Abstract

Carbon dioxide (CO2) injection has been applied extensively in hydrocarbon reservoirs for both increasing oil recovery and CO2 storage purposes. Recently, CO2 injection has been proposed to increase oil recovery and for CO2 storage in shale reservoirs. During CO2 injection in shale reservoirs, adsorption will take place on the surface of the rock, which will impact both the oil recovery and the storage capacity. This research provides a roadmap to the different types of adsorption and the adsorption measurements and calculations with emphasis on the ones most applicable during CO2 injection in shale reservoirs. The main two types of adsorption are initially explained including physisorption and chemisorption, and the major applicable adsorption isotherms are explained and their limitations are listed. The research then focusses on physisorption and its types, and hysteresis trends since chemisorption does not occur in shale reservoirs during CO2 injection. The different methods used to measure adsorption are then illustrated and explained including volumetric, gravimetric, volumetric-gravimetric, oscillometry, and impedance spectroscopy. The different calculation methods for volumetric adsorption are then explained. Finally, the most common errors that have been observed during measurement and calculation of adsorption are listed and explained, while mentioning the method to avoid each error. This research provides a guideline to the proper and accurate measurement of CO2 adsorption on shale rock during enhanced oil recovery applications and CO2 storage operations in unconventional shale reservoirs to improve the productivity and applicability of this application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Carbon dioxide (CO2) injection is currently one of the most applied enhanced oil recovery techniques in the oil industry due to several important reasons [1, 2]. Firstly, CO2 injection, either through flooding of cyclic huff-n-puff, can increase oil recovery significantly [3, 4]. Secondly, CO2 can be stored in several types of hydrocarbon reservoirs as part of the carbon storage initiative to reduce greenhouse emissions [5,6,7,8]. Recently, CO2 injection in unconventional low permeability shale reservoirs has been investigated for both enhanced oil recovery from these reservoirs, and CO2 storage ** and Firoozabadi [9]. In both applications, the CO2 will adsorb to the shale rock surface, which will have an effect of oil recovery, and also CO2 storage capacity [10,11,12].

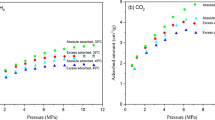

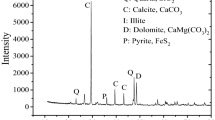

The adsorption of CO2 on the surface of shales, along with other rock, has been investigated using both computer simulation and modelling, and experimental work. Mohammad, S. [13] aimed to identify the most common sources of error associated with undergoing adsorption experiments. The errors investigated included the amount adsorbed through calculations, the void volume measured using helium, and the density of the injected gas which will affect the compressibility factor. Bahadori and Vuthaluru [14] developed a new correlation that can predict CO2 adsorption isotherms for pressures up to 17.5 psi, and 196 °C. The correlation was based on previously reported data, correlated as a function of CO2 partial pressure for different temperatures. Clarkson and Haghshenas [15] used several models and tested their applicability in modeling CO2 adsorption. They found that the simple Langmuir and Dubinin–Radushkevich models were the most adequate for modeling supercritical single component adsorption on coal and shale as long as the density value is adjusted on the simulator for the CO2 since it has a direct effect on the compressibility value. Yu [16] used BET Isotherm rather than Langmuir Isotherm to model gas adsorption in Marcellus Shale. They observed that the Langmuir isotherm does not accurately model adsorption in all cases in the Marcellus shale, and hence a combination of BET and Langmuir isotherm should be applied. They also compared the results from both isotherms and evaluated long term adsorption. Psarras [17] investigated CO2 adsorption capacity in shale cores from the Eagle Ford basin using Molecular Simulation. The impact of increasing pressure and temperature, and also change in organic content and material was investigated. Le [18] developed a new computational model to model flow of methane in fractured shale matrix based on averaging mass conservation equations. The model accounted for methane adsorption which had a strong effect on the flow of the gas and its relative permeability. They study did not use CO2 however. Sudibandriyo [19] illustrated the difference between the absolute adsorption, and Gibbs adsorption by measuring both values for the shale. They also showed that the helium compressibility can be obtained using correlation to measure the void space, whereas the CO2 values should be obtained using other methods. Lafortune [20] measured CO2 adsorption on Mesozoic Marine Basin shale samples from France using magnetic suspension balance. The samples were crushed to powder size, and used for the adsorption experiments. As the temperature increased, the adsorption decreased, while increasing the pressure resulted in an increase in adsorption. The mineral composition of the shale also affect the adsorption capacity of CO2. Luo [21] investigated adsorption of several gases including methane, CO2, and binary mixtures with different mole percentages of each gas using powdered shale samples of less than 0.5 mm particle size. They measured adsorption based on a volumetric adsorption setup, and integrated a filter disk to prevent the particles from entering into the valves. Yuan [22] attempted to use helium porosimeter to measure the volumetric adsorption capacity of Argillite rick shales. Since the volumetric based adsorption operates in the same manner as the helium porosimeter, the values they obtained were representative of the adsorption values on the shale. Lu [23] developed a novel model fully based on a numerical producer combined with Artificial Neural-Network Technique to evaluate the lost gas volume, which includes the gas volume adsorbed to the surface of the coal, which occurs during production of coal. Perez and Devegowda [24] applied Monte Carlo Simulation to model methane and CO2 adsorption. According to their results, having the rocks confined increased the adsorption capacity on the shale due to the increase in the attraction of the gas molecules which results in the density of the adsorbed phase being higher than that of the free phase.

