Abstract

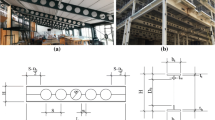

The fire performance of reinforced reactive powder concrete (RPC) beams has raised much concern due to the sensitivity of these beams to high temperature and relatively lower fire resistance. To achieve the fire-resistance ratings as specified in building design codes, a fire insulation layer is often required. However, very limited research has been conducted on the effect of fire insulation on the fire resistance of reinforced RPC beams. Hence, using the commercial software ABAQUS, a three-dimensional sequentially coupled thermal-stress finite element (FE) model was developed to simulate the response of insulated reinforced RPC beams to fire. Comparisons between the FE predictions and the existing fire test results are presented to demonstrate the accuracy of the proposed FE model. In addition, the validated FE model was used to study the effect of fire insulation parameters, including the thermal properties, thickness, height, setting mode, and local fire insulation damage, on the fire response of reinforced RPC beams. The results showed that the failure of reinforced RPC beams with partial loss of fire insulation occurred at the area of missing fire protection. Additionally, the effect of the following important parameters on the fire resistance of insulated reinforced RPC beams was investigated: compressive strength of RPC, reinforcement ratio, load ratio, thickness of RPC cover, beam width, and span-depth ratio.

Similar content being viewed by others

Abbreviations

- \(b_{{}}\) :

-

Beam width

- \(h_{{}}\) :

-

Beam depth

- \(c\) :

-

Thickness of RPC cover, i.e., distance from the outer edge of longitudinal rebar to the bottom of beam

- \(c_{\text{in}}\) :

-

Fire insulation thickness

- \(\eta\) :

-

Load ratio

- \(A_{\text{s}}\) :

-

Area of rebars

- \(A_{\text{sb}}\) :

-

Area of stirrups

- \(A_{\text{se}}\) :

-

Area of erection bars

- \(M_{\text{u}}\) :

-

Ultimate bending moment of beam at room temperature

- Q :

-

Constant load applied to the beam at elevated temperature

- T :

-

Temperature

- \(f_{\text{c,T}}\) :

-

Compressive strength of RPC at temperature T

- \(f_{\text{t,T}}\) :

-

Tensile strength of RPC at temperature T

- \(E_{\text{c,T}}\) :

-

Elastic modulus of RPC at temperature T

- \(\varepsilon_{\text{c,T}}\) :

-

Peak compressive strain of RPC at temperature T

- \(\varepsilon_{\text{t,T}}\) :

-

Peak tensile strain of RPC at temperature T

- \(\sigma_{\text{true}}\) :

-

True stress

- \(\sigma_{\text{nom}}\) :

-

Nominal stress

- \(\varepsilon_{\text{true}}\) :

-

True strain

- \(\varepsilon_{\text{nom}}\) :

-

Nominal strain

- \(h_{\text{in}}\) :

-

Fire insulation height

- t :

-

Heating time

- \(L_{0}\) :

-

Span length of beam

- \(L_{1}\) :

-

Damage length of fire insulation on the beam

- \(\mu\) :

-

Damage ratio of fire insulation, \(\mu = \frac{{L_{1} }}{{L_{0} }}\)

References

Hou XM, Cao SJ, Rong Q, Zheng WZ, Li G (2018) Effects of steel fiber and strain rate on the dynamic compressive stress-strain relationship in reactive powder concrete. Constr Build Mater 170:570–581. https://doi.org/10.1016/j.conbuildmat.2018.03.101

El-Fitiany SF, Youssef MA (2017) Fire performance of reinforced concrete frames using sectional analysis. Eng Struct 142:165–181. https://doi.org/10.1016/j.engstruct.2017.03.065

Kahanji C, Ali F, Nadjai A (2016) Experimental study of ultra-high performance fibre reinforced concrete under ISO 834 fire. In: Proceedings of the 9th international conference on structures in fire, 8-10/06, Princeton, US

ISO 834-1 (1999) Fire resistance tests-elements of building construction—part 1: general requirements. International Standard

Hou XM, Ren PF, Rong Q, Zheng WZ, Zhan Y (2019) Comparative fire behavior of reinforced RPC and NSC simply supported beams. Eng Struct 185:122–140. https://doi.org/10.1016/j.engstruct.2019.01.097

Grosshandler WL (2002) Fire resistance determination and performance prediction research needs workshop. NIST Interagency/Internal Report (NISTIR)-6890

(2007) Guide to the advanced fire safety engineering of structures. Institution of Structural Engineers, London

