Abstract

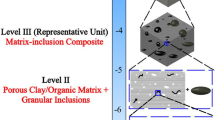

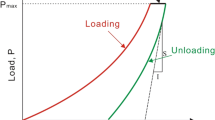

This paper presents a newly observed phenomenon of upscaling of rocks’ properties using big data nanoindentation and analytics involving Gaussian mixture modeling (GMM), leading to characterizing the cross-scale mechanical properties of four shales and one sandstone. A large number (i.e., ~ 500) of statistical indentation measurements to depths of 6–8 μm were performed on each rock, resulting in continuous depth-dependent hardness and Young’s modulus data from unknown phases, which were then segmented at various depths to extract an array of discretized subdatasets. Two-dimensional GMM of each subdataset yields the number, fraction, and properties of mechanically distinct phases, and re-assembly of these results leads to clearly discernible property-depth curves. Such improved data analytics consisting of data segmentation, GMM deconvolution, and re-assembly enables the transformation of a massive number of chaotic curves from unknown phases into a few discernible lines corresponding to identified phases, from which the mechanical properties of individual phases are accurately determined at relatively small depths. With increasing depth, initially unique mechanical properties of individual phases undergo multistage merging at the intermediate mesoscale and progressively homogenize into a unified value at large depths or macroscale (e.g., > ~ 5 μm), which is regarded as the bulk rock’s properties. More importantly, such depth-dependent transition and progressive merging and homogenization actually manifest the micromechanics of nanoindentation on a heterogeneous composite, including the indentation surround effect and rock’s microstructure (e.g., sizes and spacings of different solid particles and their properties). Compared to different micromechanical upscaling models, this newly developed big data indentation technique and pertinent data analytics enable more accurate, multi-parameter, and cross-scale characterization of highly heterogeneous materials and explicitly uncover the multi-staged, progressively-homogenized, depth-dependent upscaling of elasticity from individual constituents at the nanoscale to merged virtual interface phases at the mesoscale and to bulk material at the macroscale.

Similar content being viewed by others

References

Abedi S, Slim M, Hofmann R et al (2016) Nanochemo-mechanical signature of organic-rich shales: a coupled indentation–EDX analysis. Acta Geotech 11:559–572. https://doi.org/10.1007/s11440-015-0426-4

Ahmadov R, Vanorio T, Mavko G (2009) Confocal laser scanning and atomic-force microscopy in estimation of elastic properties of the organic-rich Bazhenov Formation. Lead Edge 28:18–23. https://doi.org/10.1190/1.3064141

Akaike H (1998) Information theory and an extension of the maximum likelihood principle. Selected papers of hirotugu akaike. Springer, New York, pp 199–213

Akono A-T, Kabir P (2016) Nano-scale characterization of organic-rich shale via indentation methods. New frontiers in oil and gas exploration. Springer International Publishing, Cham, pp 209–233

Alstadt KN, Katti KS, Katti DR (2016) Nanoscale morphology of kerogen and in situ nanomechanical properties of Green River oil shale. J Nanomech Micromech 6:4015003. https://doi.org/10.1061/(ASCE)NM.2153-5477.0000103

Anovitz LM, Cole DR, Jackson AJ et al (2015) Effect of quartz overgrowth precipitation on the multiscale porosity of sandstone: a (U)SANS and imaging analysis. Geochim Cosmochim Acta 158:199–222. https://doi.org/10.1016/j.gca.2015.01.028

Baudry J-P, Raftery AE, Celeux G et al (2010) Combining mixture components for clustering. J Comput Graph Stat 19:332–353. https://doi.org/10.1198/jcgs.2010.08111

Bennett KC, Berla LA, Nix WD, Borja RI (2015) Instrumented nanoindentation and 3D mechanistic modeling of a shale at multiple scales. Acta Geotech 10:1–14. https://doi.org/10.1007/s11440-014-0363-7

Benveniste Y (1987) A new approach to the application of Mori-Tanaka’s theory in composite materials. Mech Mater 6:147–157. https://doi.org/10.1016/0167-6636(87)90005-6

Berryman JG (1980) Long-wavelength propagation in composite elastic media II Ellipsoidal inclusions. J Acoust Soc Am 68:1820–1831. https://doi.org/10.1121/1.385172

Berryman JG (1995) Mixture theories for rock properties. Rock physics and phase relations: a handbook of physical constants. AGU, Washington, pp 205–228

Biernacki C, Celeux G, Govaert G (2000) Assessing a mixture model for clustering with the integrated completed likelihood. IEEE Trans Pattern Anal Mach Intell 22:719–725. https://doi.org/10.1109/34.865189

Bobko C, Ulm F-J (2008) The nano-mechanical morphology of shale. Mech Mater 40:318–337. https://doi.org/10.1016/j.mechmat.2007.09.006

