Abstract

Nitrate is an important ion in agriculture and industry although it is known to cause eutrophication and affect human health. Removal of nitrogen by physicochemical treatment such as sedimentation and membrane separation remains difficult. The selectivity of commercial adsorbents for nitrate is among the lowest for anions, because the selectivity of an adsorbent as an ion exchange resin is based on the valence of the ion. Layered double hydroxide acts as an anion adsorbent, and the target anion adsorbs in the interlayer of cations. In this study, we focused on nitrate adsorption by magnesium-iron layered double hydroxide. The results indicate that the magnesium to iron ratio controlled the interlayer distance. The interlayer distance increased as the magnesium to iron ratio increased. The maximum adsorption capacity for nitrate of 1.80 mmol/g suggests the optimum magnesium to iron ratio is 3. The interlayer distance for a magnesium to iron ratio of 3 is similar in size to that of nitrate. The phosphate inhibition of nitrate adsorption suggests the formation of phosphate compounds on the adsorbent’s surface.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nitrate is a major source of nitrogen promoting eutrophication in the aquatic environment, and it is also suggested to cause health hazards. It originates from agricultural, anthropogenic, and industrial activities. Nitrate is generated from the oxidation of ammonium during biologic reactions. The contribution of ammonium in nitrate generation in aquatic environments requires attention because it is the nitrogen source in many fields. Nitrate and ammonium are used as fertilizers in agriculture [1, 2] and as a pretreatment solution for metal surfaces in industry. Significant amounts of nitrate discharged to the aquatic environment from fertilizer account for groundwater pollution in many parts of the world [3].

The high solubility of nitrate hinders its removal from water as an insoluble material. Chemical and electrochemical processes are utilized for the reduction of nitrate to nitrogen [4, 5]. Biologic reduction, for example, is a major nitrate removal process [6, 7]. An intermediate of nitrate, dinitrogen monoxide, is known for its high toxicity and global warming potential. Membrane separation and adsorbents have been studied as indirect methods to remove nitrate. However, the separation efficiency of a membrane separation method such as reverse osmosis is low for nitrate. Similarly, although anionic ion-exchange resins adsorb nitrate, their selectivity is not superior to coexisting anions such as sulfate and phosphate.

Layered double hydroxide (LDH) is a well-known useful adsorbent. It usually comprises a divalent cation and a trivalent cation. The replacement of the divalent cation by the trivalent cation generates a charge variation. The interlayers of the cation layers retain anions to maintain the electric charge of the LDH. The LDH is generally represented by [M 2+1−X M 3+X (OH)2][A n−x/n ‧yH2O], where M2+ is a divalent cation, M3+ a trivalent cation, and A an anion. Many types of LDH exist including magnesium–aluminum [8, 9], magnesium–iron [10], zinc–aluminum [11], zinc–iron [12], nickel–aluminum [13], and nickel–iron [14]. The charge variation of LDH is its driving force for anion adsorption. The adsorption target of LDH is primarily phosphate [15], chromate [16], and arsenate [17]. Reports exist on nitrate adsorption by nickel–iron [18] and magnesium–iron [19] LDHs, indicating that LDHs have the potential to remove nitrate from water, although such research remains scant compared with other LDHs. The specific adsorption property of LDHs facilitates the preferential adsorption of carbonate. The carbonate ion is discharged from the interlayer by heat treatment. Calcination regenerates the LDH structure and the interlayer anion uptake through reactions during regeneration.

In this study, we synthesized calcined Mg–Fe LDH, which adsorbed nitrate through a reaction during regeneration. We focused on nitrate adsorption by the calcined Mg–Fe LDH and compared the nitrate response to those of other anions. We also investigated the influence of the magnesium to iron ratio of the LDH and evaluated its adsorption characteristics.

