Abstract

Currently, there is a growing interest in valorizing agro-food byproducts having interesting bioactives with functional and health properties. This paper deals with the use of apple pomace (AP), the most abundant by-product of apple juice industry, to formulate a novel value-added mayonnaise (AP mayo). The effect of AP on the chemical and rheological characteristics, microbiological quality, and sensory attributes of the new product was studied during a 30-day storage at refrigerated temperature. A comparison with two commercial mayo samples was also carried out. The results highlighted that the AP mayo showed a total phenol content of 2.12 mg gallic acid equivalents (GAE)/g, and improved antioxidant properties (DPPH radical-scavenging activities 2.47 mg TE/g; 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulphonic acid) diammonium salt, ABTS 3.18 mg TE/g; ferric reducing antioxidant power, FRAP 2.78 mg TE/g). After 30 days, it was more stable than the other two mayo. Moreover, AP mayo showed even higher overall acceptability scores by the assessors than the commercial samples. The results confirm that the addition of AP represents a valid approach to increase the health properties of spreads and sauces, satisfying the demand of health-conscious consumers, even those who prefer plant-based foods. The proposed healthy mayonnaise confirm the AP is a multifunctional ingredient with interesting potential applications in the formulation of new spreads/sauces with antioxidant properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nowadays, the agro-food industry produces high amounts of waste having evaluable compounds with interesting bioactivity, among which phenols. These bioactives may be useful in the food industry as natural ingredients and functional food additives, possessing health-promoting effects, including antioxidant, anti-inflammatory, and immunomodulatory properties [1, 2].

A significant amount of waste is generated by the fruit juice industry every year [3]. Among the primary by-product of apple juice industry, the apple pomace (AP) is an interesting functional and healthy ingredient, as recently reviewed [4]. In fact, recently, AP has been used to fortify meat products, to produce enriched foods (i.e., bread, sweet bakery products) and also to replace synthetic antioxidants [5,6,7].

Among spreads and sauces, conventional mayonnaise is a very popular oil in water emulsified semi-solid food product, generally obtained with egg, vegetable oil, and vinegar. An ever-faster transition to vegan diets and increased public health awareness have led manufacturers to produce egg-free, vegan, low-calorie, and functionalized mayonnaise-type products [8]. Furthermore, both for consumers and food sector specialists, the replacement of chemical additives with natural compounds/extracts is currently of great interest, also to improve the shelf-life of foods [9]. For example, ginger powder (1.0% and 1.25%) added to egg-mayonnaise saved the sensory and chemical characteristics during 20-week storage period compared to the control sample [10]. The oxidative stability of the mayonnaise enriched with grape seed extract was slightly improved through storage, even if the non-added sample showed the highest sensorial acceptability [11]. The inclusion of pea pod powder in low-fat egg-free mayonnaise led at the same time to better sensory attributes and to good physical stability of the product, as confirmed by rheological and textural parameters [12]. Other authors reported also the preparation of vegan mayonnaises adding phenol extracts from olive oil industry waste (mill wastewater or pomace) [13, 14]. A novel cholesterol-free mayonnaise with excellent stability upon 210-day storage, obtained using pickering emulsion stabilized by AP addition, was also produced [15].

This paper deals with the use of AP as multifunctional ingredient to enrich an egg-free mayonnaise (AP mayo), to obtain a new food dressing with improved healthy characteristics. The freeze-dried AP was previously evaluated for phenol profile and antioxidant properties by spectrophotometric and chromatographic methods using a high-performance liquid chromatography coupled with an UV detector (HPLC–UV). AP contribution was evaluated also from a formulation point of view, by exploiting its emulsifying properties, useful in the preparation of a food emulsion which classically contains eggs, and therefore emulsifiers of animal origin. The obtained AP mayo was analyzed for its chemical composition, physical and functional properties, and for its rheological and microbiological characteristics. The sensory, colour, and textural properties were also evaluated in comparison to two commercial mayonnaise samples, a traditional and a vegan mayo available on the market.

Materials and methods

Chemicals, reagents, and samples

Folin and Ciocalteu’s phenol reagent, 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulphonic acid) diammonium salt (ABTS), 2,2-diphenyl-1-picrylhydrazyl (DPPH radical), gallic acid, ( ±)-6-hydroxy-2,5,7,8-tetramethylchromane-2-carboxylic acid (Trolox), methanol, and ethanol were from Sigma-Aldrich (Milan, Italy). Edible-grade citric acid, analyzed according to Ph.Eur.9.3, was from Caelo Caesar and Loretz, GMBH (Hilden, Germany). Organic apples of Royal Gala variety (reported on the label) and the other items (high-oleic sunflower oil, salt, vinegar, and lecithin) for the formulation of mayonnaise were bought from a local market. Two commercial mayonnaise samples (a traditional egg-yolk mayo and a vegan rice-based mayo) were also acquired for a comparison. The ingredients of traditional egg-yolk mayo were: vegetable oils 70% (sunflower, soy), water, white wine vinegar, pasteurized egg yolk 5%, salt, modified starch, thickener: xanthan gum, concentrated lemon juice, and flavorings. The ingredients of vegan rice-based mayo were: sunflower oil, waterfall, wine vinegar, sugar, rice flour 2.3%, salt, natural flavors, modified corn starch, rice protein 0.2%, thickener: xanthan gum, and concentrate (carrot, apple).

Preparation of AP

The preparation of AP was carried out according to Cossignani and coworkers, with slight modifications [16]. The apples washed and cut into pieces (without seeds and petioles) were dipped in edible‐grade 1% citric acid solution before juice extraction by a domestic extractor (R.G.V., Como, Italy). The obtained AP was homogenized, freeze-dried (Hetodrywinner, Analytical Control De Mori, Milano, Italy), and finally milled with a blender (Oster, model n. 869-50R, Milwaukee, WI, USA). The powder obtained was sieved by steel sieves (Endecotts Ltd, London, UK) with mesh sizes of 250 μm and 400 μm to obtain three different dimensional fractions [particle size (PS): > 400 µm, 250–400 µm, < 250 µm]. Freeze-dried AP fractions were stored in amber glass jar at room temperature (r.t.) in the dark, until the successive analytical characterization.