Based on the previous work conducted on CO2 adsorption to shales, it is clear that there are several methods present to measure adsorption experimentally and using computer simulation, and also, there are more than one methods to calculate the adsorption value after conducting experiments. This research provides a detailed explanation of the different types of adsorption, and the one mostly related to CO2 adsorption to shale rock. The research also mentions the most commonly used adsorption isotherms to model CO2 adsorption to shale, and the advantages and disadvantages of each method. The research then explains the different types of physisorption, and then indicates the type that is most observed during CO2 injection in shale reservoirs. The different types of experimental methods to measure adsorption are also explained in details, and the advantages and disadvantages of each method is mentioned. The two most common methods used to quantify CO2 adsorption to shales are also shown, and the method by which they are applied is explained. By providing a comprehensive guideline to CO2 adsorption on shale rocks, this research aims to function as a roadmap to the application of experimental studies on CO2 adsorption in unconventional shale reservoirs for enhanced oil recovery and CO2 storage purposes.

2 Types of adsorption

Adsorption is defined as the adhesion of atoms, ions, gas molecules, or liquids to the surface of an adsorbent [25]. There are two main constituents during any adsorption; these include the adsorbent, and the adsorbate [26, 27]. The adsorbent is the surface on which adsorption will take place. The adsorbate is the substance which will adsorb on to the adsorbent’s surface [28]. Adsorption occurs due to the adsorbent experiencing bond deficiency, which makes it thermodynamically favorable for the adsorbent to adsorb the adsorbate [29]. Desorption will occur once the adsorbate has enough energy to overcome the force holding it to the surface of the adsorbent and free itself from the surface. The general equation for adsorption is shown [30].

There are two main types of adsorption, including physisorption, and chemisorption. Several adsorption isotherms are also present to quantify adsorption for different adsorbents and adsorbates. The main types of adsorption, along with the adsorption isotherms and a subdivision of physisorption types are shown in Fig. 1 below. Each of the parameters mentioned in the figure will be explained in details later on. The main types that can be applied effectively and accurately to CO2 adsorption on shale rocks will be pointed out as well.

2.1 Physisorption

Physisorption, also referred to as physical adsorption, is the type of adsorption that takes place between CO2 and shale during CO2 injection in unconventional shale reservoirs [31,32,33,34]. It occurs at very low heats of adsorption, usually ranging between 20 and 40 kJ/mol. This is one of two main reasons why physisorption is a reversible or partially reversible process, meaning that desorption can occur after physisorption has taken place [35]. The second reason is that physisorption does not require any activation energy. It usually forms at low temperatures, and decreases significantly with increasing temperature. During physisorption, the adsorbate will form multi-molecular layers on the adsorbent [30, 36]. The gas molecules of the CO2 are held on the surface of the shale via Van Der Waals forces, which are considered weak forces [5, 37] The main characteristics of physisorption during CO2 injection in shale reservoirs is shown in Fig. 2.

2.2 Chemisorption

Chemisorption, also referred to as chemical adsorption, does not occur during CO2 injection in shale reservoirs. It occurs at a high heat of adsorption, usually ranging from 30 to 400 kJ/mol. It requires a high activation energy to severe the bonds holding the adsorbate to the adsorbent. The adsorbate is held to the adsorbent via chemical bonds, which makes the process irreversible, unless extremely high energy is input into the system. Another main difference between physisorption and chemisorption is that during chemisorption, the adsorbate forms mono-molecular layers on the surface of the adsorbent, as opposed to the multi layers formed during physisorption [30, 38]. This is extremely advantageous for physisorption especially during CO2 storage processes in shale reservoirs since the formation of multi-layers of the CO2 on the shale surface will result in a higher volume of CO2 adsorbed, and hence, a high CO2 storage volume [39]. Figure 3 shows the main characteristics of chemisorption. The shale in Fig. 3 is for explanation purposes only, since chemisorption will not form during CO2 injection in unconventional shale reservoirs.

