Abstract

Conventional piezoelectric materials such as quartz are widely used as high precision transducers and sensors based on bulk acoustic waves. However, their operation temperature is limited by the intrinsic materials properties to about 500°C. High-temperature applications are feasible by applying materials that retain their piezoelectric properties up to higher temperatures. Here, langasite (La3Ga5SiO14) and compounds of the langasite family are the most promising candidates, since they are shown to exhibit bulk acoustic waves up to at least 1400°C. The mass sensitivity of langasite resonators at elevated temperatures is about as high as that of quartz at room temperature. Factors limiting potential use of those crystals include excessive conductive and viscous losses, deviations from stoichiometry and chemical instability. Therefore, the objective of this work is to identify the related microscopic mechanisms, to correlate electromechanical properties and defect chemistry and to improve the stability of the materials by e.g. appropriate dopants. Further application examples such as resonant gas sensors are given to demonstrate the capabilities of high-temperature stable piezoelectric materials. The electromechanical properties of langasite are determined and described by a one-dimensional physical model. Key properties relevant for stable operation of resonators are found to be shear modulus, density, electrical conductivity and effective viscosity. In order to quantify their impact on frequency and dam**, a generalized Sauerbrey equation is given. Mass and charge transport in single crystalline langasite are correlated with langasite’s defect chemistry and electromechanical properties. First of all, the dominant charge carriers are identified. Undoped langasite shows predominant ionic conduction at elevated temperatures. As long as the atmosphere is nearly hydrogen-free, the transport is governed by oxygen movement. A dominant role of hydrogen is observed in hydrogenous atmospheres since the diffusion coefficient of hydrogen is orders of magnitude higher than that of oxygen. The loss in langasite is found to be governed up to about 650°C by viscoelastic dam** related to the above mentioned movement of oxygen ions. Donor do** is shown to lower the loss contribution. Above 650°C the impact of the conductivity related loss becomes pronounced. Here, lowering the conductivity results generally in decreased losses. The evaluation of langasite’s applicability is focused on map** the regimes of gas insensitive operation. The most relevant feature with respect to frequency fluctuations of resonator devices is the formation of oxygen vacancies. In nominally hydrogen free atmospheres the calculated frequency shift becomes pronounced below oxygen partial pressures of 10 − 17, 10 − 24 and 10 − 36 bar at 1000, 800 and 600°C, respectively. Water vapor is found to shift the resonance frequency at higher oxygen partial pressures. In the hydrogen containing atmospheres applied here, langasite can be regarded as a stable resonator material above 10 − 13 bar and 10 − 20 bar at 800 and 600°C, respectively. The incorporation of OH-groups determines the frequency shift.

Similar content being viewed by others

Notes

The crystal cut designation follows [51].

In [57] the electromechanical coupling K 2 = ε 2/(ec) is considered instead of ε.

The situation is comparable to platinum electrodes applied here since their density is similar.

The property σ B reflects the bulk conductivity of polycrystalline or single crystalline langasite. In the latter case σ B equals σ R .

The amount of dopant is always given as molecular percentage of the target cation site. Strontium and praseodymium dopants refer to lanthanum. Niobium dopants are given with respect to gallium.

At 800°C the curves for p O2 = 1 and 10 − 10 bar are almost identical. At 800°C and \(p_{O2} = 10^{-20}\) bar the branch for \([A_C']-[D_C^\bullet]<0\) is not shown in order to avoid confusion because of overlap** curves. It is a nearly horizontal line at \(\sigma_B \approx 6\times 10^{-3}\) S/m.

The subscript of η R is skipped in this section.

In both publications, the inverse resonator quality factor is used to describe the loss.

The alignment of the left and right hand axis is done for data points in temperature range (2) where the viscosity dominates the loss solely (see also Fig. 37).

References

M. Pereira da Cunha, R.J. Lad, T. Moonlight, G. Bernhardt, D.J. Frankel, in High Temperature Stability of Langasite Surface Acoustic Wave Devices. Proc. IEEE Int. Ultras. Symp. (2008), pp. 205–208

I. Shrena, D. Eisele, E. Mayer, L.M. Reindl, J. Bardong, M. Schmitt, SAW-Relevant Material Properties of Langasite in the Temperature Range from 25 to 750°C: New Experimental Results. Proc. IEEE Int. Ultras. Symp. (2008), pp. 209–212

