Abstract

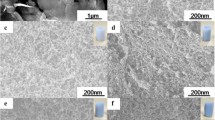

Silica aerogel is a unique nanomaterial with three-dimensional nano-porous networks. However, the microstructures of aerogels are easily damaged at high temperatures environment, weakening the thermal insulation performance. In this work, we prepared thermally stable SiOC nanospheres and then composited them with aerogel matrix. SiOC nanospheres and aerogel matrix have excellent compatibility. SiOC nanospheres can induce the aerogel matrix forming island microstructures after drying process. The presence of the island microstructure leads to a reduce of the inter-skeleton macropore size, which declines from 4.77 μm to 2 μm. The thermal conductivity decreases from 0.0813 to 0.0646 W/ (m K). The volume shrinkage and density also show a clear downward trend. In order to investigate the impact of high-temperature to thermal insulation performance, the aerogel composites are experienced different high-temperature treatment. The results demonstrate that the island microstructure of aerogel is transformed into a spherical shape after high-temperature treatment. The particle diameter increases from 5 μm to 5.7 μm when treated in 200 °C and 400 °C. Upon 400 °C, the diameter reduces from 5.7 μm to 4.4 μm at 800 °C. The variety in the size of the aerogel skeleton particles results in a reduction in the pore diameters of the interskeleton pores from 8 to 3.8 μm. The thermal conductivity decreases from 0.0667 to 0.0466 W/ (m K) treating below 400 °C and increases to 0.0712 W/ (m K), when heat treatment temperature is 800 °C. The enhancement of thermal insulation performance is attributed to the decline of macropores content between skeletons caused by swelling of aerogel particles. The diameters of macropores between skeletons reduce, which can effectively weaken the influence of gaseous heat transfer. This work provides a reference for the preparation of aerogel composites that can maintain excellent thermal insulation properties in high-temperature environment.

Graphical Abstract

Highlight

-

Excellent compatibility of SiOC nanospheres with silica aerogel matrices.

-

The addition of SiOC nanospheres leads to a decrease in the pore size of the macropores between skeletons.

-

High-temperature treatment can reduce the pore size of the skeleton macropores, which is conducive to reducing thermal conductivity.

Similar content being viewed by others

References

Fang Y, Chen S, Luo X, Wang C, Yang R, Zhang Q, Huang C, Shao T (2016) Synthesis and characterization of cellulose triacetate aerogels with ultralow densities. RSC Adv 6(59):54054–54059. https://doi.org/10.1039/c6ra06067f.

Yu Y, Li L, Huang Y, Huang L, Zhang S. (2022) Preparation and properties of low-density and high-temperature resistant yttrium doped silica aerogels. J Non-Crystall Solids 590. https://doi.org/10.1016/j.jnoncrysol.2022.121572.

Gupta P, Singh B, Agrawal AK, Maji PK (2018) Low density and high strength nanofibrillated cellulose aerogel for thermal insulation application. Mater Des 158:224–236. https://doi.org/10.1016/j.matdes.2018.08.031.

Hu K, Szkopek T, Cerruti M (2017) Tuning the aggregation of graphene oxide dispersions to synthesize elastic, low density graphene aerogels. J Mater Chem A 5(44):23123–23130. https://doi.org/10.1039/c7ta07006c.

Cao J, Wang P, Cai H, Niu B, Zhang Y, Long D (2023) Lightweight nitrogen-doped phenolic aerogels with flame-retardant and thermal-insulation properties. ACS Appl Polym Mater 5(12):10276–10288. https://doi.org/10.1021/acsapm.3c02040.

Wang H, Cao M, Zhao HB, Liu JX, Geng CZ, Wang YZ. (2020) Double-cross-linked aerogels towards ultrahigh mechanical properties and thermal insulation at extreme environment. Chem Eng J 399. https://doi.org/10.1016/j.cej.2020.125698.

Liang C, Wang Z (2019) Eggplant-derived SiC aerogels with high-performance electromagnetic wave absorption and thermal insulation properties. Chem Eng J 373:598–605. https://doi.org/10.1016/j.cej.2019.05.076.

**ong S, Yang Y, Zhang S, **ao Y, Ji H, Yang Z, Ding F (2021) Nanoporous polybenzoxazine aerogels for thermally insulating and self-extinguishing materials in aerospace applications. ACS Appl Nano Mater 4(7):7280–7288. https://doi.org/10.1021/acsanm.1c01253.