Determination of total phenol content and in vitro antioxidant activity

The bioactive compounds of AP were extracted by ultrasound-assisted extraction (UAE) following the conditions reported in a previous paper (ethanol:water, 50:50 v/v; solid/liquid ratio, 1:10 w/v; 45 °C; 45 min) using an ultrasonic bath (AU-65 model, ultrasonic/heating power 180 W, ArgoLab, Carpi, Italy) [8]. AP extract was then analyzed to evaluate the total phenol content (TPC) and in vitro antioxidant activity. The determination of TPC was performed according to Pagano and coworkers, with slight modifications [17]. Folin and Ciocalteu’s phenol reagent was used and the absorbance was measured at 765 nm. The TPC was reported as mg gallic acid equivalents per gram of dry weight apple pomace (mg GAE/g DW). The free radical-scavenging activity using ABTS assay was performed according to a previous paper with slight modifications [18]. A freshly prepared ABTS solution was added to the extracts and the absorbance was measured at 734 nm after 10 min. The free radical-scavenging activity of the sample was also evaluated by adding to the extracts the DPPH reagent (0.06 mM in ethanol). The absorbance was read after 30 min at 517 nm [18]. The reducing capacity of the extracts was evaluated using the ferric reducing antioxidant power (FRAP) assay according to a previous paper, with slight modifications [19]. The AP sample was added to the FRAP reagent and the absorbance was measured after 30 min at 593 nm. Results of ABTS, DPPH, and FRAP assays were reported as mg of Trolox equivalent per gram of dry weight apple pomace (mg TE/g DW).

HPLC–UV analysis of phenols from AP

The HPLC analysis of extracts was performed using a Thermo Spectra Series pump (Thermo Scientific, Rockford, IL, USA) coupled with a Shimadzu UV/Vis spectrophotometric detector SPD‐10A VP UV–Vis, set at a wavelength of 320 nm. The chromatographic separation was carried out with a C18 Hypersil Gold column (250 × 4.6 mm, 5 μm particle size). The composition of the mobile phase and the validation method are reported in a previous paper [5].

Optimization of AP-enriched mayonnaise formulation

For the production of AP-enriched mayonnaise (AP mayo), MODDE 5.0 experimental design software (UMETRICS AB, Umeå, Sweden) was used for optimizing the conditions. The experiments were performed using the AP with the best spectrophotometric and chromatographic parameters and the conditions showed in the worksheet (R&D section, Table 1). The following factors were considered: water content (%; 30 or 70%), lecithin (% w/v; from 0.5 to 4%), and AP content (% w/v; from 2 to 6%). Mayo samples were prepared by adding high-oleic sunflower oil (%; 70 or 30%, based on the water content), salt (1%) and vinegar (6%). The parameter “viscosity” (expressed as Pa ∙ s) was selected as response of the model. It was determined as reported in the following paragraph and measured at shear stress value of 94.7 Pa. Full factorial (two-level)-interaction experimental design including three replicated center points (N9–N11) was employed. A total of 11 experiments, carried out in random order using the conditions indicated in the worksheet, was obtained. The model was then fitted using partial least-squares analysis. The obtained preparations (N1–N11) were analyzed as reported in the following paragraphs.

Rheological measurements

The rheological profiles of the mayonnaise samples were measured by a Stresstech HR rheometer (Rheological Instruments, AB Milan, Italy) equipped with a cone-plate geometry (diameter 40 mm, angle 1°). Viscosity yield stress and oscillation measurements were performed at 25.0 ± 0.1 °C simulating the storage conditions at r.t. (n = 3 ± SD). For both the viscosity and yield stress measurement, the samples were submitted to shear stress in the range 1–100 Pa. In the case of oscillation measurements, first, it was necessary to identify the linear viscoelastic region submitting the samples to a preliminary experiment in which the frequency was fixed to 1 Hz applying a stress in the range of 0.1–100 Pa. Then, frequency sweep measurements were performed using the frequency range 0.1–10 Hz and the stress value previously determined in the linear viscoelastic region.

Physical stability studies

Mayonnaise samples (N1–N11) were submitted to the following stability studies [20]: (i) Accelerated stability studies: the samples were submitted to eight 4 °C/45 °C cycles of 48 h. Each cycle consisted in the storage of each sample alternatively at 4 °C (for 48 h) and 45 °C (for 48 h). (ii) Centrifugation test: the samples were centrifuged at 25 °C for 20 min at 3000 rpm (Hettich centrifuge, Universal 32 R).

In both cases, the appearance was evaluated in terms of phase separation.

Production of AP-enriched mayonnaise

For the preparation of an AP-enriched mayo batch, the parameters %w (%oil), %lec, and %AP were selected on the basis of the optimization results and of physical stability. The content of the other ingredients was established on the basis of the preparation reported by Flamminii and coworkers [21]. Water (30%), vinegar (6%), and salt (1%) were mixed in a backer under magnetic stirring. Then, freeze-dried AP (> 400 μm, 4%) and lecithin (2.25%) were added and mixed again until a homogeneous mixture was obtained. This mixture was maintained under magnetic stirring at r.t. for 24 h. The day after, oil (70%) was added drop by drop to the mixture, mixing at 14,000 rpm using a homogenizer (SilentCrusher M model, Heidolph Instruments GmbH & Co. KG, Schwabach, Germany). AP mayo batch was analyzed as described in the previous section “Rheological measurements” and in the following paragraphs, and compared with two commercial mayonnaises (traditional mayo and vegan mayo). Mayo samples were immediately analyzed (time 0, T0), while some aliquots were stored at refrigeration temperature (0–4 °C) in the dark for 30 days (T30). The analytical characterization (rheological, chemical–physical, microbiological properties, and colour) was done after regular time intervals (T0, T15, and T30).

Microscopic analysis

Microstructure observation of the emulsions (AP mayo batch and commercial samples) was carried out by a Nikon Eclipse 80i optical microscope (Melville, USA). The sample was put on a glass and observed using a magnification 40 X. Photographs were taken with a digital camera Nikon Coolpix 8400 mounted on the microscope.