Bozdogan H (1987) Model selection and Akaike’s Information Criterion (AIC): the general theory and its analytical extensions. Psychometrika 52:345–370. https://doi.org/10.1007/BF02294361

Bückle H (1973) Use of the hardness test to determine other material properties. In: The science of hardness testing and its research applications. pp 453–494

Budiansky B (1965) On the elastic moduli of some heterogeneous materials. J Mech Phys Solids 13:223–227. https://doi.org/10.1016/0022-5096(65)90011-6

Chen X, Vlassak JJ (2001) Numerical study on the measurement of thin film mechanical properties by means of nanoindentation. J Mater Res 16:2974–2982. https://doi.org/10.1557/JMR.2001.0408

Christensen RM (1990) A critical evaluation for a class of micro-mechanics models. J Mech Phys Solids 38:379–404. https://doi.org/10.1016/0022-5096(90)90005-O

Christensen R, Schantz H, Shapiro J (1992) On the range of validity of the Mori–Tanaka method. J Mech Phys Solids 40:69–73. https://doi.org/10.1016/0022-5096(92)90240-3

Constantinides G, Ulm F-J (2004) The effect of two types of C–S–H on the elasticity of cement-based materials: results from nanoindentation and micromechanical modeling. Cem Concr Res 34:67–80. https://doi.org/10.1016/S0008-8846(03)00230-8

Constantinides G, Ulm F-J (2007) The nanogranular nature of C–S–H. J Mech Phys Solids 55:64–90. https://doi.org/10.1016/j.jmps.2006.06.003

Constantinides G, Ulm F-J, Van Vliet K (2003) On the use of nanoindentation for cementitious materials. Mater Struct 36:191–196. https://doi.org/10.1007/BF02479557

Constantinides G, Ravi Chandran KS, Ulm FJ, Van Vliet KJ (2006) Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater Sci Eng A 430:189–202. https://doi.org/10.1016/j.msea.2006.05.125

da Silva WRL, Němeček J, Štemberk P (2013) Application of multiscale elastic homogenization based on nanoindentation for high performance concrete. Adv Eng Softw 62–63:109–118. https://doi.org/10.1016/J.ADVENGSOFT.2013.04.007

de Souza GB, Foerster CE, da Silva SLR, Lepienski CM (2006) Nanomechanical properties of rough surfaces. Mater Res 9:159–163. https://doi.org/10.1590/s1516-14392006000200009

Dempster AP, Laird NM, Rubin DB (1977) Maximum likelihood from incomplete data via the EM algorithm. J R Stat Soc Ser B 39:1–38. https://doi.org/10.1111/j.2517-6161.1977.tb01600.x

Doebelin N (2018) Profex user manual

Doebelin N, Kleeberg R (2015) Profex: a graphical user interface for the Rietveld refinement program BGMN. J Appl Crystallogr 48:1573–1580. https://doi.org/10.1107/S1600576715014685

Donnelly E, Baker Shefford P, Boskey Adele L, van der Meulen Marjolein CH (2006) Effects of surface roughness and maximum load on the mechanical properties of cancellous bone measured by nanoindentation. J Biomed Mater Res Part A 77A:426–435. https://doi.org/10.1002/jbm.a.30633

Du J, Hu L, Meegoda JN, Zhang G (2018) Shale softening: observations, phenomenological behavior, and mechanisms. Appl Clay Sci 161:290–300. https://doi.org/10.1016/j.clay.2018.04.033

Duan K, Kwok CY, Ma X (2017) DEM simulations of sandstone under true triaxial compressive tests. Acta Geotech 12:495–510. https://doi.org/10.1007/s11440-016-0480-6

Durst K, Göken M, Vehoff H (2004) Finite element study for nanoindentation measurements on two-phase materials. J Mater Res 19:85–93. https://doi.org/10.1557/jmr.2004.19.1.85

Dvorkin J, Nur A, Yin H (1994) Effective properties of cemented granular materials. Mech Mater 18:351–366. https://doi.org/10.1016/0167-6636(94)90044-2

Eliyahu M, Emmanuel S, Day-Stirrat RJ, Macaulay CI (2015) Mechanical properties of organic matter in shales mapped at the nanometer scale. Mar Pet Geol 59:294–304. https://doi.org/10.1016/j.marpetgeo.2014.09.007

Ferrari M (1991) Asymmetry and the high concentration limit of the Mori–Tanaka effective medium theory. Mech Mater 11:251–256. https://doi.org/10.1016/0167-6636(91)90006-L

Fischer-Cripps AC (2011) Nanoindentation, 3rd edn. Springer-Verlag, New York

Gupta I, Sondergeld C, Rai C (2020) Fracture toughness in shales using nano-indentation. J Pet Sci Eng 191:107222. https://doi.org/10.1016/j.petrol.2020.107222

Han Q, Qu Z, Ye Z (2018) Research on the mechanical behaviour of shale based on multiscale analysis. R Soc Open Sci 5:181039. https://doi.org/10.1098/rsos.181039