** S, Wang Y, Zhang X, Cao K, Su J, Shen J, Wang X. (2023) Fire-resistant polyimide-silica aerogel composite aerogels with low shrinkage, low density and high hydrophobicity for aerospace applications. Polymer Testing 129. https://doi.org/10.1016/j.polymertesting.2023.108259.

Randall JP, Meador MA, Jana SC (2011) Tailoring mechanical properties of aerogels for aerospace applications. ACS Appl Mater Interfaces 3(3):613–626. https://doi.org/10.1021/am200007n.

Yan Z, Ding Y, Huang M, Li J, Han Q, Yang M, Li W (2023) MXene/CNTs/Aramid aerogels for electromagnetic interference shielding and joule heating. ACS Appl Nano Mater 6(7):6141–6150. https://doi.org/10.1021/acsanm.3c00249.

Zhu E, Pang K, Chen Y, Liu S, Liu X, Xu Z, Liu Y, Gao C (2022) Ultra-stable graphene aerogels for electromagnetic interference shielding. Sci China Mater 66(3):1106–1113. https://doi.org/10.1007/s40843-022-2208-x.

Wang Y-Y, Zhang F, Li N, Shi J-F, Jia L-C, Yan D-X, Li Z-M (2023) Carbon-based aerogels and foams for electromagnetic interference shielding: a review. Carbon 205:10–26. https://doi.org/10.1016/j.carbon.2023.01.007.

Joshi DN, Kim D (2023) NaBr-impregnated graphene aerogel for ammonia-based adsorption heat pump application. ACS Mater Lett 5(7):1886–1891. https://doi.org/10.1021/acsmaterialslett.3c00374.

Liu Y, Tang P, Zhu Y, **e W, Yang P, Zhang Z, Liu B. (2021) Green aerogel adsorbent for removal of organic compounds in shale gas wastewater: High-performance tuning and adsorption mechanism. Chem Eng J 416. https://doi.org/10.1016/j.cej.2021.129100.

Pan F, Zhang B, Ding Y, Wang L, **e F, Cai W, Liu S, Zhou J (2018) New composite aerogel-like adsorbents for thiophene based on π-complexation. Sep Purif Technol 192:46–54. https://doi.org/10.1016/j.seppur.2017.09.073.

Yang MY, Tang GH, Sheng Q, Guo L, Zhang H. (2022) Atomic-level sintering mechanism of silica aerogels at high temperatures: structure evolution and solid thermal conductivity. Int J Heat Mass Transfer 199. https://doi.org/10.1016/j.ijheatmasstransfer.2022.123456.

Cai H, Jiang Y, Feng J, Chen Q, Zhang S, Li L, Feng J (2020) Nanostructure evolution of silica aerogels under rapid heating from 600 °C to 1300 °C via in-situ TEM observation. Ceram Int 46(8):12489–12498. https://doi.org/10.1016/j.ceramint.2020.02.011.

Cai H, Jiang Y, Feng J, Zhang S, Peng F, **ao Y, Li L, Feng J. (2020) Preparation of silica aerogels with high temperature resistance and low thermal conductivity by monodispersed silica sol. Mater Des 191. https://doi.org/10.1016/j.matdes.2020.108640.

Huang D, Guo C, Zhang M, Shi L (2017) Characteristics of nanoporous silica aerogel under high temperature from 950 °C to 1200 °C. Mater Des 129:82–90. https://doi.org/10.1016/j.matdes.2017.05.024.

Zhang W, Ding E, Zhang W, Li J, Luo C, Zhang L (2023) Microstructure controllable polyimide/MXene composite aerogels for high-temperature thermal insulation and microwave absorption. J Mater Chem C 11(28):9438–9448. https://doi.org/10.1039/d3tc01210g.

Song M, Jiang J, Qin H, Ren X, Jiang F (2020) Flexible and super thermal insulating cellulose nanofibril/emulsion composite aerogel with quasi-closed pores. ACS Appl Mater Interfaces 12(40):45363–45372. https://doi.org/10.1021/acsami.0c14091.

Okafor PE, Tang G (2023) Study of effective thermal conductivity of a novel SiO2 aerogel composite for high-temperature thermal insulation. Int J Heat Mass Transfer 212. https://doi.org/10.1016/j.ijheatmasstransfer.2023.124242.

Liu H, Zhao X (2022) Thermal conductivity analysis of high porosity structures with open and closed pores. Int J Heat Mass Transfer 183. https://doi.org/10.1016/j.ijheatmasstransfer.2021.122089.