3 Adsorption isotherms

Several adsorption isotherms have been developed along the years to model adsorption. Each of these isotherms has its own assumptions and limitations, which makes only a few of them applicable for accurate quantification of CO2 adsorption on shale reservoirs. An adsorption isotherm predicts adsorption capacity of the adsorbate on the adsorbent at a specific temperature, hence the name isotherm, which comes from isothermal, measuring constant temperature. The main adsorption isotherms will be explained, with a main focus on those applicable to CO2 adsorption in shale reservoirs.

3.1 Henry’s isotherm

Henry’s Adsorption Isotherm was developed in 1803. It is the simplest form of adsorption isotherm and is usually referred to as the linear adsorption isotherm. The surface area of the adsorbate adsorbed onto the surface of the adsorbent is assumed to be proportional to the partial pressure of the injected gas. It is modeled using the equation [40].

where X is the fraction of the surface of the adsorbent covered, Pp is the partial pressure, and KH is Henry’s adsorption constant, which is equal to:

where δs is the surface number density, which is the concentration of adsorbate molecules on the surface of the adsorbent, and δ(z) is the number density at free phase of adsorbate.

Henry’s Isotherm is best used to describe the initial stage of the adsorption. It is not fully applicable however in complex adsorption processes, and thus is not the most suitable isotherm to use when modelling CO2, or any other gas, adsorption to shale rock surface [41].

3.2 Freundlich isotherm

Freundlich and Kuster developed the first non-linear adsorption isotherm in 1906. It was an empirical formula developed for gas adsorbates. The formula is presented [41].

where x is the mass of the adsorbate that is adsorbed, m is the total mass of the adsorbent, P is the pressure of the adsorbate, in this case CO2 gas, and K and n are constants unique to each adsorbate at a specific temperature.

The Freundlich Isotherm has several drawbacks including that it is only applicable for gases, it is an empirical formula, and it does not function properly at high pressures. It can be used to model CO2 adsorption on shales at very low pressures, but deviates from the true value as the pressure increases, and thus it is not applicable in modeling real field applications since most of them are at relatively high pressures.

3.3 Langmuir isotherm

Langmuir developed the first scientifically based adsorption formula. The formula was developed in 1918 to model gas adsorption on solid surfaces. It was derived based on statistical thermodynamics. The formula is shown [42].

where Kads is the adsorption equilibrium constant, [AS] represents the adsorbate molecules that have adsorbed to the surface of the adsorbent, [A] represents the adsorbate concentration, and [S] represents the surface of the adsorbent.

Langmuir defined the fraction of adsorption sites on the adsorbent that have been occupied by the adsorbate as θ. The sites that are not occupied can be represented as [1 − θ]. By using these definitions, the following formula is reached [42].

Using the above formula, and the definition of Kads, mentioned previously, the final form of the Langmuir Adsorption Isotherm can be reached. This is shown.

The Langmuir Adsorption Isotherm has a wide range of applicability, especially that it can be used to model both physisorption and chemisorption. It is one of the most applied isotherms to model CO2 adsorption to shale rocks. The isotherm does have some drawbacks however, which are manifested in the assumptions made during its development. These assumptions include that the adsorbent has a specific number of sites where the adsorbate can get adsorbed, the adsorption will occur in only one layer, hence the isotherm can only model monolayer adsorption, and the adsorption sites are energetically equivalent and the adsorbed molecules do not interact [43].

3.4 Brunauer–Emmett–Teller isotherm

The Langmuir isotherm assumes monolayer adsorption, which maybe applicable in chemisorption, however, it will deviate from the true solution in physisorption, which takes place between CO2 and shale, since physisorption involves multi-layer adsorption. The BET Adsorption Isotherm was developed in 1938, and is an improved version of the Langmuir Adsorption Isotherm. BET can account for multi-layer adsorption, which in turn can properly model physisorption. It has been applied by many researchers to model CO2 adsorption in shale reservoirs, and has proven to be superior to the Langmuir isotherm in many cases. The BET isotherm formula is shown [44].

where Pe and Po are the equilibrium and saturation pressures of the adsorbate at the temperature of adsorption, v is the adsorbed gas quantity, vm is the monolayer adsorbed gas quantity, c is the BET constant equal to:

where E1 is the heat of adsorption for the first layer, E2 is the heat of adsorption for the second and higher layers, and is equal to the heat of liquefaction.

The BET isotherm essentially applies the Langmuir isotherm to multiple layers while taking into consideration the difference in adsorption between each layer. The BET is one of the most suited isotherms that can model physisorption, and thus can accurately model CO2 adsorption to shale. It has two drawbacks however, which include that it assumes that the gas molecules only interact with the adjacent layers, above and beneath it, and it is considered complex to use, compared to the other isotherms [44].

