Abstract

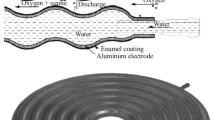

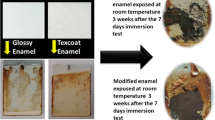

Transitioning skutterudite (SKD) thermoelectric technology from space to terrestrial power generation requires oxidation suppression technology. One approach involves the development of protective coatings consisting of the following properties: (i) low thermal conductivity to prevent parasitic heat loss, (ii) low electrical conductivity to prevent short-circuiting, (iii) coefficient(s) of thermal expansion matching that of the thermoelectric material, and (iv) adequate thermal stability and mechanical strength for durability. In this work, n-type Ba0.05Yb0.025CoSb3 and p-type Ce0.9Co0.5Fe3.5Sb12 were coated with a silica-based enamel to prevent their oxidation. This work demonstrates the efficacy of enamel coatings for suppressing oxidation of n-type SKD, and for the first time, p-type SKD in static and thermal cyclic heating tests up to 600 °C in air. The coating process, physical characterization of the enamel, and materials characterization data are presented and discussed.

Similar content being viewed by others

References

Tritt TM, Subramanian MA (2006) Thermoelectric materials, phenomena, and applications: a bird’s eye view. MRS Bull 31:188–198

Snyder GJ, Toberer ES (2008) Complex thermoelectric materials. Nat Mater 7:105–114

Uher C (2006) Skuttetudite-based thermoelectrics. In: Rowe DM (ed) Thermoelectrics handbook: macro to nano. CRC Press, Boca Raton, Chapter 34, pp 1–17

Nolas GS, Morelli DT, Tritt TM (1999) Skutterudites: a phonon-glass-electron crystal approach to advanced thermoelectric energy conversion applications. Annu Rev Mater Sci 29:89–116

Sales BC, Mandrus D, Williams BK (1996) Filled skutterudite antimonides: a new class of thermoelectric materials. Science 272:1325–1328

Shi X, Yang J, Salvador JR, Chi M, Cho JY, Wang H, Bai S, Yang J, Zhang W, Chen L (2011) Multiple-filled skutterudites: high thermoelectric figure of merit through separately optimizing electrical and thermal transports. J Am Chem Soc 133:7837–7846

Salvador JR, Cho JY, Ye Z, Moczygemba JE, Thompson AJ, Sharp JW, Konig JD, Maloney R, Thompson T, Sakamoto J, Wang H, Wereszczak AA, Meisner GP (2013) Thermal to electrical energy conversion of skutterudite-based thermoelectric modules. J Electron Mater 42:1389–1399

Sakamoto JS, Schock H, Caillat T, Fleurial J-P, Maloney R, Lyle M, Ruckle T, Timm E, Zhang L (2011) Skutterudite-based thermoelectric technology for waste heat recovery: progress towards a 1 kW generator. Sci Adv Mater 3:1–12

Yang J, Stabler FR (2009) Automotive application of thermoelectric materials. J Electron Mater 38:1245–1251

Li H, Tang X, Zhang Q, Uher C (2009) High performance InxCeyCo4Sb12 thermoelectric materials with in situ forming nanostructured InSb phase. Appl Phys Lett 94:102114

Melnyk G, Bauer E, Rogl P, Skolozdra R, Seidl E (2000) Thermoelectric properties of ternary transition metal antimonides. J Alloy Compd 296:235–242

Garcia-Canadas J, Powell AV, Kaltzoglou A, Vaqueiro P, Min G (2013) Fabrication and evaluation of a skutterudite-based thermoelectric module for high-temperature applications. J Electron Mater 42:1369–1374

Zawadzka K, Godlewska E, Mars K, Nocun M (2011) Oxidation resistant coating for CoSb3, 9th European Conference on Thermoelectrics B_25_P

Dong H, Li X, Huang X, Zhou Y, Jiang W, Chen L (2013) Improved oxidation resistance of thermoelectric skutterudites coated with composite glass. Ceram Int 39:4551–4557

Sakamoto JS, Snyder G, Calliat T, Fleurial J-P, Jones SM, Paik J-A (2006) System and method for suppressing sublimation using opacified aerogel. US Patent application no. 20060090475 A1, May 04 2006

Qiu P, **a X, Huang X, Gu M, Qiu Y, Chen L (2014) Pesting-like oxidation phenomenon of p-type filled skutterudite Ce0.9Fe3CoSb12. J Alloy Compd 612:365–371

Hara R, Inoue S, Kaibe HT, Sano S (2003) Aging effects of large-size n-type CoSb3 prepared by spark plasma sintering. J Alloy Compd 349:297–301

Godlewska E, Zawadzka K, Adamczyk A, Mitoraj M, Mars K (2010) Degradation of CoSb3 in air at elevated temperatures. Oxid Met 74:113–124

Leszczynski J, Wojciechowski KT, Malecki AL (2011) Studies on thermal decomposition and oxidation of CoSb3. J Therm Anal Calorim 105:211–222

**a X, Qiu P, Shi X, Li X, Huang X, Chen L (2012) High-temperature oxidation behavior of filled skutterudites YbyCo4Sb12. J Electron Mater 41:2225–2231

**a X, Qiu P, Huang X, Wan S, Qui Y, Li X (2014) Chen L (2014) Oxidation behavior of filled skutterudite CeFe4Sb12 in air. J Electron Mater 43:1639–1644

Pilling NB, Bedworth RE (1923) The oxidation of metals in high temperature. J Inst Met 29:529–591

Zhang Y, Li G, Zhang J, Zhang L (2004) Shape-controlled growth of one-dimensional Sb2O3 nanomaterials. Nanotechnology 15:762–765

Ozawa K, Sakka Y, Amano M (1998) Preparation and electrical conductivity of three types of antimonic acid films. J Mater Res 13:830–833

Svensson C (1975) Refinement of the crystal structure of cubic antimony trioxide Sb2O3. Acta Crystallogr A B31:2016–2018

Eagleson M (1994) Concise encyclopedia chemistry. Walter De Gruyter, Germany, p 18

Rogl G, Zhang L, Rogl P, Grytsiv A, Falmbigl M, Rajs D, Kriegisch M, Muller H, Bauer E, Koppensteiner J, Schranz W, Zehetbauer M, Henkie Z, Maple MB (2010) Thermal expansion of skutterudites. J Appl Physics 107:043507

Tang XF, Chen LD, Goto T, Hirai T, Yuan RZ (2001) Synthesis and thermoelectric properties of filled skutterudite compounds CeyFexCo4−xSb12 by solid state reaction. J Mater Sci 36:5435–5439. doi:10.1023/A:1012473428845

Chubilleau C, Lenoir B, Masschelein P, Dauscher A, Candolfi C, Guilmeau E, Godart C (2013) High temperature thermoelectric properties of CoSb3 skutterudites with PbTe inclusions. J Mater Sci 48:2761–2766. doi:10.1007/s10853-012-6891-3

Richardson RE (1961) Blowing frame for tempering glass sheets. US Patent no. 2968126, January 17 1961

Acknowledgements

The authors would like to acknowledge support from General Motors and the Department of Energy, Energy Efficiency, and Renewable Energy under Award Number DE-EE0005432.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, YS., Thompson, T., Kim, Y. et al. Protective enamel coating for n- and p-type skutterudite thermoelectric materials. J Mater Sci 50, 1500–1512 (2015). https://doi.org/10.1007/s10853-014-8711-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8711-4