Colour analysis

The colour of the mayonnaise samples was measured during the storage using the ColorMeter RGB Colorimeter app (White Marten GmbH, Stuttgart, Germany) for iOS on an iPhone XS with iOS 13.7. The app was calibrated against a reference colorimeter, a Chroma Meter Minolta CR 200 (Konica Minolta Inc. Tokyo, Japan). In this way, we were able to measure the average colour of the entire product to replicate the consumer’s perception. The methodology used has already been described by the authors in previous manuscripts [5, 6]. The CIELAB scale was used to express results. The CIELAB colour space covers the entire range of human colour perception and it is based on the opponent colour model of human vision. It expresses colour as three values: L* for lightness, a* for red-green opponent colours, and b* for yellow-blue opponent colours.

Determination of pH and microbiological analysis of mayonnaise samples

To measure the pH of mayonnaise samples, an S40 Seven-Multi digital pH-meter (Mettler-Toledo Italia, Novate Milanese, Italy) was used after mixing 10 g of mayonnaise with 90 mL of distilled water. Samples were homogenized with a stomacher at 260 rotations for 1 min. Measurements were carried out in triplicate for AP mayo and the two commercial ones, during the storage. For each analysis, eight bacterial populations were evaluated: total aerobic mesophilic flora, Lactobacillus spp., Lactococcus spp., enterococci, Staphylococcus spp., Enterobacteriaceae, total coliforms, and Pseudomonas spp. The methodology used for the microbiological analysis has already been described by the authors in a previous work [22]. At the end, the number of colonies was converted to the log of colony forming units (CFU) per gram (log CFU/g), and the mean was calculated for each analysis. Sensitivity for spread plate was 102 CFU/g and for pour plate was 10 CFU/g, and the 95% confidence limit was set between ± 37% and ± 12% (i.e., plates with a number of CFU ranging from 30 to 300). Analyses were carried out in triplicate for AP mayo and the two commercial ones.

Determination of TPC and antioxidant properties of mayonnaise samples

Mayonnaise samples were subjected to extraction on the basis of a previous paper, with slight modifications [23]. Briefly, after the addition of methanol to mayonnaise, samples were gently vortexed (model ZX3 advanced vortex mixer, VELP Scientifica Srl, Usmate, Italy) for about 30 s and subjected to UAE for 15 min at r.t. The extracts were then filtered using a syringe filter (nylon membrane 25 mm, 0.45 µm pore size, VWR international, Milan, Italy) and methanol was removed under vacuum at 30 °C. The extracts were kept at 4 °C until further analysis, as reported in the section “Determination of total phenol content and in vitro antioxidant activity”.

Sensory evaluation of mayonnaise samples

A panel test was performed on AP mayo and on commercial samples. The panel consisted of 18 previously trained assessors. The tasters were asked to test the AP mayo and the two commercial mayonnaise samples for the following characteristics: colour intensity, colour uniformity, emulsion stability, odour (global intensity), acid odour, salty flavour, acid flavour, bitter flavour, sweet flavour, rancid flavour, flavour intensity, after-taste, spreadability, homogeneity, consistency/density, creaminess, graininess, and overall acceptability. Each assessor was given sheets with a seven-point (unnumbered to avoid biased assessment) scale for each characteristic: 7 = maximum intensity and 1 = minimum intensity. The evaluations were performed in individual booths, built according to the criteria of the ISO 4121:2003 [24]. Water and unsalted bread were provided to cleanse the palate between samples. Assessments were carried out under natural light at 20 ± 2 °C. The individual scores by each assessor were then averaged to give a score for the taste panel as a whole. Three evaluations for each different batch of mayonnaise were performed. Each evaluation was carried out in different test sessions at the same time of day, between 10 and 12 a.m.

Statistical analysis

All analytical determinations were performed at least three times (n = 3), and the results were reported as mean value and standard deviation (SD). Statistical significance was measured through one-way analysis of variance (ANOVA) followed by Tukey’s honestly significant difference post hoc test. A p value less than 0.05 (p < 0.05) was considered statistically significant. The correlation analysis was carried out by linear regression model. OriginPro 9.0 (OriginLab Corporation, Northampton, MA, USA) was used as statistical software.

Results and discussion

Spectrophotometric and chromatographic characterization of AP

AP from Royal Gala apples was characterized by spectrophotometric and chromatographic procedures after its homogenization, freeze-drying, and sieving.

First, the isolation of the bioactive molecules from AP was carried out by UAE, using the conditions described in a previous paper [16]. Among innovative unconventional techniques, UAE was chosen as the most performing method to obtain extracts with high bioactive content and high antioxidant activity [25, 26].

The obtained extracts were analyzed by spectrophotometric procedures to evaluate the TPC and in vitro antioxidant activity (DPPH, ABTS, and FRAP) and the related results are shown in Online Resource 1 (Table 1S). The results obtained for AP with PS higher than 400 μm showed the highest value of TPC and DPPH (p < 0.05). The DPPH assay is widely used in phytochemistry to evaluate the properties of plant constituents to scavenge free radicals. The method is based on the spectrophotometric measurement of the DPPH concentration change resulting from the reaction with an antioxidant. Also, the FRAP value was the highest for AP with PS higher than 400 μm, even if it was not statistically different from the others (p > 0.05). FRAP assay is a typical electron transfer-based method that measures the reduction of ferric ion (Fe3+)–ligand complex to the intensely blue-coloured ferrous (Fe2+) complex by antioxidants in an acidic medium. Regarding the ABTS results, the highest value was found for AP with PS 250–400 µm, but the difference with the other samples was not statistically significant (p > 0.05). This method is based on decolorization that occurs when the radical cation ABTS•+ is reduced to ABTS (2, 2'-azino-bis (3-ethylbenzthiazoline-6-sulphonic acid). The trend of spectrophotometric data of homogenized and freeze-dried AP (PS > 400 µm) was in accordance with the data reported in a previous paper about AP with the same PS [16]. To make a comparison with literature data, the wide variability of the obtained results must be considered. This is attributable to numerous factors, among which agronomic, pedoclimatic, and technological ones [27, 28]. The extraction methods and conditions used to isolate the bioactives from food matrix have also great importance [29]. Some researchers studied 11 different cider apple pomaces and reported TPC values from 2.3 to 15.1 g GAE/kg of dry matter [27]. Similar values of TPC and antioxidant activity, determined by DPPH, ABTS, and FRAP assays, were found in some previous works regarding AP from apples of Red Delicious variety [5, 6].

