Abstract

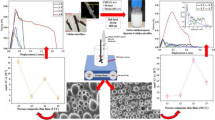

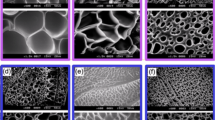

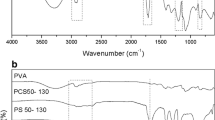

To date, epoxidized natural rubber (ENR) latex is still far from being commercially available for the production of dipped latex goods although the process was reported in 1922. Therefore, the objective of this work is to establish an understanding on the colloidal properties of ENR latex and relate them to coagulation and film formation. To do so, ENR latex was first prepared from low ammonia preserved natural rubber (LATZ) latex and then concentrated (C-ENR) using a patented process via membrane separation technology. NMR was used to determine the epoxidation level and ring opening in the ENR latex. The LATZ latex and both epoxidized latexes (ENR and C-ENR) were characterized for their particle size distribution, morphology, zeta potential and rheological properties. NMR analysis revealed an epoxidation level of 26% with < 2% ring opening. Particle size analysis showed C-ENR latex to have a narrow size distribution with no flocculation upon sonication. Zeta potential analysis as a function of pH showed a lower isoelectric point for C-ENR latex compared to LATZ latex. Zeta potential was also low for C-ENR latex compared to LATZ latex above pH 5 indicating an outward shift in the shear plane of the latex particle due to adsorption of the nonionic surfactant. Rheology of the latexes was studied using steady-state and oscillatory measurements. Elastic overshoot was observed for C-ENR latex at volume fraction (ϕ) of 0.490–0.584 indicating strong particle–particle interaction. The calculated maximum packing fraction (ϕp) of C-ENR latex was 0.721 compared to the ϕp of 0.815 for LATZ latex. The lower ϕp was attributed to the adsorbed nonionic surfactant layer on C-ENR latex particles. Oscillatory measurements showed that C-ENR latex behaved as dominantly elastic material from ϕ of 0.4975–0.584. At ϕ of 0.497 (= 48.5 wt%), the adsorbed polymer layers start to interact with each other. At this ϕ, the calculated adsorbed nonionic surfactant layer thickness (Δ) was 35 nm. As the latex concentration was increased, the latex became more elastic due to the interpenetration and compression of the surfactant layers. At the highest latex ϕ of 0.584 (= 57.6 wt%), tan δ was 0.3 resulting in an Δ of 20 nm. This thick layer of adsorbed surfactant hinders the coagulation of particles by salt during dip** thereby prohibiting the film formation process required to make the latex dipped products.

Similar content being viewed by others

References

Pummer R, Burkard PA (1922) Über kautschuk. Eur J Inorg Chem 55(10):3458–3472

Kolthoff IM, Lee TS, Mairs MA (1973) Use of perbenzoic acid in analysis of unsaturated compounds. J Appl Polym Sci, Polym Chem Ed 2:206–220

Saffer A, Johnson BL (1948) Measurement of internal double bonds in polymers by perbenzoic acid addition. Ind Eng Chem 40:538–541

Rorx C, Pautrat R, Cheritat R, Pinagzi C (1964) Epoxidation of 1,4 cis-polyisoprenes. Compt Rend Seances Acad Sci 258:5442–5445

Mairs JA, Todd J (1932) The oxidation of caoutchouc, gutta-percha and balata with hydrogen peroxide. J Chem Soc 386–399

Colclough T (1962) New method of modifying natural rubber. Trans Inst Rubber Ind 38:11

Gelling I (1991) Epoxidised natural rubber. J Nat Rubber Res 6(3):184–205

Farley PS, Banthorpe DV, Porter M (1992) Effect of adventitious iron on epoxidation of natural rubber latex. J Nat Rubb Res 7(3):157–167

Baker CSL, Gelling IR, Azemi S (1986) Epoxidised natural rubber. J Nat Rubb Res 1(2):135–144

Bac NV, Mihailov M, Terlemezyan L (1991) On the stability of natural rubber latex acidified by aetic acid and subsequent epoxidation by peracetic acid. Eur Polym J 27(60):557–563