Hardiman M, Vaughan TJ, McCarthy CT (2012) The effect of fibre constraint in the nanoindentation of fibrous composite microstructures: a finite element investigation. Comput Mater Sci 64:162–167. https://doi.org/10.1016/j.commatsci.2012.04.033

Hay J, Crawford B (2011) Measuring substrate-independent modulus of thin films. J Mater Res 26:727–738. https://doi.org/10.1557/jmr.2011.8

Hay J, Agee P, Herbert E (2010) Continuous stiffness measurement during instrumented indentation testing. Exp Tech 34:86–94. https://doi.org/10.1111/j.1747-1567.2010.00618.x

Herrmann J, Rybacki E, Sone H, Dresen G (2018) Deformation experiments on Bowland and Posidonia shale−Part I: strength and Young’s modulus at ambient and in situ pc–T conditions. Rock Mech Rock Eng 51:3645–3666. https://doi.org/10.1007/s00603-018-1572-4

Hornby BE, Schwartz LM, Hudson JA (1994) Anisotropic effective-medium modeling of the elastic properties of shales. Geophysics 59:1570–1583. https://doi.org/10.1190/1.1443546

Hou D, Zhang G, Pant RR et al (2016) Nanoindentation characterization of a ternary clay-based composite used in ancient Chinese construction. Materials (Basel) 9:866. https://doi.org/10.3390/ma9110866

Hu C, Li Z (2015) A review on the mechanical properties of cement-based materials measured by nanoindentation. Constr Build Mater 90:80–90. https://doi.org/10.1016/j.conbuildmat.2015.05.008

Hu C, Gao Y, Zhang Y, Li Z (2016) Statistical nanoindentation technique in application to hardened cement pastes: influences of material microstructure and analysis method. Constr Build Mater 113:306–316. https://doi.org/10.1016/j.conbuildmat.2016.03.064

Huang Y, Shen WQ, Shao JF et al (2014) Multi-scale modeling of time-dependent behavior of claystones with a viscoplastic compressible porous matrix. Mech Mater 79:25–34. https://doi.org/10.1016/J.MECHMAT.2014.08.003

Jizba DL (1991) Mechanical and acoustical properties of sandstones and shales. Stanford University, Stanford

Johnston JE, Christensen NI (1995) Seismic anisotropy of shales. J Geophys Res 100:5991–6003. https://doi.org/10.1029/95JB00031

Jung Y-G, Lawn BR, Martyniuk M et al (2004) Evaluation of elastic modulus and hardness of thin films by nanoindentation. J Mater Res 19:3076–3080. https://doi.org/10.1557/JMR.2004.0380

Kanitpanyacharoen W, Kets FB, Wenk H-R, Wirth R (2012) Mineral preferred orientation and microstructure in the Posidonia Shale in relation to different degrees of thermal maturity. Clays Clay Miner 60:315–329. https://doi.org/10.1346/CCMN.2012.0600308

Keribin C (2000) Consistent estimation of the order of mixture models. Sankhyā Indian J Stat Ser A 62:49–66

Kim D, Seo B (2014) Assessment of the number of components in Gaussian mixture models in the presence of multiple local maximizers. J Multivar Anal 125:100–120. https://doi.org/10.1016/j.jmva.2013.11.018

Koerner H, Price G, Pearce NA et al (2004) Remotely actuated polymer nanocomposites–stress-recovery of carbon-nanotube-filled thermoplastic elastomers. Nat Mater 3:115. https://doi.org/10.1038/nmat1059

Koesoemadinata A, El-Kaseeh G, Banik N et al (2011) Seismic reservoir characterization in Marcellus shale. In: SEG Technical Program Expanded Abstracts 2011. Society of Exploration Geophysicists, pp 3700–3704

Komada T, Anderson MR, Dorfmeier CL (2008) Carbonate removal from coastal sediments for the determination of organic carbon and its isotopic signatures, δ13C and Δ14C: comparison of fumigation and direct acidification by hydrochloric acid. Limnol Oceanogr Methods 6:254–262. https://doi.org/10.4319/lom.2008.6.254

Kong L, Ostadhassan M, Zamiran S et al (2019) Geomechanical upscaling methods: comparison and verification via 3D printing. Energies. https://doi.org/10.3390/en12030382

Korsunsky AM, McGurk MR, Bull SJ, Page TF (1998) On the hardness of coated systems. Surf Coatings Technol 99:171–183. https://doi.org/10.1016/S0257-8972(97)00522-7

Krakowiak KJ, Wilson W, James S et al (2015) Inference of the phase-to-mechanical property link via coupled X-ray spectrometry and indentation analysis: application to cement-based materials. Cem Concr Res 67:271–285. https://doi.org/10.1016/j.cemconres.2014.09.001

