Search

Search Results

-

Process parameters and their effect on metal transfer in gas metal arc welding: a driving force perspective

In gas metal arc welding (GMAW), the optimization of process parameters and the control of metal transfer is pivotal for achieving superior welding...

-

Analysis of Heat Treatment and Its Effects on the Machinability of Inconel 718 Products Manufactured with Wire and Arc Additive Manufacturing Technique

This work analyzes the effects of different heat treatments on Inconel 718 samples produced with the Wire and Arc additive manufacturing (WAAM)...

-

Heat input control in horizontal lap joint welding through active wire preheating in GMAW-P

In gas metal arc welding (GMAW) the arc power, in general, increases when the wire feed speed is increased. Thus, controlling heat input into the...

-

Arc Welding Processes: Gas Tungsten Arc Welding: Pulse Current, Hot Wire and Activated Flux-Assisted GTAW: Plasma Arc Welding: Principle, System, Application

This chapter presents the influence of process parameters of pulse GTA welding process on the development of sound weld joint. Further, the concept...

-

Welding thermal efficiency in cold wire gas metal arc welding

Cold wire gas metal arc welding (CW-GMAW) has been increasingly used in heavy-gauge manufacturing where high deposition rates are required. In such...

-

Antibacterial and Virucidal Evaluation of Ultrafine Wire Arc Sprayed German Silver Coatings

Copper and its alloys are known as antimicrobial agents that can be used in public places; however, pure copper has a low wear resistance and tends...

-

Additive Manufacturing of Metal Components by Thermal Spray Deposition on 3D-Printed Polymer Parts

Metals were deposited using wire-arc spray-on components made by 3D printing with polyvinyl alcohol (PVA), a water-soluble polymer. The polymer was...

-

Corrosion Performance of Wire Arc Deposited Zinc Aluminum Pseudo Alloy and Zinc 15 Aluminum Alloy Coatings on Steel in Chloride Environment

This study investigated the corrosion performance of wire arc deposited zinc-aluminum pseudo alloy coating (Zn-Al pseudo alloy) with higher aluminum...

-

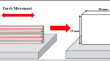

Influence of Interwire Distance and Arc Length on Welding Process and Defect Formation Mechanism in Double-Wire Pulsed Narrow-Gap Gas Metal Arc Welding

The effects of interwire distance (

d ) and arc length correction coefficient (C c ) on the arc behaviors, droplet transfer and welding process stability...

-

Optimizing Parameters of Arc-Sprayed Fe-Based Coatings Using the Response Surface Methodology

Arc-sprayed Fe-based coatings can provide a cheaper and more effective way of protecting cutting tools made of 65Mn steel against abrasive wear. Due...

-

Microstructure and Wear Resistance of Amorphous FeMnCrNiBNb Coating Prepared by High-Speed Arc Spraying

A novel Fe-based amorphous coating has been prepared on a 17CrNiMo6 substrate by high-speed arc spraying (HVAS). Using an orthogonal experimental...

-

Effect of Process Parameters on Twin Wire Arc Sprayed Steel Coatings

There has been a growing interest in additive manufacturing technologies for the protection and repair of metallic structural components. Among the...

-

Visualization and control of the free-flight transfer phenomenon in the wire feed control process

Gas metal arc (GMA) welding requires improved process stability, higher quality and efficiency, and quantitative control of the heat input and...

-

Mechanical Performance and Failure Mechanism of Layered Walls Produced by Wire Arc Additive Manufacturing in Metal Transfer Pulsed Mode

The Wire Arc Additive Manufacturing (WAAM) is a technique for 3D printing of metallic pieces. Aluminum alloys are particularly studied due to their...

-

Wire Based Directed Energy Deposition of JBK-75

Applications and adoption of metal additive manufacturing (AM) are increasing for fabrication of low volume, complex components with novel materials,...

-

Cold Gas Spray Inner Diameter Coatings and Their Properties

Due to recent developments, cold gas spraying technology can now be used to create inner diameter coatings for cylinder inner diameters > 70 mm. The...

-

Microstructure, mechanical, and corrosion resistance of copper nickel alloy fabricated by wire-arc additive manufacturing

Copper–nickel alloys were obtained by wire-arc additive manufacturing (WAAM) and thoroughly analyzed spectro- and microscopically. Mechanical...

-

Wire Arc Additive Manufacturing: A Comprehensive Review and Research Directions

Over the past years, the demand for the wire arc additive manufacturing (WAAM) is potentially increased, and it has become a promising alternative to...

-

In-Situ Alloying in Gas Metal Arc Welding for Wire and Arc Additive Manufacturing

The use of low transformation temperature (LTT) alloys seems to be a promising way for reducing the residual stress level of fusion welded...

-

Assessment of Process, Parameters, Residual Stress Mitigation, Post Treatments and Finite Element Analysis Simulations of Wire Arc Additive Manufacturing Technique

Wire arc additive manufacturing (WAAM) technique became an emerging manufacturing technology because of its cost-effective in creating large-scale...