4 Physisorption types

Since physisorption is more complex than chemisorption in terms of forming multi-layers of adsorbate on the adsorbent, several physisorption types have been observed. These types can be grouped into six major divisions based on the behavior of the adsorption quantity at different partial pressures. Relative pressure is defined as the sample pressure divided by the saturation vapor pressure [45]. Using relative pressure allows for the removal of the effect of temperature on the sample change in pressure and thus allows for the creation of an isotherm [46]. Different isotherms will depend on the saturation vapor pressure. The relative pressure ranges from 0 to 1, where a relative pressure of 1 represents a complete saturation, meaning that all adsorption sites available have been occupied by the CO2 [47, 48]. Based on the properties of the fluid and the rock, the relation between the relative pressure and the adsorption will change. The six main types of physisorption isotherms are shown in Table 1.

5 Adsorption hysteresis

Adsorption hysteresis is the process of adsorption then desorption of the adsorbate on the adsorbent, usually during multi-layer physisorption, due to the capillary condensation in mesopores structures [49]. The four most commonly observed hysteresis loops are shown in Fig. 4. The four loops are usually observed as a sequence of extremity, beginning from H1, which is considered the least extreme, up to H4, which is the most extreme. H2 and H3 are considered intermediates. The desorption branch of the hysteresis loop will take one of the four shales seen in Fig. 4 and is a strong function of the adsorbate rather than the adsorbent, and so in CO2 adsorption on shale, the desorption will be a strong function of the CO2 conditions such as temperature, and partial pressure rather than the shale adsorption sites. Type H4 is the most commonly seen in shale since it is associated with narrow slit-like pores, indicated by micro-porosity [50].

Types of physisorption hysteresis behavior [49]

6 Adsorption measurement

Several methods have been applied to measure the adsorption value [51, 52]. The main methods applied include volumetric, gravimetric, volumetric-gravimetric, oscillometry, and impedance spectroscopy. Each of these method will be explained, and the main advantages and disadvantages of each will be pointed out.

6.1 Volumetric measurement

The volumetric method of measuring adsorption is considered one of the simplest, yet effective methods of measuring adsorption in terms of the mechanism [53]. The mechanism is based on Boyles Volumetric Gas Expansion law [54]. An illustration of the setup for volumetric adsorption measurement is shown in Fig. 5.

The volumetric adsorption apparatus is composed of a reference cell, where the adsorbate, CO2, is initially pressurized, and heated to the design conditions. The sample cell contains the adsorbate sample, shale, and is connected to the reference cell and separated via a high pressure valve. The reference cell should be smaller in volume than the sample cell to allow sufficient gas expansion to be observed; this will help reduce the difficulty in observing the equilibrium pressure. Once both cells are ready, and the CO2 in the reference cell is pressurized and heated, the valve is opened and the gas is allowed to expand. Once the equilibrium pressure is reached, the adsorption value can be calculated. The volumetric method has several advantages that make it a widely used method, however, it also has some major disadvantages that must be noted and accounted for when using this method to avoid error in the adsorption value. The main advantages and disadvantages of the volumetric method are presented in Table 2.

6.2 Gravimetric measurement

The gravimetric method to measure adsorption is based on mass rather than pressure. Using the microbalance, the difference in mass can indicate the amount of gas that has adsorbed to the shale [55]. The setup is nearly identical to the volumetric setup, with the only difference being that the pressure transducers are replaced with the microbalance. An illustration of the gravimetric adsorption measurement setup is shown in Fig. 6.

The gravimetric adsorption measurement method has many advantages [56, 57], and also has some major drawbacks both of which should be known before conducting the experiment to avoid errors. The advantages and disadvantages of the gravimetric adsorption method are presented in Table 3.

6.3 Volumetric–gravimetric measurement

Since both the volumetric and the gravimetric adsorption measurement methods have some advantages and disadvantages, combining both to measure adsorption was performed in order to overcome some of the disadvantages. This was referred to as the volumetric-gravimetric method [56]. An illustration of the setup used to conduct the volumetric-gravimetric adsorption measurements is shown in Fig. 7.

The setup is a combination of both the volumetric and the gravimetric adsorption setups, explained previously. The volumetric adsorption setup is connected to a microbalance, and hence both the pressure difference and the weight change can be recorded. The main advantage of this setup is the extremely high accuracy since both the pressure change and weight change results can be compared. The disadvantages of the setup are the high complexity of the new setup due to the presence of both the pressure transducers and the microbalance, and the large volume of adsorbent, shale, needed since the volumetric measurement of the setup will be inaccurate without a large volume [56].