Kumar V, Sondergeld CH, Rai CS (2012) Nano to macro mechanical characterization of shale. In: SPE Annual Technical Conference and Exhibition. Society of Petroleum Engineers, San Antonio, Texas, USA

Lee S-H, Wang S, Pharr GM, Xu H (2007) Evaluation of interphase properties in a cellulose fiber-reinforced polypropylene composite by nanoindentation and finite element analysis. Compos Part A Appl Sci Manuf 38:1517–1524. https://doi.org/10.1016/j.compositesa.2007.01.007

Leisen D, Kerkamm I, Bohn E, Kamlah M (2012) A novel and simple approach for characterizing the Young’s modulus of single particles in a soft matrix by nanoindentation. J Mater Res 27:3073–3082. https://doi.org/10.1557/jmr.2012.391

Li X, Bhushan B (2002) A review of nanoindentation continuous stiffness measurement technique and its applications. Mater Charact 48:11–36. https://doi.org/10.1016/S1044-5803(02)00192-4

Li M, Chen W, Cheng Y-T, Cheng C-M (2009) Influence of contact geometry on hardness behavior in nano-indentation. Vacuum 84:315–320. https://doi.org/10.1016/j.vacuum.2009.07.001

Li C, Ostadhassan M, Abarghani A et al (2019) Multi-scale evaluation of mechanical properties of the Bakken shale. J Mater Sci 54:2133–2151. https://doi.org/10.1007/s10853-018-2946-4

Liu K, Ostadhassan M, Bubach B (2018a) Application of nanoindentation to characterize creep behavior of oil shales. J Pet Sci Eng 167:729–736. https://doi.org/10.1016/j.petrol.2018.04.055

Liu K, Ostadhassan M, Bubach B et al (2018b) Statistical grid nanoindentation analysis to estimate macro-mechanical properties of the Bakken Shale. J Nat Gas Sci Eng 53:181–190. https://doi.org/10.1016/J.JNGSE.2018.03.005

Lu Y, Li Y, Wu Y et al (2020) Characterization of shale softening by large volume-based nanoindentation. Rock Mech Rock Eng 53:1393–1409. https://doi.org/10.1007/s00603-019-01981-8

Luo S, Lu Y, Wu Y et al (2020) Cross-scale characterization of the elasticity of shales: statistical nanoindentation and data analytics. J Mech Phys Solids 140:103945. https://doi.org/10.1016/J.JMPS.2020.103945

Ma F, Song J, Luo S et al (2019) Distinct responses of nanostructured layered muscovite to uniform and nonuniform straining. J Mater Sci 54:1077–1098. https://doi.org/10.1007/s10853-018-2887-y

Maiti SN, Subbarao R (1991) Mechanical properties of isotactic polypropylene/wood flour composites. Int J Polym Mater Polym Biomater 15:1–16. https://doi.org/10.1080/00914039108031517

Maitra R, Melnykov V (2010) Simulating data to study performance of finite mixture modeling and clustering algorithms. J Comput Graph Stat 19:354–376. https://doi.org/10.1198/jcgs.2009.08054

Mavko G, Mukerji T, Dvorkin J (2009) The rock physics handbook: tools for seismic analysis of porous media, 2nd edn. Cambridge University Press, Cambridge

McLachlan G, Peel D (2000) Finite Mixture Models. Wiley, New York

McLachlan GJ, Peel D, Basford KE, Adams P (1999) The EMMIX software for the fitting of mixtures of normal and t-components. J Stat Softw 4:1–14. https://doi.org/10.18637/jss.v004.i02

Melnykov V, Chen W-C, Maitra R (2012) MixSim: An R package for simulating data to study performance of clustering algorithms. J Stat Softw 51:1. https://doi.org/10.18637/jss.v051.i12

Miller M, Bobko C, Vandamme M, Ulm F-J (2008) Surface roughness criteria for cement paste nanoindentation. Cem Concr Res 38:467–476. https://doi.org/10.1016/j.cemconres.2007.11.014

Mokhtari M, Honarpour MM, Tutuncu AN, Boitnott GN (2016) Characterization of elastic anisotropy in Eagle Ford shale: impact of heterogeneity and measurement scale. SPE Reserv Eval Eng 19:429–439. https://doi.org/10.2118/170707-PA

Morad S, Al-Ramadan K, Ketzer JM, De Ros LF (2010) The impact of diagenesis on the heterogeneity of sandstone reservoirs: A review of the role of depositional facies and sequence stratigraphy. Am Assoc Pet Geol Bull 94:1267–1309. https://doi.org/10.1306/04211009178

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall 21:571–574. https://doi.org/10.1016/0001-6160(73)90064-3

O’Connell RJ, Budiansky B (1974) Seismic velocities in dry and saturated cracked solids. J Geophys Res 79:5412–5426. https://doi.org/10.1029/JB079i035p05412