H. Fritze, High-temperature bulk acoustic wave sensors. Meas. Sci. Technol. 22, 12002 (2011). 28 pp

O. Knacke, O. Kubaschewski, H. Hesselmann, Thermochemical Properties of Inorganic Substances (Springer, New York, 1991)

R.W. Cernosek, J.R. Bigbie, M.T. Anderson, J.H. Small, P.S. Sawyer, in High Temperature Hydrocarbon Gas Sensing with Mesoporous SiO 2 Thin Films on TSM Resonators. Solid-State Sensor and Actuator Workshop, Hilton Head Island, South Carolina, 8–11 November 1998

D. Damjanovic, Materials for high temperature piezoelectric transducers. Curr. Opin. Solid State Mater. Sci. 3, 469–473 (1998)

L. Reindl, G. Scholl, T. Ostertag, H. Scherr, U. Wolff, F. Schmidt, Theory and application of passive SAW radio transponder as sensors. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 45, 1281–1292 (1998)

R. Fachberger, G. Bruckner, G. Knoll, R. Hauser, J. Biniasch, L. Reindl, Applicability of LiNbO3, langasite and GaPO4 in high temperature SAW sensors operating at radio frequencies. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 51(11), 1427–1431 (2004)

D.P. Birnie III, Analysis of diffusion in lithium niobate. J. Mater. Sci. 28, 302–315 (1993)

M. Strassburg, J. Senawiratne, N. Dietz, U. Haboeck, A. Hoffmann, V. Noveski, R. Dalmau, R. Schlesser, Z. Sitar, The growth and optical properties of large, high-quality AlN single crystals. J. Appl. Phys. 6, 5870–5876 (2004)

A.D. Katnani, K.I. Papathomas, Kinetics and initial stages of oxidation of aluminum nitride: thermogravimetric analysis and x-ray photoelectron spectroscopy study. J. Vac. Sci. Technol. A5, 1335–1340 (1987)

A. Bellosi, E. Landi, A. Tampieri, Oxidation behavior of aluminum nitride. J. Mater. Res. 8, 565–572 (1993)

O. Ambacher, M.S. Brandt, R. Dimitrov, R.A. Fischer, A. Miehr, T. Metzger, M. Stutzmann, Thermal stability and desorption of group III nitrides prepared by MOCVD. J. Vac. Sci. Technol. 14, 3532–3542 (1996)

K. Shimamura, H. Takeda, T. Kohno, T. Fukuda, Growth and characterization of lanthanum gallium silicate La3Ga5SiO14 single crystals for piezoelectric applications. J. Cryst. Growth 163, 388–392 (1996)

B. Chai, J.L. Lefaucheur, Y.Y. Ji, H. Qiu, in Growth and Evaluation of Large Size LGS (La 3 Ga 5 SiO 14), LGN (La 3 Ga 5,5 Nb 0,5 O 14) and LGT (La 3 Ga 5,5 Ta 0,5 O 14) Single Crystals. IEEE Int. Freq. Contr. Symp. (1998), pp. 748–760

P.W. Krempl, Quartzhomeotypic gallium orthophosphate: a new high tech piezoelectric crystal. Ferroelectrics 202, 65–69 (1997)

K. Jacobs, P. Hofmann, D. Klimm, J. Reichow, M. Schneider, Structural phase transformations in crystalline gallium orthophosphate. J. Solid State Chem. 149, 180–188 (2000)

F. Krispel, C. Reiter, J. Neubig, F. Lenzenhuber, P.W. Krempl, W. Wallnöfer, P.M. Worsch, in Properties and Applications of Singly Rotated GaPO 4 Resonators. IEEE Int. Freq. Contr. Symp. (2003), pp. 668–673

S. Uda, S.Q. Wang, N. Konishi, H. Inaba, J. Harada, Growth habits of 3 and 4-inch langasite single crystals. J. Cryst. Growth 237–239, 707–713 (2002)

P. Krempl, G. Schleinzer, W. Wallnöfer, Gallium phosphate, GaPO4: a new piezoelectric crystal material for high-temperature sensorics. Sens. Actuators, A 61, 361–363 (1997)

F. Krispel, H. Thanner, P. Krempl, C. Reiter, P. Worsch, W. Wallnof̈er, in GaP0 4 Resonators With Q Factors of Some Millions in the Fundamental Mode. IEEE International Frequency Control Symposium (2002), pp. 342–346

H. Fritze, O. Schneider, G. Borchardt, in High Temperature Bulk Acoustic Wave Properties of Gallium Orthophosphate and Langasite, Sensor 2003 Proceedings, (AMA Service GmbH) (2003)