Beyler C, Beitel J, Iwankiw N, Lattimer B (2007) Fire resistance testing for performance-based fire design of buildings, Final Report. Quincy

Gao WY, Dai JG, Teng JG et al (2013) Finite element modeling of reinforced concrete beams exposed to fire. Eng Struct 52(9):488–501. https://doi.org/10.1016/j.engstruct.2013.03.017

Gao WY, Dai JG, Teng JG (2014) Simple method for predicting temperatures in reinforced concrete beams exposed to a standard fire. J Compos Constr 17(4):573–589. https://doi.org/10.1260/2F1369-4332.17.4.573

Wu B, Lu JZ (2009) A numerical study of the behaviour of restrained RC beams at elevated temperatures. Fire Saf J 44(4):522–531. https://doi.org/10.1016/j.firesaf.2008.10.006

Ožbolt J, Bošnjak J, Periškić G, Sharma A (2014) 3D numerical analysis of reinforced concrete beams exposed to elevated temperature. Eng Struct 58(2):166–174. https://doi.org/10.1016/j.engstruct.2012.11.030

Kodur VKR, Dwaikat M, Raut N (2009) Macroscopic FE model for tracing the fire response of reinforced concrete structures. Eng Struct 31(10):2368–2379. https://doi.org/10.1016/j.engstruct.2009.05.018

Kodur VKR, Dwaikat M (2008) A numerical model for predicting the fire resistance of reinforced concrete beams. Cem Concr Compos 30(5):431–443. https://doi.org/10.1016/j.cemconcomp.2007.08.012

Kodur VKR, Dwaikat M (2007) Performance-based fire safety design of reinforced concrete beams. J Fire Prot Eng 17(4):293–320. https://doi.org/10.1177/2F1042391507077198

Kodur VKR, Dwaikat MB (2008) Effect of fire-induced spalling on the response of reinforced concrete beams. Int J Concr Struct Mater 2(2):71–81

Wu HJ, Lie TT, Hu JY (1993) Fire resistance of beam-slab specimens: experimental studies. Internal Report No. 641, Institute for Research in Construction, National Research Council Canada. https://doi.org/10.4224/20375891

Lin TD, Gustaferro AH, Abrams MS (1981) Fire endurance of continuous reinforced concrete beams. Continuously Reinforced Concrete Pavements.

Dotreppe JC, Franssen JM (1985) The use of numerical models for the fire analysis of reinforced concrete and composite structures. Eng Anal 2(2):67–74. https://doi.org/10.1016/0264-682X(85)90056-5

Abid M, Hou XM, Zheng WZ, Hussain RR (2017) High temperature and residual properties of reactive powder concrete—a review. Constr Build Mater 147:339–351. https://doi.org/10.1016/j.conbuildmat.2017.04.083

Abid M, Hou XM, Zheng WZ, Hussain RR (2019) Effect of fibers on high-temperature mechanical behavior and microstructure of reactive powder concrete. Materials 12(2):329. https://doi.org/10.3390/ma12020329

EN 1992-1-2 (2004) Eurocode 2: Design of Concrete Structures–Part 1-2, General rules-structural fire design. European Standard

Zheng WZ, Wang R, Wang Y (2014) Experimental study on thermal parameter of reactive powder concrete. J Build Struct 35(9):107–114. https://doi.org/10.14006/j.jzjgxb.2014.09.014

Lie TT (1994) Fire resistance of circular steel columns filled with bar-reinforced concrete. J Struct Eng 120(5):1489–1509. https://doi.org/10.1061/(ASCE)0733-9445(1994)120:5(1489)

Abid M, Hou XM, Zheng WZ et al (2019) Creep behavior of steel fiber reinforced reactive powder concrete at high temperature. Constr Build Mater 205:321–331. https://doi.org/10.1016/j.conbuildmat.2019.02.019

Zheng WZ, Luo BF, Wang Y (2014) Microstructure and mechanical properties of RPC containing PP fibres at elevated temperatures. Mag Concr Res 66(8):397–408. https://doi.org/10.1680/macr.13.00232

Zheng WZ, Luo BF, Wang Y (2013) Compressive and tensile properties of reactive powder concrete with steel fibres at elevated temperatures. Constr Build Mater 41(2):844–851. https://doi.org/10.1016/j.conbuildmat.2012.12.066

Zheng WZ, Luo BF, Wang Y (2015) Stress–strain relationship of steel-fibre reinforced reactive powder concrete at elevated temperatures. Mater Struct 48(7):2299–2314. https://doi.org/10.1617/s11527-014-0312-9

