Abstract

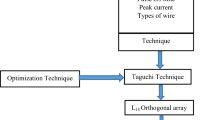

This article highlights the application of multiple criteria optimization using the Grey relation analysis (GRA) and Weightage principal component analysis (WPCA) method in EDM of Inconel X-750. Taguchi’s based design of experiment L9 orthogonal array (OA) was used to perform machining operations using a copper tool. When machining comes to accuracy, higher dimensional tolerances, extreme surface finish, cutting of hard materials, there is an extreme need for non-traditional techniques like EDM. The effects of process parameter namely, peak current (\(I_{\text{p}}\)), pulse on time (\(T_{\text{on}}\)), pulse off time (\(T_{\text{off}}\)) and voltage (V) on Material removal rate (MRR) and Surface roughness (Ra) has been studied. The optimal parametric setting obtained from WPCA and GRA approach are found as 15 amp, 74 µs, 8 µs, 40 voltage, and 18 amp, 63 µs, 9 µs, 60 voltages, respectively. Outcomes of confirmatory tests show that WPCA gives better agreement with actual results which is highly desired for an efficient machining environment. Also, a comparative study of both the developed hybrid modules was performed to evaluate the feasibility. Outcomes reveal that WPCA improved the preferred solution value by 12.67%. The result of ANOVA confirms the most influencing parameter on machining performances.

Similar content being viewed by others

Abbreviations

- GRA:

-

Grey relation analysis

- GRC:

-

Grey relation coefficient

- GRG:

-

Grey relation grade

- MRR:

-

Material removal rate

- Ra:

-

Surface roughness

- ANOVA:

-

Analysis of variance

- MPI:

-

Multi-performance index

- OA:

-

Orthogonal array

- Min:

-

Minute

- mm:

-

Milli meter

- Nm:

-

Newton meter

- N:

-

Newton

- LB:

-

Lower is better

- HB:

-

Higher is better

- S/N:

-

Single to noise

- N:

-

Normalize

- PCA:

-

Principal component analysis

- TOPSIS:

-

Techniques for order of preference by similarity to ideal solution

- VIKOR:

-

Vlse Kriterijumska Optimizacija Kompromisno Resenje

- RSM:

-

Response surface methodology

- NSGA-II:

-

Nondominated sorting genetic algorithm-II

- AHP:

-

Analytic hierarchy process

References

Ali RA, Mia M, Khan AM, Chen W, Gupta MK, Pruncu CI (2019) Multi-response optimization of face milling performance considering tool path strategies in machining of Al-2024. Materials. https://doi.org/10.3390/ma12071013

Anand G, Satyanarayana S, Hussain MM (2017) Optimization of process parameters in EDM with magnetic field using grey relational analysis with taguchi technique. Mater Today Proc 4(8):7723–7730. https://doi.org/10.1016/j.matpr.2017.07.107

Bhosle RB, Sharma SB (2017) Multi-performance optimization of micro-EDM drilling process of Inconel 600 alloy. Mater Today Proc 4(2):1988–1997. https://doi.org/10.1016/j.matpr.2017.02.045

Bijeta Nayak B, Abhishek K, Sankar Mahapatra S, Das D (2018) Application of WPCA based taguchi method for multi-response optimization of abrasive jet machining process. Mater Today Proc 5(2):5138–5144. https://doi.org/10.1016/j.matpr.2017.12.095

Biswas A, Bhaumik S, Majumdar G, Datta S, Mahapatra SS (2011) Bead geometry optimization of submerged arc weld: exploration of weighted principal component analysis (WPCA). Appl Mech Mater 110–116:790–798. https://doi.org/10.4028/www.scientific.net/amm.110-116.790

Das MK, Kumar K, Barman TK, Sahoo P (2014a) Optimization of MRR and surface roughness in PAC of EN 31 steel using weighted principal component analysis. Proc Technol 14(2014):211–218. https://doi.org/10.1016/j.protcy.2014.08.028

Das MK, Kumar K, Barman TK, Sahoo P (2014b) Optimization of WEDM process parameters on EN31steel by weighted principal component analysis. IOSR J Mech Civ Eng 2014:30–33

Das D, Mishra PC, Singh S, Chaubey AK, Routara BC (2018) Machining performance of aluminium matrix composite and use of wpca based taguchi technique for multiple response optimization. Int J Ind Eng Comput 9(4):551–564. https://doi.org/10.5267/j.ijiec.2017.10.001

Durairaj M, Sudharsun D, Swamynathan N (2013) Analysis of process parameters in wire EDM with stainless steel using single objective Taguchi method and multi objective grey relational grade. Proc Eng 64:868–877. https://doi.org/10.1016/j.proeng.2013.09.163

Gopalsamy BM, Mondal B, Ghosh S (2009) Optimisation of machining parameters for hard machining: grey relational theory approach and ANOVA. Int J Adv Manuf Technol 45(11–12):1068–1086. https://doi.org/10.1007/s00170-009-2054-3

Goud M, Sharma AK (2017) On performance studies during micromachining of quartz glass using electrochemical discharge machining. J Mech Sci Technol 31(3):1365–1372. https://doi.org/10.1007/s12206-017-0236-8