6.4 Oscillometry measurement

Oscillometry adsorption measurement is based on the oscillation of the sample cell, which results is a beam distortion which can be used to measure adsorption. An illustration of the setup is shown in Fig. 8. The setup consists of an oscillating disk filled with the adsorbent, shale. The disk is fixed to a torsional wire and is stabilized by a steam beneath it. At the bottom of the stem, a small mirror is fixed. A laser beam is directed to the mirror as the oscillating disk is rotating. The beam is reflected via the mirror, and based on the angle of the oscillating disk, the reflection of the laser beam will create two angles, referred to as α1 and α2. The reflected beams are received by the diodes which produce electric signals of opposite signs, and hence the time when the reflected beam is crossing the area between the two diodes can be detected very accurately. The oscillation of the pendulum will produce several time signals which will be used to calculate angular frequency and logarithmic decrement, using a Gaussian Minimization procedure. This can then be used to measure the adsorption value [56].

The main advantage of using the oscillometry method to measure adsorption is the measuring apparatus since it allows for the determination of both the total mass of the adsorbent and the adsorbate without using helium method. The oscillometry does have some disadvantages as well. The advantages and disadvantages of the oscillometry adsorption method are summarized in Table 4.

6.5 Impedance spectroscopy

When a weakly electric material, such as shale, is exposed to a static or alternating electric field, the molecular state of the material is changed. The nuclei of the atoms or the molecules are shifted in the direction of the electric field, whereas the electrons are moved in the opposite direction, hence dipole moments are created. The sum of the dipole moments in the material are referred to as the dielectric polarization of the material and can measured using impedance [56]. By applying oscillating-electric field, specific impedance curves can obtained, which are unique to different materials. A molecular interpretation of the curves can be used to quantify the adsorption value. An illustration of the setup is shown in Fig. 9.

The main advantages of using the impedance spectroscopy adsorption measurements and the main disadvantages of using this method are presented in Table 5 in order to avoid error when measuring adsorption using this method.

7 Volumetric adsorption calculations

Calculation of the adsorption value takes place after the experiment has been conducted. Since there are several methods to conduct the adsorption experiments as shown above, there are multiple equations that are applied based on the results obtained using the experimental method. For example, if the volumetric method is used, the equilibrium value obtained will be a pressure reading and so the input to the equations must be a pressure reading in order to obtain the adsorption value, however, if the impedance spectroscopy experimental method is used, an impedance value will be input to a different equation to obtain the adsorption value. Since this research is focused on CO2 adsorption to shale rocks, the equations explained will be related to the volumetric method, since this is the most widely used adsorption measurement technique for CO2 adsorption to shale [58,59,60]. There are two main methods used to perform the adsorption calculation for the volumetric experimental method including the absolute adsorption calculation, and the Gibbs adsorption calculation, both of which will be explained [61].

Generally, adsorption is a function of the adsorbent, which is the shale, the adsorbate, which is the CO2, and the volume of the CO2 adsorbed. The general adsorption equation is shown.

where Vtotal is the total volume of the system, Vsolid is the volume of the shale in the sample cell, Vgas is the volume of the CO2 injected, and Vads is the volume of the CO2 adsorbed.

When the shale sample is placed in the sample cell, the shale grains will not fill up the whole cell since some voids will remain between the grains. It is crucial that these void spaces are measured since the total volume of the adsorbent and the adsorbate will be incorrect if the void space is not measured. The general definition of the void space is given as:

where Vvoid is the void space volume. The void space is usually measured before the adsorption experiment and a gas with very low adsorption potential is used, usually helium. The void space is calculated based on the pressure, temperature, compressibility, and volume of the gas in the pump and the cell. The equation for the void space is shown [61].

where Ph is the pressure of the helium in the pump, \(\Delta {\text{V}}\) is the change in volume of the helium between the pump and the cells, P2 and P1 are the pressure of the helium after and before expansion respectively, z1 and z2 are the compressibility of the helium before and after expansion, and T is the temperature of the cells.

After calculating the void space, the CO2 adsorption can be calculated based on the total volume injected and the total volume unadsorbed based on the number of moles using the following equation.

where nads is the number of moles of CO2 adsorbed to the shale, ninj is the total number of moles of CO2 injected, and nundas is the number of moles of CO2 that were not adsorbed.

For both the absolute and the Gibbs calculation methods, the number of moles of CO2 injected is agreed upon, and is calculated as follows.

Where R is the universal gas constant, equal to 8.314 J/mol∙K.

The difference between the absolute and the Gibbs adsorption value is mainly in the number of moles of CO2 that are unadsorbed. This difference will be indicated when explaining each calculation method and its principles.

7.1 Gibbs adsorption

Gibbs adsorption calculation neglects the volume occupied by the adsorbed phase when calculating the volume of unadsorbed gas. The adsorbed CO2 on the shale rock will occupy some volume in the sample cell, and thus will affect the value of the unadsorbed Co2 volume calculated. The Gibbs calculation assumes that the volume occupied by the adsorbed CO2 is not occupied. This will result in some error in the adsorption capacity calculation. The equation for the Gibbs adsorption is shown [19].