K. Jacobs, P. Hofmann, D. Klimm, OH impurities in GaPO4 crystals: correlation between infrared absorption and mass loss during thermal treatment. J. Cryst. Growth 237–239, 837–842 (2002)

R.-U. Barz, M. Grassl, P. Gille, Study of anisotropic effects in hydrothermal growth of gallium orthophosphate single crystals. Ann. Chim. Sci. Mat. 26, 95–98 (2001)

K. Jacobs, P. Hofmann, J. Reichow, Physico-chemical aspects of the hydrothermal growth of GaPO4. Ann. Chim. Sci. Mat. 26, 85–90 (2001)

O. Cambon, P. Yot, D. Balitsky, A. Goiffon, E. Philippot, B. Capelle, J. Detaint, Crystal growth of GaPO4, a very promising material for manufacturing BAW devices. Ann. Chim. Sci. Mat. 26, 79–84 (2001)

S. Zhang, Y. Fei, B.H.T. Chai, E. Frantz, D.W. Snyder, X. Jiang, T.R. Shrout, Characterization of piezoelectric single crystal YCa4O(BO3)3 for high temperature applications. Appl. Phys. Lett. 92, 202905 (2008)

S. Zhang, E. Frantz, R. **a, W. Everson, J. Randi, D.W. Snyder, T.R. Shrout, Gadolinium calcium oxyborate piezoelectric single crystals for ultrahigh temperature (>1000°C) applications. J. Appl. Phys. 104, 084103 (2008)

F. Yu, S. Zhang, X. Zhao, D. Yuan, Q. Wang, T.R. Shrout, High temperature piezoelectric properties of yttrium calcium oxyborate single crystals. Phys. Status Solidi - RRL 4, 103–105 (2010)

D. Cachau-Herreillat, J. Bennazha, A. Goiffon, A. Ibanez, E. Philippot, X-ray, DTA and crystal growth investigation on AlPO4-GaPO4 and AlPO4-AlAsO4 systems. Eur. J. Solid State Inorg. Chem. 29, 1295–1307 (1992)

H. Fritze, High temperature piezoelectric materials: Defect chemistry and electro-mechanical properties. J. Electroceramics 17, 625–630 (2006)

J. Sauerwald, H. Fritze, E. Ansorge, S. Schimpf, S. Hirsch, B. Schmidt, in Electromechanical Properties of Langasite Structures at High Temperatures. International Workshop on Integrated Electroceramic Functional Structures, Berchtesgaden, Germany, 6–8 June 2005

B.V. Mill, Y.V. Pisarevsky, in Langasite-type Materials: From Dicovery to Present State. Proc. IEEE/EIA Int. Freq. Control Symp. (2000), pp. 133–144.

A.N. Gotalskaya, D.I. Drezin, V.V. Bezdelkin, V.N. Stassevich, in Pecularities of Technology, Physical Properties and Applications of New Piezoelectric Material Langasite (La 3 Ga 5 SiO 14). IEEE Int. Freq. Contr. Symp. (1993), pp. 339–347.

J. Bohm, E. Chilla, C. Flannery, H.-J. Fröhlich, T. Hauke, R. Heimann, M. Hengst, U. Straube, Czochralski growth and characterization of piezoelectric single crystals with langasite structure: LGS, LGN and LGT. Part II: Piezoelectric and elastic properties. J. Cryst. Growth 216, 293–298 (2000)

J. Boy, R. Besson, E. Bigler, R. Bourquin, B. Dulmet, in Theoretical and Experimental Studies of the Force-Frequency Effect in BAW LGS and LGT Resonators. IEEE Int. Freq. Contr. Symp. (2001), pp. 223–226

S. Ganschow, C. Cavalloni, P. Reiche, R. Uecker, Growth of La3Ga5SiO14: a modern material for high-temperature piezoelectric application. Proc. SPIE 2373, 55–58 (1995)

H. Takeda, S. Tanaka, S. Izukawa, H. Shimizu, T. Nishida, T. Shiosaki, in Effective Substitution of Aluminum for Gallium in Langasite-type Crystals for A Pressure Sensor Use at High Temperature. IEEE Ultras. Symp. (2005), pp. 560–563

E.N. Domoroshchina, A.B. Dubovskii, G.M. Kuz’micheva, G.V. Semenkovich, Influence of point defects on the electrical conductivity and dielectric properties of langasite. Inorg. Mater. 41, 1378–1381 (2005)

H. Fritze, H.L. Tuller, G. Borchardt, T. Fukuda, High temperature properties of langasite. Mater. Res. Soc. Symp. Proc. 604, 65–70 (2000)

