Abstract

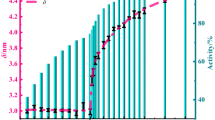

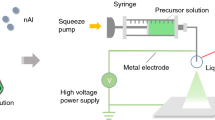

Aluminum (Al) fluoropolymer composites are widely used in the field of energetic materials. At present, it is a research hotspot to improve the agglomeration of nano-aluminum powder in fluoropolymer and make micro-nano-Al/fluorine rubber (F2601) composites. In this study, it was the first step to modify the surface of nano-aluminum (n-Al) powders, and then Al/F2601 composite microspheres were prepared by Pickering emulsion. The effects of oil–water ratio, solid content and fluorine–aluminum ratio on the stability of the emulsion were investigated. Al/F2601 microspheres with particle sizes of about ≤ 50 μm and different surface pores were prepared by controlling various conditions, which appeared the thermal decomposition peak between 485.5 °C and 524.9 °C. The combustion process of samples in the air was recorded by a high-speed camera, the composites with different F2601 contents burn stably and show a clear pattern of combustion velocity, and the maximum linear combustion velocity is up to 30.7 cm s−1.

Similar content being viewed by others

Data availability

A DOI to an electronic repository.

Code availability

A DOI to an electronic repository.

References

Sun WZ, Li YN, Li WK, Han ZW (2021) Preparation of n-Al@PVDF composites by electrospray method and study on its combustion properties. Chin J Explos Propellants 44:856–864. https://doi.org/10.14077/j.issn.1007-7812.202104025

He W, Lyu JY, Tang DY, He GQ, Liu PJ, Yan QL (2020) Control the combustion behavior of solid propellants by using core-shell Al-based composites. Combust Flame 221:441–452. https://doi.org/10.1016/j.combustflame.2020.07.006

Lyu JY, Yu JH, Tang DY, He W, Tao BW, Guo X, Yan QL (2020) Unexpected burning rate independence of composite propellants on the pressure by fine interfacial control of fuel/oxidizer. Chem Eng J 388:124320. https://doi.org/10.1016/j.cej.2020.124320

Zhang K, Rossi C, Alphonse P, Tenailleau C, Cayez S, Chane-Ching JY (2009) Integrating Al with NiO nano honeycomb to realize an energetic material on silicon substrate. Appl Phys A 94:957–962. https://doi.org/10.1007/s00339-008-4875-6

Tarver CM (2010) High energy materials, propellants, explosives and pyrotechnics, propellants explos. Pyrotech 35:494–494. https://doi.org/10.1002/prep.201000098

Ji J, Liang L, Xu H, **ang GF, Li HZ, Li PY, Zhou X, Guo XD (2022) Facile solvent evaporation synthesis of core-shell structured Al@ PVDF nanoparticles with excellent corrosion resistance and combustion properties. Combust Flame 238:111925. https://doi.org/10.1016/j.combustflame.2021.111925

Gaurav M, Ramakrishna PA (2016) Effect of mechanical activation of high specific surface area aluminium with PTFE on composite solid propellant. Combust Flame 166:203–215. https://doi.org/10.1016/j.combustflame.2016.01.019

Kettwich SC, Kappagantula K, Kusel BS, Avjian EK, Danielson ST, Miller HA, Pantoya ML, Iacono ST (2014) Thermal investigations of nano-aluminum/perfluoropolyether core-shell impregnated composites for structural energetics. Thermochim Acta 591:45–50. https://doi.org/10.1016/j.tca.2014.07.016

Zhao B, Sun S, Luo Y, Chen Y (2020) Fabrication of polytetrafluoroethylene coated micron aluminium with enhanced oxidation. Materials 13:3384. https://doi.org/10.3390/ma13153384

Yan T, Ren H, Ma AE, Jiao QJ, Wan HX (2019) Effect of fluororubber coating on the properties of nano-aluminum powders. Acta Armamentarh 40:1611–1617. https://doi.org/10.3969/j.issn.1000-1093.2019.08.008

Huang SD, Pan M, Deng SL, Jiang Y, Zhao JH, Ben LW, Tang SKY, Zheng XL (2019) Modified micro-emulsion synthesis of highly dispersed Al/PVDF composites with enhanced combustion properties. Adv Eng Mater 21:1801330. https://doi.org/10.1002/adem.201801330

Gan LY (2019) Study on the mechanism of formation and thermal reaction of nano-aluminum/F2604 composite particles. Master Dissertation, Nan**g University of Science & Technology

Padhye R, Aquino AJA, Tunega D, Pantoya M (2017) Fluorination of an alumina surface: modeling aluminum-fluorine reaction mechanisms. ACS Appl Mater Interfaces 9:24290–24297. https://doi.org/10.1021/acsami.7b05372

Cheng YZ, Wang Q, Ren H, Yan T (2022) Preparation and characterization of n-Al@PVDF@CL-20 composite energetic particles assembled via microfluidic method. Chin J Energ Mater 30:341–348. https://doi.org/10.11943/CJEM2021317

Guo CP, Tian L, Li YQ, Duan XH, Feng XJ, Gao B (2022) Design and preparation of spheroidicity core-shell CL-20/TNT co-crystal @Al composite by pickering emulsion. Chin J Energ Mater 30:483–490. https://doi.org/10.11943/CJEM2021270

Deng H, Yi Z, Shen Q, Qin M, Sun Y, Luo G (2022) Enhancing the combustion properties of interface optimized metastable intermixed composites PVDF/μ-Al by noncovalently functionalized graphene. Mater Des 223:111103. https://doi.org/10.1016/j.matdes.2022.111103