Sanchayan S, Foster SJ (2016) High temperature behaviour of hybrid steel-PVA fibre reinforced reactive powder concrete. Mater Struct 49(3):769–782. https://doi.org/10.1617/s11527-015-0537-2

Y. Ju, L. Wang, H. Liu, K. Tian (2015) An experimental investigation of the thermal spalling of polypropylene-fibered reactive powder concrete exposed to elevated temperatures. Sci Bull 60(23):2022–2053. https://doi.org/10.1007/s11434-015-0939-0

EN 1993-1-2 (2005) Eurocode 3: design of steel structures—part 1-2: general rules-structural fire design. European Standard

Li GQ, Wang PJ (2013) Advanced analysis and design for fire safety of steel structures. Zhejiang University Press, Hangzhou. https://doi.org/10.1007/978-3-642-34393-3

Wang YC (2002) Steel and composite structures: behaviour and design for fire safety. CRC Press, Boca Raton

Jimenez M, Duquesne S, Bourbigot S (2006) Characterization of the performance of an intumescent fire protective coating. Surf Coat Technol 201(3–4):979–987. https://doi.org/10.1016/j.surfcoat.2006.01.026

Xue YD, Zhang SP, Yang WL (2015) Influence of expanded vermiculite on fire protection of intumescent fireproof coatings for steel structures. J Coat Technol Res 12(2):357–364. https://doi.org/10.1007/s11998-014-9626-3

Puri RG, Khanna AS (2017) Intumescent coatings: a review on recent progress. J Coat Technol Res 14(1):1–20. https://doi.org/10.1007/s11998-016-9815-3

Jimenez M, Duquesne S, Bourbigot S (2006) Intumescent fire protective coating: toward a better understanding of their mechanism of action. Thermochim Acta 449(1–2):16–26. https://doi.org/10.1016/j.tca.2006.07.008

Dodds N, Gibson AG, Dewhurst D, Davies JM (2000) Fire behaviour of composite laminates. Compos Part A Appl Sci Manuf 31(7):689–702. https://doi.org/10.1016/S1359-835X(00)00015-4

Mouritz AP, Gibson AG (2006) Fire properties of polymer composite materials. Springer Netherlands, Dordrecht. https://doi.org/10.1007/978-1-4020-5356-6

Correia JR, Gomes MM, Pires JM et al (2013) Mechanical behaviour of pultruded glass fibre reinforced polymer composites at elevated temperature: Experiments and model assessment. Compos Struct 98(3):303–313. https://doi.org/10.1016/j.compstruct.2012.10.051

Vandersall H (1971) Intumescent coating system, their development and chemistry. J Fire Flamm 2, 97–140

Rhys JA (1980) Intumescent coatings and their uses. Fire Mater 4(3):154–156. https://doi.org/10.1002/fam.810040308

Hou XM, Ren PF, Rong Q, Zheng WZ, Zhan Y (2019) Effect of fire insulation on fire resistance of hybrid-fiber reinforced reactive powder concrete beams. Compos Struct 209:219–232. https://doi.org/10.1016/j.compstruct.2018.10.073

Wang WY, Li GQ (2009) Behavior of steel columns in a fire with partial damage to fire protection. J Constr Steel Res 65(6):1392–1400. https://doi.org/10.1016/j.jcsr.2009.01.004

Wang WY, Li GQ (2009) Fire-resistance study of restrained steel columns with partial damage to fire protection. Fire Saf J 44(8):1088–1094. https://doi.org/10.1016/j.firesaf.2009.08.002

Li GQ, Wang WY, Chen SW (2009) A simple approach for modeling fire-resistance of steel columns with locally damaged fire protection. Eng Struct 31(3):617–622. https://doi.org/10.1016/j.engstruct.2008.11.004

Wang WY, Li GQ, Kodur VKR (2013) Approach for modelling fire insulation damage in steel columns. J Struct Eng 139(4), 491–503. https://doi.org/10.1061/(ASCE)ST.1943-541X.0000688

Dong K, Hu KX, Gao WY (2016) Fire behavior of full-scale CFRP-strengthened RC beams protected with different insulation systems. J Asian Architect Build Eng 15(3):581–588. https://doi.org/10.3130/jaabe.15.581

Li L (2010) Mechanical behavior and design method for reactive powder concrete beams. Dissertation, Harbin Institute of Technology, China

Iding RH (2003) Calculating structural response to fire.