O’Connell RJ, Budiansky B (1977) Viscoelastic properties of fluid-saturated cracked solids. J Geophys Res 82:5719–5735. https://doi.org/10.1029/JB082i036p05719

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583. https://doi.org/10.1557/JMR.1992.1564

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res 19:3–20. https://doi.org/10.1557/jmr.2004.19.1.3

Penumadu D, Dutta AK, Luo X, Thomas KG (2009) Nano and neutron science applications for geomechanics. KSCE J Civ Eng 13:233–242. https://doi.org/10.1007/s12205-009-0233-2

Pethica JB, Oliver WC (1989) Mechanical properties of nanometre volumes of material: Use of the elastic response of small area indentations. MRS Proc 130:13. https://doi.org/10.1557/PROC-130-13

Sabatakakis N, Koukis G, Tsiambaos G, Papanakli S (2008) Index properties and strength variation controlled by microstructure for sedimentary rocks. Eng Geol 97:80–90. https://doi.org/10.1016/J.ENGGEO.2007.12.004

Saha R, Nix WD (2001) Soft films on hard substrates—nanoindentation of tungsten films on sapphire substrates. Mater Sci Eng A 319–321:898–901. https://doi.org/10.1016/S0921-5093(01)01076-0

Saha R, Nix WD (2002) Effects of the substrate on the determination of thin film mechanical properties by nanoindentation. Acta Mater 50:23–38. https://doi.org/10.1016/S1359-6454(01)00328-7

Schieber J, Baird G (2001) On the origin and significance of pyrite spheres in Devonian black shales of North America. J Sediment Res 71:155–166. https://doi.org/10.1306/051600710155

Schwarz G (1978) Estimating the dimension of a model. Ann Stat 6:461–464. https://doi.org/10.1214/aos/1176344136

Sebastiani M, Moscatelli R, Ridi F et al (2016) High-resolution high-speed nanoindentation map** of cement pastes: unravelling the effect of microstructure on the mechanical properties of hydrated phases. Mater Des 97:372–380. https://doi.org/10.1016/j.matdes.2016.02.087

Seiphoori A, Whittle AJ, Krakowiak KJ, Einstein HH (2017) Insights into diagenesis and pore structure of Opalinus shale through comparative studies of natural and reconstituted materials. Clays Clay Miner 65:135–153. https://doi.org/10.1346/CCMN.2017.064055

Seo B, Kim D (2012) Root selection in normal mixture models. Comput Stat Data Anal 56:2454–2470. https://doi.org/10.1016/j.csda.2012.01.022

Shukla P, Kumar V, Curtis M et al (2013) Nanoindentation studies on shales. In: 47th U.S. Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association, San Francisco, California, p 10

Shukla P, Taneja S, Sondergeld C, Rai C (2015) Nanoindentation measurements on rocks. Fracture, fatigue, failure, and damage evolution, vol 5. Springer, Cham, pp 99–105

Sondergeld CH, Rai CS (2011) Elastic anisotropy of shales. Lead Edge 30:324–331. https://doi.org/10.1190/1.3567264

Sone H, Zoback MD (2013a) Mechanical properties of shale-gas reservoir rocks−part 1: static and dynamic elastic properties and anisotropy. Geophysics 78:D381–D392. https://doi.org/10.1190/geo2013-0050.1

Sone H, Zoback MD (2013b) Mechanical properties of shale-gas reservoir rocks−part 2: ductile creep, brittle strength, and their relation to the elastic modulus. Geophysics 78:D393–D402. https://doi.org/10.1190/geo2013-0051.1

Sreekanth MS, Bambole VA, Mhaske ST, Mahanwar PA (2009) Effect of concentration of mica on properties of polyester thermoplastic elastomer composites. J Miner Mater Charact Eng 8:271. https://doi.org/10.4236/jmmce.2009.84024

Sudharshan Phani P, Oliver WC (2019) A critical assessment of the effect of indentation spacing on the measurement of hardness and modulus using instrumented indentation testing. Mater Des 164:107563. https://doi.org/10.1016/j.matdes.2018.107563

Sun W-J, Kothari S, Sun CC (2018) The relationship among tensile strength, Young’s modulus, and indentation hardness of pharmaceutical compacts. Powder Technol 331:1–6. https://doi.org/10.1016/j.powtec.2018.02.051

Syed Asif SA, Pethica JB (1997) Nano scale creep and the role of defects. MRS Proc 436:201. https://doi.org/10.1557/PROC-436-201

Te WuT (1966) The effect of inclusion shape on the elastic moduli of a two-phase material. Int J Solids Struct 2:1–8. https://doi.org/10.1016/0020-7683(66)90002-3

Tuck JR, Korsunsky AM, Bhat DG, Bull SJ (2001) Indentation hardness evaluation of cathodic arc deposited thin hard coatings. Surf Coatings Technol 139:63–74. https://doi.org/10.1016/S0257-8972(00)01116-6

