Abstract

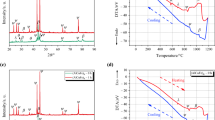

The influence of MgO content in slag on wetting and corrosion behavior between slag and MgO–C refractory was investigated. It can be known from the high-temperature wetting experiment that as the MgO content in the slag increases, the final contact angle between the slag and the MgO–C refractory gradually increases and the penetration depth of the slag into the refractory gradually decreases from 60.54 μm (when the MgO content is 8%) to 28.11 μm (when the MgO content is 12%). The CaO and SiO2 in the slag penetrate into the MgO–C refractory along the pores or surface cracks formed by carbon oxidation and react with MgO to generate a large amount of low-melting compound CaO–MgO–SiO2, which accelerates the corrosion of the refractory. As the MgO content in slag increases, the viscosity of the slag increases and the fluidity becomes worse, so that the mass transfer and diffusion of molecules or ions in the slag are weakened. In addition, the increase in MgO reduces the activity of FeO in the slag, which inhibits the interfacial chemical reaction, thereby weakening the wetting effect caused by the reaction.

Similar content being viewed by others

References

X.M. Ren, B.Y. Ma, S.M. Li, H.X. Li, G.Q. Liu, W.G. Yang, F. Qian, S.X. Zhao, J.K. Yu, J. Iron Steel Res. Int. 28 (2021) 38–45.

Y. Zou, A. Huang, R. Wang, L. Fu, H. Gu, G. Li, Corros. Sci. 167 (2020) 108517.

A. Huang, Y. Wang, Y. Zou, H. Gu, L. Fu, Ceram. Int. 44 (2018) 14617–14624.

S. Amini, M. Brungs, S. Jahanshahi, O. Ostrovski, ISIJ Int. 46 (2006) 1554–1559.

X. Yang, Z. He, J. Yu, Y. Zhang, L. Yuan, F. Mao, Ceram. Int. 46 (2020) 10180–10185.

S. Riaz, Ironmak. Steelmak. 39 (2012) 409–413.

X.M. Ren, B.Y. Ma, S.M. Li, H.X. Li, G.Q. Liu, S.X. Zhao, W.G. Yang, F. Qian, J.K. Yu, J. Aust. Ceram. Soc. 55 (2019) 913–920.

L.M. Chen, L.F. Zhang, P. Shen, Chin. J. Eng. 40 (2018) 1139–1157.

X. Yang, Y.Y. Zhang, L. Yuan, F.X. Mao, J.K. Yu, Z.J. He, JOM 72 (2020) 3521–3528.

Y.F. Pan, H.X. Zhao, Y. Wu, S.Q. Li, K. Hou, Z.F. Yuan, Iron and Steel 48 (2013) No. 5, 35–40.

J. Park, J. Jeon, K. Lee, J.H. Park, Y. Chung, Metall. Mater. Trans. B 47 (2016) 1832–1838.

D. **e, T. Tran, S. Jahanshahi, High Temp. Mater. Process. 20 (2001) 293–302.

S.M. Seo, D.S. Kim, Y.H. Paik, Met. Mater. Int. 7 (2001) 479–483.

P. Shen, L.F. Zhang, W. Yang, Y. Wang, Iron and Steel 51 (2016) No. 12, 31–40.

Z. Yuan, Y. Wu, H. Zhao, H. Matsuura, F. Tsukihashi, ISIJ Int. 53 (2013) 598–602.

S.H. Heo, K. Lee, Y. Chung, Trans. Nonferrous Met. Soc. China 22 (2012) 870–875.

J. Park, K. Lee, J.J. Pak, Y. Chung, ISIJ Int. 54 (2014) 2059–2063.

Z.Y. Liu, J.K. Yu, X. Yang, E.D. **, L. Yuan, Materials 11 (2018) 883.

Z.Y. Liu, L. Yuan, E.D. **, X. Yang, J.K. Yu, Ceram. Int. 45 (2019) 718–724.

H. Wang, R. Caballero, D. Sichen, J. Eur. Ceram. Soc. 38 (2018) 789–797.

T. Yoon, K. Lee, B. Lee, Y. Chung, ISIJ Int. 57 (2017) 1327–1333.

N. Siddiqi, B. Bhoi, R.K. Paramguru, V. Sahajwalla, O. Ostrovski, Ironmak. Steelmak. 27 (2000) 367–372.

D.Y. Wang, X.B. Li, H.H. Wang, Y. Mi, M.F. Jiang, Y.C. Zhang, J. Non-Cryst. Solids 358 (2012) 1196–1201.

A.A. Kazakov, Russian Metall. 6 (1997) 25–29.

B.J. Monaghan, S.A. Nightingale, Q. Dong, M. Funcik, Engineering 2 (2010) 496–501.

H.H. Wang, Y.J. Xu, K. Jiang, B. Ge, T.P. Qu, D.Y. Wang, Mater. Rep. 31 (2017) No. 20, 96–100.

D. **e, C. Garlick, T. Tran, ISIJ Int. 45 (2005) 175–182.

M. Guo, S. Parada, P.T. Jones, E. Boydens, J.V. Dyck, B. Blanpain, P. Wollants, J. Eur. Ceram. Soc. 29 (2009) 1053–1060.

Acknowledgements

The authors thank team partners from the Research Institute of Mass Energy Optimization and New Technology of Metallurgy for their valuable contribution to this work and preparation of this paper. This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51874171 and 51974154) and supported by University of Science and Technology Liaoning talents program (601009840-09).

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Bai, Rq., Liu, Sy., Mao, Fx. et al. Wetting and corrosion behavior between magnesia–carbon refractory and converter slags with different MgO contents. J. Iron Steel Res. Int. 29, 1073–1079 (2022). https://doi.org/10.1007/s42243-021-00695-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00695-y