H. Fritze, H.L. Tuller, Langasite for high temperature bulk acoustic wave applications. Appl. Phys. Lett. 78, 976–977 (2001)

H. Fritze, H. Seh, H.L. Tuller, G. Borchardt, Operation limits of langasite high temperature nanobalances. J. Eur. Ceram. Soc. 21, 1473–1477 (2001)

J. Stade, L. Bohaty, M. Hengst, R.B. Heimann, Electro-optic, piezoelectric and dielectric properties of langasite (La3Ga5SiO14), langanite (La3Ga5.5Nb0.5O14) and langataite (La3Ga5.5Ta0.5O14). Cryst. Res. Technol. 37, 1113–1120 (2002)

D.R. Lide (ed.), CRC Handbook of Chemistry and Physics, 84th edn. (CRC Press, Boca Raton, 2003)

C. Klemenz, M. Berkowski, B. Deveaud-Pledran, D.C. Malocha, in Defect Structure of Langasite-type Crystals: A Challange for Applications. IEEE Int. Freq. Contr. Symp. (2002), pp. 301–306

R. Fachberger, E. Riha, E. Born, W. Ruile, P. Pongratz, S. Kronholz, in Homogeneity of Langasite and Langatate Wafers. IEEE Int. Freq. Contr. Symp. (2002), pp. 311–319

G.M. Kuz’micheva, V.B. Rybakov, E.N. Domoroshchina, A.B. Dubovskii, X-ray diffraction study of an inhomogeneous langasite (La3Ga5SiO14) crystal. Inorg. Mater. 38, 1040–1047 (2002)

G. Sauerbrey, Verwendung von Schwingquarzen zur Wägung dünner Schichten und zur Mikrowägung. Z. Phys. 155, 206–222 (1959)

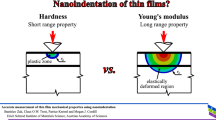

E. Benes, Improved quartz microbalance technique. J. Appl. Phys. 56, 608–626 (1984)

S.S. Narine, A.J. Slavin, Use of the quartz crystal microbalance to measure the mass of submonolayer deposits: Measuring the stoichiometry of surface oxides. J. Vac. Sci. Technol. A16, 1857–1862 (1998)

IEEE Standard on Piezoelectricity, ANSI/IEEE Std. 176-1987 (The Institute of Electrical and Electronic Engineers, New York, 1988)

D.A. Berlincourt, D. Curran, H. Jaffe, in Physical Acoustics, Principles and Methods. Piezoelectric and Piezomagnetic Materials and their Function in Transducers, vol. 1, part A. (Academic, New York, 1964), Ch. 3, pp. 169–270

T. Ikeda, Fundamentals of Piezoelectricity (Oxford University Press, Oxford, 1990)

J. Vig, Quartz crystal resonators and oscillators (2001). www.ieee-uffc.org/freqcontrol/tutorials/. Accessed 8 June 2001

D. Salt, Hy-Q Handbook of Quartz Crystal Devices (Van Nostrand Reinhold, Wokingham, 1987)

B. Zimmermann, R. Lucklum, P. Hauptmann, J. Rabe, S. Büttgenbach, Electrical characterisation of high-frequency thickness shear-mode resonators by impedance analysis. Sens. Actuators, B 76, 47–57 (2001)

K.W. Kwok, H.L.W. Chan, C.L. Choy, Evaluation of the material parameters of piezoelectric materials by various methods. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 44(4), 733–742 (1997)

J.G. Smith, Influence of moving domain walls and jum** lattice defects on complex material coefficients of piezoelectrics. IEEE Trans. Sonics Ultrason. SU-23(3), 168–174 (1976)

G. Arlt, The role of domain walls on the dielectric, elastic and piezoelectric properties of ferroelectric ceramics. Ferroelectrics 76, 451–458 (1987)

W. Göpel, J. Hesse, J.N. Zehmel, Sensors, a comprehensive survey, vol. 7 (VCH, Weinheim, 1994)

H.F. Tiersten, Linear Piezoelectric Plate Vibration (Plenum, New York, 1969)

H. Fritze, M. Schulz, H. Seh, H.L. Tuller, Sensor application-related defect chemistry and electromechanical properties of langasite. Solid State Ion. 177, 2313–2316 (2006)

B.A. Martin, H.E. Hager, Velocity profile on quartz crystals oscillating in liquids. J. Appl. Phys. 65, 2630–2635 (1989)