Ulm F-J, Abousleiman Y (2006) The nanogranular nature of shale. Acta Geotech 1:77–88. https://doi.org/10.1007/s11440-006-0009-5

Ulm F-J, Vandamme M, Bobko C et al (2007) Statistical indentation techniques for hydrated nanocomposites: concrete, bone, and shale. J Am Ceram Soc 90:2677–2692. https://doi.org/10.1111/j.1551-2916.2007.02012.x

Vernik L, Nur A (1992) Ultrasonic velocity and anisotropy of hydrocarbon source rocks. Geophysics 57:727–735. https://doi.org/10.1190/1.1443286

Wang K, Ng S-K, McLachlan GJ (2009) Multivariate skew t mixture models: applications to fluorescence-activated cell sorting data. Digital image computing: techniques and applications. IEEE, Melbourne, pp 526–531

Wei Z, Zhang G, Chen H et al (2009) A simple method for evaluating elastic modulus of thin films by nanoindentation. J Mater Res 24:801–815. https://doi.org/10.1557/jmr.2009.0126

Wilson MD, Pittman ED (1977) Authigenic clays in sandstones: recognition and influence on reservoir properties and paleoenvironmental analysis. J Sediment Res 47:3–31. https://doi.org/10.1306/212F70E5-2B24-11D7-8648000102C1865D

Wilson W, Sorelli L, Tagnit-Hamou A (2018) Automated coupling of nanoindentation and quantitative energy-dispersive spectroscopy (NI-QEDS): a comprehensive method to disclose the micro-chemo-mechanical properties of cement pastes. Cem Concr Res 103:49–65. https://doi.org/10.1016/j.cemconres.2017.08.016

Wu Y, Li Y, Luo S et al (2020) Multiscale elastic anisotropy of a shale characterized by cross-scale big data nanoindentation. Int J Rock Mech Min Sci 134:104458. https://doi.org/10.1016/j.ijrmms.2020.104458

**ang D, Chen Z, Yang Z et al (2017) Probing the mechanical properties of shales by nanoindentation. In: Geotechnical Frontiers 2017. American Society of Civil Engineers, Orlando

Yang S-Q (2016) Experimental study on deformation, peak strength and crack damage behavior of hollow sandstone under conventional triaxial compression. Eng Geol 213:11–24. https://doi.org/10.1016/J.ENGGEO.2016.08.012

Yang H, Luo S, Zhang G, Song J (2017) Elasticity of clay shale characterized by nanoindentation. In: 51st U.S. Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association, San Francisco, California, USA

Yasui M, Schulson EM, Renshaw CE (2017) Experimental studies on mechanical properties and ductile-to-brittle transition of ice-silica mixtures: Young’s modulus, compressive strength, and fracture toughness. J Geophys Res Solid Earth 122:6014–6030. https://doi.org/10.1002/2017jb014029

Yin H, Dvorkin J (1994) Strength of cemented grains. Geophys Res Lett 21:903–906. https://doi.org/10.1029/93GL03535

Zeng Q, Wu Y, Liu Y, Zhang G (2019) Determining the micro-fracture properties of Antrim gas shale by an improved micro-indentation method. J Nat Gas Sci Eng 62:224–235. https://doi.org/10.1016/j.jngse.2018.12.013

Zeszotarski JC, Chromik RR, Vinci RP et al (2004) Imaging and mechanical property measurements of kerogen via nanoindentation. Geochim Cosmochim Acta 68:4113–4119. https://doi.org/10.1016/j.gca.2003.11.031

Zhang G, Germaine JT, Martin RT, Whittle AJ (2003) A simple sample-mounting method for random powder X-ray diffraction. Clays Clay Miner 51:218–225. https://doi.org/10.1346/CCMN.2003.0510212

Zhang G, Wei Z, Ferrell RE (2009) Elastic modulus and hardness of muscovite and rectorite determined by nanoindentation. Appl Clay Sci 43:271–281. https://doi.org/10.1016/j.clay.2008.08.010

Zhang J, Hu L, Pant R et al (2013) Effects of interlayer interactions on the nanoindentation behavior and hardness of 2:1 phyllosilicates. Appl Clay Sci 80–81:267–280. https://doi.org/10.1016/j.clay.2013.04.013

Zhang Y, Zhang Z, Sarmadivaleh M et al (2017) Micro-scale fracturing mechanisms in coal induced by adsorption of supercritical CO2. Int J Coal Geol 175:40–50. https://doi.org/10.1016/J.COAL.2017.04.002

Zhu W, Hughes JJ, Bicanic N, Pearce CJ (2007) Nanoindentation map** of mechanical properties of cement paste and natural rocks. Mater Charact 58:1189–1198. https://doi.org/10.1016/j.matchar.2007.05.018

Zhu W, Fonteyn MTJ, Hughes J, Pearce C (2009) Nanoindentation study of resin impregnated sandstone and early-age cement paste specimens. Nanotechnology in construction 3. Springer, Berlin, Heidelberg, pp 403–408