Merillas B, Gómez Álvarez-Arenas TE, Villafañe F, Rodríguez-Pérez MÁ (2023) Reaching a near zero radiative heat transfer by the inclusion of modified multiwalled-carbon nanotubes (MWCNTs) in polyurethane-polyisocyanurate aerogels. Mater Today Chem 34. https://doi.org/10.1016/j.mtchem.2023.101789.

Lamy-Mendes A, Malfait WJ, Sadeghpour A, Girão AV, Silva RF, Durães L (2021) Influence of 1D and 2D carbon nanostructures in silica-based aerogels. Carbon 180:146–162. https://doi.org/10.1016/j.carbon.2021.05.004.

Fricke RCAJ (1986) Infrared radiative heat transfer in highly transparent silica aerogel. Solar Energy 36. https://doi.org/10.1016/0038-092X(86)90153-2.

Zhao X, Brozena AH, Hu L (2021) Critical roles of pores and moisture in sustainable nanocellulose-based super-thermal insulators. Matter 4(3):769–772. https://doi.org/10.1016/j.matt.2021.02.002.

Wang F, Mao J (2021) Aerogel constructed by ultrasmall mn-doped silica nanoparticles for superior lithium-ion storage. ACS Appl Mater Interfaces 13(24):28181–28187. https://doi.org/10.1021/acsami.1c05620.

Kim G-P, Lee M, Lee YJ, Bae S, Song HD, Song IK, Yi J (2016) Polymer-mediated synthesis of a nitrogen-doped carbon aerogel with highly dispersed Pt nanoparticles for enhanced electrocatalytic activity. Electrochim Acta 193:137–144. https://doi.org/10.1016/j.electacta.2016.02.064.

Zhao X, Zhang J, Wang X, Zhang J, Liu B, Yi X (2019) Polyimide aerogels crosslinked with MWCNT for enhanced visible-light photocatalytic activity. Appl Surf Sci 478:266–274. https://doi.org/10.1016/j.apsusc.2019.01.209.

Afroze JD, Tong L, Abden MJ, Yuan Z, Chen Y (2021) Hierarchical honeycomb graphene aerogels reinforced by carbon nanotubes with multifunctional mechanical and electrical properties. Carbon 175:312–321. https://doi.org/10.1016/j.carbon.2021.01.002.

Jaxel J, Markevicius G, Rigacci A, Budtova T (2017) Thermal superinsulating silica aerogels reinforced with short man-made cellulose fibers. Compos Part A Appl Sci Manuf 103:113–121. https://doi.org/10.1016/j.compositesa.2017.09.018.

Mazrouei-Sebdani Z, Naeimirad M, Peterek S, Begum H, Galmarini S, Pursche F, Baskin E, Zhao S, Gries T, Malfait WJ. (2022) Multiple assembly strategies for silica aerogel-fiber combinations – A review. Mater Des 223. https://doi.org/10.1016/j.matdes.2022.111228.

Yi Z, Zhang X, Yan L, Huyan X, Zhang T, Liu S, Guo A, Liu J, Hou F (2022) Super-insulated, flexible, and high resilient mullite fiber reinforced silica aerogel composites by interfacial modification with nanoscale mullite whisker. Compos Part B Eng 2022, 230. https://doi.org/10.1016/j.compositesb.2021.109549.

Peng F, Jiang Y, Feng J, Cai H, Feng J, Li L (2021) Thermally insulating, fiber-reinforced alumina–silica aerogel composites with ultra-low shrinkage up to 1500 °C. Chem Eng J 411. https://doi.org/10.1016/j.cej.2021.128402.

Li Z, Gong L, Cheng X, He S, Li C, Zhang H (2016) Flexible silica aerogel composites strengthened with aramid fibers and their thermal behavior. Mater Des 99:349–355. https://doi.org/10.1016/j.matdes.2016.03.063.

He J, Shen Y, Evans DG (2008) A nanocomposite structure based on modified MCM-48 and polystyrene. Microporous Mesoporous Mater 109(1-3):73–83. https://doi.org/10.1016/j.micromeso.2007.04.051.

Gong S, Lei Y, Li X, Li J, Jiang Z, He Y, Li Y, Sun Z, Song H, Chen X (2024) New strategy to further enhance the thermal insulation performance of silica aerogel: Decline the macropore content between skeletons. J Non-Crystalline Solids 631. https://doi.org/10.1016/j.jnoncrysol.2024.122915.

Horvat G, Pantić M, Knez Ž, Novak Z (2022). A brief evaluation of pore structure determination for bioaerogels. Gels 8 (7). https://doi.org/10.3390/gels8070438.