Ruksakulpiwat C, Nuasaen S, Poonsawat C, Khansawai P (2008) Synthesis and modification of epoxidized natural rubber from natural rubber latex. Adv Mater Res 47–50:734–737

Gelling IR (1983) Epoxidized Cis 1.4-polyisoprene rubber. British Patent 2113692 A. Publication: Aug 10, 1983

Dazylah D, Ma’zam MS (2010) Vulcanisation and coagulant dip** of epoxidised natural rubber. Pertanika J Sci Technol 18(2):421–425

Ruslimie CA, Norhanifah MY, Fatimah RMR, Asrul M (2015). Effect of pre-vulcanization time on the latex particles, surface morphology and strength of epoxidised natural rubber films, CAMS-2015: 3rd International Conference on Chemical, Agricultural and Medical Sciences, 10-11 Dec 2015 Singapore, pp 64–69

Epoxidised Natural Rubber, Malaysian Rubber Research and Development Board, 1983

Blackley DC (1997) Polymer latices science and technology: types of latices, vol 2. Chapman and Hall, London

Devaraj V, Zairossani MN, Pretibaa S (2006) Membrane separation as a cleaner processing technology for natural raw rubber processing. J Appl Mem Sci Technol 4:13–22

Mohd Nor Z, Devaraj V, Rasdi FRM, Rahim MAA, Dazylah D (2017). Epoxidised natural rubber (ENRL) concentrate in dipped product application. P12017700457

Devaraj V, Zairossani M, Preetiba S, Aimi I (2012) An ultrafiltration system for concentration of latices and a process utilizing the system. Malaysian Patent Application No. PI 2012004868

ISO (2014) ISO 124 Latex, rubber—determination of total solids content

ISO (2005). ISO 126 Natural rubber latex concentrate—determination of dry rubber content

ISO (2011). ISO 125 Natural rubber latex concentrate—determination of alkalinity

MRB In-house Test Method UPB/P/022 (2017) Determination of epoxidised level via proton nuclear magnetic resonance spectroscopy, Malaysian Rubber Board

Hunter RJ (1981) Zeta potential in colloid science: principles and applications. Academic Press, London

Manroshan S (2018) The colloidal properties of commercial natural rubber latex concentrates. J Rubb Res 21(2):119–134

Kronberg B (2001) Chapter 22: measuring adsorption. In: Holmberg K (ed) Handbook of applied surface and colloid chemistry. Wiley, England

Vincent B (1974) The effect of adsorbed polymers on dispersion stability. Adv Colloid Interface Sci 4:193–277

Bingham EC (1922) Fluidity and plasticity. McGraw-Hill, New York

Quemada D (1998) Rheological modeling of complex fluids. I. The concept of effective volume fraction revisited. Eur Phys J AP 1:119–127

Pestridge C, Tadros ThF (1988) Rheological investigation of depletion flocculation of concentrated sterically stabilized polystyrene latex dispersions. Coll Surf 31:325–346

Nestor J, Obiols-Rabasa M, Esquena J, Solans C, Levecke B, Booten K, Tadros ThF (2008) Viscoelastic properties of polystyrene and poly(methyl methacrylate) dispersions sterically stabilized by hydrophobically modified inulin (polyfructose) polymeric surfactant. J Colloid Interface Sci 319:152–159

Acknowledgements

The authors would like to thank the Director General of Malaysian Rubber Board for permission to publish this paper. The assistances rendered by Mr. Hishamudin Samat for the preparation of ENR and C-ENR latexes, Miss Fauziah Jalani for the colloidal properties characterization of the latexes and Mr. Suhaimi Mohamed for SEM analysis are highly appreciated. The authors would also like to acknowledge Veronica Charlotte for language editing. This work was made possible through funding provided by the Malaysian Rubber Board Internal Grant S2019/Ekoprena/2019 (36)/719.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we do not have any commercial or associate interest that represents a conflict of interest in connection with the work submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, M., Mohd Rasdi, F.R. Colloidal properties of epoxidized natural rubber latex prepared via membrane separation technology. J Rubber Res 22, 153–167 (2019). https://doi.org/10.1007/s42464-019-00029-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-019-00029-4