Acknowledgements

The authors are grateful to China National Petroleum Corporation and Solvay for providing the shale and sandstone samples, respectively. The first author acknowledges the Graduate Research Scholarship from the US Clay Minerals Society that partially supported this study. The authors also thank Dr. Marco Keiluweit and Ms. Mariela Garcia in the Stockbridge School of Agriculture at the University of Massachusetts Amherst for the TOC measurements. This work also made use of the Shared Experimental Facilities (i.e., X-ray diffractometer) at MIT, supported in part by the MRSEC Program of the National Science Foundation under award number DMR1419807.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Criteria for Results Filtering

For the purpose of clarification in the following discussion, use of different subscripts is explained here: (1) μm, n, r denotes the mean values of H and E of the mth phase in the nth solution derived from the model with r phases, where m = 1, 2, …, k, n = 1, 2, …, 1000, and r = 1, 2, …, N; (2) the same notation rule is applied to other parameters, except that logLn, r represents the logarithmic likelihood value of the nth solution of the model with r phases. Not all the 8000 fitted solutions were desired with the consideration of both the statistical perspective and the rationality in mechanical testing, so only those solutions that would satisfy all the following criteria (1)–(4) were selected for further analysis:

-

1.

The successful application of statistical nanoindentation is based on an important premise that the mechanical properties of individual phases of the studied composites have sufficient contrast that can be captured by nanoindentation testing at small scales. It means that a rational solution should not display severe overlaps between the adjacent distributions of two or more different phases. For any two distributions (i.e., corresponding to Phase A and Phase B) in a solution with r > 1, the pairwise overlap between Phase A and B can be defined as ωab = ωa|b + ωb|a, where ωa|b given below is the misclassification probability that the random variable x originates from Phase B but is mistakenly assigned to Phase A, and vice versa (Maitra and Melnykov 2010):

$$\omega_{{\text{a|b}}} = \Pr \left[ {\pi_{{\text{b, n, r }}} g({\mathbf{x}} \, ; \, {\varvec{\mu}}_{{\text{b, n, r}}} \, , \, {{\varvec{\Sigma}}}_{{\text{b, n, r}}} ) < \pi_{{\text{a, n, r }}} g({\mathbf{x}} \, ; \, {\varvec{\mu}}_{{\text{a, n, r}}} \, , \, {{\varvec{\Sigma}}}_{{\text{a, n, r}}} )|{\mathbf{x}}\sim g({\varvec{\mu}}_{{\text{b, n, r}}} \, , \, {{\varvec{\Sigma}}}_{{\text{b, n, r}}} )} \right].$$(10)In this study, the pairwise overlaps of all phases were calculated using the R package MixSim (Melnykov et al. 2012), and the maximum pairwise overlap was limited to 0.5, i.e. the solution that had two phases with over 50% chance of misclassification was excluded from subsequent analysis.

-

2.

According to the data published in the literature (Zhang et al. 2013; Abedi et al. 2016; Akono and Kabir 2016; Sun et al. 2018), a positive correlation is usually observed between the hardness and Young’s modulus measured by nanoindentation. Therefore, the covariance term of each unrestricted variance–covariance matrix should be positive. Likewise, for any two distributions (e.g., Phase A and Phase B when r > 1) in a solution, their mean values μ = (μ_H, μ_E) were required to satisfy that both μ_Ea, n, r ≥ μ_Eb, n, r and μ_Ha, n, r ≥ μ_Hb, n, r held true.

-

3.

For any two different solutions (e.g., Solutions C and D) having the same k (i.e., using the same model to fit the data but with different initializing parameters), they should have enough contrast in their estimates of parameters to be considered “unique”. In this work, the maximum difference calculated as follows was required to be greater than 5% if Solution C was not a duplicate of Solution D (presumably μ_Hm+1, n, r ≥ μ_Hm, n, r and μ_Em+1, n, r ≥ μ_Em, n, r):

