Abstract

This paper presents a novel and effective strategy for modelling three-dimensional periodic representative volume elements (RVE) of particulate composites. The proposed method aims to generate an RVE that can represent the microstructure of particulate composites with hollow spherical inclusions for homogenization (e.g., deriving the full-field effective elastic properties). The RVE features periodic and randomised geometry suitable for the application of periodic boundary conditions in finite element analysis. A robust algorithm is introduced following the combined theories of Monte Carlo and collision driven molecular dynamics to pack spherical particles in random spatial positions within the RVE. This novel technique can achieve a high particle-matrix volume ratio of up to 50% while still maintaining geometric periodicity across the domain and random distribution of inclusions within the RVE. Another algorithm is established to apply periodic boundary conditions (PBC) to precisely generate full field elastic properties of such microstructures. Furthermore, a user-friendly automatic ABAQUS CAE plug-in tool ‘Gen_PRVE’ is developed to generate three-dimensional RVE of any spherical particulate composite or porous material. Gen_PRVE provides users with a great deal of flexibility to generate Representative Volume Elements (RVEs) with varying side dimensions, sphere sizes, and periodic mesh resolutions. In addition, this tool can be effectively utilized to conduct a rapid mesh convergence study, an RVE size sensitivity study, and investigate the impact of inclusion/matrix volume fraction on the solution. Lastly, examples of these applications are presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Composite materials are created by combining two or more materials with different properties to fit the requirement of a particular structure for a particular purpose. They can be tailored to offer many special advantages to satisfy the need of modern industries. Examples of such advanced properties are strength/stiffness-to-weight ratio, good conductivity, and heat and sound insulation. One of the broad classes of composite materials is particulate composites with hollow spherical inclusions such as hollow polymer particles [1] and fly ash cenospheres [2]. The addition of hollow spheres to a matrix grants the composite excellent characteristics such as low density, thermal insulation, and sound absorption [3,4,5].

The structural geometry of particulate composites with hollow spherical inclusions are often described at the nanoscale or micro-scale levels depending on the average size of the spheroids [6, 7]. For many purposes, multiscale analysis is useful for mechanical and thermal expansion analysis [8,9,10]. In such analysis, a representative volume element is often modelled at the lower length scale in which it qualifies to represent the composite as whole in the upper scale [11, 12]. Generating an RVE that accurately represents the random distribution of inclusions while maintaining geometric and mesh periodicity across its domain is a challenging task. Such complex random and periodic geometries require robust and sophisticated code that automates the process of generating random inclusions, controlling periodicity in terms of geometry and mesh, and applying periodic boundary conditions (PBC). A precisely representative element must be subjected to appropriate boundary conditions where the element is constrained to deform as a part of the upper scale not as a standalone element. Periodic boundary conditions can set up the finite element model to deform accordingly rather than the simplest set up of kinematic uniform boundary conditions (KUBC) [13]. Nevertheless, unlike KUBC nodal PBC requires precise periodic discretisation and periodic geometry.

Satisfying those conditions is convoluted as commercial FE software are not equipped with periodic discretisation solutions. Arguably, KUBC would effortlessly yield a similar approximation to PBC [14]. However, PBC is more precise and converges better and precision is often necessary and costly. While approximate periodic boundary conditions (BC) can be readily extended to non-periodic geometries and meshes by constraining parallel faces rather than nodes, the most advanced and accurate BC approach is demonstrated to be full nodal periodic BC. This approach ensures faster convergence to numerical solutions, especially for the smallest Representative Volume Element (RVE) sizes [13].

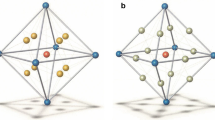

Several authors have introduced frameworks for modelling 3D RVEs with solid spheroids [15, 16], non-hollow ellipsoids [17, 18], RVEs with unidirectional fibres [19, 20], and woven composites [21,22,23]. Unlike the aforementioned inclusion types, hollow spheres can be appropriately described as shell elements rather than solid elements. Yet, the literature on microstructure modelling of particulate composite with hollow spherical inclusion is scarce or rather limited. The unique and challenging part of such RVEs is that the matrix and inclusion parts are meshed differently (solid and shells), which complicates maintaining periodic geometry.

