Abstract

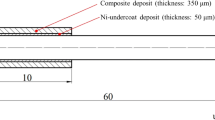

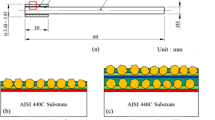

Cr-C-Ni-diamond composite deposits with synthetic diamond particles of 50 μm in average size were electroplated onto a medium-carbon steel rod to fabricate electroplated diamond grinding rods. To make an electroplated Cr-C-Ni-diamond grinding rod with a high diamond density, three sequential electroplating processes were proposed, including Ni undercoating, Ni-diamond co-electroplating, and Cr-C strengthen-electroplating. The Cr-C strengthening deposit was prepared in an eco-friendly Cr3+-based plating bath. A composite Cr-C-Ni-diamond deposit with multi-layered diamond particles could be prepared on the steel rod substrate by repeating the proposed three sequential electroplating processes. After electroplating, some of the prepared grinding rods were annealed at 500 °C for 30 min to increase the hardness of Cr-C deposit. As-plated and annealed electroplated Cr-C-Ni-diamond grinding rods with one- and two-layered diamond particles were used to grind slots in Al2O3 plates in a depth of 5 mm to evaluate their grinding-life performances. Based on the results of grinding tests, the ground length of an electroplated Cr-C-Ni-diamond grinding rod was significantly increased after annealing at 500 °C for 30 min, and the length was further extended by electroplating two layers of Cr-Cs-Ni-diamond composite deposit. A relatively long ground length of 1320 mm was achieved from the 500 °C-annealed electroplated diamond grinding rod with two-layered diamonds, but only 30 mm from the as-plated one. It was evidenced that an anneal-hardened Cr-C deposit can serve as a competent strengthening layer in the electroplated diamond tool.

Similar content being viewed by others

References

Costa MM, Flores P, Pereira D, Buciumeanu M, Cabral A, Fredel M, Silva FS, Henriques B, Miranda G (2018) Nickel-cobalt-based materials for diamond cutting tools. Int J Adv Manuf Technol 95:1059–1067

de Oliveira LJ, Bobrovnitchii GS, Filgueira M (2007) Processing and characterization of impregnated diamond cutting tools using a ferrous metal matrix. Int J Refract Met Hard Mater 25:328–335

Dhokey NB, Utpat K, Gosavi A, Dhoka P (2013) Hot-press sintering temperature response of diamond cutting tools and its correlation with wear mechanism. Int J Refract Met Hard Mater 36:289–293

Kim SK, Yoo HJ (1998) Formation of bilayer Ni–SiC composite coatings by electrodeposition. Surf Coat Technol 108-109:564–569

Wang SC, Wei WCJ (2003) Kinetics of electroplating process of nano-sized ceramic particle/Ni composite. Mater Chem Phys 78:574–580

Shi L, Sun C, Gao P, Zhou F, Liu W (2006) Mechanical properties and wear and corrosion resistance of electrodeposited Ni–Co/SiC nanocomposite coating. Appl Surf Sci 252:3591–3599

Pan B, Yang Y, Zhang Y (2019) Extraction of diamond grain topography from diamond tool surface using 3D surface measurement coupled with image analysis. Measurement 133:9–13

Shen X, Wang X, Sun F (2019) Fabrication and evaluation of monolayer diamond grinding tools by hot filament chemical vapor deposition method. J Mater Process Technol 265:1–11

Zhou H, Du N, Zhu L, Shang J, Qian Z, Shen X (2015) Characteristics investigation of Ni-diamond composite electrodeposition. Electrochim Acta 151:157–167

Wang L, Gao Y, Xue Q, Liu H, Xu T (2005) Effects of nano-diamond particles on the structure and tribological property of Ni-matrix nanocomposite coatings. Mater Sci Eng A 390:313–318