7.2 Absolute adsorption

Absolute adsorption takes into consideration the volume occupied by the adsorbed phase when the unadsorbed volume is calculated. The volume occupied by the adsorbed CO2 on the shale surface will affect the remaining volume that can be occupied by the unadsorbed CO2, which shows that the absolute adsorption will yield much more realistic results compared to the Gibbs volume [61]. The number of moles of CO2 adsorbed therefore becomes as follows.

8 Main sources of error in volumetric adsorption determination

When measuring and calculating the adsorption value, several common errors have been made which will affect the adsorption quantity severely. These errors are extremely commonplace and have been noticed amongst many researchers. In this section, this research summarizes the main errors that are associated with the adsorption calculation using the volumetric adsorption method, especially for CO2 adsorption, and explains the error and how to avoid it. The main errors are presented in Table 6 [13, 56, 62, 63].

9 Conclusions

During the application of CO2 injection in unconventional shale reservoirs, CO2 adsorption is an imperative factor that will impact enhanced oil recovery potential, and CO2 storage capacity. This research provides a roadmap to the different types of adsorption and adsorption isotherms and measurement techniques to function as a guideline for the accurate application of experimental CO2 adsorption in shale reservoirs. The main conclusions obtained from this research are summarized below.

-

Adsorption is a function of both the adsorbate and the adsorbent. This shows that in order to properly study CO2 adsorption to shale, both the CO2 and shale properties should be considered.

-

The most applicable isotherm to model CO2 adsorption to shale is the BET since it overcomes the limitations of the Langmuir isotherm.

-

Adsorption hysteresis is extremely important since it can give an indication of the adsorption–desorption cycle and thus can hint to the actual capacity of CO2 that can be stored.

-

The most common experimental methods used to measure adsorption are the volumetric and the gravimetric methods due to their simplicity and high accuracy as long as they are conducted properly.

-

Different adsorption methods will have different sources of error. Each method must therefore be studied thoroughly in order to avoid conducting errors that may impact the accuracy of the results.

References

Al Ismail MI et al (2014) The effect of CO2 adsorption on permeability anisotropy in the eagle ford shale. Unconv Resour Technol Conf. https://doi.org/10.15530/URTEC-2014-1921520

Liu Q et al (2018) Macroscale mechanical and microscale structural changes in chinese wufeng shale with supercritical carbon dioxide fracturing. Soc Pet Eng. https://doi.org/10.2118/181369-PA

Meng X et al (2017) Experimental and numerical study of enhanced condensate recovery by gas injection in shale gas-condensate reservoirs. Soc Pet Eng. https://doi.org/10.2118/183645-PA

Reynolds MM, Buendia J (2017) Permanently sequester anthropogenic carbon dioxide—through hydraulic fracturing. Soc Pet Eng. https://doi.org/10.2118/185033-MS

Kang SM et al (2011) Carbon dioxide storage capacity of organic-rich shales. Soc Pet Eng. https://doi.org/10.2118/134583-PA

Ibrahim AF, Nasr-El-Din HA (2015) Carbon dioxide sequestration in coal formations. Int Pet Technol Conf. https://doi.org/10.2523/IPTC-18278-MS

Khaleel, M. et al., 2018. Amine-functionalized hierarchical zeolites for carbon dioxide capture. Society of Exploration Geophysicists

Golshahi N et al (2019) Asphaltene structural changes induced by carbon dioxide injection. Offshore Technol Conf. https://doi.org/10.4043/29730-MS

** Z, Firoozabadi A (2016) Thermodynamic modeling of phase behavior in shale media. Soc Pet Eng. https://doi.org/10.2118/176015-PA

Orr FM (2004) Storage of carbon dioxide in geologic formations. Soc Pet Eng. https://doi.org/10.2118/88842-JPT

Hall FE et al (1994) Adsorption of pure methane, nitrogen, and carbon dioxide and their binary mixtures on wet fruitland coal. Soc Pet Eng. https://doi.org/10.2118/29194-MS

Kazemi M, Takbiri-Borujeni A (2016) Molecular dynamics study of carbon dioxide storage in carbon-based organic nanopores. Soc Pet Eng. https://doi.org/10.2118/181705-MS

Mohammad S et al (2009) Experimental uncertainties in volumetric methods for measuring equilibrium adsorption. Energy Fuels 23:2810–2820. https://doi.org/10.1021/ef8011257

Bahadori A, Vuthaluru H (2010) Rapid prediction of carbon dioxide adsorption isotherms for molecular sieves using simple correlation. Soc Pet Eng. https://doi.org/10.2118/122882-PA

