Abstract

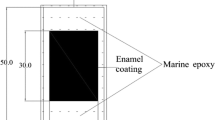

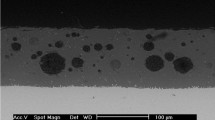

A comparative study of different enamels and the effect of inhibitor-loaded nanocontainers on corrosion protection performance of the enamel coatings in NaCl solution are reported. The study shows that mesoporous silica nanoparticles loaded with corrosion inhibitor 8-hydroxyquinoline can be blended in commercial enamels effectively texturizing its glossy nature and reducing corrosion propagation of cold rolled steel in the absence of a standard primer in the aggressive environment. The presence of the inhibiting nanocomposite in the enamel coating effectively controlled the deleterious effect of corrosive ions reaching the substrate surface and decreased the delamination effect thereby suppressing the excessive formation of rust. ATR–FTIR was used to evaluate the enamels before and after exposure to the corrosive solution. Immersion test, electrochemical impedance spectroscopy (EIS) measurements and potentiodynamic polarization (PP) studies were performed in 3.5 wt.% NaCl. Both unscratched and scratched enamel-coated surfaces were evaluated and the results revealed that the textured enamel coatings provided enhanced corrosion protection. The most effective corrosion protection for the scribed enamel coatings was observed from E-C3. Three weeks after the immersion test were observed that underneath the textured enamel was a less corroded substrate surface, but underneath the glossy enamel was a more corroded substrate surface. The presence of the inhibitor-loaded fillers positively influenced the corrosion protection efficiency of the enamels.

Graphical abstract

Similar content being viewed by others

References

N. Perez, Electrochemistry and Corrosion Science, in Electrochemistry and Corrosion Science: Second Edition (Springer International Publishing, Cham, 2016). https://doi.org/10.1007/978-3-319-24847-9

Difference Between Enamel and Paint, n.d., http://www.differencebetween.net/science/chemistry-science/difference-between-enamel-and-paint/. Accessed 20 March 2019

I.G. Berdzenishvili, Functional Corrosion-Resistant Enamel Coatings and Their Adherence Strength, Acta Phys Polonica A, 2012, 121, p 178–180.

G.S. Gonçalves, A.F. Baldissera, L.F. Rodrigues, E.M.A. Martini and C.A. Ferreira, Alkyd Coatings Containing Polyanilines for Corrosion Protection of Mild Steel, Synth. Met., 2011, 161(3–4), p 313–323. https://doi.org/10.1016/j.synthmet.2010.11.043

M. Yeganeh and M. Saremi, Corrosion Inhibition of Magnesium Using Biocompatible Alkyd Coatings Incorporated by Mesoporous Silica Nanocontainers, Prog. Org. Coat., 2015, 79(C), p 25–30. https://doi.org/10.1016/j.porgcoat.2014.10.015

B. Qian, M. Michailidis, M. Bilton, T. Hobson, Z. Zheng and D. Shchukin, Tannic Complexes Coated Nanocontainers for Controlled Release of Corrosion Inhibitors in Self-Healing Coatings, Electrochim. Acta, 2019, 297, p 1035–1041. https://doi.org/10.1016/j.electacta.2018.12.062

D. Borisova, H. Möhwald and D.G. Shchukin, Mesoporous Silica Nanoparticles for Active Corrosion Protection, ACS Nano Am Chem Soc, 2011, 5(3), p 1939–1946. https://doi.org/10.1021/nn102871v

T. Peng, R. **ao, Z. Rong, H. Liu, Q. Hu, S. Wang, X. Li and J. Zhang, Polymer Nanocomposite-Based Coatings for Corrosion Protection, Chem. An Asian J., 2020, 15(23), p 3915–3941. https://doi.org/10.1002/asia.202000943

D. Snihirova, L. Liphardt, G. Grundmeier and F. Montemor, Electrochemical Study of the Corrosion Inhibition Ability of “Smart” Coatings Applied on AA2024, J. Solid State Electrochem., 2013, 17(8), p 2183–2192. https://doi.org/10.1007/s10008-013-2078-3

A.C. Balaskas, M. Curioni and G.E. Thompson, Effectiveness of 2-Mercaptobenzothiazole, 8-Hydroxyquinoline and Benzotriazole as Corrosion Inhibitors on AA 2024–T3 Assessed by Electrochemical Methods, Surf. Interface Anal., 2015, 47(11), p 1029–1039. https://doi.org/10.1002/sia.5810

L. Cao, H. Zhang, C. Cao, J. Zhang, F. Li and Q. Huang, Quaternized Chitosan-Capped Mesoporous Silica Nanoparticles as Nanocarriers for Controlled Pesticide Release, Nanomaterials, 2016, 6(7), p 126. https://doi.org/10.3390/nano6070126

Y. Zhu, J. Shi, H. Chen, W. Shen and X.D.-M. and U. Mesoporous, , A Facile Method to Synthesize Novel Hollow Mesoporous Silica Spheres and Advanced Storage Property, Microporous Mesoporous Mater., 2005, 84(1–3), p 218–222.

C. Balzer, A.M. Waag, S. Gehret, G. Reichenauer, F. Putz, N. Hüsing, O. Paris, N. Bernstein, G.Y. Gor and A.V. Neimark, Adsorption-Induced Deformation of Hierarchically Structured Mesoporous Silica—Effect of Pore-Level Anisotropy, Langmuir, 2017, 33(22), p 5592–5602. https://doi.org/10.1021/acs.langmuir.7b00468

L.T. Zhuravlev, The Surface Chemistry of Amorphous Silica Zhuravlev Model, Colloids Surfaces A Physicochem. Eng. Asp., 2000, 173(1–3), p 1–38. https://doi.org/10.1016/S0927-7757(00)00556-2

J. Thompson, “A Guide to Choosing Household Paint,” Domain, 2014, p 1–6, https://www.domain.com.au/living/guide-choosing-household-paint/. Accessed 20 March 2019

Corrosionpredia, “Enamel,” 2015, p 1956–1957, https://www.corrosionpedia.com/definition/456/enamel. Accessed 20 March 2019

P. Flowers, K. Theopold, and R. Langley, Electrochemistry, Chemistry, Rice University, n.d., https://opentextbc.ca/chemistry/chapter/17-6-corrosion/

Acknowledgments

The award of CSIR-TWAS Postgraduate Fellowship is gratefully acknowledged for the first author. The authors are grateful to Mr. Brahmakumar, Mr. Giri and Mr. Arun of NIIST workshop unit for their support toward carrying out this project. Also acknowledged are Mr. Kiran for TEM facility and Mr. Harish Raj for the SEM facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Surface Engineering. The issue was organized by Dr. M.K. Banerjee, Malaviya National Institute of Technology, Jaipur.

Rights and permissions

About this article

Cite this article

Ulaeto, S.B., Pancrecious, J.K. & Rajan, T.P.D. Anticorrosive Enamels: Evaluation of Nanocomposite Additives on Enamel Efficiency on Cold Rolled Steel. J. of Materi Eng and Perform 30, 4103–4116 (2021). https://doi.org/10.1007/s11665-021-05881-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05881-3