heat thermal energy storage. Heat Transf Eng. 2019. https://doi.org/10.1080/01457632.2019.1685240.

Pizzolato A, Sharma A, Ge R, Maute K, Verda V, Sciacovelli A. Maximization of performance in multi-tube latent heat storage: optimization of fins topology, effect of materials selection and flow arrangements. Energy. 2019. https://doi.org/10.1016/j.energy.2019.02.155.

Shah RK, Sekulic DP. Fundamentals of heat exchanger design. Hoboken: Wiley; 2003.

Wang Q, Zeng M, Ma T, Du X, Yang J. Recent development and application of several high-efficiency surface heat exchangers for energy conversion and utilization. Appl Energy. 2014;135:748–77. https://doi.org/10.1016/j.apenergy.2014.05.004.

Lotfi B, Sundén B, Wang Q. An investigation of the thermo-hydraulic performance of the smooth wavy fin-and-elliptical tube heat exchangers utilizing new type vortex generators. Appl Energy. 2016;162:1282–302. https://doi.org/10.1016/j.apenergy.2015.07.065.

Shahsavar A, Khosravi J, Mohammed HI, Talebizadehsardari P. Performance evaluation of melting/solidification mechanism in a variable wave-length wavy channel double-tube latent heat storage system. J Energy Storage. 2020;27:101063.

Zhang J, Kundu J, Manglik RM. Effect of fin waviness and spacing on the lateral vortex structure and laminar heat transfer in wavy-plate-fin cores. Int J Heat Mass Transf. 2004;47(8):1719–30. https://doi.org/10.1016/j.ijheatmasstransfer.2003.10.006.

Elshafei EAM, Awad MM, El-Negiry E, Ali AG. Heat transfer and pressure drop in corrugated channels. Energy. 2010;35(1):101–10. https://doi.org/10.1016/j.energy.2009.08.031.

Dong J, Chen J, Zhang W, Hu J. Experimental and numerical investigation of thermal -hydraulic performance in wavy fin-and-flat tube heat exchangers. Appl Therm Eng. 2010;30(11):1377–86. https://doi.org/10.1016/j.applthermaleng.2010.02.027.

Anvari AR, Javaherdeh K. Experimental investigation of newtonian and non-newtonian liquid flow in wavy and straight mini-channel cross-flow plate heat exchangers. Strojniski Vestnik-J Mech Eng. 2019;65(1):41–9.

Kashani S, Ranjbar A, Abdollahzadeh M, Sebti S. Solidification of nano-enhanced phase change material (NEPCM) in a wavy cavity. Heat Mass Transf. 2012;48(7):1155–66.

Abdollahzadeh M, Esmaeilpour M. Enhancement of phase change material (PCM) based latent heat storage system with nano fluid and wavy surface. Int J Heat Mass Transf. 2015;80:376–85.

Shahsavar A, Goodarzi A, Mohammed HI, Shirneshan A, Talebizadehsardari P. Thermal performance evaluation of non-uniform fin array in a finned double-pipe latent heat storage system. Energy. 2020;193:116800. https://doi.org/10.1016/j.energy.2019.116800.

Ghalambaz M, Zhang J. Conjugate solid-liquid phase change heat transfer in heatsink filled with phase change material-metal foam. Int J Heat Mass Transf. 2020;146:118832. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118832.

Ye W-B, Zhu D-S, Wang N. Numerical simulation on phase-change thermal storage/release in a plate-fin unit. Appl Therm Eng. 2011;31(17):3871–84. https://doi.org/10.1016/j.applthermaleng.2011.07.035.

Assis E, Katsman L, Ziskind G, Letan R. Numerical and experimental study of melting in a spherical shell. Int J Heat Mass Transf. 2007;50(9):1790–804. https://doi.org/10.1016/j.ijheatmasstransfer.2006.10.007.

Voile V, Prakash C. A fixed grid numerical modeling methodology for convection diffusion mushy region phase-change problem. Int J Heat Mass Transf. 1987;30(9):1709–19.

Ghalambaz M, Roşca Natalia C, Roşca Alin V, Pop I. Mixed convection and stability analysis of stagnation-point boundary layer flow and heat transfer of hybrid nanofluids over a vertical plate. Int J Numer Methods Heat Fluid Flow. 2019;. https://doi.org/10.1108/HFF-08-2019-0661.

Esapour M, Hosseini MJ, Ranjbar AA, Pahamli Y, Bahrampoury R. Phase change in multi-tube heat exchangers. Renew Energy. 2016;85:1017–25. https://doi.org/10.1016/j.renene.2015.07.063.

Mat S, Al-Abidi AA, Sopian K, Sulaiman MY, Mohammad AT. Enhance heat transfer for PCM melting in triplex tube with internal–external fins. Energy Convers Manag. 2013;74:223–36. https://doi.org/10.1016/j.enconman.2013.05.003.

Pourrahmani H, Moghimi M, Siavashi M, Shirbani M. Sensitivity analysis and performance evaluation of the PEMFC using wave-like porous ribs. Appl Therm Eng. 2019;150:433–44. https://doi.org/10.1016/j.applthermaleng.2019.01.010.

Norouzi AM, Siavashi M, Khaliji Oskouei M. Efficiency enhancement of the parabolic trough solar collector using the rotating absorber tube and nanoparticles. Renew Energy. 2020;145:569–84. https://doi.org/10.1016/j.renene.2019.06.027.

Izadi A, Siavashi M, **ement jet hydrogen, air and CuH2O nanofluid cooling of a hot surface covered by porous media with non-uniform input jet velocity. Int J Hydrog Energy. 2019;44(30):15933–48. https://doi.org/10.1016/j.ijhydene.2018.12.176.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shahsavar, A., Ali, H.M., Mahani, R. et al. Numerical study of melting and solidification in a wavy double-pipe latent heat thermal energy storage system. J Therm Anal Calorim 141, 1785–1799 (2020). https://doi.org/10.1007/s10973-020-09864-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09864-9