Aiming to obtain a more detailed information on the qualitative and quantitative composition of the extracts showing the described properties, a deep characterization of extracts was carried out by HPLC–UV analysis. The results are reported in Online Resource 2 (Table 2S), together with the TPC–HPLC value (total phenol content calculated as sum of contents of the individual phenols). The chromatographic analysis, validated in a previous paper, allowed to quantify quercetin derivatives, chlorogenic acid, and phloridzin [5]. Quercetin-3-O-rutinoside (rutin) was always below the limit of quantification (LOQ). Generally, quercetin-3-O-galactoside was the most abundant phenol compound, followed by quercetin-3-O-arabinofuranoside, regardless of AP particle size. In accordance with the trend of TPC and antioxidant data, the AP with PS > 400 μm also showed the highest TPC–HPLC value (p < 0.05) due to the highest content for most phenols. In fact, the content of the individual phenols of this fraction was ever significantly higher than that detected for AP with PS < 250 (p < 0.05), while only some compounds were more abundant with respect to AP with PS 250–400 μm (p < 0.05). It is widely demonstrated that the qualitative and quantitative composition of phenols in AP changed in a wide range [27,28,29,30]. As an example, Antonic et al. (2020) reported phloridzin from 8 to 1435.4 mg/kg DW, chlorogenic acid from 26 to 2298 mg/kg DW, and quercitrin from 69 to 373.8 mg/kg DW [30]. In a previous paper, the same phenols were found for AP from Royal Gala or Red Delicious variety [5, 6, 16].

Correlation studies between spectrophotometric parameters and TPC–HPLC were also carried out. Very good correlation values have been obtained for TPC vs DPPH (R2 = 0.9537), TPC vs FRAP (R2 = 0.9552), and TPC vs TPC–HPLC (R2 = 0.9628).

Optimization of AP mayo production

AP with the best spectrophotometric and chromatographic parameters was used to optimize the formulation of AP mayo, studying the influence of three selected variables (water %, lecithin %, AP %) on viscosity by an experimental design (Table 1).

The screening objective was selected and the full factorial (two-level)-interaction experimental design was chosen. The experimental design reported high values regarding the percentage of the variation of the response explained by the model (R2 = 0.9726) and the percentage of the variation of the response predicted by the model (Q2 = 0.6997).

Figure 1 shows the coefficient plot of the considered factors (%w, %lec, and %AP) and some of their interactions. It can be observed that the response was positively influenced by %w and %AP, while %lec exhibited an inverse correlation, as well as the interactions (%w*lec and %lec*AP).

Figure 2A–C shows the three-dimensional contour plots which indicate the viscosity predicted by the software MODDE 5.0., as a function of: AP and water content (2.25% lec), Fig. 2A; lecithin and water content (4% AP), Fig. 2B; AP and lecithin content (50% w), Fig. 2C. It can be noted that the highest viscosity values were obtained when the AP% was 6% and water was 70%.

Three-dimensional contour plots showing the viscosity predicted by the software MODDE 5.0., as a function of: AP and water content, when the percentage of lecithin was fixed at 2.25% (A); lecithin and water content, when the percentage of AP was fixed at 4% (B); AP and lecithin content, when the percentage of water was fixed at 50% (C)

A preliminary evaluation about the physical stability of the prepared mayonnaise samples was performed to make a selection of the most suitable composition to submit to further investigations. Samples were submitted to two different stability assays. The accelerated stability assay showed a separation of the two phases (Online Resource 3, Fig. 1S) for all the samples, except for N9, N10, and N11 (replicates of the same composition).

On the basis of the results obtained by experimental design and physical stability, the following conditions (70% w, 2.25% lec, and 4% AP) were selected for the preparation of the mayonnaise for further investigation.

Rheological measurements of mayo samples

The most suitable formulation resulted that of the replicated sample (N9–N11, hereinafter named AP mayo) that for this reason was further characterized and compared with two commercial mayonnaise samples, one traditional (containing eggs) and the other vegan. The products were first compared in terms of rheological properties.

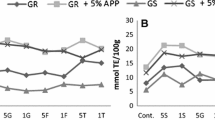

First, viscosity was measured, and in all cases, a shear thinning behavior was observed (Fig. 3A). The rheograms show substantial differences among the analyzed samples. The vegan mayonnaise is the most viscous formulation as testified by the low shear rate values measured; moreover, it should be underlined that the behavior does not change along the period investigated (T0–T30). AP mayo sample showed the best flow properties as testified by the shear rate values measured in the shear stress range investigated (0–150 1/s vs 0–35 1/s for AP mayo and traditional, respectively). These differences are ascribable to the different microstructure of the emulsions. In fact, pictures of the samples taken by the optical microscope (Fig. 4) highlight that AP mayo shows coarse and irregular oil droplets dispersed in the external water phase. The droplet dimensions decrease in the case of traditional becoming fine in the case of vegan mayo. This suggests that the decrease of oil droplets’ dimensions (strongly influenced by the emulsification/homogenization method adopted, unknown for the commercial formulations) is responsible for the increase of the total surface area of the oil phase with a consequent increase in the interfacial surface between the oil (lipophilic phase) and water (hydrophilic) phases. This is responsible for higher viscosities as reported also in literature [31]. The explanation of this resides mainly in the highly dispersed phase concentration obtained when the dispersed phase is fine. In this case, the distance among the droplets decreases with a consequent increase of the droplet–droplet interactions. This is responsible for an increased resistance to flow under shear stress solicitations, bringing to high viscosity values measured. In fact, the viscosity of the emulsion external phase is very important in the rheological conditioning of the final products [31].

Plot of shear stress (Pa) vs shear rate (1/s) registered at 25 °C at different times (T0, T15, and T30) for AP mayo and the two commercial ones (n = 3 ± SD) (A); frequency sweep tests showing the frequency dependence of the elastic G’ and loss G’’ moduli of the investigated mayonnaises. Data represent the average of three independent determinations (B)

It is possible to observe that AP mayo flow properties did not change substantially within 30 days, suggesting that, despite it is less viscous than the other two products, it does not undergo substantial changes during the investigated storage period resulting more stable.

In the case of traditional mayo, it is possible to observe an increase of viscosity from T0 to T30. This means that this formulation is more susceptible to modifications within 30 days testified by the modified flow properties.

