Search

Search Results

-

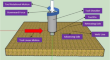

An investigation into optimizing the friction stir welding factors (FSWF) for yellow brass

Friction stir welding (FSW) is a green, environmentally amicable, and solid-state joining technology. In this research, FSW is successfully executed...

-

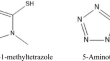

Comparative studies of tetrazole derivatives on the corrosion inhibition of copper and commercial brass in simulated seawater

The corrosion inhibition of copper and its alloys in seawater using organic inhibitors has received much interest. Electrochemical techniques were...

-

The effect of high-pressure cutting fluid supply on the chip breakability of lead-free brass alloys

To improve machinability and in particular chip breakability, brass alloys are usually alloyed with small quantities of lead. Due to environmental...

-

Effect of Brass Content and Speed of Cut on Machining Outcomes of Copper–2% Silver Alloy

Copper is one of the ductile materials which is difficult to machine, but extensively used in variety of applications such as electrical, thermal and...

-

Preliminary Thermo-mechanical Characterization of Brass Alloys

Thermomechanical evaluation depends on the material and its characteristics. Several parameters were used for this purpose: temperature, holding time...

-

Optimization of Composition, Cold Rolling Scheme, and Structure of Brass Strip Billets for Continuous High-Frequency Pressure Welding

AbstractThe article presents the results of analysis of the influence of the thickness, deformation scheme, grain size, and chemical composition of...

-

Refinement of the Voigt Hypothesis for Copper and Brass

AbstractAccording to the Voigt hypothesis, the internal frictional coefficient of metals is frequency-independent. Experiments with copper and brass...

-

Failure Analysis of a Brass Synchronizer Ring in the Gearbox of Vehicle

Synchronizers are the heart for vehicles. The reliability of synchronizer ring in the gearbox affects the operation of the entire systems of...

-

Novel drawing technology for high area reduction manufacturing of ultra-thin brass wires

A significant increase in roughness of dieless-drawn wires due to the strain-induced roughness phenomenon has been documented. For small-diameter...

-

Investigations on Bio-machining of Brass Using Staphylococcus Aureus

Micro-machining is a widely accepted technique of accurate metal removal on a microscopic scale. A subset of this is chemical machining, which uses...

-

On the function of lead (Pb) in machining brass alloys

Lead has traditionally been added to brass alloys to achieve high machinability, but the exact mechanisms at work are still debated. Lead-free brass...

-

Influence of sub-surface deformation induced by machining on stress corrosion cracking in lead-free brass

New stricter regulations on lead (Pb) content in brass for use in certain applications is driving the industry from traditional leaded brass towards...

-

Morphology of Finished Brass Surface by Thermal Additive Centrifugal Abrasive Flow Machining Process Using Novel Electrode

Thermal additive centrifugal abrasive flow machining (TACAFM) is the latest hybrid of abrasive flow machining, which involves a combination of...

-

Recycling of brass melting slag through the high-temperature oxidation-leaching process

Brass melting slag is a valuable secondary resource for the recovery of copper and zinc. The hydrometallurgical recovery process of this material is...

-

Dry Ice Cooling Effect on Friction Stir Welded AA6061 Alloy Using Brass Interlayer

This study investigated the impact of employing dry ice cooling and a brass interlayer on the metallurgical and mechanical behavior of AA6061 welded...

-

Microstructural Investigation of CuZn40Pb2 Brass: Effects of the Isothermal Heat Treatment

Hot forming process involves the plastic deformation of metal alloys such as steel and copper to produce pieces. The influence of holding time and...

-

Investigation of tensile properties of PLA–brass composite using FDM

Fused deposition modeling (FDM) is an additive manufacturing technique used to build complete three-dimensional models from a range of materials for...

-

Kinetics of Brass Waste by Hydrogen Reduction for Recovery of Valuable Metals

Gaseous reduction by hydrogen was proposed to decrease carbon dioxide emissions during the recovery of zinc and copper from brass waste. The...

-

The Influence of the Rake Angle on the Cutting of Low-Lead and Lead-Free Brass Alloys

Components manufactured from brass alloys are widely used in plumbing systems. Traditionally, lead is added to the alloy to improve the...

-

Machine learning surface roughnesses in turning processes of brass metals

Machine learning approaches can help facilitate the optimization of machining processes. Model performance, including accuracy, stability, and...