G. Sauerbrey, Messung von Plattenschwingungen sehr kleiner Amplitude durch Lichtmodulation. Z. Phys. 178, 457–471 (1964)

J. Schreuer, J. Rupp, C. Thybaut, J. Stade, in Temperature Dependence of Elastic, Piezoelectric and Dielectric Properties of La 3 Ga 5 SiO 14 and La 3 Ga 5.5 Ta 0.5 O 14 : An Application of Resonant Ultrasound Spectroscopy. IEEE Ultras. Symp. (2002), pp. 360–363

T. Schneider, S. Doerner, P. Hauptmann, H. Fritze, D. Richter, Novel impedance interface for resonant high-temperature gas sensors. Sens. Actuators, B 111–112, 187–192 (2005)

C. Reiter, P.W. Krempl, H. Thanner, W. Wallnöfer, P.M. Worsch, Material properties of GaPO4 and their relevance for application. Ann. Chim. Sci. Mat. 26, 91–94 (2001)

Piezocryst GmbH, Data sheet: GaPO4 material constants, Update 11/2005 (2001). http://www.piezocryst.com. Accessed 14 August 2001

M. Schulz, H. Fritze, U. Straube, in Determination of Material Parameters of Langasite (La 3 Ga 5 SiO 14) at Elevated Temperatures. 345th Wilhelm and Else Heraeus Seminar: “Acoustic Wave Based Sensors: Fundamentals, Concepts, New Applications,” Bad Honnef, Germany, 11–13 April 2005

M. Schulz, Untersuchung der Eigenschaften von Langasit für Hochtemperaturanwendungen, Ph.D. thesis, Technische Unversität Clausthal, 2007

J.J. Martin, in Acoustic Loss in Cultured Quartz. IEEE Int. Freq. Contr. Symp. (1996), pp. 170–178

J.J. Martin, in High-temperature Acoustic Loss In Thickness-Shear Mode Quartz Resonators. IEEE/EIA Int. Freq. Contr. Symp. (2000), pp. 359–363

T. Norby, Solid-state protonic conductors: principles, properties, progress and prospects. Solid State Ion. 125, 1–11 (1999)

J. Crank, The Mathematics of Diffusion (Oxford University Press, Oxford, 1975)

T. Ishihara, H. Matsuda, Y. Takita, Oxide ion conductivity in doped NdAlO3 perovskite-type oxides. J. Electrochem. Soc. 141, 3444–3449 (1994)

N.J. Long, F. Lecarpentier, H.L. Tuller, Structure and electrical properties of Ni-substituted lanthanum gallate perovskites. J. Electroceram. 3(4), 399–407 (1999)

C. Klemenz, High-quality La3Ga5.5Ta0.5O14 and La3Ga5.5Nb0.5O14 LPE films for oscillators and resonators. J. Cryst. Growth 250, 34–40 (2003)

D.P. Butt, Y. Park, T.N. Taylor, Thermal vaporization and deposition of gallium oxide in hydrogen. J. Nucl. Mater. 264, 71–77 (1999)

B.A. Maksimov, S.S. Kazantsev, V.N. Molchanov, I.A. Verin, B.V. Mill, Crystal structure and microtwinning of monoclinic La3SbZn3Ge2O14 crystals of the langasite family. Crystallogr. Rep. 49, 585–590 (2004)

H. Seh, H.L. Tuller, Defects and transport in langasite I: acceptor-doped (La3Ga5SiO14). J. Electroceram. 16, 115–125 (2006)

H. Seh, H.L. Tuller, Defects and transport in langasite II: donor-doped La3Ga4.75Nb0.25SiO14. J. Electroceramics 15, 192–202 (2005)

H. Seh, H. Fritze, H.L. Tuller, Defect chemistry of langasite III: predictions of electrical and gravimetric properties and application to operation of high temperature crystal microbalance. J. Electroceramics 18, 130–147 (2007)

H. Seh, Langasite bulk acoustic wave resonant sensor for high temperature applications. Ph.D. thesis, Department of Materials Science and Engineering, MIT, Cambridge, MA, USA, 2005

K. Schulgasser, Relationship between single-crystal and polycrystal electrical conductivity. J. Appl. Phys. 47, 1880–1886 (1976)

H. Kimura, S. Uda, X. Huang, S. Koh, in Equilibrium Phase diagram of Incongruent-Melting Langatate (La 3 Ta 0.5 Ga 5.5 O 14) and the Influence of Growth Atmosphere and Impurity Ir on the Resistivity of Langatate. 15th International Conference on Crystal Growth, Salt Lake City, USA, 12–17 August 2007 (preliminary abstract: http://www.crystalgrowth.us/iccg15)