Clarkson CR, Haghshenas B (2013) Modeling of supercritical fluid adsorption on organic-rich shales and coal. Soc Pet Eng. https://doi.org/10.2118/164532-MS

Yu W et al (2016) Modeling gas adsorption in marcellus shale with langmuir and BET isotherms. Soc Pet Eng. https://doi.org/10.2118/170801-PA

Psarras P et al (2017) Methane and CO2 adsorption capacities of kerogen in the eagle ford shale from molecular simulation. Acc Chem Res. https://doi.org/10.1021/acs.accounts.7b00003

Le TD et al (2017) A new matrix/fracture multiscale coupled model for flow in shale-gas reservoirs. Soc Pet Eng. https://doi.org/10.2118/181750-PA

Sudibandriyo M et al (2003) Adsorption of methane, nitrogen, carbon dioxide, and their binary mixtures on dry activated carbon at 318.2 K and pressures up to 13.6 MPa. Langmuir 19(13):5323–5331. https://doi.org/10.1021/la020976k

Lafortune S et al (2014) Assessing CO2 adsorption capacities onto shales through gravimetric experiments: a first step in the feasibility study of coupling “Fracking” with carbon storage. Energy Proc 63(5933–5937):1876–6102. https://doi.org/10.1016/j.egypro.2014.11.629

Luo X et al (2015) Adsorption of methane, carbon dioxide and their binary mixtures on Jurassic shale from the Qaidam Basin in China. Int J Coal Geol 150–151:210–223. https://doi.org/10.1016/j.coal.2015.09.004

Yuan H et al. (2017) Investigation on gas-adsorption-induced swelling and permeability evolutions of cox argillite. In: 23ème Congrès Français de Mécanique, France

Lu M et al (2017) A new method for the estimation of lost gas during the measurement of the gas content of coal. Soc Pet Eng. https://doi.org/10.2118/176976-PA

Perez F, Devegowda D (2017) Methane and carbon dioxide adsorption in kerogen models using molecular simulations, Mewbourne School of Petroleum and Geological Engineering. The University of Oklahoma, Norman

Bouzgarrou S et al (2015) Experimental adsorption and modelisation of CO2 on adsorbents collected from Elborma field in South Tunisia. J Surf Eng Mater Adv Technol 5:52–63. https://doi.org/10.4236/jsemat.2015.51006

Kecheng Z et al (2019) Molecular simulation of carbon dioxide and methane adsorption in shale organic nanopores. Energy Fuels 33(3):1785–1796. https://doi.org/10.1021/acs.energyfuels.8b02851

Al-Mutarreb AM et al. (2018) The influence of shales characteristics on CO2 adsorption behaviour under sub-critical conditions. IOP conference series: earth and environmental science. Doi: https://doi.org/10.1088/1755-1315/164/1/012031

Chareonsuppanimit P et al (2012) High-pressure adsorption of gases on shales: measurements and modeling. Int J Coal Geol 95:34–46. https://doi.org/10.1016/j.coal.2012.02.005

Heller R, Zoback M (2014) Adsorption of methane and carbon dioxide on gas shale and pure mineral samples. J Unconv Oil Gas Resour 8:14–24. https://doi.org/10.1016/j.juogr.2014.06.001

Zhang P (2016) Adsoprtion and desorption isotherms. Kere-Search Group, Portland

Eliebid M et al (2017) Adsorption role in shale gas recovery and the feasibility of CO2 in shale enhanced gas recovery: a study on shale gas from Saudi Arabia. Soc Pet Eng. https://doi.org/10.2118/187667-MS

Manju M, Joewondo P (2014) CO2 sorption capacity in clay–rich shales with moisture content. In: 14th Greenhouse gas control technologies conference Melbourne 21–26 October (GHGT-14). SSRN: https://ssrn.com/abstract=3365692

Ngo T (2015) Reservoir capacity estimates in shale plays based on experimental adsorption data. Masters Thesis

Lutynski M et al (2017) CO2 sorption of Pomeranian gas bearing shales—the effect of clay minerals. Energy Proc 125:457–466. https://doi.org/10.1016/j.egypro.2017.08.153

Clarkson CR (2003) Application of a new multicomponent gas adsorption model to coal gas adsorption systems. Soc Pet Eng. https://doi.org/10.2118/78146-PA

Aljamaan H et al (2017) Multiscale imaging of gas adsorption in shales. Soc Pet Eng. https://doi.org/10.2118/185054-MS

Sathre R, Masanet E (2013) Prospective life-cycle modeling of a carbon capture and storage system using metal-organic frameworks for CO2 capture. RSC Adv 3:4964–4975

Jedli H et al (2017) Carbon dioxide adsorption isotherm study on various cap rocks in a batch reactor for CO2 sequestration processes. Appl Clay Sci 136(199–207):0169–1317. https://doi.org/10.1016/j.clay.2016.11.022