Many recent publications were dedicated into merely the random packing of particles to achieve high volume fracture (45–60%), while others focused on generating periodic meshes to prepare the RVE for the application of PBC [41] introduced a novel algorithm for hard spheres packing based on the concept of molecular dynamics (MD) and the law of elastic collision using a time driven simulation. The MD algorithm can achieve up to 45–60% [29, 41,42,43] volume fraction for a low computational cost. In the original algorithm, particles were assigned null radii, a random position, and velocity vector. These particles were set in motion, and their radii increased incrementally over time. Whenever two spheres collided, their position and velocity were updated accordingly. The process continued until either a desired volume fraction or jamming limit was reached. In the current study, a new procedure is introduced that combines both RSA and MD methods to increase flexibility and overcome the limitations of each method.

2.3 Procedure of random spheres packing (main program)

RSA is restricted to a 30% volume fraction, while the original MD-based algorithm is limited to equal sized spheres. Herein, a novel procedure is proposed to pack up to 50% volume fraction of different spheres based on the user input of mean radii and variance \({s}^{2}\) along with the side lengths of the RVE \([{L}_{x}, {L}_{y}, {L}_{z}]\). The concept is to start with the RSA and carry on with the MD-based algorithm. The RSA will generate spheres up to 10% volume fraction. The sizes of the generated spheres are initially scaled down to account for the increase from 5% to the desired volume fraction \({V}_{f}\). The mean of the down scaled radii \({\mu }_{ri}\) can be derived from the desired mean radii \({\mu }_{r}\) using Eq. (1).

Appendix 1 features a flowchart depicting the procedure for random sphere packing. The execution of this process is guided by Algorithms 1 to h, as outlined in Appendix 2. Additionally, Appendix 3 encompasses the mathematical formulation of the equations utilized in the procedure. Algorithm 1 handles the sphere packing program and calls Algorithms 2 to 6. Algorithm 2 generates a set of down-scaled spheres with the specified statistical input. The output of this step, \(\left[{r}_{i}, {R}_{i}\right],\) where \({r}_{i}\) and \({R}_{i}\) represent, respectively, the radius of the sphere and its vector position, will be used as an input on the second stage along with the true volume fraction and the side lengths of the RVE. The MD-based algorithm will start by initializing time to zero and assigning a random velocity vector \({v}_{i}\) to each sphere. Algorithm 3 identifies the first binary collision between spheres \([i,j,{t}_{cmin}]\), based on the positions \({r}_{i}\), velocities \({v}_{i}\), and radii growth rate \({a}_{i}\). Meanwhile, Algorithm 4 identifies the first collision with the RVE domain \([i,k,{t}_{smin}]\). Subsequently, the first collision event (binary collision or with RVE domain) is detected where:

The position vectors and radii are then updated based on dt with the following equation:

Next, if the binary collision takes place first \((dt={t}_{smin})\) the velocity vectors of the collided spheres are updated using Algorithm 5, otherwise if a sphere collided with the RVE domain first, periodic images are created via Algorithm 6. Finally, the true volume fraction of the current step \({V}_{n}\) is calculated, and the loop ends when the desired \({V}_{f}\) is achieved \(({V}_{n}\ge {V}_{f})\).

Figure 2 presents three generated RVEs with different volume fraction of 30, 40, and 50%. A computer equipped with Intel i9 12900k 5.2 GHz processor and 96 GB RAM could generate 50% volume fraction and 62 spheres in less than four minutes. The generation time is significantly influenced by the number of particles, irrespective of the RVE or particle sizes. For instance, a high-volume fraction and smaller particle size would lead to a larger number of particles and, consequently, incur a higher computational cost.

2.4 Random sequential adsorption

Algorithm 2 describes the random sequential adsorption (RSA). It starts with generating random coordinate within the RVE and random radius based on \({\mu }_{ri}\) and \({s}^{2}\). The algorithm uses Eqs. (5) and (6) to identify the overlap** between the adsorption attempts of sphere “i” and every previously adsorbed sphere “j”,

If \(d>{d}_{min}\) is the case with every previously adsorbed sphere, the new sphere is accepted. Otherwise, a new spatial position is sought. In this step, only internal spheres are packed. Intersection spheres with matrix domains and their periodic images are to be created within the MD-based algorithm.

2.5 Detection of first binary collision

Algorithm 3 summarizes the steps of detecting the first binary collision. The collision time between each pair of spheres \((i \& j)\) can be computed with Eqs. (7)–(9):

which can be solved with:

A collision would occur if \(\alpha\) or \(\beta\) are negative values and if \({\beta }^{2}-\alpha \gamma\) is a positive value, the \({t}_{cij}\) is calculated via Eq. (13). Otherwise, no collision would happen (e.g. \({t}_{cij}=\infty\))

The minimum collision time \({t}_{c}={\text{min}}({t}_{cij})\) is when the first binary collision occurs between two spheres \(i\) and \(j\).

