Abstract

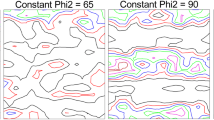

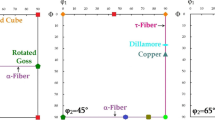

Evolution of Goss texture in an Al–Cu–Mg alloy during cold rolling was investigated by three-dimensional orientation distribution functions, electron back-scattered diffraction and transmission electron microscopy. The results showed that with increasing reduction from 23.7 to 80%, Goss textures gradually transformed into Brass texture through the activation of sole {111}<110> slip systems. When rolling reduction further increased from 80 to 86.3%, Goss texture rather than Brass started to rotate towards Copper and S components. The formation of Copper and S textures at these high reductions was attributed to the activation of {110}<110> and {001}<110> non-octahedral slip systems.

Similar content being viewed by others

References

Engler O, Vatne HE, Nes E. The roles of oriented nucleation and oriented growth on recrystallization textures in commercial purity aluminum. Mater Sci Eng A. 1996;205:187–98.

Hjelen J, Ørsund R, Nes E. On the origin of recrystallization textures in aluminium. Acta Metall. 1991;39:1377–404.

Liu WC, Morris JG. Quantitative analysis of texture evolution in cold-rolled, continuous-cast AA 5xxx-series aluminum alloys. Metall Mater Trans A. 2004;35A:265–77.

Leffers T, Ray RK. The brass-type texture and its deviation from the copper-type texture. Prog Mater Sci. 2009;54:351–96.

Smallman RE, Green D. The dependence of rolling texture on stacking fault energy. Acta Metall. 1964;12:145–54.

Schulthess TC, Turchi PEA, Gonis A, Nieh TG. Systematic study of stacking fault energies of random Al-based alloys. Acta Mater. 1998;46:2215–21.

Duckham A, Knutsen RD, Engler O. Influence of deformation variables on the formation of Copper-type shear bands in Al–1Mg. Acta Mater. 2001;49:2739–49.

Bowen AW. Texture development in high strength aluminum alloys. Mater Sci Technol. 1990;6:1058–70.

Alvi MH, Cheong SW, Suni JP, Weiland H, Rollett AD. Cube texture in hot-rolled aluminum alloy 1050(AA1050)–nucleation and growth behavior. Acta Mater. 2008;56:3098–108.

Engler O, Hirsch J, Lücke K. Texture development in Al-1.8 wt% Cu depending on the precipitation state—ΙΙ. Recrystallization textures. Acta Metall. 1995;43:121–38.

Zhao Q, Liu ZY, Li SS, et al. Evolution of the Brass texture in an Al–Cu–Mg alloy during hot rolling. J Alloys Compd. 2017;691:786–99.

Liu ZY, Li FD, **a P, Bai S, Gu YX, Yu DE, Zeng SM. Mechanisms for Goss-grains induced crack deflection and enhanced fatigue crack propagation resistance in fatigue stage II of an AA2524 alloy. Mater Sci Eng A. 2015;625:271–7.

Zhao Q, Liu ZY, Huang TT, **a P, Li FD. Enhanced fracture toughness in an annealed Al–Cu–Mg alloy by increasing Goss/Brass texture ratio. Mater Charact. 2016;119:47–54.

Liu WC, Morris JG. Effect of hot and cold deformation on the β fiber rolling texture in continuous cast AA 5052 aluminum alloy. Scr Mater. 2005;52:1317–21.

Contrepois Q, Maurice C, Driver JH. Hot rolling textures of Al–Cu–Li and Al Zn-Mg-Cu aeronautical alloys: experiments and simulations to high strains. Mater Sci Eng A. 2010;527:7305–12.

Bate PS, Huang Y, Humphreys FJ. Development of the ‘‘brass’’ texture component during the hot deformation of Al–6Cu–0.4Zr. Acta Mater. 2004;52:4281–9.

Liu WC, Zhai T, Man C-S, et al. Effect of initial texture on texture evolution in cold-rolled AA 5182 aluminium alloy. Philos Mag. 2004;84:3305–21.