Another important rheological characterization consisted in the measurement of the yield stress value at the three time points (T0, T15, and T30). The yield stress is expressed as the stress value necessary to induce the flow of a semi-solid material and it is a very important parameter to know in terms of usability of the product such as its release from a tube/dispenser or withdrawal from a jar.

As reported in Table 2, vegan mayonnaise showed the highest values (confirmed by the high viscosity value measured). According to the previous observations about viscosity measurement, the highly dispersed oil phase (fine droplets) is responsible for this behavior as reported in the literature [32]. Moreover, an increase from T0 to T30 was observed suggesting rheological product changes, becoming more thick and more viscous and thus requiring a higher force to flow in comparison to T0. During the investigation time of this property (T0–T15 and T0–T30), values were statistically different (p < 0.05). Generally, it is recommended to store mayonnaise at 4 °C after opening. As the samples were stored in refrigerator after opening (T0), probably the observed modifications may be attributable to the storage temperature. In fact, Katsaros and coworkers observed that the yield stress value decreases (as consequence of apparent viscosity decrease) as the storage temperature increases and this is attributable to the protein fraction of mayonnaise, folded at high temperatures (high flow properties) and unfolded at low temperatures [33]. Thus, it is reasonable to think that decreasing the temperature to 4 °C the yield value increases.

The values obtained from AP mayo and traditional mayo are comparable (p > 0.05, not statistically significant, comparing T0 values) suggesting that the behavior of the prepared mayonnaise is comparable with the commercial traditional one. This aspect is very important as it can influence the acceptability by final user who, not perceiving substantial differences related to texture, can be further encouraged to consume the new product.

The measurement of the viscoelastic properties performed at T0 and T30 showed similar behavior with the storage modulus (G′) greater than the loss modulus (G″), typical for emulsions (Fig. 3B) [34]. This behavior is due to the three-dimensional network formed by the interaction between droplets in mayonnaises [34]. In the case of AP mayo, the difference is not relevant and this is probably due to the droplet size of the internal phase, larger than the two commercial products. In fact, it is reasonable to think that the small droplets of the commercial mayonnaises are able to form a more resistant network conferring a higher elastic character to the product than AP mayo. The prevalence of the elastic modulus (G’) suggests that the formulation is stable in particular under mechanical solicitations (e.g., filling procedure in the tubes, jar glass).

Evaluation of pH and colour of mayo samples

Mayonnaise is a stabilized oil–water emulsion characterized by low pH, which plays an important role in its structure and stability. The low pH is due to some of the ingredients, mainly vinegar [35]. Table 3 shows the values of pH, together with the colour coordinates (L*, a*, and b*) of mayonnaise samples at different times (T0, T15, and T30). In our study, samples showed the following pH values at T0: traditional mayo 4.60 ± 0.23, vegan mayo 2.30 ± 0.16 and AP mayo 2.35 ± 0.21. During storage, commercial samples (both egg yolk and vegan) showed a good pH stability, while pH of AP mayo samples raised (from 2.25 ± 0.07 at T15 to 3.84 ± 0.06 at T30). The addition of AP among the ingredients brought to a final product with pH similar to the commercial vegan mayo (the difference was not statistically significant with p < 0.05). Some authors reported lower pH in mayonnaise produced with the addition of apple peel than the control [36]. Other authors reported a similar pattern in mayonnaise produced with other ingredients of vegetable origin, such as olive leaf phenol extract [21]. This behavior is probably due to both the mild sourness of the ingredient and the hydrolysis of triglycerides with the consequence increase in free fatty acid content [37].

Colour analysis of mayonnaise samples

Colour deeply influences consumer choices. Generally, the average consumer is used to the typical light-yellow colour of mayonnaise due to the main ingredients (egg yolk and oil). The addition of different ingredients can lead to colour changes which could influence the consumer's final choice. With regard to colorimetric analysis results (Table 3), AP mayo showed lower L* coordinate values than commercial samples; the difference was found to be statistically significant (p < 0.05). The L* coordinate indicates the brightness of the sample; consequently, the mayonnaise enriched with AP resulted darker than the others. Also, with regard to a* coordinate, a statistically significant difference (p < 0.05) was observed between the AP mayo and the commercial samples. In this case, mayonnaise with AP was the only sample showing positive values (therefore tending more toward red). As regards the b* coordinate, on the other hand, no statistically significant differences (p > 0.05) were observed at the beginning of the experiment, while statistically significant higher values were observed for AP mayo at T15 and T30 (p < 0.05). The values of the colorimetric coordinates obtained in our study are comparable to those reported by other authors who have produced mayonnaise with the addition of AP [15]. This study concluded that AP mayo presented different colour from traditional mayo. This effect is certainly linked to the original colour of AP which tends to be brownish, with higher a* coordinates compared to egg yolk and oil. Other studies have shown that the addition of different products of vegetable origin to mayonnaise (such as edible refined sunflower oil and olive leaf phenol extract) has a visible effect on the colour of the final product [21, 38]. The colour maintained a good stability through the entire storage period.

Phenol content and antioxidant activity of mayo samples

The following step was the evaluation of the phenol content and antioxidant activity of the AP mayo and commercial samples. Table 4 shows the results of the spectrophotometric assays. With regard to TPC, the highest value was obtained for AP mayo (2.12 mg GAE/g; p < 0.05), while lower value was found for traditional and vegan mayo (1.67 and 0.83 mg GAE/g, respectively; p < 0.05).

To evaluate the antioxidant activity of extracts from mayo samples, three complementary in vitro assays were carried out. According to TPC values, DPPH data showed the highest value (2.47 mg TE/g; p < 0.05) for AP mayo, while lower and similar values were found for the other two samples (1.75 and 1.71 mg TE/g for traditional and vegan mayo, respectively; p > 0.05).

The free radical-scavenging activity of mayo extracts was also determined by the ABTS assay. According to the trend of TPC and DPPH results, the most interesting result of the ABTS assay was obtained for AP mayo (3.18 mg TE/g), with respect to the others (p < 0.05). Lower values were found for traditional (2.93 mg GAE/g) and for vegan mayo (1.70 mg GAE/g). Moreover, FRAP assay was carried out and the results are in agreement with those of the previous spectrophotometric assays. In fact, FRAP result was the highest for AP mayo (2.78 mg TE/g), even if the difference was statistically significant only with the traditional mayo result.