P.G. Shewmon, Diffusion in Solids (McGraw-Hill, New York, 1963)

J. Maier, Mass transport in the presence of internal defect reactions-concept of conservative ensembles: IV tracer diffusion and intercorrelation with chemical diffusion and ion conductivity. J. Am. Ceram. Soc. 76, 1228–1232 (1993)

A. Kaminskii, B. Mill, G. Khodzhabagyan, A. Konstantinova, O.A.I., I. Silvestrova, Investigation of trigonal (La1 − x Nd x )3Ga5SiO14 crystals: I. Growth and optical properties. Phys. Stat. Sol. (A) 80, 387–398 (1983)

I.H. Jung, Y.H. Kang, K. Joo, A. Yoshikawa, T. Fukuda, K. Auh, Ca3Ga2Ge4O14 (CGG)-type Sr3Nb0.95Ga3.083Si2O14 single crystal grown by the Czochralski method for piezoelectric applications. Mater. Lett. 51, 129–134 (2001)

B.H.T. Chai, A.N.P. Bustamante, M.C. Chou, in A New Class of Ordered Langasite Structure Compounds. IEEE/EIA Int. Freq. Contr. Symp. (2000), pp. 163–168

F.A. Kröger, The Chemistry of Imperfect Crystals (North Holland, Amsterdam, 1964)

Y.-M. Chiang, D.P. Birnie III, W.D. Kingery, Physical Ceramics (Wiley, New York, 1996)

R.H. Doremus, Diffusion of Reactive Molecules in Solids and Melts (Wiley, New York, 2002)

R. Glöckner, A. Neiman, Y. Larring, T. Norby, Protons in Sr3(Sr1 + x Nb2 − x )O9 − 3x/2 perovskite. Solid State Ion. 125, 369–376 (1999)

S. Suzuki, S. Nakashima, In-situ IR measurements of OH species in quartz at high temperatures. Phys. Chem. Miner. 26, 217–225 (1999)

F. Shimojo, K. Hoshino, H. Okazaki, Effects of doped acceptor ions on proton diffusion in perovskite oxides: a first-principles molecular dynamics simulation. J. Phys.: Condens. Matter 10, 285–294 (1998)

I.E. Animitsa, A.Y. Neiman, A.R. Sharafutdinov, M.G. Kazakova, Strontium tantalates with a perovskite structure: their conductivity and high-temperature interaction with water. Russ. J. Electrochem. 37, 266–272 (2001)

J. Schreuer, C. Thybaut, M. Prestat, J. Stade, E. Haussuhl, in Towards an Understanding of the Anomalous Electromechanical Behaviour of Langasite and Related Compounds at High Temperatures. IEEE Ultras. Symp. (2003), pp. 196–199

W. Johnson, S. Kim, S. Uda, in Acoustic Loss in Langasite and Langanite. Proc. IEEE Int. Freq. Contr. Symp. (2003), pp. 646–649

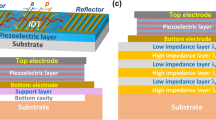

E. Ansorge, S. Schimpf, S. Hirsch, J. Sauerwald, H. Fritze, B. Schmidt, Evaluation of langasite (La3Ga5SiO14) as a material for high temperature microsystems. Sens. Actuators A 130–131, 393–396 (2006)

E. Ansorge, B. Schmidt, J. Sauerwald, H. Fritze, Langasite for microelectro-mechanical systems. Phys. Status Solidi A 208, 377–389 (2011)

J. Sauerwald, D. Richter, H. Fritze, Micromachined piezoelectric structures for high-temperature sensors. J. Electroceramics 22, 180–184 (2009)

J. Sauerwald, D. Richter, E. Ansorge, B. Schmidt, H. Fritze, Langasite based miniaturized functional structures—preparation, high-temperature properties and applications. Phys. Status Solidi A 208, 390–403 (2011)

H. Fritze, O. Schneider, H. Seh, H.L. Tuller, G. Borchardt, High temperature bulk acoustic wave properties of langasite. Phys. Chem. Chem. Phys. 5, 5207–5214 (2003)

S.L. Firebaugh, K.F. Jensen, M.A. Schmidt, Investigation of high-temperature degradation of platinum thin films with an in-situ resistance measurement apparatus. J. Microelectromech. Syst. 7, 128–135 (1998)

K. Inoue, S. Katsuo, Propagation characteristics of surface acoustic waves on langasite. Jpn. J. Appl. Phys. 37, 2909–2913 (1998)