2 Materials and methods

2.1 Mg–Fe LDH

The LDH was synthesized by a precipitation method involving 1.0 mol/l MgCl2 and 1.0 mol/l FeCl3 solutions. The solutions were mixed to yield magnesium to iron ratios (Mg/Fe ratio) of 2:4. The mixture was added to 1.0 mol/l Na2CO3 solution, precipitating Mg/Fe-LDH crystals. The solution was adjusted to a pH of 10 using 4.0 mol/l NaOH solution during synthesis. The growth of Mg/Fe-LDH crystals occurred under several conditions with carbonate, which was placed in the interlayer. The precipitate was collected by centrifugal separation (2500g, 3 min) and rinsed with distilled deionized water. The purified Mg/Fe-LDH was dried at 50°C for 48 h, decarbonated by thermal treatment in an argon atmosphere at 400°C, and ground in a mortar to 100 μm particles.

2.2 Analytical method

Ion chromatography is a reliable method for the analysis of anions in liquid samples including water. We used an ion chromatograph (IC850, Metrohm, Switzerland) equipped with a non-suppressor type anion analytical column (TSK-gel IC-Anion PWXL, Tosoh, Japan) to analyze anions in the solutions. The analytical samples were filtered by membrane filter (0.45 μm, Advantec Toyo, Japan). The carbonate content in the Mg–Fe LDH was analyzed by a carbon–sulfur simultaneous analysis device (EMIA-510, HORIBA, Ltd., Japan). Thermal behavior was analyzed by thermogravimetry/differential thermal analysis meter (TG/DTA, DTG-60, Shimadzu, Japan).

The adsorbent was analyzed by x-ray diffraction (XRD), involving Cu Kα1 radiation for investigation of the material structure (XRD-6100, Shimadzu, Japan). The diffracted scan range was 5–60 degrees 2θ, increasing at an interval of 0.05 degrees.

2.3 Adsorption experiment

All experiments involved calcined LDH, and the properties were examined through batch-type experiments. The nitrate solution was prepared using NaNO3, and those for other anions also required sodium compounds. The initial concentration of the solution was adjusted to 10 mmol/l and pH 10 using 1 mol/l NaOH. The adsorption experiments proceeded for 24 h at 25°C with rotary shaking or stirring of the mixture using a magnetic bar.

3 Results and discussion

3.1 Preparation of calcined MG–FE LDH

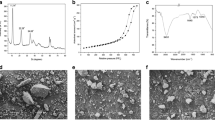

The anion is adsorbed by the positive charge of the Mg–Fe LDH, with the charge variation generated by the ratio of the divalent to the trivalent cation in the Mg–Fe LDH. The adsorbent structure was influenced by the molar ratio of the Mg–Fe LDH as shown in Fig. 1. All samples display peaks around 11 and 23 degrees 2θ. The 2θ degree of the Mg–Fe LDH peaks shifted with changes in the Mg/Fe ratio. The interlayer distances of the synthesized Mg–Fe LDHs (Di) are presented in Table 1, calculated according to the following:

The distance of the Mg–Fe LDHs (Dr) was calculated using the peak at 11.6 degrees from Brgg’s law. The cation layer distance (Dc) was 0.48 nm; it is the thickness of magnesium hydroxide as the main component of Mg–Fe LDH.

Iron hydroxide replaced magnesium hydroxide as the main component of Mg–Fe LDH. Since the diameter of iron hydroxide is larger than that of magnesium hydroxide, the 2θ degree of the XRD peak increased with the replacement. The interlayer distance decreased because of increased interaction between the cation layers and anions in the interlayer. It was shown that the interlayer distance can control the mixture ratio.

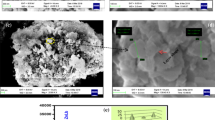

The structural transition of the Mg–Fe LDH was analyzed by thermal dilatometry and differential thermal analysis (TD/DTA), and the endothermal response is displayed in Fig. 2. The differential thermal curve exhibits peaks between 200 and 370°C. The Mg–Fe LDH was calcined for 24 h, and the effect of the calcination temperature on the adsorbent structure and the amount of carbonate is shown in Fig. 3 and Table 2, respectively. The peaks of the calcined Mg–Fe LDH mostly disappeared, with the peak for magnesium oxide observed after 400°C. The carbonate content decreased with increasing calcination temperature. Carbonate removal from Mg–Fe LDH was almost complete at 500°C. The first peak represents the elimination of water from the Mg–Fe LDH, and therefore Mg–Fe LDH peaks were observed by XRD analysis, with the decrease of carbonate concentration not larger than that at > 400°C. The second peak is attributed to carbonate removal. The Mg–Fe LDH structure decomposed because of the imbalance between the interlayer and the cation layer without carbonate. This decomposition of the Mg–Fe LDH was confirmed by XRD analysis.