It can be summarized that for all antioxidant assays, statistically significant differences were found between AP mayo and the other samples, with the exception of FRAP data, which was not statistically different from the vegan one (p > 0.05). From a comparison with literature data regarding mayonnaises added with bioactives, the TPC and the antioxidant activity values of the dressings are rarely reported. As an example, De Bruno and collaborators reported TPC values of 353 and 404 mg GAE/kg, DPPH values of 74 and 100 µmol TE/100 g, and ABTS values of 590 and 752 µmol TE/100 g for mayonnaises added with two different olive mill wastewater phenol extracts, and stored for 45 days at 10 °C [13].

After 180-day storage at 25 °C, mayonnaises added with eugenol–lean clove extract and mustard showed TPC values of 0.98 and 0.24 mg GAE/g, and DPPH values of 29.98 and 111.31 μg/mL (IC50), respectively [23].

The obtained results indicate that the mayo enriched with AP, proposed in this work, represents a new value-added spread with antioxidant properties.

Microbiological analysis of mayo samples

Mayonnaise is a relatively microbiologically stable product mainly due to its low pH (< 4.5) and the presence of organic acids, acetic acid in particular. These ingredients lower the final pH of the product, contribute to the typical flavour, and represent hurdles for the bacterial growth [39]. In our study, the bacterial populations investigated (total aerobic mesophilic flora, Lactobacillus spp., Lactococcus spp., enterococci, Staphylococcus spp., Enterobacteriaceae, total coliforms, and Pseudomonas spp) showed levels below the limit of detection of the methodology (10 CFU/g) at all time of analysis, both in commercial samples (traditional mayo and vegan mayo) and in AP mayonnaise. These results indicate that AP can be used as an ingredient in the production of mayonnaise with hygienic and safety characteristics comparable to the traditional commercial alternatives, without any risk for the consumer.

Sensory evaluation of mayo samples

Results of the sensory evaluation are reported in the spider plots shown in Fig. 5A–C. As regards appearance attributes, the highest score for colour intensity was obtained by the traditional egg-yolk mayo (5.72) followed by AP mayo (4.72) and vegan mayo (3.44). The two commercial samples obtained highest and similar scores for both colour uniformity (6.61 traditional egg-yolk mayo and 6.28 vegan mayo) and emulsion stability (6.83 and 6.50 respectively), while the AP mayo showed lower average values (4.11 for colour uniformity and 4.89 for emulsion stability). The global odour intensity was higher for the commercial samples (4.76 traditional mayo and 5.00 vegan mayo) and lower for AP mayo (3.61), while all samples obtained very similar scores for the acid odour. As regards basic tastes, all samples obtained similar scores for flavour intensity. The after-taste, defined as the taste remaining in the mouth after eating or drinking something, was stronger for the commercial mayo (4.76 traditional mayo and 4.61 vegan mayo) compared to AP mayo (3.78). Salty flavour was higher for traditional mayo (4.17) followed by vegan mayo (3.89) and AP mayo (3.33). AP mayo obtained the highest scores for both acid (4.94) and bitter flavour (2.67), followed by vegan mayo (4.72 and 2.22, respectively) and traditional mayo (4.22 and 1.89, respectively). The highest score for sweet flavour was obtained by the vegan mayo (2.89) followed by AP mayo (2.61) and traditional mayo (2.28). The vegan mayo obtained also the highest score for rancid flavour (2.67), while AP mayo (1.50) and traditional mayo obtained lower scores (1.39).

As regards texture attributes, the two commercial mayo obtained higher scores for spreadability (6.44 both), homogeneity (6.39 traditional mayo and 6.33 vegan mayo), consistency/density (5.83 and 5.33, respectively), and creaminess (5.83 and 5.61, respectively), while AP mayo obtained lower scores (spreadability 5.06, homogeneity 4.50, consistency/density 3.72, and creaminess 4.28).

An opposite pattern was observed for graininess, where AP mayo obtained the highest score 3.17 followed by vegan mayo (1.44) and traditional egg-yolk mayo (1.33). The highest score for overall acceptability was obtained by the traditional mayo (5.44) followed by the AP mayo (4.72) and the vegan mayo (3.72).

The addition of AP among the ingredients did not increase the bitterness neither the saltiness of the final product. Other vegetable ingredients, such as olive leaf phenol extracts, are known to increase the bitterness of the mayonnaise when added among the ingredients [21]. At the same time, the addition of AP did not increase the perception of salty flavour by the assessors: these two aspects are probably linked, considering that it is reported in the literature that bitter compounds can enhance the salt perception [40]. It is worth noticing that in many basic tastes, the AP mayo has obtained better evaluation by the assessors if compared with the vegan mayo. In our study, AP mayo obtained worst scores in texture attributes and emulsion stability if compared with commercial products, both traditional and vegan. The traditional mayonnaise is a typical oil in water emulsion where the egg yolk acts as an emulsifier and plays a dominating role in the texture and stability of the product. In commercial vegan alternatives, the egg-yolk role is replaced with additives, such as emulsifiers and thickeners [8, 41, 42]. In a study by Lu and coworkers, three types of mayonnaise were produced with the addition of AP particles using different emulsification methods: micro-jet, ultrasonic, and high-speed-shear methods [15]. The authors reported a good emulsion stability measured with visual inspection in a very long storage period (210 days) but observed some colour modifications. Another study investigated the possibility to modify AP with wet-milled process (a low-cost and environmentally acceptable physical modification method, already successfully utilized in food industries to produce nano/micrometer size particles for mayonnaise production) [43]. They reported a superior stability of emulsion and an enhancement of emulsion properties for smaller particles [34]. In this study, AP mayo obtained higher overall acceptability scores by the assessors than the commercial vegan mayo. This is an important indication for the possibility to use AP in the production of vegan alternatives to the traditional mayonnaise recipe.

Conclusion

In conclusion, the results of this study suggested that AP represents a valid multifunctional ingredient able to contribute to the structuring of the emulsion and its chemical–physical stability. Thanks to emulsifier and thickening capacities, in fact, AP represents a suitable texturizing agent allowing to obtain a mayonnaise with rheological properties similar to the traditional product, with excellent stability and good shelf-life. The health properties of the AP-based innovative dressing are no less relevant, in fact it is an egg- and cholesterol-free mayonnaise characterized by the presence of bioactive compounds which contribute to the functional properties. Based on these remarks, this innovative product can satisfy health-conscious consumers, also meeting the demand of those who prefer plant-based foods. Another aspect to underline is also its contribution to the good organoleptic characteristics of the product. All that is very important in the perspective to attract the consumer and to stimulate him in the choice of this new product.