R. Fowler, L. Nordheim, Electron emission in intense electric fields. Proc. R. Soc. Lond. A-Contain Pap. Biol. Character 119, 173–181 (1928)

C.A. Spindt, I. Brodie, L. Humphrey, E.R. Westerberg, Physical properties of thin-film field emission cathodes with molybdenum cones. J. Appl. Phys. 47, 5248–5263 (1976)

H. Fritze, H.L. Tuller, Erfassen eines Umwelteinflusses durch Änderung der Leitfähigkeit der Sensorschicht eines piezoelektrischen Materials Europäisches Patent Nr. 1695074

D. Richter, H. Fritze, T. Schneider, P. Hauptmann, in Selectivity Improvement of High Temperature Resonant Gas Sensors by Application of Different Electrode Layouts. Sensor, Internat. Conf. (Wunstorf: AMA Service), vol. 12, pp. 19–24 (2005)

J.A. Kosinski, R.A. Pastore, Jr., E. Bigler, M. Pereira da Cunha, C.D. Malocha, J. Detaint, in A Review of Langasite Material Constants from BAW and SAW Data: Toward an Improved Data Set. IEEE Int. Freq. Contr. Symp. (2001), pp. 278–286

J.A. Kilner, R.A. De Souza, I.C. Fullarton, Surface exchange of oxygen in mixed conducting perovskite oxides. Solid State Ion. 86–88, 703–709 (1996)

A.D. Le Claire, The analysis of grain boundary diffusion measurement. Br. J. Appl. Phys. 14, 351–356 (1963)

P. Fielitz, G. Borchardt, M. Schmücker, H. Schneider, How to measure volume diffusivities and grain boundary diffusivities of oxygen in polycrystalline oxides. Solid State Ion. 160, 75–83 (2003)

M. Schulz, H. Fritze, H.L. Tuller, H. Seh, Diffusion related implications for langasite resonator operation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 51/11, 1381–1387 (2004)

W.H. Press, B.P. Flannery, S.A. Teukolsky, W.T. Vetterling, Numerical Recipes in Pascal. (Cambridge University Press, New York, 1994)

Acknowledgements

The contributions of the coworkers from Clausthal University of Technology, especially Dr. M. Schulz, Dr. D. Richter, J. Sauerwald and E. Ebeling, are highly acknowledged. Their experimental work and feedback helped substantially to broaden the knowledge about the high-temperature piezoelectric materials. Further, the author thanks Prof. G. Borchardt, Clausthal University of Technology, Dr. C. Rüscher, Leibniz University Hannover and Dr. H. Baumann, University of Frankfurt, for the support of the SIMS analysis, the FT-IR measurements and the gallium implantation, respectively. The tight collaboration with Prof. H.L. Tuller and Dr. H. Seh from Massachusetts Institute of Technology is one of the important driving forces of this work. Research grants from German Research Foundation (DFG) and German Government (BMBF) supported this work.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Crystal growth

Nominally undoped and doped langasite single crystals are prepared by the Institute for Crystal Growth, Berlin-Adlershof, Germany (IKZ Berlin) using the Czochralski technique [37]. Thereby, the starting powder is prepared by mixing stoichiometric amounts of La2O3, Ga2O3, and SiO2 (purity 4N). After calcination, the material is charged into a crucible and heated. Subsequently, the crystals are pulled at a rate of 1.5 mm/h under N2–2% O2. Since the crystals are grown in iridium crucibles undoped material appears transparent independent of its treatment in oxidizing or reducing atmospheres. Intentionally doped langasite single crystals are also provided by IKZ Berlin. The growth process corresponds to that described above except for the partial replacement of lanthanum or gallium by the dopants, namely strontium, praseodymium and niobium.

Appendix B: Materials data

The bulk conductivity of the resonator materials is determined by impedance spectroscopy in the frequency range from 10 to 1 MHz. The low frequency intercept of the R S C S -semicircle in the complex impedance plane represents the resistance of the parallel arrangement and is converted in the bulk conductivity σ R . Further, the dielectric constant ε R is extracted from the data. The resonance spectra of the piezoelectric resonators are determined by recording the real R and imaginary X parts of the impedance spectra in the vicinity of the resonance frequency using an high-speed network analyzer.