$$\max \left\{ \begin{gathered} \max \left( {\left| {\frac{{\pi_{{\text{1, c, r}}} - \pi_{{\text{1, d, r}}} }}{{\min \;(\pi_{{\text{1, c, r}}} , \, \pi_{{\text{1, d, r}}} )}}} \right| \, , \ldots , \, \left| {\frac{{\pi_{{\text{k, c, r}}} - \pi_{{\text{k, d, r}}} }}{{\min \;(\pi_{{\text{k, c, r}}} , \, \pi_{{\text{k, d, r}}} )}}} \right|} \right) \\ \, \max \left( {\left| {\frac{{\mu \_H_{{\text{1, c, r}}} - \mu \_H_{{\text{1, d, r}}} }}{{\min \;(\mu \_H_{{\text{1, c, r}}} , \, \mu \_H_{{\text{1, d, r}}} )}}} \right| \, , \ldots , \, \left| {\frac{{\mu \_H_{{\text{k, c, r}}} - \mu \_H_{{\text{k, d, r}}} }}{{\min \;(\mu \_H_{{\text{k, c, r}}} , \, \mu \_H_{{\text{k, d, r}}} )}}} \right|} \right) \, \\ \max \left( {\left| {\frac{{\mu \_E_{{\text{1, c, r}}} - \mu \_E_{{\text{1, d, r}}} }}{{\min \;(\mu \_E_{{\text{1, c, r}}} , \, \mu \_E_{{\text{1, d, r}}} )}}} \right| \, , \ldots , \, \left| {\frac{{\mu \_E_{{\text{k, c, r}}} - \mu \_E_{{\text{k, d, r}}} }}{{\min \;(\mu \_E_{{\text{k, c, r}}} , \, \mu \_E_{{\text{k, d, r}}} )}}} \right|} \right) \\ \end{gathered} \right\} \ge 0.05.$$(11)For any two solutions (e.g., Solutions E and F) having different k, the solution derived from a more complicated model (i.e., model with more parameters) should provide a higher logarithmic likelihood, i.e., logLe, r < logLf, r+1.

-

4.

For Gaussian mixtures with unrestricted covariance matrices, it is almost inevitable to have some spurious solutions (Seo and Kim 2012). Generally, a spurious solution has one or more phases which overfit a small localized random pattern in the data rather than any other underlying group structure, resulting in a solution with a high likelihood but very small generalized variance and mixing proportion of the overfitted phase (McLachlan and Peel 2000; Kim and Seo 2014). In addition, prior studies on composites have shown that their mechanical properties can only be significantly enhanced when the amount of additive or filling phase reaches above ~ 5 wt.% (Maiti and Subbarao 1991; Koerner et al. 2004; Sreekanth et al. 2009). Thus, the final constraint specified a critical concentration of 5% to identify and eliminate the spurious solutions, i.e. the fraction of each phase for a qualified solution should be at least 5% (i.e., πm, n, r ≥ 0.05).

Appendix B: Upscaling Models for Calculation of Bulk Rock Properties

In geophysics, the Voigt and Reuss models are widely used to estimate the theoretical maximum and minimum elastic moduli of the dry rock frame, respectively, based on the known constituents and their volumetric fractions (Sone and Zoback 2013a, b). The Voigt upper bound is determined by assuming that the strain is uniform throughout the bulk rock, while the Reuss lower bound is obtained by assuming an iso-stress situation. For a heterogeneous rock with k phases, the two bounds are then calculated by:

where k is the number of mechanically distinct phases; Er the Young’s modulus of the rth identified phase with a volumetric fraction of fr. Then the effective Young’s modulus of the bulk rock is often estimated by taking the average of the upper and lower bounds, known as the Voigt-Reuss-Hill (VRH) average:

However, the stress and strain are generally nonuniform in rocks. Similar to the aforementioned bounding methods, the Mori–Tanaka (MT) model uses the average local stress and strain fields in the matrix-inclusion structure of a composite to predict the homogenized moduli, Khom and Ghom, of the composites (Mori and Tanaka 1973; Benveniste 1987), which can be determined by (da Silva et al. 2013; Huang et al. 2014):

where K1 and G1 particularly denote the bulk and shear moduli of the matrix in the composite. The bulk modulus Kr and shear modulus Gr of the rth phase can be calculated by its Young’s modulus Er and Poisson’s ratio νr, which is assumed to be 0.2 for all phases:

The third model used in this study is the self-consistent (SC) approximation that estimates the effective moduli of a composite by not only using the volumetric fractions and properties of individual phases, but also including their geometric information, such as sphere, needle, and disk (Budiansky 1965; Wu 1966; O’Connell and Budiansky 1974, 1977). The self-consistent (SC) effective moduli \(K_{{{\text{SC}}}}^{*}\) (i.e., bulk modulus) and \(G_{{{\text{SC}}}}^{*}\) (i.e., shear modulus) of the bulk composite can be approximated by (Berryman 1980, 1995):

where P*r and Q*r are geometric factors of the rth phase (refer to Table 4 in Berryman 1995). Eqs. (20) and (21) are coupled and thus need to be solved simultaneously by iterations, and the self-consistent effective Young’s modulus can then be calculated by Eq. (17) with the converged solutions of \(K_{{{\text{SC}}}}^{*}\) and \(G_{{{\text{SC}}}}^{*}\).

Rights and permissions

About this article

Cite this article

Luo, S., Kim, D., Wu, Y. et al. Big Data Nanoindentation and Analytics Reveal the Multi-Staged, Progressively-Homogenized, Depth-Dependent Upscaling of Rocks’ Properties. Rock Mech Rock Eng 54, 1501–1532 (2021). https://doi.org/10.1007/s00603-020-02337-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-020-02337-3