2.6 Detection of first collision between a sphere and the matrix domain.

Algorithm 4 presents the calculation steps of the collision time between each non-intersecting sphere and the matrix domain. Equation (14) are used to calculate the collision time with the master and image faces:

2.7 Post binary-collision velocity update

The first two spheres that collided from Algorithm 3 and their periodic images (if they exist) need to be updated. Algorithm 5 details the steps for calculating the new velocities by obtaining the unit vector:

Decomposing the component of the velocity vector:

Calculate the new velocity vector of the collided spheres \((i {\text{and}} j)\):

And finally, an identical velocity vector is assigned for every periodic image of the collided spheres \(i\) or \(j\).

2.8 Creation of periodic images of spheres

To maintain periodicity across the matrix domain, intersecting spheres with matrix domain should have periodic images via Algorithm 6. For example, if a sphere intersects with the matrix corners (C0) where:

Then, 7 periodic images of this sphere should be created with the following coordinates:

If a sphere intersects with the other seven corners, periodic images are also formed. In the case of an intersection with an edge, three periodic images will intersect with the other three parallel edges. Lastly, if the sphere intersects with a face, only one periodic image will be created to intersect with the other parallel face.

3 Generation of periodic geometry

The objective of creating a periodic arrangement of spherical inclusions that intersect with the RVE domain is to produce a periodic geometry and a mesh that enables the implementation of periodic boundary conditions. These boundary conditions entail imposing identical deformation on each opposing pair of nodes when subjected to a particular stress state [44]. To achieve this, it is necessary to ensure that the mesh at the borders of the RVE is periodic, as demonstrated in Fig. 3. The subsequent section will delve into boundary conditions in greater detail, while also presenting a new technique for generating periodic geometry and meshes using the scripting interface of the ABAQUS CAE commercial finite element software.

The output of the RSA algorithm, discussed in the previous section, is a 2-dimensional array that contains the details of the spherical inclusions. Those details are the coordinates and diameter of each sphere as follows:

Creating the geometry of each particle separately using the user interface would not be practical for the RVE of a particulate composite, as it typically contains numerous particles. Instead, an automated script can be utilised, which employs a loop to automatically generate the geometry of all the spheres, as outlined in Algorithm 7 “Gen_PGeom”. The spheroids are produced as shell parts, and intersecting spheroids with the RVE borders are trimmed by a dummy/temporary larger object. Consequently, the geometry of three RVE master faces \({F}_{x0}, {F}_{y0}, {F}_{z0}\) is created as shell elements, and the overlap** area between the master faces and the inclusions is trimmed, as depicted in Fig. 4. It should be noted that all parts are generated as shell elements at this stage but will be converted to 3D solid elements in subsequent stages. This innovative and efficient approach is currently being proposed to generate a periodic mesh across the faces and edges of the RVE with precision.

Algorithm 7 is utilized for the generation of a master faces and b intersecting hollow spheroids

4 Generation of periodic meshes

Creating a periodic mesh across the RVE is a more complex process than generating periodic geometry. While geometric periodicity is maintained across the RVE domain, the discretisation within the RVE is neither periodic nor symmetrical. Currently, most commercial finite element software packages are unable to automatically produce a periodic mesh from periodic geometry. Some authors have proposed solutions that involve applying periodic boundary conditions with a non-periodic mesh. For instance, Omairey [25] developed a plug-in tool in ABAQUS CAE that automatically applies periodic boundary conditions. In their algorithm, opposite nodes with the closest planar coordinates are constrained together, but only if the specified mesh map** accuracy is satisfied. However, this may not be an optimal solution, particularly in instances where poor mesh map** results in node pairs that cannot be captured within an acceptable map** accuracy limit. The optimal solution is to create an exact periodic mesh across the faces and edges of the RVE domain. However, this is not a straightforward process as composite microstructures are typically complex. The intersection of a spheroid (or other inclusion) with a plane would result in a complex geometry that cannot be easily meshed. Commercial software packages can only mesh such objects by utilizing unstructured meshing techniques, which do not require pre-established mesh patterns. Although these techniques are the most flexible, they provide the least control as the pattern is unpredictable. In addition, software such as NETGEN [45] that is not specifically designed for finite element analysis can generate periodic meshes from geometry. Their innovative algorithm generates high-quality triangle/tetrahedron meshes (for 2D and 3D geometry) based on skewness and aspect ratio in four subsequent computational steps: spatial points, edges, face, and volume mesh generation. Although effective, transferring geometric information between non-FE software and common commercial FE software is usually not straightforward and can be restricted or limited.

