Abstract

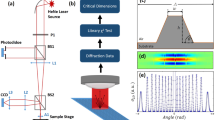

This chapter describes in-process measurement of subwavelength structures. Especially, from the viewpoint of affinity with in-process measurement, this chapter focuses on optical measurement, which provides in-process evaluation of engineering microstructure surfaces beyond the diffraction limit. First, application of optical super-resolution using structured light illumination to semiconductor patterns inspection is shown. Second, a new type of optical depth measurement of subwavelength microgrooves using an interference measuring method, which can measure the depth of microgrooves, with widths less than the diffraction limit, is described. Third, as an example of application of near-field optics for in-process measurement for quality of subwavelength structures, nano-thickness inspection of residual layer thickness during nanoimprint lithography is demonstrated. Through concrete examples, the possibility of an optical measurement method for the in-process measurement of subwavelength structures is discussed.

Similar content being viewed by others

References

Aigouy L, Lahrech A, GrÃsillon S, Cory H, Boccara AC, Rivoal JC (1999) Polarization effects in Apertureless scanning near-field optical microscopy: an experimental study. Opt Lett 24(4):187–189

Balla T, Spearing SM, Monk A (2008) An assessment of the process capabilities of nanoimprint lithography. J Phys D Appl Phys 41:174001–174010

Bruzzone AAG, Costa HL, Lonardo PM, Lucca DA (2008) Advances in engineered surfaces for functional performance. Ann CIRP 57(2):750–769

Calaon M, Hansen HN, Tosello G, Garnaes J, Norregaard J, Li W (2015) Microfluidic chip designs process optimization and dimensional quality control. Microsyst Technol 21:561–570

Chou SY, Krauss PR, Renstom PJ (1996) Nanoimprint lithography. J Vac Sci Technol B 14:4129–4133

de Groot P, de Lega XC, Liesener J, Darwin M (2008) Metrology of optically-unresolved features using interferometric surface profiling and RCWA modeling. Opt Exp 16(6):3970–3975

Gao P, Pedrini G, Osten W (2013) Structured illumination for resolution enhancement and autofocusing in digital holographic microscopy. Opt Lett 38(8):1328–1330

Gass J, Dakoff A, Kim MK (2003) Phase imaging without 2π ambiguity by multiwavelength digital holography. Opt Lett 28(13):1141–1143

Gustafsson MGL (2000) Surpassing the lateral resolution limit by a factor of two using structured illumination microscopy. J Microsc 198(2):82–87

Hansen HN, Carneiro K, Haitjema H, De Chiffre L (2006) Dimensional micro and nano metrology. Ann CIRP 55(2):721–743

Ho YL, Portela A, Lee Y, Maeda E, Tabata H, Delaunay JJ (2014) Hollow Plasmonic U-Cavites with high-aspect-ratio nanofins sustaining strong optical vortices for light trap** and sensing. Adv Opt Mater 2(6):522–528

Kawata S, Inouye Y (1995) Scanning probe optical microscopy using a metallic probe tip. Ultramicroscopy 57:313–317

Kudo R, Usuki S, Takahashi S, Takamasu K (2009) Fundamental verification for 2-dimensional super-resolution optical inspection for semiconductor defects by using standing wave illumination shift. Proceedings of IMEKO world congress, Lisbon, TC2

Kudo R, Usuki S, Takahashi S, Takamasu K (2011) Experimental analysis of influence of error on super-resolution optical inspection using standing wave illumination. Proceedings of the 10th international symposium of measurement technology and intelligent instruments, A5–4, Daejeon, pp 1–6

Lee H (2005) Effect of imprinting pressure on residual layer thickness in ultraviolet nanoimprint lithography. J Vac Sci Technol 23(3):1102–1106

Lehmann P, Niehues J, Tereschenko S (2014) 3-D optical interference microscopy at the lateral resolution. Int J Optomechtron 8(4):231–234

Lucy LB (1974) An iterative technique for the rectification of observed distributions. Astron J 79:745–754

Mico V, Zalevsky Z, Garcia-Martinez P, Garcia J (2006) Superresolved imaging in digital holography by superposition of tilted wavefronts. Appl Opt 45(5):822–828

Nishioka H, Takahashi S, Takamasu K (2006) A super-resolution microscopy with standing evanescent light and image reconstruction method. Proceedings of IMEKO world congress, Rio de Janeiro, TC2

Peng KQ, Wang X, Li L, Wu XL, Lee ST (2010) High-performance silicon Nanohole solar cells. Am Chem Soc 132(20):6872–6873

Takahashi S (2015) The gap between observation with light and geometric measurement. J Jpn Soc Mech Eng 118(1161):14–17

Takahashi S, Okada S, Nishioka H, Usuki S, Takamasu K (2008) Theoretical and numerical analysis of lateral resolution improvement characteristics for fluorescence microscopy using standing evanescent light with image retrieval. Meas Sci Technol 19:084006

Takahashi S, Ikeda Y, Takamasu K (2013) Study on nano thickness inspection for residual layer of nanoimprint lithography using near-field optical enhancement of metal tip. CIRP Ann 62(1):527–530

Takahashi S, ** C, Ye S, Michihata M, Takamasu K (2017) Theoretical analyses of in-process depth measurements of fine microgrooves based on near-field optical response. CIRP Ann 66(1):503–506

Usuki S, Nishioka H, Takahashi S, Takamasu K (2006) Development of super-resolution optical inspection system for semiconductor defects using standing wave illumination shift. Proceedings of SPIE 6375, Boston, 637508

Usuki S, Nishioka H, Takahashi S, Takamasu K (2008) Super-resolution optical measurement for ultra-precision machined surface defects by using structured light illumination shift (1st report): theoretical verification of resolution property. J Jpn Soc Precis Eng 74(5):498–503

Usuki S, Nishioka H, Takahashi S, Takamasu K (2010) Experimental verification of super-resolution optical inspection for semiconductor defect using standing wave illumination shift. Int J Adv Manuf Technol 46(9–12):863–875

Wingerden J, Frankena HJ, Smorenburg C (1991) Liner approximation for measurement errors in phase shifting interferometry. Appl Phys 30(19):2718–2729

Yuan C, Zhai H, Liu H (2008) Angular multiplexing in pulsed digital holography for aperture synthesis. Opt Lett 33(20):2356–2358

Yuan C, Situ G, Pedrini G, Ma J, Osten W (2011) Resolution improvement in digital holography by angular and polarization multiplexing. Appl Opt 50(7):B6–b11

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this entry

Cite this entry

Takahashi, S. (2019). In-Process Measurement of Subwavelength Structures. In: Gao, W. (eds) Metrology. Precision Manufacturing. Springer, Singapore. https://doi.org/10.1007/978-981-10-4912-5_15-1

Download citation

DOI: https://doi.org/10.1007/978-981-10-4912-5_15-1

Received:

Accepted:

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-4912-5

Online ISBN: 978-981-10-4912-5

eBook Packages: Springer Reference EngineeringReference Module Computer Science and Engineering