Ke X, Zhang WQ, Zhang DP, **ao L, Hao GZ, Jang W, Cheng JH (2021) Preparation and properties analysis of Al/PVDF energetic microspheres. Chin J Explos Propellants 44:865–872. https://doi.org/10.14077/j.i.sn.1007-7812,202108037

Huang C, Yang Z, Li Y, Zheng B, Yan Q, Guan L, Luo G, Li S, Nie F (2020) Incorporation of high explosives into nano-aluminum based microspheres to improve reactivity. Chem Eng J 383:123110. https://doi.org/10.1016/j.cej.2019.123110

Lyu JY, Chen S, He W, Zhang XX, Tang DY, Liu PJ, Yan QL (2019) Fabrication of high-performance graphene oxide doped PVDF/CuO/Al nanocomposites via electrospinning. Chem Eng J 368:129–137. https://doi.org/10.1016/j.cej.2019.02.170

Ke X, Guo S, Zhang G, Zhou X, **ao L, Hao GZ, Wang N, Jiang W (2018) Safe preparation, energetic performance and reaction mechanism of corrosion-resistant Al/PVDF nanocomposite films. J Mater Chem A 6:17713–17723. https://doi.org/10.1039/c8ta05758c

Gong Y, Zhou W, Sui X, Kou Y, Xu L, Duan Y, Chen F, Li Y, Liu X, Cai H, Chen Q, Dang ZM (2019) Core-shell structured Al/PVDF nanocomposites with high dielectric permittivity but low loss and enhanced thermal conductivity. Polym Eng Sci 59:103–111. https://doi.org/10.1002/pen.24872

Kaykılarlı C, Küçükelyas B, Akçamlı N, Uzunsoy D, Cansever N (2022) Processing and characterization of Al-4Cu matrix co mposites reinforced with few layered graphene. Trans Indian Inst Met 75:2379–2388. https://doi.org/10.1007/s12666-022-02606-5

Li XL (2010) Studies on the preparation and properties of PVDF/Al2O3 hybrid membrane. Master dissertation, South China University of Technology

Wang A, Maini S, Hickey JP, Wen JZ (2022) Solution synthesis of core-shell n-Al@ CuO based on electrostatic self-assembly for enhanced energetic performance. Chem Eng J Adv 11:100323. https://doi.org/10.1016/j.ceja.2022.100323

Li Y, Li J, Wang B, Ma H, Han Z (2022) An approach to the induced reaction mechanism of the combustion of the nano-Al/PVDF composite particles. Surf Coat Technol 429:127912. https://doi.org/10.1016/j.surfcoat.2021.127912

Zhang AY, Zhu YF, Lu YW, Zhai H, Zheng B, Zen X, Guo CP (2018) Preparation of ultrafine spherical CL-20/DNT composites by ultrasonic assisted emulsion method and study on its properties. Chin J Explos Propellant 41:455–460. https://doi.org/10.14077/j.issn.1007-7812.2018.05.006

Gao QX (2010) The suprastructure organic-inorganic hybrid microspheres fabricated through pickering emulsion droplet template method. Master dissertation, South China University of Technology

Yang TL, Zhao ZH, **ao JJ, Wang HK, Yang FQ, Qiu ZM (2018) Surface modification process of nano-Al2O3 with stearic acid. J Nanchang Univ (Eng Technol). https://doi.org/10.13764/j.cnki.ncdg.2018.01.002

Yao EG, Zhao FQ, Hao HX, Xu SY, Gao HX, Li X (2012) Preparation of aluminum nanopowders coated with perfluorotetradecanoic acid and its ignition and combustion characteristics. Chin J Explos Propellant 35:70–75. https://doi.org/10.14077/j.issn.1007-7812.2012.06.011

Wu CC, Nie JX, Li SW, Jiao QJ, Wang D, Guo XY (2023) µAl-based reactive materials with improved energy efficiency by using the fluorine-containing oxidizer perfluoropolyether as an interfacial laye. Combust Flame 248:112554. https://doi.org/10.1016/j.combustflame.2022.112554

He W, Liu PJ, Gong F, Tao B, Gu J, Yang Z, Yan QL (2018) Tuning the reactivity of metastable intermixed composite n-Al/PTFE by polydopamine interfacial control. ACS Appl Mater Interfaces 38:32849–32858. https://doi.org/10.1021/acsami.8b10197

Campbel LL, Hill KJ, Smith DK, Pantoya ML (2020) Thermal analysis of microscale aluminum particles coated with perfluorotetradecanoic (PFTD) acid. J Therm Anal Calorim 145:289–296. https://doi.org/10.1007/s10973-020-09742-4

Acknowledgements

None

Author information

Authors and Affiliations

Contributions

MY was involved in writing—original draft and investigation; DG contributed to methodology, data curation, and writing—review and editing; TW was involved in data curation; JG contributed to data curation and formal analysis; XZ was involved in data curation and resources; QW contributed to data curation, validation, and resources; CG was involved in conceptualization, resources, and project administration.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Experiments involving human tissue are not covered in this article.

Additional information

Handling Editor: Maude Jimenez.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, M., Gao, D., Wen, T. et al. Efficient construction of Al/F microspheres in Pickering emulsion to regulate combustion reactivity. J Mater Sci 59, 2828–2840 (2024). https://doi.org/10.1007/s10853-024-09371-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09371-4