Some publications are solely dedicated to generating periodic meshes of RVEs [46]. However, their procedures can be unnecessarily lengthy and tailored for their specific matrix-inclusion form. In some cases, the inclusion needs to be meshed as a shell with a thickness to resemble hollow particles, while the matrix must be meshed with solid elements. Consequently, both the matrix and inclusion cannot be modelled as a single part, as they are meshed differently and assigned different material properties.

In the present work, a simple yet effective procedure is proposed to generate a high-quality mesh for periodic geometries. The proposed method exploits the ABAQUS CAE scripting interface to assemble and translate existing 2D elements from a single geometry to create a periodic replica of faces and edges. Although the procedure is introduced with the application of a matrix with hollow and spherical inclusion, the concept can be applied to all types of periodic geometries.

Carrying out from the last step of the earlier section, all the shell parts, the inclusions, and three master faces \({F}_{x0}, {F}_{y0}, {F}_{z0}\), were merged and meshed with triangular elements as shown in Fig. 5a. The meshing process involved equitably seeding the edges to ensure the nodes on opposite edges were restrained. Merging and meshing these elements as a single entity guarantees precise nodal coordinates between the inclusion elements, master, and image faces. Subsequently, the focus shifts to mirroring individual discrete elements instead of geometric parts. To accomplish this, Algorithm 8 was devised to categorise the elements by their position and create corresponding periodic images. The algorithm extracts the mesh connectivity data and arranges them into a 2D array, then translates each element based on its location to the positive direction using the translation vector in Eqs. (29)–(33). Algorithm 8 “Gen_Pmesh” generates a mesh connectivity array of triangular elements that resembles a periodic RVE mesh as shown in Fig. 5b. Next, a built-in function within ABAQUS CAE is utilized to convert a triangular mesh to linear or quadratic tetrahedron elements as shown in Fig. 5c.

This tool converts fully enclosed linear triangular shell elements into a solid mesh of tetrahedral elements using a bottom-up technique. The built-in function ensures the generation of a high-quality mesh, particularly concerning the aspect ratio. The aspect ratio, denoting the ratio between the longest edge and the shortest normal dropped from a vertex to the opposite face (normalized with respect to a perfect tetrahedral), defines a good quality mesh within the range of 1 to 10. Achieving this quality requires careful consideration, ensuring that the minimum distance between spheres and the domain is significantly larger than the mesh size.

The process of modelling the periodic matrix geometry and mesh is now complete, but the inclusions still need to be generated. Different options can be considered for the inclusions, such as using hollow spheres as shell components, solid spheres, or voids to mimic porous materials. Furthermore, appropriate contact properties between the matrix and inclusions must be established. The computational time for generating an extra-fine periodic mesh, comprising 714,750 tetrahedral elements for an RVE with a size of 2 microns, where the mesh size is 2% of its side length, is less than 17 min.

5 Periodic boundary conditions

After the modelling of the RVE geometry is completed, it needs to undergo virtual testing to obtain its macroscopic mechanical properties. The boundary conditions that govern the physical mechanisms of material deformation are a set of constraints that must be established. It is necessary to impose appropriate boundary conditions to the RVE to generate the solution of this homogenization technique \((E, G,\upsilon )\). Different boundary conditions could result in different solutions [13]. Choosing the appropriate boundary conditions is critical to ensure the accuracy of the results and maintain the RVE's representativeness. Two major types of boundary conditions are usually imposed to obtain the elastic properties: kinematic uniform boundary conditions (KUBCs) and periodic boundary conditions.

Kinematic uniform boundary conditions (KUBCs) are applied by imposing uniform displacements at the boundaries of the RVE. This type of BCs is widely used in micromechanics. Owing to its simplicity and its ease of application, several authors have used this type of BCs to find the effective properties of composite materials [47,48,49]. Nonetheless, the KUBC approach treats the RVE as a single unit cell, disregarding the fact that it is a constituent of a larger body on a higher scale. Therefore, the KUBC approach may not be entirely representative at the macroscopic level. According to ** and testing. Furthermore, the study conducted an effective mesh convergence study through "Gen_PRVE" using different mesh resolutions of 10%, 7.5%, 5%, 4%, and 3% to evaluate the convergence of the solution with finer meshes. Size sensitivity analysis of RVE was performed via "Gen_PRVE" to determine the minimum size of the periodic RVE required to represent the upper scale. Finally, an experimental validation is conducted for the elastic homogenization generated by Gen_PRVE, demonstrating an acceptable margin of error of less than 3%.