The fit procedure to determine the materials properties requires room-temperature data as initial values. They are taken from different publications and listed in Table 11. In addition, key values determined independently by pulse-echo measurements using the actual langasite crystals are given [69]. The high-temperature data of the piezoelectric material used for the parameter study correspond to some extend to those of langasite. The extrapolation up to 1400°C is done

-

Linearly for the dielectric constant and the piezoelectric coefficient as given for 500, 1000 and 1400°C in Table 12,

-

Parabolically for the shear modulus as given in Table 12,

-

Exponentially for the conductivity and viscosity according to \(\sigma_{\!R}\,T = \sigma_0 e^{-E_\sigma/k_B T}\) and \(\eta_R = \eta_0 e^{-E_\eta/k_B T}\) as given in Figs. 6 and 10, respectively.

C.1 Diffusion coefficients

1.1 16 O/18O exchange

Self-diffusion coefficients can be extracted by analysis of the movements of stable tracers within a given sample. Oxygen diffusion measurements base commonly on the exchange of the stable tracer isotope 18O with low natural abundance (0.206 at%), with that of naturally occurring 16O in the solid.

In order to prepare the samples, pre-annealing runs are performed in artificial air at the same temperature and p O2 as the subsequent diffusion runs. Thereby, the period of time is chosen to be at least four times longer than that of the tracer diffusion. After pre-annealing, the samples are temporarily moved into a cooler area of the furnace (ΔT = 250°C) to replace the gas atmosphere with 18O2 enriched gas (typically 80–90%). The samples are then exposed to the tracer at temperatures ranging from 500 up to 1000°C to achieve the 18O–16O exchange. Subsequently, the resulting concentration profiles are determined by secondary ion mass spectrometry (SIMS, Cameca IMS 3f) or secondary neutral mass spectrometry (SNMS, VG SIMS Lab).

The 18O concentration at the surface of the sample c S is potentially lower than the concentration in the surrounding gas environment c G . Therefore, the surface exchange kinetics must be taken into consideration.

1.2 C.2 Diffusion in single crystals

The diffusion model given in [112] describes the such situations for a single diffusion mechanism. Here, the surface exchange kinetics and the bulk diffusion are expressed by k and D, respectively

The measured depth profiles are fitted by a least square regression procedure based upon the diffusion solution according to Eq. 74

where y, t and c BG are the depth, the diffusion time and the natural background 18O concentration, respectively.

1.3 C.3 Diffusion in polycrystalline materials

The analytical solution in the form of Eq. 74 cannot be applied if more than one diffusion mechanism takes place simultaneously. For example, polycrystalline samples exhibit diffusion in the volume and the grain boundaries. The common way to plot the corresponding diffusion profiles is to express the logarithm of the concentration as a function of depth to the power of 6/5. The grain boundary term is then visible as the linear part of the concentration profile, and from the slope the grain boundary diffusion coefficient can be calculated [113] when the volume diffusion coefficient is known. In this study, the analytical approach proposed in [114] is used. The linear part of the depth profile, plotted versus x 6/5 and extrapolated to x = 0, represents the contribution of grain boundaries, \(c_{GB}^{\,0}\) , approximated by

Here, λ and D are the grain boundary length per unit area and the bulk diffusion coefficient, respectively. The grain boundary length may be extracted by processing cross sections of the specimen. Examples for diffusion profiles and cross sections of the specimen are given in [115]. A typical grain boundary length per unit area is \(\lambda = (\,0.7 {\small \pm\,}0.1)\ \mu\)m − 1.

1.4 C.4 Ion implantation

The determination of the gallium diffusion coefficients can be performed using the stable isotope 71Ga. The small difference in abundance of the gallium isotopes 69Ga and 71Ga (61 and 39 at%, respectively) requires the application of large quantities of 71Ga. Nevertheless, a poor signal resolution during analysis has to be expected.

The isotope 71Ga is implanted into the specimens at the University of Frankfurt, Germany. The tracer, extracted from a gallium arsenate plasma, is accelerated to 50 keV and focused on the surface of y-cut langasite plates. The total amount of implanted 71Ga ions is about 8 × 1016 ions/cm2. To avoid electrical charging of the surface, the samples are treated with an additional electron beam. The subsequent diffusion runs are performed in air at temperatures from 700 up to 1000°C.

71Ga is implanted by a 50 keV accelerator. Damage of the lattice in the implanted region is, therefore, expected and the evaluation of the diffusion coefficients must account for the damaged region. Fick’s second law still describes the transport. But the equation has to be solved numerically by e.g. using the Crank-Nicolson scheme [116]. Details are presented in [115].

Rights and permissions

About this article

Cite this article

Fritze, H. High-temperature piezoelectric crystals and devices. J Electroceram 26, 122–161 (2011). https://doi.org/10.1007/s10832-011-9639-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-011-9639-6