3.2 Adsorption of nitrate ions

The influence of the calcination temperature on the adsorbed amounts is presented in Table 3. Nitrate adsorption reached saturation after 24 h, and the calcined Mg–Fe LDH showed the highest adsorption amounts at 400°C. The Mg–Fe LDH structure was regenerated from magnesium oxide as calcined LDH at 400°C and 500°C after adsorption experiments (Fig. 4). Although magnesium oxide peaks were observed for the regenerated Mg–Fe LDH calcined at 500°C, the XRD peak intensities indicate that the crystallinity of that calcined at 500°C was higher than that at 400°C. Magnesium oxide does not adsorb nitrate ions, and the adsorption capacity of calcined LDH at 500°C was decreased. Therefore, it was shown that the calcined LDH at 400°C had the highest nitrate adsorption capacity. The influence of the Mg/Fe ratio on the adsorbed amount (Table 4) shows the adsorbed amounts are associated with an Mg/Fe ratio of 3. The maximum nitrate adsorption amount in the Mg–Fe LDH of 1.72 mmol/g was obtained at an Mg/Fe of 3, since its content represents the maximum adsorption capacity of the Mg–Fe LDH, with an Mg/Fe of 3 as the optimum ratio of the LDH.

After the adsorption experiments, the pH of the solution increased to > 11.5. The calcined Mg–Fe LDH adsorbed the anion and was regenerated. This regeneration is represented by the following reaction:

The hydroxide increased with adsorption of nitrate and regeneration of Mg–Fe LDH. The calcined Mg–Fe LDH dissolved without regeneration to the Mg–Fe LDH structure in acidic conditions. The calcined Mg–Fe LDH was suggested as appropriate for a batch-type adsorption process because of its resistance to acid conditions. The adsorption isotherm at pH = 10 in Fig. 5 is approximated by the Langmuir equation. The theoretical adsorbed amount of 1.80 from the equation at pH = 10 surpassed that from the experiment.

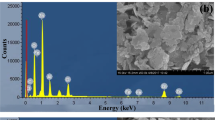

The relationships between the adsorption amounts and ionic sizes are given in Table 5. The nitrate, nitrite, and carbonate approximate ellipsoids, while others are circular. The interlayer distance of the Mg–Fe LDH is narrower than that of others. The adsorbed amounts of nitrate, nitrite, chloride, and sulfate are similar, and the amount of phosphate is highest among the anions. The interlayer distance of Mg–Fe LDH became wide compared with the initial one. The XRD peaks after adsorption experiments became broader with an increase of ionic size, and the peak of LDH was not observed from that of the adsorbed phosphate. Since phosphate forms passive compounds with many cations, some iron phosphate and/or magnesium phosphate appears, with low solubility formed. However, the XRD did not reveal peaks for iron phosphate and magnesium phosphate.

The amount of adsorbed nitrate relative to other ions is presented in Fig. 6. The amount adsorbed decreased relative to other anions. This is attributed to phosphate inhibiting nitrate adsorption on the Mg–Fe LDH. The inhibition is explained by the stronger adsorption force of Mg–Fe LDH for the trivalent phosphate compared with the monovalent nitrate.

4 Conclusions

This study demonstrated the adsorption of nitrate by calcined Mg–Fe LDH. The interlayer distance showed a strong positive correlation with the magnesium to iron ratio. The crystal structure of the Mg–Fe LDH decomposed during the calcination process, and the calcined Mg–Fe LDH was regenerated after nitrate adsorption. The optimum magnesium to iron ratio was 3 and calcination temperature was 400°C. The amounts of nitrate and nitrite adsorbed by the Mg–Fe LDH surpass the quantities reported for other LDHs. The nitrate adsorbed was 1.80 mmol/g in alkaline condition, and the adsorption response was approximated by the Langmuir equation. The adsorption capacity of the Mg–Fe LDH for common anions in water remained constant, except for phosphate.