Liu J, Morris JG. Texture and grain-boundary evolutions of continuous cast and direct chill cast AA 5052 aluminum alloy during cold rolling. Metall Mater Trans A. 2003;34:951–66.

Liu WC, Morris JG. Texture evolution of polycrystalline AA 5182 aluminum alloy with an initial {001}<110> texture during rolling. Scr Mater. 2002;47:487–92.

Huang YC, Liu Y, Li Q, Liu X, Yang CG. Relevance between microstructure and texture during cold rolling of AA3104 aluminum alloy. J Alloys Compd. 2016;673:383–9.

Liu WC, Zhai T, Morris JG. Texture evolution of continuous cast and direct chill cast AA 3003 aluminum alloys during cold rolling. Scr Mater. 2004;51:83–8.

Liu WC, Morris JG. Kinetics of the formation of the b fiber rolling texture in continuous cast AA 5xxx series aluminum alloys. Scr Mater. 2002;47:743–8.

Wu X, Tao N, Hong Y, Xu B, Lu J, Lu K. Microstructure and evolution of mechanically-induced ultrafine grain in surface layer of Al-alloy subjected to USSP. Acta Mater. 2002;50:2075–84.

Chen YX, Yang YQ, Feng ZQ, Zhao GM, Huang B, Luo X, Zhang YS, Zhang W. Microstructure, microtexture and precipitation in the ultrafine-grained surface layer of an Al–Zn–Mg–Cu alloy processed by sliding friction treatment. Mater Charact. 2017;123:189–97.

Hong C, Huang X, Winther G. Dislocation content of geometrically necessary boundaries aligned with slip planes in rolled aluminium. Philos Mag. 2013;93:3118–41.

Zhao Q, Liu ZY, Bai S, et al. Coincidence site lattice boundary mechanism for the preferred growth of Goss and Cube grains during annealing in an Al–Cu–Mg alloy. Mater Charact. 2018;141:193–211.

Chen YO, Yi DQ, Jiang Y, Wang B, Xu DZ, Li SC. Twinning and orientation relationships of T-phase precipitates in an Al matrix. J Mater Sci. 2013;48:3225–31.

Shin DH, Kim I, Kim J, Park KT. Grain refinement mechanism during equal-channel angular pressing of a low-carbon steel. Acta Mater. 2001;49:1285–92.

Daaland O, Nes E. Origin of Cube texture during hot rolling of commercial Al–Mn–Mg alloys. Acta Mater. 1996;44:1389–411.

Chen HS, Godfrey A, Hansen N, **e JX, Liu Q. Microstructure-grains orientation relationship in coarse grain nickel cold-rolled to large strain. Mater Sci Eng A. 2008;483–484:157–60.

Yao ZY, Huang GJ, Godfrey A, Liu W, Liu Q. Dislocation boundary structure from low to medium strain of cold rolling AA3104 aluminum alloy. Metall Mater Trans A. 2009;40A:1487–4896.

Sidor J, Petrov RH, Kestens L. Texture control in aluminum sheets by conventional and asymmetric rolling. Compr Mater Process. 2014;3:447–98.

Engler O, Hirsch J. Texture control by thermomechanical processing of AA6xxx Al–Mg–Si sheet alloys for automotive applications—a review. Mater Sci Eng A. 2002;336:249–62.

Acknowledgements

The authors are grateful for financial support from Hubei Provincial Natural Science Foundation of China (2018CFB177), National Natural Science Foundation of China (51901073), National Key Research and Development Program of China (2016YFB0300901), PhD research startup foundation of Hubei University of Automotive Technology (BK201702), and Key Laboratory of Automotive Power Train and Electronics (Hubei University of Automotive Technology).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, Q., Liu, Z., Hu, Y. et al. Evolution of Goss texture in an Al–Cu–Mg alloy during cold rolling. Archiv.Civ.Mech.Eng 20, 24 (2020). https://doi.org/10.1007/s43452-020-00023-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00023-3