Lu H, Zhao XL, Han LH (2009) Fire behaviour of high strength self-consolidating concrete filled steel tubular stub columns. J Constr Steel Res 65(10–11):1995–2010. https://doi.org/10.1016/j.jcsr.2009.06.013

EN 1991-1-2 (2002) Eurocode 1: Actions on structures–Part 1-2: General actions-actions on structures exposed to fire. European Standard

Mimoso JM (1987) Theoretical bases for building applications–technical information for buildings. Lisboa

Angus Law, Jamie Stern-Gottfried, Martin Gillie, Guillermo Rein (2011) The influence of travelling fires on a concrete frame. Eng Struct 33:1635–1642. https://doi.org/10.1016/j.engstruct.2011.01.034

Luo BF (2013) Study on explosive spalling rules and mechanical properties of reactive powder concrete at elevated temperatures. Dissertation, Harbin Institute of Technology, China

Gernay T, Millard A, Franssen JM (2013) A multiaxial constitutive model for concrete in the fire situation: theoretical formulation. Int J Solids Struct 50(22–23):3659–3673. https://doi.org/10.1016/j.ijsolstr.2013.07.013

Li LY, Purkiss J (2005) Stress-strain constitutive equations of concrete material at elevated temperatures. Fire Saf J 40(7):669–686. https://doi.org/10.1016/j.firesaf.2005.06.003

ABAQUS (2008) ABAQUS standard user’s manual. Version 6.8, vol. I–III. Pawtucket (America): Hibbitt, Karlsson & Sorensen, Inc.

Rafi MM, Nadjai A, Ali F (2008) Finite element modelling of carbon fiber-reinforced polymer reinforced concrete beams under elevated temperatures. ACI Struct J 105(6):701–710.

Sherwan Albrifkani, Yong C. Wang (2016) Explicit modelling of large deflection behaviour of restrained reinforced concrete beams in fire. Eng Struct 121:97–119. http://dx.doi.org/10.1016/j.engstruct.2016.04.032

Wan FX, Zheng WZ (2012) Thickness value of fireproof coating for slabs strengthened with carbon fiber sheet bonded with an inorganic adhesive. J Harbin Inst Technol 44(2):11–16.

Incropead FP, Dewitt DP, Bergman TL, Lavine AS (2007) Fundamentals of heat and mass transfer, 6th edn. Wiley, Hoboken

GB50016-2014 (2014) Code for fire protection design of buildings. Chinese Standard

DBJ/T 15-81-2011 (2011) Code for fire resistance design of concrete structures in buildings. Guangdong, China

Kodur VKR, Dwaikat MB (2011) Design equation for predicting fire resistance of reinforced concrete beams. Eng Struct 33(2):602–614. https://doi.org/10.1016/j.engstruct.2010.11.019

El-Fitiany SF, Youssef MA (2009) Assessing the flexural and axial behavior of reinforced concrete members at elevated temperatures using sectional analysis. Fire Saf J 44(5):691–703. https://doi.org/10.1016/j.firesaf.2009.01.005

Capua DD, Mari AR (2007) Nonlinear analysis of reinforced concrete cross-sections exposed to fire. Fire Saf J 42(2):139–149. https://doi.org/10.1016/j.firesaf.2006.08.009

GB50010-2010 (2010) Code for design of concrete structures. Chinese Standard

GB/T 31387-2015 (2015) Reactive Powder Concrete. Chinese Standard

Cui ZQ, Hou XM, Ren PF, Zheng WZ, Abid M (2019) Determining the fire resistance and minimum reinforcement ratio for hybrid-fiber RPC simply-supported beams. Mag Concr Res (unpublished manuscript)

Acknowledgements

The research presented in this paper is supported by National Natural Science Foundation of China (Grant Nos. 51578184 and 51408167), Natural Science Foundation of Heilongjiang Province (Grant No. QC2017058), and Fundamental Research Funds for Harbin University of Science and Technology (Grant No. LGYC2018JQ018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Stress–Strain Relationship of RPC at Elevated Temperatures

Appendix: Stress–Strain Relationship of RPC at Elevated Temperatures

-

(1)

Compressive strength of RPC at elevated temperatures [55]

$$\frac{{f_{\text{c,T}}^{{}} }}{{f_{{{\text{c}},20}}^{{}} }} = \, 0.96 - 0.958\left( {\frac{T}{1000}} \right)\quad 20\,^{ \circ } {\text{C}} \le T \le 800\,^{ \circ } {\text{C}}$$(2)where \(f_{{{\text{c}},20}}^{{}}\) and \(f_{\text{c,T}}^{{}}\) are the compressive strength of RPC at 20 °C and temperature T (unit: °C), respectively.