References

Liu GD, Wu WL, Zhang J (2005) Regional differentiation of non-point source pollution of agriculture-derived nitrate nitrogen in groundwater in northern China. Agric Ecosyst Environ 107:211–220

Panno SV, Hackley KC, Hwang HH, Kelly WR (2001) Determination of the sources of nitrate contamination in karst springs using isotopic and chemical indicators. Chem Geology 179:113–128

De Boer W, Klein Gunnewiek PJA, Veenhuis M, Bock E, Laanbroek HJ (1991) Nitrification at low pH by aggregated chemolithotrophic bacteria. Appl Environ Micrbiol 57:3600–3604

Huang CP, Wang HW, Chiu PC (1998) Nitrate reduction by metallic iron. Water Res 32:2257–2264

Choe S, Chang YY, Hwang KY, Khim J (2000) Kinetics of reductive denitrification by nanoscale zero-valent iron. Chemosphere 41:1307–1311

Obaja D, Mace S, Costa J, Sans C, Mata-Alvarez J (2003) Nitrification, denitrification and biological phosphorus removal in piggery wastewater using a sequencing batch reactor. Biores Technol 87:103–111

Lu HJ, Chandran K, Stensel D (2014) Microbial ecology of denitrification in biological wastewater treatment. Water Res 64:237–254

Tronto J, dos Reis MJ, Silverio F, Balbo VR, Marchetti JM, Valim JB (2003) In vitro release of citrate anions intercalated in magnesium aluminium layered double hydroxides. J Phys Chem Solids 65:475–480

Hu G, Wang N, O’Hare D, Davis JJ (2007) Synthesis of magnesium aluminium layered double hydroxides in reverse microemulsions. J Mator Chem 17:2257–2266

Meng WQ, Li F, Evans DG, Duan X (2004) Preparation and intercalation chemistry of magnesium-iron(III) layered double hydroxides containing exchangeable interlayer chloride and nitrate ions. Mater Res Bull 39:185–1193

Iftekhar S, Kucuk ME, Srivastava V, Repo E, Sillanpaa M (2018) Application of zinc-aluminium layered double hydroxides for adsorptive removal of phosphate and sulfate: equilibrium, kinetic and thermodynamic. Chemosphere 209:470–479

Zhang H, Wen X, Wang YX (2007) Synthesis and characterization of sulfate and dodecylbenzenesulfonate intercalated zinc-iron layered double hydroxides by one-step coprecipitation route. J Solid State Chem 180:1636–1647

Barik G, Padhan E, Dash B, Sarangi K, Subbaiah T (2014) Preparation of layered nickel aluminium double hydroxide from waste solution of nickel. Miner Eng 69:107–112

Saiah FBD, Su BL, Bettahar N (2008) Nickel-iron layered double hydroxide (LDH): textural properties upon hydrothermal treatments and application on dye sorption. J Hazard Mater 165:206–217

Kamimoto Y, Ichino R, Kiso Y, Hosotani T, Min KH, Jung YJ (2013) Removal of phosphite and sulfate from electroless nickel–phosphorus plating bath with hydrotalcite for the management of watershed. Desalin Water Treat 51:4050–4055

Prasanna SV, Kamath PV (2008) Chromate uptake characteristics of the pristine layered double hydroxides of Mg with Al. Solid State Sci 10:260–266

Kang DJ, Yu XL, Tong SR, Ge MF, Zuo JC, Cao CY, Song WG (2013) Performance and mechanism of Mg/Fe layered double hydroxides for fluoride and arsenate removal from aqueous solution. Chem Eng J 228:731–740

Tezuka S, Chitraker R, Sonoda A, Ooi K, Tomida T (2004) Studies on selective adsorbents for oxo-anions. Nitrate ion-exchange properties of layered double hydroxides with different metal atoms. Green Chem 6:104–109

Sasai R, Norimatsu W, Matsumoto Y (2012) Nitrate-ion-selective exchange ability of layered double hydroxide consisting of MgII and FeIII. J Hazard Mater 215–216:311–314

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kamimoto, Y., Okamoto, N., Hagio, T. et al. Development of magnesium–iron layered double hydroxide and application to nitrate removal. SN Appl. Sci. 1, 1399 (2019). https://doi.org/10.1007/s42452-019-1240-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42452-019-1240-7