Data availability

Data sharing is not applicable to this article.

References

Faustino M, Veiga M, Sousa P, Costa EM, Silva S, Pintado M (2019) Agro-food byproducts as a new source of natural food additives. Molecules 24:1056. https://doi.org/10.3390/molecules24061056

Capanoglu E, Nemli E, Tomas-Barberan F (2022) Novel approaches in the valorization of agricultural wastes and their applications. J Agric Food Chem 70:6787–6804. https://doi.org/10.1021/acs.jafc.1c07104

Kandemir K, Piskin E, **ao J, Tomas M, Capanoglu E (2022) Fruit juice industry wastes as a source of bioactives. J Agric Food Chem 70:6805–6832. https://doi.org/10.1021/acs.jafc.2c00756

Lyu F, Luiz SF, Perdomo Azeredo DS, Cruz AG, Ajlouni S, Ranadheera CS (2020) Apple pomace as a functional and healthy ingredient in food products: a review. Processes 8:319. https://doi.org/10.3390/pr8030319

Pollini L, Blasi F, Ianni F, Grispoldi L, Moretti S, Di Veroli A, Cossignani L, Cenci-Goga BT (2022) Ultrasound-assisted extraction and characterization of polyphenols from apple pomace, functional ingredients for beef burger fortification. Molecules 27:1933. https://doi.org/10.3390/molecules27061933

Grispoldi L, Ianni F, Blasi F, Pollini L, Crotti S, Cruciani D, Cenci-Goga BT, Cossignani L (2022) Apple pomace as valuable food ingredient for enhancing nutritional and antioxidant properties of Italian salami. Antioxidants 11:1221. https://doi.org/10.3390/antiox11071221

Manzoor S, Masoodi FA, Rashid R, Dar MM (2022) Effect of apple pomace-based antioxidants on the stability of mustard oil during deep frying of French fries. LWT Food Sci Technol 163:113576. https://doi.org/10.1016/j.lwt.2022.113576

Mirzanajafi-Zanjani M, Yousefi M, Ehsani A (2019) Challenges and approaches for production of a healthy and functional mayonnaise sauce. Food Sci Nutr 7:2471–2484. https://doi.org/10.1002/fsn3.1132

Blasi F, Cossignani L (2020) An overview of natural extracts with antioxidant activity for the improvement of the oxidative stability and shelf life of edible oils. Processes 8:956. https://doi.org/10.3390/pr8080956

Kishk YFM, Elsheshetawy HE (2013) Effect of ginger powder on the mayonnaise oxidative stability, rheological measurements, and sensory characteristics. Ann Agric Sci 58:213–220. https://doi.org/10.1016/j.aoas.2013.07.016

Altunkaya A, Hedegaard RV, Harholt J, Brimer L, Gökmen V, Skibsted LH (2013) Oxidative stability and chemical safety of mayonnaise enriched with grape seed extract. Food Funct 4:1647–1653. https://doi.org/10.1039/c3fo60204d

Rudra SG, Hanan E, Sagar VR, Bhardwaj R, Basu S, Sharma V (2020) Manufacturing of mayonnaise with pea pod powder as a functional ingredient. J Food Meas Charact 14:2402–2413. https://doi.org/10.1007/s11694-020-00487-0

De Bruno A, Romeo R, Gattuso A, Piscopo A, Poiana M (2021) Functionalization of a vegan mayonnaise with high value ingredient derived from the agro-industrial sector. Foods 10:2684. https://doi.org/10.3390/foods10112684

Akcicek A, Karasu S, Bozkurt F, Kayacan S (2022) Egg yolk-free vegan mayonnaise preparation from pickering emulsion stabilized by gum nanoparticles with or without loading olive pomace extracts. ACS Omega 7:26316–26327. https://doi.org/10.1021/acsomega.2c02149

Lu Z, Zhou S, Ye F, Zhou G, Gao R, Qin D, Zhao G (2021) A novel cholesterol-free mayonnaise made from Pickering emulsion stabilized by apple pomace particles. Food Chem 15:353. https://doi.org/10.1016/j.foodchem.2021.129418

Cossignani L, Ianni F, Blasi F, Pollini L, Di Michele A, Pagano C, Ricci M, Perioli L (2023) Investigation on apple pomace as thickening agent with antioxidant properties. Plants 12:906. https://doi.org/10.3390/plants12040906

Pagano C, Perioli L, Blasi F, Bastianini M, Chiesi C, Cossignani L (2017) Optimisation of phenol extraction from wine using layered double hydroxides and technological evaluation of the bioactive-rich powder. Int J Food Sci Technol 52:2582–2588. https://doi.org/10.1111/ijfs.13544

Urbani E, Blasi F, Simonetti MS, Chiesi C, Cossignani L (2016) Investigation on secondary metabolite content and antioxidant activity of commercial saffron powder. Eur Food Res Technol 242:987–993. https://doi.org/10.1007/s00217-016-2687-z

Pollini L, Riccio A, Juan C, Tringaniello C, Ianni F, Blasi F, Mañes J, Macchiarulo A, Cossignani L (2020) Phenolic acids from Lycium barbarum leaves: in vitro and in silico studies of the inhibitory activity against porcine pancreatic α-amylase. Processes 8:1388. https://doi.org/10.3390/pr8111388

Pagano C, Calarco P, Ceccarini MR, Beccari T, Ricci M, Perioli L (2019) Development and characterization of new topical hydrogels based on alpha lipoic acid-hydrotalcite hybrids. Cosmetics 6:35. https://doi.org/10.3390/cosmetics6020035

Flamminii F, Di Mattia CD, Sacchetti G, Neri L, Mastrocola D, Pittia P (2020) Physical and sensory properties of mayonnaise enriched with encapsulated olive leaf phenolic extracts. Foods 9:997. https://doi.org/10.3390/foods9080997