-

(2)

Peak compressive strain of RPC at elevated temperatures [55]

$$\frac{{\varepsilon_{\text{c,T}} }}{{\varepsilon_{0} }} = \, 0.696 + 12.1\left( {\frac{T}{1000}} \right) - 39.7\left( {\frac{T}{1000}} \right)^{2} + 48.8\left( {\frac{T}{1000}} \right)^{3} \quad 20\,^{ \circ } {\text{C}} \le T \le 800\,^{ \circ } {\text{C}}$$(3)where \(\varepsilon_{ 0}\) and \(\varepsilon_{\text{c,T}}\) are the peak compressive strain of RPC at 20 °C and temperature T, respectively.

-

(3)

Elastic modulus of RPC at elevated temperatures [55]

The elastic modulus of RPC at temperature T\((E_{\text{c,T}}^{{}} )\) is set to be the tangent modulus at the 0.5 \(f_{\text{c,T}}\) point of the compressive stress–strain curve at temperature T.

-

(4)

Compressive stress–strain relationship of hybrid-fiber reinforced RPC at elevated temperatures [55]

$$y = \left\{ {\begin{array}{*{20}c} {mx + (3 - 2m)x^{2} + (m - 2)x^{3} \;\;\;{\kern 1pt} 0{\kern 1pt} \le x \le 1} \\ {\frac{x}{{n(x - 1)^{2} + x}}{\kern 1pt} \;\;{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;\;{\kern 1pt} {\kern 1pt} \;\;x \ge 1} \\ \end{array} } \right.$$(4)where \(x = \varepsilon /\varepsilon_{\text{c,T}}\), \(y = \sigma /f_{\text{c,T}}\); \(\varepsilon\) is the compressive strain, \(\sigma\) is the compressive stress; m and n are parameters corresponding to the ascending and descending curves respectively, which can be obtained from Table 5.

Table 5 Equation parameters in different temperature ranges -

(5)

Tensile strength of RPC at elevated temperatures [55]

$$\frac{{f_{\text{t,T}}^{{}} }}{{f_{{{\text{t}},20}}^{{}} }} = \, 0.972 - 0.82\left( {\frac{T}{1000}} \right)\quad 20\,^{ \circ } {\text{C}} \le T \le 800\,^{ \circ } {\text{C}}$$(5)where \(f_{t,20}^{{}}\) and \(f_{t,T}^{{}}\) are the tensile strength of RPC at 20 °C and temperature T, respectively.

-

(6)

Peak tensile strain of RPC at elevated temperatures

$$\varepsilon_{\text{t,T}} = \frac{{f_{\text{t,T}}^{{}} }}{{E_{\text{c,T}} }}$$(6)where \(\varepsilon_{\text{t,T}}\) is peak tensile strain of RPC at temperature T.

-

(7)

Tensile strength stress–strain relationship of RPC at elevated temperatures [49]

$$y = \left\{ {\begin{array}{*{20}c} {1.17x + 0.65x^{2} - 0.83x^{3} \;\;\;{\kern 1pt} 0{\kern 1pt} \le x \le 1} \\ {\frac{x}{{5.5(x - 1)^{2.2} + x}}{\kern 1pt} \;\;\;\;{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \;\;\;\;\;\;\;\;\;\;\;\;\;\;x \ge 1} \\ \end{array} } \right.$$(7)where \(x = {\varepsilon \mathord{\left/ {\vphantom {\varepsilon {\varepsilon_{\text{t,T}} }}} \right. \kern-0pt} {\varepsilon_{\text{t,T}} }}\),\(y = {\sigma \mathord{\left/ {\vphantom {\sigma {f_{\text{t,T}}^{{}} }}} \right. \kern-0pt} {f_{\text{t,T}}^{{}} }}\); \(\varepsilon\) is the tensile strain, \(\sigma\) is the tensile stress.

Rights and permissions

About this article

Cite this article

Ren, P., Hou, X., Rong, Q. et al. Quantifying Fire Insulation Effects on the Fire Response of Hybrid-Fiber Reinforced Reactive Powder Concrete Beams. Fire Technol 56, 1487–1525 (2020). https://doi.org/10.1007/s10694-019-00937-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-019-00937-2