Abstract

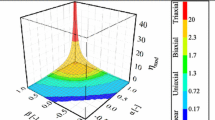

The present paper proposes two methodologies of identifying hyperelastic material parameters of thin structural silicones based on so-called direct and inverse methods. Based on part I of this paper, analytical investigations were performed to conduct homogeneous experiments with structural silicones. To obtain more insight wether or not an experiment provides a homogeneous stress state, the so-called triaxiality was introduced, which allows one to illustrate differences between homogeneous and inhomogeneous experiments. With the help of this scalar, it was possible to design experimental test setups, which ensure a homogeneous stress and strain distribution within the tested rubber-like material. Furthermore an engineering approach to determine the testing speed of arbitrary experiments dependent on one reference testing speed and experiment was presented. This approach ensured equivalent strain energies between arbitrary and reference test specimens during testing, by which expensive strain rate controlled experiments can be relinquished. Based on these analytical studies, experimental data could be provided for the material parameter identification, which exhibits firstly a nearly homogeneous stress state in accordance to the desired stress and strain field of the applied mathematical model and secondly providing nearly equivalent strain energies within different experimental test set-ups and geometries of test specimens. Returning to the present paper, the first methodology identifies simultaneously hyperelastic material parameters based on a set of conventional and homogeneous experimental tests, like uniaxial tension and uniaxial compression, biaxial tension as well as shear-pancake tests. The second methodology determines inversely hyperelastic material parameters utilizing the inverse Finite Element Method based on one single unconventional and inhomogeneous experimental test, here a microindentation test. The main idea is to obtain reliable hyperelastic material parameters based on a single, inhomogeneous experiment to avoid many, time-consuming homogeneous experiments. To validate the inversely determined hyperelastic material parameters, simultaneous multi-experiment data fits are performed to relate the obtained material parameters to those of the microindentation tests. Considering the set of homogeneous experiments, two classical hyperelastic constitutive equations (Neo-Hooke and Mooney–Rivlin) were utilized to determine constitutive parameters. Due to the simplicity of the classical material laws, a more sophisticated, novel phenomenological hyperelastic material law will be proposed and compared with the results of the classical models respectively the results obtained by a modern hyperelastic material model after Kaliske & Heinrich, which generally delivers outstanding results for the material parameter identification.

Similar content being viewed by others

Change history

13 December 2017

The name of the second author contained a ty** error. The original article has been corrected.

Abbreviations

- UT:

-

Uniaxial tension test

- UC:

-

Uniaxial compression test

- BT:

-

Biaxial tension test

- SPC:

-

Shear pancake test

- MI:

-

Microindentation test

- MPI:

-

Material parameter identification

- iFEM:

-

Inverse finite element method

- FEMU:

-

Finite element model updating

- TRM:

-

Trust region method

- LAR:

-

Least absolute residuals

- MOP:

-

Meta model of optimal prognosis

- RMSE:

-

Root mean squared error

- \({\left( \bullet \right) _{\mathrm{{iso}}}}\) :

-

Isochoric/volume-preserving

- tr\(\left( \bullet \right) \) :

-

Trace of argument

- Grad\(\left( \bullet \right) \) :

-

Gradient of argument

- F :

-

Deformation gradient

- J :

-

Relative volume

- C :

-

Right Cauchy-Green tensor

- b :

-

Left Cauchy-Green tensor

- \({\bar{\mathbf{b}}}\) :

-

Isochoric left Cauchy-Green tensor

- \(\lambda _i\) :

-

Principal stretches

- \(\varepsilon _i^{\mathrm{{eng}}}\) :

-

Engineering strain

- \({I_{\mathbf{{ b}}}}\) :

-

First principal strain invariant of \(\mathbf b \)

- \({II_{\mathbf{{ b}}}}\) :

-

Second principal strain invariant of \(\mathbf b \)

- \({III_{\mathbf{{ b}}}}\) :

-

Third principal strain invariant of \(\mathbf b \)

- \(t_i\) :

-

Principal engineering stress

- \(\sigma _i\) :

-

Principal Cauchy stress

- p :

-

Hydrostatic stress

- \(\varPsi ( \bullet )\) :

-

Helmholtz free energy

- \(\mathcal {S}\) :