Jangra K, Grover S, Aggarwal A (2011) Simultaneous optimization of material removal rate and surface roughness for WEDM of WCCo composite using grey relational analysis along with Taguchi method. Int J Ind Eng Comput 2(3):479–490. https://doi.org/10.5267/j.ijiec.2011.04.005

Khullar VR, Sharma N, Kishore S, Sharma R (2017) RSM- and NSGA-II-based Multiple performance characteristics optimization of EDM parameters for AISI 5160. Arab J Sci Eng 42(5):1917–1928. https://doi.org/10.1007/s13369-016-2399-5

Kumar Mohanty U, Rana J, Sharma A (2017) Multi-objective optimization of electro-discharge machining (EDM) parameter for sustainable machining. Mater Today Proc 4(8):9147–9157. https://doi.org/10.1016/j.matpr.2017.07.271

Kumar R, Pradhan MK, Kumar R (2014) Modeling and optimization of end milling parameters on aluminum 6061 alloy using GRA based Taguchi method coupled with PCA. Proceedings of the 5th International Conference on Manufacturing Technology, Design and Research, IIT Guwahati, (Aimtdr), 10–15. https://doi.org/10.13140/2.1.4297.6324

Kumar A, Majumder H, Vivekananda K, Maity KP (2017) NSGA-II approach for multi-objective optimization of wire electrical discharge machining process parameter on Inconel 718. Mater Today Proc 4(2):2194–2202. https://doi.org/10.1016/j.matpr.2017.02.066

Lahane D (2013) Multi-response optimization of Wire-EDM process using principal component analysis. IOSR J Eng 02(08):38–47. https://doi.org/10.9790/3021-02833847

Mishra BP, Routara BC (2017) An experimental investigation and optimisation of performance characteristics in EDM of EN-24 alloy steel using Taguchi method and grey relational analysis. Mater Today Proc 4(8):7438–7447. https://doi.org/10.1016/j.matpr.2017.07.075

Mishra PC, Das DK, Ukamanal M, Routara BC, Sahoo AK (2015) Multi-response optimization of process parameters using Taguchi method and grey relational analysis during turning AA 7075/SIC composite in dry and spray cooling environments. Int J Ind Eng Comput 6(4):445–456. https://doi.org/10.5267/j.ijiec.2015.6.002

Padhi PC, Mahapatra SS, Yadav SN, Tripathy DK (2014) Optimization of correlated quality characteristics in WEDM process using taguchi approach coupled with principal component analysis. J Manuf Sci Prod 13(3):199–208. https://doi.org/10.1515/jmsp-2013-0011

Pamuji DR, Wahid MA, Rohman A, Sonief AA, Choiron MA (2018) Optimization of multiple response using Taguchi-WPCA in ST 60 tool steel turning process with minimum quantity cooling lubrication (MQCL) method. Aceh Int J Sci Technol 7(1):44–55. https://doi.org/10.13170/aijst.7.1.8708

Panda A, Sahoo AK, Rout AK (2016) Investigations on surface quality characteristics with multi-response parametric optimization and correlations. Alex Eng J 55(2):1625–1633. https://doi.org/10.1016/j.aej.2016.02.008

Prasanna P, Sashank TVSSP, Manikanta B, Aluri P (2017) Optimizing the process parameters of electrical discharge machining on AA7075–SiC Alloys. Mater Today Proc 4(8):8517–8527. https://doi.org/10.1016/j.matpr.2017.07.198

Rajmohan T (2019) Experimental investigation and optimization of machining parameters in drilling of fly ash-filled carbon fiber reinforced composites. Part Sci Technol 37(1):21–30. https://doi.org/10.1080/02726351.2016.1205686

Sathisha N, Somashekhar J, Shivakumar S, Badiger RI (2012) Parametric optimization of electro chemical spark machining using Taguchi based grey relational analysis. IOSR J Mech Civ Eng (IOSR-JMCE) 2278:46–52

Satpathy A, Tripathy S, Senapati NP, Brahma MK (2017) Optimization of EDM process parameters for AlSiC-20% SiC reinforced metal matrix composite with multi response using TOPSIS. Mater Today Proc 4(2):3043–3052. https://doi.org/10.1016/j.matpr.2017.02.187

Selvarajan L, Narayanan CS, Jeyapaul R (2015) Optimization of EDM hole drilling parameters in machining of MoSi-SiC intermetallic/composites for improving geometrical tolerances. J Adv Manuf Syst 14(4):259–272. https://doi.org/10.1142/S0219686715500171

Singh V, Bhandari R, Yadav VK (2016) An experimental investigation on machining parameters of AISI D2 steel using WEDM. Int J Adv Manuf Technol 93(1–4):203–214. https://doi.org/10.1007/s00170-016-8681-6

Yadav S, Kumar Verma R (2019) Multi objective optimization modules in electrical discharge machining processes. Int J Appl Eng Res 14(2):162–168. Retrieved from http://www.ripublication.com

Acknowledgements

The authors are very grateful to the Department of Mechanical Engineering, Madan Mohan Malaviya University of Technology Gorakhpur, India for extending all possible help in carrying out this research work directly or indirectly.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pratap, P., Kumar, J. & Verma, R.K. Experimental investigation and optimization of process parameters during electric discharge machining of Inconel X-750. Multiscale and Multidiscip. Model. Exp. and Des. 3, 161–171 (2020). https://doi.org/10.1007/s41939-020-00069-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-020-00069-z