Data availability

The data that support the findings of this study are available on request from the corresponding author.

References

Ramli RA (2017) Hollow polymer particles: a review. RSC Adv 7(83):52632–52650

Żyrkowski M et al (2016) Characterization of fly-ash cenospheres from coal-fired power plant unit. Fuel 174:49–53. https://doi.org/10.1039/C7RA10358A

Poveda R, Gupta N, Porfiri M (2010) Poisson’s ratio of hollow particle filled composites. Mater Lett 64(21):2360–2362. https://doi.org/10.1016/j.matlet.2010.07.063

Wichaita W, Polpanich D, Tangboriboonrat P (2019) Review on synthesis of colloidal hollow particles and their applications. Ind Eng Chem Res 58(46):20880–20901. https://doi.org/10.1021/acs.iecr.9b02330

McDonald CJ, Devon MJ (2002) Hollow latex particles: synthesis and applications. Adv Colloid Interface Sci 99(3):181–213. https://doi.org/10.1016/s0001-8686(02)00034-9

Bertling J, Blömer J, Kümmel R (2004) Hollow microsperes. Chem Eng Technol 27(8):829–837. https://doi.org/10.1002/ceat.200406138

Ngu L-N, Wu H, Zhang D-K (2007) Characterization of Ash cenospheres in fly ash from Australian power stations. Energy Fuels 21(6):3437–3445. https://doi.org/10.1021/ef700340k

Elbana A et al (2022) Multi-scale modelling of particulate composite. Environ Sci Proc 12(1):23. https://doi.org/10.3390/environsciproc2021012023

Fish J, Wagner GJ, Keten S (2021) Mesoscopic and multiscale modelling in materials. Nat Mater 20(6):774–786. https://doi.org/10.1038/s41563-020-00913-0

Karabasov S et al (2021) Multiscale modelling: approaches and challenges. Philos Trans R Soc A Math Phys Eng Sci 372(2021):20130390. https://doi.org/10.1098/rsta.2013.0390

Böhm HJ (1998) A short introduction to basic aspects of continuum micromechanics. Cdl-fmd Report, vol 3. https://www.ilsb.tuwien.ac.at/links/downloads/ilsbrep206.pdf

Hill R (1963) Elastic properties of reinforced solids: some theoretical principles. J Mech Phys Solids 11(5):357–372. https://doi.org/10.1016/0022-5096(63)90036-X

Okereke M, Keates S (2018) Finite element applications. Springer, Cham. https://doi.org/10.1007/978-3-319-67125-3

Schneider K, Klusemann B, Bargmann S (2017) Fully periodic RVEs for technological relevant composites: not worth the effort! J Mech Mater Struct 12(4):471–484. https://doi.org/10.2140/jomms.2017.12.471

Annapragada SR, Sun D, Garimella SV (2007) Prediction of effective thermo-mechanical properties of particulate composites. Comput Mater Sci 40(2):255–266. https://doi.org/10.1016/j.commatsci.2006.12.008

Xu W et al (2016) Analytical effective elastic properties of particulate composites with soft interfaces around anisotropic particles. Compos Sci Technol 129:10–18. https://doi.org/10.1016/j.compscitech.2016.04.011

Pierard O et al (2007) Micromechanics of elasto-plastic materials reinforced with ellipsoidal inclusions. Int J Solids Struct 44(21):6945–6962. https://doi.org/10.1016/j.ijsolstr.2007.03.019

Shen L, Yi S (2001) An effective inclusion model for effective moduli of heterogeneous materials with ellipsoidal inhomogeneities. Int J Solids Struct 38(32–33):5789–5805. https://doi.org/10.1016/S0020-7683(00)00370-X

Bahmani A et al (2018) Three-dimensional microscopic assessment of randomly distributed representative volume elements for high fiber volume fraction unidirectional composites. Compos Struct 192:153–164. https://doi.org/10.1016/j.compstruct.2018.02.075

Raghavan P, Ghosh S (2005) A continuum damage mechanics model for unidirectional composites undergoing interfacial debonding. Mech Mater 37(9):955–979. https://doi.org/10.1016/j.mechmat.2004.10.003

Wintiba B et al (2017) An automated procedure for the generation and conformal discretization of 3D woven composites RVEs. Compos Struct 180:955–971. https://doi.org/10.1016/j.compstruct.2017.08.010