Grispoldi L, Karama M, Sechi P, Iulietto MF, Cenci-Goga BT (2020) Effect of the addition of starter cultures to ground meat for beef burger preparation. Microbiol Res 11:8623. https://doi.org/10.4081/mr.2020.8623

Chatterjee D, Bhattacharjee P (2015) Use of eugenol-lean clove extract as a flavoring agent and natural antioxidant in mayonnaise: product characterization and storage study. J Food Sci Technol 52:4945–4954. https://doi.org/10.1007/s13197-014-1573-6

International Standards Organisation (ISO) (2003) ISO 4121:2003. Sensory analysis-guidelines for the use of quantitative response scales. ISO, Geneva

Chang Y, Shi X, He F, Wu T, Jiang L, Normakhamatov N, Sharipov A, Wang T, Wen M, Aisa HA (2022) Valorization of food processing waste to produce valuable polyphenolics. J Agric Food Chem 70:8855–8870. https://doi.org/10.1021/acs.jafc.2c02655

Kumar K, Srivastav S, Sharanagat VS (2021) Ultrasound assisted extraction (UAE) of bioactive compounds from fruit and vegetable processing by-products: a review. Ultrason Sonochem 70:105325. https://doi.org/10.1016/j.ultsonch.2020.105325

García DY, Valles BS, Picinelli-Lobo A (2009) Phenolic and antioxidant composition of by-products from the cider industry: apple pomace. Food Chem 117:731–738. https://doi.org/10.1016/j.foodchem.2009.04.049

Butkeviciute A, Abukauskas V, Janulis V, Kviklys D (2022) Phenolic content and antioxidant activity in apples of the ‘Galaval’ cultivar grown on 17 different rootstocks. Antioxidants 11:266. https://doi.org/10.3390/antiox11020266

Perussello CA, Zhang Z, Marzocchella A, Tiwari BK (2017) Valorization of apple pomace by extraction of valuable compounds. Compr Rev Food Sci Food Saf 16:776–796. https://doi.org/10.1111/1541-4337.12290

Antonic B, Jancikova S, Dordevic D, Tremlova B (2020) Apple pomace as food fortification ingredient: a systematic review and meta-analysis. J Food Sci 85:2977–2985. https://doi.org/10.1111/1750-3841.15449

Zhu Y, Gao H, Liu W, Zou L, McClements DJ (2020) A review of the rheological properties of dilute and concentrated food emulsions. J Texture Stud 51:45–55. https://doi.org/10.1002/aic.690421119

Pal R (1999) Yield stress and viscoelastic properties of high internal phase ratio emulsions. Colloid Polym Sci 277:583–588. https://doi.org/10.1007/s003960050429

Katsaros G, Tsoukala M, Giannoglou M, Taoukis P (2020) Effect of storage on the rheological and viscoelastic properties of mayonnaise emulsions of different oil droplet size. Helyon 6:e05788. https://doi.org/10.1016/j.heliyon.2020.e05788

Lu Z, Ye F, Zhou G, Gao R, Qin D, Zhao G (2020) Micronized apple pomace as a novel emulsifier for food O/W Pickering emulsion. Food Chem 330:127325. https://doi.org/10.1016/j.foodchem.2020.127325

Keerthirathne TP, Ross K, Fallowfield H, Whiley H (2016) A review of temperature, ph, and other factors that influence the survival of salmonella in mayonnaise and other raw egg products. Pathogens 5:63. https://doi.org/10.3390/pathogens5040063

Khalid MU, Shabbir MA, Mustafa S, Hina S, Quddoos MY, Mahmood S, Maryam Faisal F, Rafique A (2021) Effect of apple peel as an antioxidant on the quality characteristics and oxidative stability of mayonnaise. Appl Food Res 1:100023. https://doi.org/10.1016/j.afres.2021.100023

Tavakoli R, Karami M, Bahramian S, Emamifar A (2021) Production of low-fat mayonnaise without preservatives: using the ultrasonic process and investigating of microbial and physicochemical properties of the resultant product. Food Sci Nutr 9:2676–2685. https://doi.org/10.1002/fsn3.2227

Sikimic VM, Popov-Raljic JV, Zlatkovic BP, Lakic N (2010) Colour determination and change of sensory properties of mayonnaise with different contents of oil depending on length of storage. Sens Transducers 2010(112):138–165. https://doi.org/10.3390/s90301996

Tayfur M, Çakır S, Orkun T, Ercan A, Yabancı N (2013) Microbial quality of retail mayonnaise-base salads. Afr J Microbiol Res 7:2269–2273. https://doi.org/10.5897/AJMR12.1291

Amerine MA, Pangborn RM, Roessler EB (2013) Principles of sensory evaluation of food. Departments of Viticulture and Enology, Food Science and Technology, and Mathematics, University of California, Davis

Bai L, Huan S, Rojas OJ, McClements DJ (2021) Recent innovations in emulsion science and technology for food applications. J Agric Food Chem 69:8944–8963. https://doi.org/10.1021/acs.jafc.1c01877

Ma Z, Boye JI (2012) Advances in the design and production of reduced-fat and reduced-cholesterol salad dressing and mayonnaise: a review. Food Bioproc Tech 6:648–670. https://doi.org/10.1007/s11947-012-1000-9

Ullah I, Yin T, **ong S, Huang Q, Zia-ud-Din QL, Zhang J, Javaid AB (2018) Effects of thermal pre-treatment on physicochemical properties of nano-sized Okara (soybean residue) insoluble dietary fiber prepared by wet media milling. J Food Eng 237:18–26. https://doi.org/10.1016/j.jfoodeng.2018.05.017

Acknowledgements

The authors would like to thank Egidia Costanzi and Giuseppa Verducci for their support in the experimental procedures.

Funding

Open access funding provided by Università degli Studi di Perugia within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

Conceptualization: FB and LC. Formal analysis: LM, FI, CP, and LG. Investigation: LM, FI, CP, and LG. Methodology: FI and CP. Writing—original draft preparation: CP, LG, and FB. Writing—review and editing: FB, BCG, LP, and LC. Supervision: LP, BCG, and LC. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Ethics approval

This study does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mangiapelo, L., Ianni, F., Pagano, C. et al. Role of apple pomace in the formulation of a novel healthy mayonnaise. Eur Food Res Technol 249, 2835–2847 (2023). https://doi.org/10.1007/s00217-023-04331-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04331-9