-

Objective function

- \(\varPhi _{{k}}\) :

-

Trigger function

- p :

-

Vector of material parameters

References

Arruda, E.M., Boyce, M.C.: A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J. Mech. Phys. Solids 41(2), 389–412 (1993)

Avril, S., Bonnet, M., Bretelle, A.S., Grediac, M., Hild, F., Ienny, P., Latourte, F., Lemosse, D., Pagano, S., Pagnacco, E.: Overview of identification methods of mechanical parameters based on full-field measurements. Exp. Mech. 48(4), 381–402 (2008). https://doi.org/10.1007/s11340-008-9148-y

Berselli, G., Vertechy, R., Pellicciari, M., Vassura, G.: Hyperelastic modeling of rubber-like photopolymers for additive manufacturing processes. In: Hoque M. (ed.) Rapid Prototy** Technology—Principles and Functional Requirements, pp. 135–152. InTech (2011). https://doi.org/10.5772/20174

Chaves, E.W.V.: Notes on Continuum Mechanics. Springer, Berlin (2013)

Chen, Z., Scheffer, T., Seibert, H., Diebels, S.: Macroindentation of a soft polymer: identification of hyperelasticity and validation by uni/biaxial tensile tests. Mech. Mater. 64, 111–127 (2013). https://doi.org/10.1016/j.mechmat.2013.05.003

Cottin, N., Felgenhauer, H.P., Natke, H.G.: On the parameter identification of elastomechanical systems using input and output residuals. Ingenieur-Archiv 54(5), 378–387 (1984). https://doi.org/10.1007/bf00532820

Deam, R.T., Edwards, S.F.: The theory of rubber elasticity. Philos. Trans. R. Soc. Lond. A Math. Phys. Sci. 280(1296), 317–353 (1976)

Dow Corning Europe SA.: On macroscopic effects of heterogeneity in elastoplastic media at finite strain. glasstec (2017)

Drass, M., Schneider, J.: Constitutive modeling of transparent structural silicone adhesive—TSSA. In: Schrödter J. (ed.) 14. Darmstädter Kunststofftage, vol. 14 (2016a)

Drass, M., Schneider, J.: On the mechanical behavior of transparent structural silicone adhesive (TSSA). In: Material Modelling, Multi-Scale Modelling, Porous Media, pp 446–451. CRC Press (2016b). https://doi.org/10.1201/9781315641645-74

Drass, M., Schwind, G., Schneider, J., Kolling, S.: Adhesive connections in glass structures-part i: experiments and analytics on thin structural silicone. Glass Struct. Eng. (2017). https://doi.org/10.1007/s40940-017-0046-5

Edwards, S.F., Vilgis, T.A.: The tube model theory of rubber elasticity. Rep. Prog. Phys. 51(2), 243 (1988)

Farhat, C., Hemez, F.M.: Updating finite element dynamic models using an element-by-element sensitivity methodology. AIAA J. 31(9), 1702–1711 (1993)

Gorash, Y., Comlekci, T., Hamilton, R.: Cae-based application for identification and verification of hyperelastic parameters. Proc. Inst. Mech. Eng. L J. Mater. Des. Appl. (2015) https://doi.org/10.1177/1464420715604004

Hadamard, J.: Sur les problèmes aux dérivés partielles et leur signification physique. Princet. Univ. Bull. 13, 49–52 (1902)

Hartmann, S.: Parameter estimation of hyperelasticity relations of generalized polynomial-type with constraint conditions. Int. J. Solids Struct. 38(44), 7999–8018 (2001). https://doi.org/10.1016/S0020-7683(01)00018-X

Hauser, C., Walz, B., Mainçon, P., Barnardo, C.: Application of inverse fem to earth pressure estimation. Finite Elem. Anal. Des. 44(11), 705–714 (2008). https://doi.org/10.1016/j.finel.2008.03.005

Heinrich, G., Straube, E.: On the strength and deformation dependence of the tube-like topological constraints of polymer networks, melts and concentrated solutions. i. The polymer network case. Acta Polym. 34(9), 589–594 (1983). https://doi.org/10.1002/actp.1983.010340909

Holzapfel, G.A.: Nonlinear Solid Mechanics, vol. 24. Wiley Chichester, Hoboken (2000)