Merillas B, Villafañe F, Rodríguez-Pérez MÁ (2022) Super-insulating transparent polyisocyanurate-polyurethane aerogels: analysis of thermal conductivity and mechanical properties. Nanomaterials 12 (14). https://doi.org/10.3390/nano12142409.

Dong B, Han Y, Wang T, Lei Z, Chen Y, Wang F, Abadikhah H, Khan SA, Hao L, Xu X et al. (2020) Hard SiOC microbeads as a high-performance lithium-ion battery anode. ACS Appl Energy Mater 3(10):10183–10191. https://doi.org/10.1021/acsaem.0c01910.

Zhao Z, Cui Y, Kong Y, Ren J, Jiang X, Yan W, Li M, Tang J, Liu X, Shen X (2021) Thermal and mechanical performances of the superflexible, hydrophobic, silica-based aerogel for thermal insulation at ultralow temperature. ACS Appl Mater Interfaces 13(18):21286–21298. https://doi.org/10.1021/acsami.1c02910.

Fortuniak W, Pospiech P, Mizerska U, Chojnowski J, Slomkowski S, Nyczyk-Malinowska A, Wojteczko A, Wisla-Walsh E, Hasik M (2018) Generation of meso- and microporous structures by pyrolysis of polysiloxane microspheres and by HF etching of SiOC microspheres. Ceram Int 44(1):374–383. https://doi.org/10.1016/j.ceramint.2017.09.184.

**a K, Li C, Zhang H, Zhao S, Li W, Han F, Li Y, Liu X (2023) The structure evolution of hollow SiOC ceramic microspheres prepared with solvothermal method. Ceram Int 49(3):4082–4090. https://doi.org/10.1016/j.ceramint.2022.09.133.

Tang X, Sun A, Chu C, Yu M, Ma S, Cheng Y, Guo J, Xu G (2017) A novel silica nanowire-silica composite aerogels dried at ambient pressure. Mater Des 115:415–421. https://doi.org/10.1016/j.matdes.2016.11.080.

Fricke J, Lu X, Wang P, Buttner D, Heinemann U (1992) Optimization of monolithic silica aerogel insulants. Int J Heat Mass Transf 35:2305–2309. https://doi.org/10.1016/0017-9310(92)90073-2.

**ng S, Ji Q, Jiao X, Chen D (2023) A two-step route to SiO2 nanofiber-reinforced aerogel composites with lightweight and high temperature resistance for thermal insulation. ACS Appl Nano Mater 6(11):9939–9948. https://doi.org/10.1021/acsanm.3c01940.

Liu Y, Zhao Z, Kong Y, Chu C, Tang J, Ren J, Shen X (2022) Facile preparation of nano-SiO2 composites with excellent high-temperature thermal insulation performance. Ceram Int 48(19):27486–27492. https://doi.org/10.1016/j.ceramint.2022.06.041.

Wu Q, Yang L, Chen Z, Yin L, Yang M, Liu T, Li M, Cui S (2023) A flexible silica aerogel paper with temperature-switch opacifier for thermal insulation. J Mater Res Technol 24:4037–4046. https://doi.org/10.1016/j.jmrt.2023.04.022.

Zhang J-X, Zhang J, Ye X-L, Ma X-M, Liu R, Sun Q-L, Zhou Y-L (2023) Ultralight and compressive SiC nanowires aerogel for high-temperature thermal insulation. Rare Met 42(10):3354–3363. https://doi.org/10.1007/s12598-023-02370-5.

Li J, Ahmad Z, Chen J, Chen H, Tao J (2024) Fabrication of SiC nanofiber aerogel felt with high-temperature thermal insulation performance. J Eur Ceram Soc 44(4):1923–1931. https://doi.org/10.1016/j.jeurceramsoc.2023.11.008.

Acknowledgements

This work was financially supported by the Bridge Aerogel Materials Foundation (H2022064).

Author information

Authors and Affiliations

Contributions

Shengxin Gong: Writing – original draft, Investigation, Data curation, Methodology, Formal analysis. Ziyu Sun: Investigation, Data curation, Methodology, Formal analysis, Software. Huaihe Song: Conceptualization, Formal analysis. **aohong Chen: Writing – review & editing, Data curation, Conceptualization.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gong, S., Sun, Z., Song, H. et al. SiOC nanospheres reinforced silica aerogel with excellent compatibility and excellent thermal insulation under high temperature conditions. J Sol-Gel Sci Technol 110, 875–886 (2024). https://doi.org/10.1007/s10971-024-06417-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-024-06417-6