Pierreux G, Van Hemelrijck D, Massart TJ (2019) Automated generation of 3D orthogonal woven composites RVEs including yarn cross-section variations. Compos Sci Technol 176:90–102. https://doi.org/10.1016/j.compscitech.2019.03.023

Han X et al (2020) Efficient multiscale modeling for woven composites based on self-consistent clustering analysis. Comput Methods Appl Mech Eng 364:112929. https://doi.org/10.1016/j.cma.2020.112929

**a Z, Zhang Y, Ellyin F (2003) A unified periodical boundary conditions for representative volume elements of composites and applications. Int J Solids Struct 40(8):1907–1921. https://doi.org/10.1016/S0020-7683(03)00024-6

Omairey SL, Dunning PD, Sriramula S (2019) Development of an ABAQUS plugin tool for periodic RVE homogenisation. Eng Comput 35:567–577. https://doi.org/10.1007/s00366-018-0616-4

Feder J (1980) Random sequential adsorption. J Theor Biol 87(2):237–254. https://doi.org/10.1016/0022-5193(80)90358-6

Stachurski ZH (2015) Fundamentals of amorphous solids: structure and properties. Wiley. ISBN: 978-3-527-33707-1

Ghossein E, Lévesque M (2012) A fully automated numerical tool for a comprehensive validation of homogenization models and its application to spherical particles reinforced composites. Int J Solids Struct 49(11–12):1387–1398. https://doi.org/10.1016/j.ijsolstr.2012.02.021

Tian W et al (2021) An algorithm for generation of RVEs of composites with high particle volume fractions. Compos Sci Technol 207:108714. https://doi.org/10.1016/j.compscitech.2021.108714

Cho YJ, Lee W, Park YH (2017) Finite element modeling of tensile deformation behaviors of iron syntactic foam with hollow glass microspheres. Materials 10(10):1201. https://doi.org/10.3390/ma10101201

Yu W, Qian M, Li H (2016) Elastic and plastic properties of epoxy resin syntactic foams filled with hollow glass microspheres and glass fibers. J Appl Polym Sci. https://doi.org/10.1002/app.44188

Carolan D et al (2020) Micromechanical modelling of syntactic foam. Compos B Eng 183:107701. https://doi.org/10.1016/j.compositesb.2019.107701

Catalanotti G (2016) On the generation of RVE-based models of composites reinforced with long fibres or spherical particles. Compos Struct 138:84–95. https://doi.org/10.1016/j.compstruct.2015.11.039

Sahu SK, Rama Sreekanth PS (2022) Multiscale RVE modeling for assessing effective elastic modulus of HDPE based polymer matrix nanocomposite reinforced with nanodiamond. Int J Interact Des Manuf (IJIDeM). https://doi.org/10.1007/s12008-022-01080-z

Yun J-H, Jeon Y-J, Kang M-S (2022) Analysis of elastic properties of polypropylene composite materials with ultra-high molecular weight polyethylene spherical reinforcement. Materials 15(16):5602. https://doi.org/10.3390/ma15165602

Shahzamanian MM et al (2022) Thermo-mechanical properties prediction of Ni-reinforced Al2O3 composites using micro-mechanics based representative volume elements. Sci Rep 12(1):11076. https://doi.org/10.1038/s41598-022-14685-x

Wang E et al (2020) Characterization of initial and subsequent yield behaviors of closed-cell aluminum foams under multiaxial loadings. Compos B Eng 202:108247. https://doi.org/10.1016/j.compositesb.2020.108247

Tashkinov MA, Shalimov AS (2021) Modeling of the effect of microscale morphological parameters on the deformation behavior of porous materials with a metal matrix. Phys Mesomech 24(5):618–624. https://doi.org/10.1134/S1029959921050131

He Y et al (2021) Construction of 3-D realistic representative volume element failure prediction model of high density rigid polyurethane foam treated under complex thermal-vibration conditions. Int J Mech Sci 193:106164. https://doi.org/10.1016/j.ijmecsci.2020.106164

Heydari A et al (2022) Real 3D structure-based finite element simulation of elastomer foams: effect of the foaming agent content. Ind Eng Chem Res 61(23):7881–7890. https://doi.org/10.1021/acs.iecr.1c04484

Lubachevsky BD, Stillinger FH, Pinson EN (1991) Disks vs. spheres: contrasting properties of random packings. J Stat Phys 64:501–524. https://doi.org/10.1007/BF01048304

Torquato S, Jiao Y (2010) Robust algorithm to generate a diverse class of dense disordered and ordered sphere packings via linear programming. Phys Rev E 82(6):061302. https://doi.org/10.1103/PhysRevE.82.061302