Tsubota T, Tanii S, Ishida T, Nagata M, Matsumoto Y (2005) Composite electroplating of Ni and surface-modified diamond particles with silane coupling regent. Diam Relat Mater 14:608–612

Huang W, Zhao Y, Wang X (2013) Preparing a high-particle-content Ni/diamond composite coating with strong abrasive ability. Surf Coat Technol 235:489–494

Wang L, Gao Y, Liu H, Xue Q, Xu T (2005) Effects of bivalent Co ion on the co-deposition of nickel and nano-diamond particles. Surf Coat Technol 191:1–6

Pushpavanam M, Manikandan H, Ramanathan K (2007) Preparation and characterization of nickel–cobalt-diamond electro-composites by sediment co-deposition. Surf Coat Technol 201:6372–6379

Huang CA, Yang SW, Shen CH, Cheng KC, Wang H, Lai PL (2019) Fabrication and evaluation of electroplated Ni–diamond and Ni–B–diamond milling tools with a high density of diamond particles. Int J Adv Manuf Technol 104:2981–2989

Yuttanant B, Kanokwan S, Sawalee S, Supin S (2010) Pulse co-electrodeposition and characterization of NiW-WC composite coatings. J Alloys Compd 506:151–154

Roberto G, Gianpaolo O (2011) Chromium electrodeposition from Cr(III) aqueous solutions. Surf Coat Technol 205:3947–3955

Wasekar NP, Sundararajan G (2015) Sliding wear behavior of electrodeposited Ni–W alloy and hard chrome coatings. Wear 342-343:340–348

Hong G, Siow KS, Zhiqiang G, Hsieh AK (2001) Hard chromium plating from trivalent chromium solution. Plat Surf Finish 88:69–75

Zeng Z, Wang L, Liang A, Zhang J (2006) Tribological and electrochemical behavior of thick Cr-C alloy coatings electrodeposited in trivalent chromium bath as an alternative to conventional Cr coatings. Electrochim Acta 52:1366–1373

Song YB, Chin DT (2002) Current efficiency and polarization behavior of trivalent chromium electrodeposition process. Electrochim Acta 48:349–356

Protsenko V, Danilov F (2009) Kinetics and mechanism of chromium electrodeposition from formate and oxalate solutions of Cr(III) compounds. Electrochim Acta 54:5666–5672

Kim D, Kim M, Nam KS, Chang S, Kwon SC (2003) Duplex coating for improvement of corrosion resistance in chromium deposit. Surf Coat Technol 169-170:650–654

Saravanan G, Mohan S, Gnanamuthu RM, Vijayakumar J (2008) Effect of AlCl3, CH3SO3H on thickness, current efficiency and corrosion properties of brush plated Cr(III) formate urea baths. Surf Eng 24:458–463

Huang CA, Lin CK, Chiou W-A, Hsu F-Y (2011) Microstructure study of the hardening mechanism of Cr–Ni alloy deposits after flame heating for a few seconds. Surf Coat Technol 206:325–329

Huang CA, Yang SW, Liu YW, Lai PL (2019) Effect of Cu and Ni undercoatings on the electrochemical corrosion behaviour of Cr–C-coated steel samples in 0.1 M H2SO4 solution with 1 g/L NaCl. Coatings 9:531

Huang CA, Chen JY, Chuang CH, Mayer J (2017) Properties of Cr–C–Al2O3 deposits prepared on a Cu substrate using Cr3+–based plating baths. Powder Metall Met Ceram 55:596–602

Acknowledgments

The authors, Ching An Huang and Po Liang Lai, thank the Chang Gung Medical Foundation for supporting this work under contract number of CMRPD2H0251.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, C.A., Shen, C.H., Yang, S.W. et al. Fabrication and evaluation of electroplated diamond grinding rods strengthened with Cr-C deposit. Int J Adv Manuf Technol 110, 2541–2550 (2020). https://doi.org/10.1007/s00170-020-05989-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05989-1