Abstract

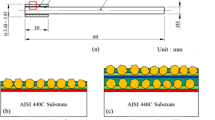

Ni–diamond and Ni–B–diamond composite deposits were electroplated with a current density of 20 A/dm2 on a steel cylinder with a diameter of 6.0 mm in a Ni-Watt bath with different tetramethylammonium borohydride (TMAB) concentrations and 300-g/L synthetic diamond particles with sizes between 30 and 50 μm. Prior to Ni–diamond or Ni–B–diamond composite electroplating, a Ni undercoating with a thickness of 50 μm was electroplated on the steel cylinder. During composite electroplating, diamond particles were intermittently stirred with different stirring cycles in the plating bath. Experimental results show the distribution of diamond particles in the Ni or Ni–B deposit depends strongly on the stirring cycle. A composite deposit with a high diamond density can be achieved with intermittent stirring by using an on the period of 5 s and an off period of 80 s. From the results of milling test, an electroplated Ni–B–diamond milling tool with a high milling ability can be achieved after annealing at 300 °C or 500 °C for 30 min.

Similar content being viewed by others

References

Costa MM, Flores P, Pereira D, Buciumeanu M, Cabral A, Fredel M, Silva FS, Henriques B, Miranda G (2018) Nickel-cobalt-based materials for diamond cutting tools. Int J Adv Manuf Tech 95:1059–1067

de Oliveira LJ, Bobrovnitchii GS, Filgueira M (2007) Processing and characterization of impregnated diamond cutting tools using a ferrous metal matrix. Int J Refract Met H 25:328–335

Dhokey NB, Utpat K, Gosavi A, Dhoka P (2013) Hot-press sintering temperature response of diamond cutting tools and its correlation with wear mechanism. Int J Refract Met H 36:289–293

Kim SK, Yoo HJ (1998) Formation of bilayer Ni–SiC composite coatings by electrodeposition. Surf Coat Tech 108-109:564–569

Wang SC, Wei WCJ (2003) Kinetics of electroplating process of nano-sized ceramic particle/Ni composite. Mater Chem Phys 78:574–580

Shi L, Sun C, Gao P, Zhou F, Liu W (2006) Mechanical properties and wear and corrosion resistance of electrodeposited Ni–Co/SiC nanocomposite coating. Appl Surf Sci 252:3591–3599

Zhou H, Du N, Zhu L, Shang J, Qian Z, Shen X (2015) Characteristics investigation of Ni-diamond composite electrodeposition. Electrochim Acta 151:157–167

Wang L, Gao Y, Xue Q, Liu H, Xu T (2005) Effects of nano-diamond particles on the structure and tribological property of Ni-matrix nanocomposite coatings. Mat Sci Eng A 390:313–318

Tsubota T, Tanii S, Ishida T, Nagata M, Matsumoto Y (2005) Composite electroplating of Ni and surface-modified diamond particles with silane coupling regent. Diam Relat Mater 14:608–612

Hou KH, Han T, Sheu HH, Ger M-D (2014) Preparation and wear resistance of electrodeposited Ni–W/diamond composite coatings. Appl Surf Sci 308:372–379

Yao Y, Yao S, Zhang L, Wang H (2007) Electrodeposition and mechanical and corrosion resistance properties of Ni–W/SiC nanocomposite coatings. Mater Lett 61:67–70

Lee EC, Choi JW (2001) A study on the mechanism of formation of electrocodeposited Ni–diamond coatings. Surf Coat Tech 148:234–240

Lee HK, Lee HY, Jeon JM (2007) Codeposition of micro- and nano-sized SiC particles in the nickel matrix composite coatings obtained by electroplating. Surf Coat Tech 201:4711–4717

Suzuki T, Konno T (2014) Improvement in tool life of electroplated diamond tools by Ni-based carbon nanotube composite coatings. Precis Eng 38:659–665

Wang L, Gao Y, Liu H, Xue Q, Xu T (2005) Effects of bivalent Co ion on the co-deposition of nickel and nano-diamond particles. Surf Coat Tech 191:1–6

Pushpavanam M, Manikandan H, Ramanathan K (2007) Preparation and characterization of nickel–cobalt-diamond electro-composites by sediment co-deposition. Surf Coat Tech 201:6372–6379

Lee KH, Chang D, Kwon SC (2005) Properties of electrodeposited nanocrystalline Ni–B alloy films. Electrochim Acta 50:4538–4543

Ogihara H, Udagawa K, Saji T (2012) Effect of boron content and crystalline structure on hardness in electrodeposited Ni–B alloy films. Surf Coat Tech 206:2933–2940

Liang Y, Li YS, Yu QY, Zhang YX, Zhao WJ, Zeng ZX (2015) Structure and wear resistance of high hardness Ni-B coatings as alternative for Cr coatings. Surf Coat Tech 264:80–86

Lekka M, Offoiach R, Lanzutti A, Mughal MZ, Sebastiani M, Bemporad E, Fedrizzi L (2018) Ni-B electrodeposits with low B content: effect of DMAB concentration on the internal stresses and the electrochemical behaviour. Surf Coat Tech 344:190–196

Fang X, ** G, Cui XF, Liu JN (2016) Evolution characteristics of residual stress in metastable Ni-B alloy coatings identified by nanoindentation. Surf Coat Tech 305:208–214

Acknowledgments

The authors, Ching An Huang and Po Liang Lai, thank the Chang Gung Medical Foundation for supporting this work under contract number of CMRPD2H0251.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, C.A., Yang, S.W., Shen, C.H. et al. Fabrication and evaluation of electroplated Ni–diamond and Ni–B–diamond milling tools with a high density of diamond particles. Int J Adv Manuf Technol 104, 2981–2989 (2019). https://doi.org/10.1007/s00170-019-04174-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04174-3