Chen G et al (2016) Research of CO2 and N2 adsorption behavior in K-illite slit pores by GCMC method. J Sci Rep 6:37579. https://doi.org/10.1038/srep37579

Henry W (1803) Experiments on the quantity of gases absorbed by water, at different temperature and under different pressures. Philos Trans R Soc Lond 93:29–42

Foo KY, Hameed BH (2010) Insights into the modeling of adsorption isotherm systems. Chem Eng J 156:2–10. https://doi.org/10.1016/j.cej.2009.09.013

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica, and platinum. J Am Chem Soc 40(9):1361–1403. https://doi.org/10.1021/ja02242a004

Czepirski L et al (2000) Some generalization of langmuir adsorption isotherm. Internet J Chem 3:14

Brunauer S et al (1938) Adsorption of gases in multimolecular layer. J Am Chem Soc 60(2):309–319. https://doi.org/10.1021/ja01269a023

Ehrburger-Dolle F (1999) A new way to analyze adsorption isotherms. Langmuir 15(18):6004–6015. https://doi.org/10.1021/la981349r

Cook M, Douglas H (1949) Extrapolation of adsorption isotherms to high relative pressures and the determination of the surface pressure of adsorbed films on solids. J Am Chem Soc 71(3):791–797. https://doi.org/10.1021/ja01171a009

Van Dongen RH et al (1971) Physical adsorption at high relative pressures. Surf Sci 28(1):237–257. https://doi.org/10.1016/0039-6028(71)90097-5

Brown T et al (2019) Pressure-varying Langmuir parameters and stepped nitrogen adsorption on alumina and silica. Phys Chem J R Soc Chem 21:2558–2566

Sing, K., 1984. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. International Union of Pure and Applied Chemistry, Physical Chemistry Division, Commission on Colloid and Surface Chemistry Including Catalysis

Thommes M et al (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC technical report). J Pure Appl Chem 87:1–19

Zhao H et al (2017) Sorption hysteresis of light hydrocarbons and carbon dioxide in shale and kerogen. Sci Res. https://doi.org/10.1038/s41598-017-13123-7

Shi J et al (2019) Competitive adsorption phenomenon in shale gas displacement processes. RSC Adv 2019(9):25326–25335. https://doi.org/10.1039/C9RA04963K

Santos JM, Akkutlu IY (2013) Laboratory measurement of sorption isotherm under confining stress with pore-volume effects. Soc Pet Eng. https://doi.org/10.2118/162595-PA

Rani S et al (2015) Comparison of void volume for volumetric adsorption studies on shale from India. J Nat Gas Sci Eng 26:725–729. https://doi.org/10.1016/j.jngse.2015.07.012

Fuji T et al (2015) Evaluation of CO2 sorption capacity of rocks using a gravimetric method for CO2 geological sequestration. Energy Proc 1(1):3723–3730. https://doi.org/10.1016/j.egypro.2009.02

Keller J, Staudt R (2005) Gas adsorption equilibria, experimental methods and adsorptive isotherms. Springer Science, Berlin

Yang S et al (2016) Effects of multicomponent adsorption on enhanced shale reservoir recovery by CO2 injection coupled with reservoir geomechanics. Soc Pet Eng. https://doi.org/10.2118/180208-MS

Smit B et al (2014) Introduction to carbon capture and sequestration. Imperial College Press, London

Yanian Z et al (2015) Study on controlling factors of shale gas adsorption. Acta Geol Sin 89:300–301

Tajnik T et al (2013) Investigation of adsorption properties of geological materials for CO2 storage. Int J Energy Res 37:952–958. https://doi.org/10.1002/er.2901

Charoensuppanimit P et al (2016) Measurement and modeling of gas adsorption on shales. Energy Fuels J 30(3):2309–2319. https://doi.org/10.1021/acs.energyfuels.5b02751

Mohagheghian E et al (2015) Carbon dioxide compressibility factor determination using a robust intelligent method. J Supercrit Fluids 101(140–149):0896–8446. https://doi.org/10.1016/j.supflu.2015.03.014

Gasparik M et al (2015) High-pressure/high-temperature methane-sorption measurements on carbonaceous shales by the manometric method: experimental and data-evaluation considerations for improved accuracy. Soc Pet Eng. https://doi.org/10.2118/174543-PA

Acknowledgements

The author wishes to thank Missouri University of Science and Technology for its support through the Chancellors Distinguished Fellowship.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fakher, S., Imqam, A. A review of carbon dioxide adsorption to unconventional shale rocks methodology, measurement, and calculation. SN Appl. Sci. 2, 5 (2020). https://doi.org/10.1007/s42452-019-1810-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-1810-8