Segurado J, Llorca J (2002) A numerical approximation to the elastic properties of sphere-reinforced composites. J Mech Phys Solids 50(10):2107–2121. https://doi.org/10.1016/S0022-5096(02)00021-2

Gitman I, Askes H, Sluys L (2007) Representative volume: existence and size determination. Eng Fract Mech 74(16):2518–2534. https://doi.org/10.1016/j.engfracmech.2006.12.021

Schöberl J (1997) NETGEN An advancing front 2D/3D-mesh generator based on abstract rules. Comput Vis Sci 1(1):41–52. https://doi.org/10.1007/s007910050004

Schneider K, Klusemann B, Bargmann S (2016) Automatic three-dimensional geometry and mesh generation of periodic representative volume elements for matrix-inclusion composites. Adv Eng Softw 99:177–188. https://doi.org/10.1016/j.advengsoft.2016.06.001

He Q-C (2001) Effects of size and boundary conditions on the yield strength of heterogeneous materials. J Mech Phys Solids 49(11):2557–2575. https://doi.org/10.1016/S0022-5096(01)00068-0

Huet C (1999) Coupled size and boundary-condition effects in viscoelastic heterogeneous and composite bodies. Mech Mater 31(12):787–829. https://doi.org/10.1016/S0167-6636(99)00038-1

Melro A, Camanho P, Pinho S (2008) Generation of random distribution of fibres in long-fibre reinforced composites. Compos Sci Technol 68(9):2092–2102. https://doi.org/10.1016/j.compscitech.2008.03.013

Okereke M, Akpoyomare A (2013) A virtual framework for prediction of full-field elastic response of unidirectional composites. Comput Mater Sci 70:82–99. https://doi.org/10.1016/j.commatsci.2012.12.036

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Flow chart—procedure for random sphere packing

Appendix 2: Computational algorithms

Algorithm 1: Random packing of non-intersecting spheroids

Algorithm 2: Random positioning of non-intersecting spheres within the RVE

Algorithm 3: Detection of first binary collision

Algorithm 4: Detection of collisions with the cube domain

Algorithm 5: Post binary-collision velocity update

Algorithm 6: Creating periodic images of spheres collided with the matrix domain

Algorithm 7: Generation of periodic geometry

Algorithm 8: Generate periodic mesh from periodic geometry

Algorithm 9: Implementation of periodic boundary conditions to periodic RVE

Appendix 3: Mathematical formulation

Main program | ||

|---|---|---|

Eq# | Equation | Description |

1 | \(\frac{4}{3}\pi \mu_{ri}^3 = \frac{0.05}{{V_f }}\left( {\frac{4}{3}\pi \mu_r^3 } \right)\) | Determining the scaled-down mean radius \(\mu_{ri}\) to be from 5% to the target volume fraction \(V_f\) |

\(\mu_{ri} = \sqrt[3]{{\frac{{~0.05(\mu _r )^3 }}{{V_f }}}}\) | Solving for \(\mu_{ri}\) | |

2 | \(\Delta t = min (t_s , t_c )\) | The initial collision event occurs at the minimum time between the first binary collision, denoted as ‘\(t_s ,\)‘and the first collision between a sphere and a matrix domain ‘\(t_c\)’ |

3 | \(r_i^{n + 1} = r_i^n + v_i^n \Delta t^n\) | Update the position vector \(r_i^n\) using its velocity vector and the minimum collision time |

4 | \(R_i^{n + 1} = R_i^n + a_i \Delta t^n\) | Adjust the sphere radius by incorporating the radius growth rate ‘a' and the time increment \(\Delta t^n\) |

Random sequential adsorption | ||

|---|---|---|

Eq# | Equation | Description |

5 | \(d_{min} = \left( {R_i + R_j } \right)\) | To prevent overlap, the minimum distance \(d_{min}\) should be the sum of the two sphere radii |

6 | \(d = \sqrt {{\left( {x_i - x_j } \right)^2 + \left( {y_i - z_j } \right)^2 + \left( {z_i - z_j } \right)^2 }}\) | Calculating the distance between two spheres using the Pythagorean theorem |

Detection of first binary collision | ||

|---|---|---|

Eq# | Equation | Description |

7 | \(\left\| {\Delta r^n - \Delta v^n t} \right\| = \left[ {(R_i^n + R_j^n ) + (2at)} \right]\) | The collision time "t" is defined as the moment when the new distance between two spheres, denoted as \(\left\| {\Delta r^n - \Delta v^n t} \right\|\), becomes equal to the sum of their respective radii, including the radius growth in radius \(\left[ {(R_i^n + R_j^n ) + (2at)} \right]\) |

8 | \(\left\| {\Delta r^n } \right\| = r_i^n - r_j^n\) | \(\left\| {\Delta r^n } \right\|\) represents the distance between two spheres, calculated as the magnitude of the difference between their respective position vectors, denoted as \(r_i^n - r_j^n\) |

9 | \(\left\| {\Delta v^n } \right\| = v_i^n - v_j^n\) | \(\left\| {\Delta v^n } \right\|\) denotes the disparity in the velocity vectors of two spheres |

10 | \(\alpha t^2 + 2\beta t + \gamma = 0\) | Solving Eq. (7) results in a quadratic equation for the variable "t" |

11 | \(\alpha = \left\| {\Delta v^n } \right\|^2 - (2a)^2\) | Computing \(\alpha\) to solve Eq. (7) |

12 | \(\beta = \Delta r^n \cdot \Delta v^n - (R_i^n + R_j^n )(2a)\) | Computing \(\beta\) to solve Eq. (7) |

13 | \(\gamma = \left\| {\Delta r^n } \right\|^2 - (R_i^n + R_j^n )^2\) | Computing \(\gamma\) to solve Eq. (7) |

14 | \(t_{cij} = \frac{1}{\alpha }\left[ { - \beta - \sqrt {\beta^2 - \alpha \gamma } } \right]\) | Computing the collision time between spheres "i" and "j" occurs only when (\(\beta \le { }0\) or \(\alpha < { }0\)) and (\(\beta^2 - { }\alpha { }\gamma \ge { }0\)); otherwise, \((t_{cij} = \infty )\) indicating no collision |

\(t_c = {\text{min}}(t_{cij} )\) | The initial collision event takes place at the minimum time among all potential collisions | |

Detection of first collision between a sphere and the matrix domain | ||

|---|---|---|

Eq# | Equation | Description |

15 | \(D_i = \left\{ {\begin{array}{*{20}l} {(r_i^n + v_i^k \cdot \Delta t) - R_i } \hfill & {{\text{collision}}\;{\text{with}}\; {\text{master}}\;{\text{faces}}} \hfill \\ {L - R_i^n - (r_i^n + v_i^k \cdot \Delta t)} \hfill & {{\text{collision}}\;{\text{with}}\;{\text{image}}\;{\text{faces}}} \hfill \\ \end{array} } \right.\) | Computing \(D_i\), the distance between each sphere and the surface domain |

\(t_{si} = \left\{ {\begin{array}{*{20}l} {\frac{{\left[ {R_i^n - r_i^n } \right]}}{{\left[ {v_i^k - a_i } \right]}}} \hfill & {{\text{collision}}\;{\text{with}}\; {\text{master}}\;{\text{faces}}} \hfill \\ {\frac{{\left[ {L - R_i^n - r_i^n } \right]}}{{\left[ {v_i^k + a_i } \right]}}} \hfill & {{\text{collision}}\;{\text{with}}\;{\text{image}}\;{\text{faces}}} \hfill \\ \end{array} } \right.\) | The time \(t_{si}\) represents the duration required for each sphere to collide with the matrix domain, taking into account its velocity and radius growth rate | |

Post binary-collision velocity update | ||

|---|---|---|

Eq# | Equation | Description |

16 | \(u = (r_i^{n + 1} - r_j^{n + 1} )/r_i^{n + 1} - r_j^{n + 1}\) | Determining the unit vector ‘u’ for the upcoming collision between spheres 'i' and 'j' |

17 | \(v_z^n = \left( {v_z^n \cdot n} \right)u\;{\text{where }}\;z = \{ i,j\}\) | Decomposing the unit vector into parallel component |

18 | \(\bot v_z^n = v_z^n - v_z^n \; {\text{where }}\; z = \{ i,j\}\) | Decomposing the unit vector into perpendicular component |

19 | \(v_i^{n + 1} = \left[ {v_j^n + (2a_i )u} \right] + \bot v_i^n\) | Calculate the new velocity vector of the collided sphere \(i\): |

20 | \(v_j^{n + 1} = \left[ {v_i^n - (2a_i )u} \right] + \bot v_j^n\) | Calculate the new velocity vector of the collided sphere \(j\): |

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Elbana, A., Khennane, A. & Hazell, P.J. Multiscale modelling of particulate composites with spherical inclusions. Engineering with Computers (2024). https://doi.org/10.1007/s00366-024-01954-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00366-024-01954-8