Horgan, C.O., Smayda, M.G.: The importance of the second strain invariant in the constitutive modeling of elastomers and soft biomaterials. Mech. Mater. 51, 43–52 (2012). https://doi.org/10.1016/j.mechmat.2012.03.007

Iman, R.L.: Latin Hypercube Sampling. Wiley, Hoboken (2008). https://doi.org/10.1002/9780470061596.risk0299

Iman, R.L., Conover, W.J.: A distribution-free approach to inducing rank correlation among input variables. Commun. Stat. Simul. Comput. 11(3), 311–334 (1982). https://doi.org/10.1080/03610918208812265

James, H.M., Guth, E.: Theory of the elastic properties of rubber. J. Chem. Phys. 11(10), 455–481 (1943). https://doi.org/10.1063/1.1723785

Kaliske, M., Heinrich, G.: An extended tube-model for rubber elasticity: statistical-mechanical theory and finite element implementation. Rubber Chem. Technol. 72(4), 602–632 (1999)

Khajehsaeid, H., Naghdabadi, R., Arghavani, J.: A strain energy function for rubber-like materials. Const. Models Rubber 8, 205 (2013)

Kolling, S., Bois, P.A.D., Benson, D.J., Feng, W.W.: A tabulated formulation of hyperelasticity with rate effects and damage. Comput. Mech. 40(5), 885–899 (2007). https://doi.org/10.1007/s00466-006-0150-x

Kuhn, W.: Über die gestalt fadenförmiger moleküle in lösungen. Kolloid-Zeitschrift 68(1), 2–15 (1934). https://doi.org/10.1007/BF01451681

Kuhn, W.: Beziehungen zwischen molekülgröße, statistischer molekülgestalt und elastischen eigenschaften hochpolymerer stoffe. Kolloid-Zeitschrift 76(3), 258–271 (1936a). https://doi.org/10.1007/BF01451143

Kuhn, W.: Gestalt und eigenschaften fadenförmiger moleküle in lösungen (und im elastisch festen zustande). Angew. Chem. 49(48), 858–862 (1936b). https://doi.org/10.1002/ange.19360494803

Kuhn, W., Grün, F.: Beziehungen zwischen elastischen konstanten und dehnungsdoppelbrechung hochelastischer stoffe. Kolloid-Zeitschrift 101(3), 248–271 (1942). https://doi.org/10.1007/BF01793684

Le Saux, V., Marco, Y., Bles, G., Calloch, S., Moyne, S., Plessis, S., Charrier, P.: Identification of constitutive model for rubber elasticity from micro-indentation tests on natural rubber and validation by macroscopic tests. Mech. Mater. 43(12), 775–786 (2011)

Mainçon, P.: Inverse fem i: load and response estimates from measurements. In: Proceedings of 2nd International Conference on Structural Engineering, Mechanics and Computation, Cape Town, South Africa (2004a)

Mainçon, P.: Inverse fem ii: dynamic and non-linear problems. In: Proceedings of 2nd International Conference on Structural Engineering, Mechanics and Computation, Cape Town, South Africa (2004b)

Marckmann, G., Verron, E.: Comparison of hyperelastic models for rubber-like materials. Rubber Chem. Technol. 79(5), 835–858 (2006). https://doi.org/10.5254/1.3547969

Marco, Y., Le Saux, V., Bles, G., Calloch, S., Charrier, P.: Identification of local constitutive model from micro-indentation testing. Const. Models Rubber VII, 177–182 (2011)

Marlow, R.: A general first-invariant hyperelastic constitutive model in constitutive models for rubber iii. In: Proceedings of European conference London, pp. 15–17 (2003)

Miehe, C., Schänzel, L.M.: Phase field modeling of fracture in rubbery polymers. Part i: finite elasticity coupled with brittle failure. J. Mech. Phys. Solids 65, 93–113 (2013). https://doi.org/10.1016/j.jmps.2013.06.007

Miehe, C., Göktepe, S., Lulei, F.: A micro-macro approach to rubber-like materials–part i: the non-affine micro-sphere model of rubber elasticity. J. Mech. Phys. Solids 52(11), 2617–2660 (2004)

Mooney, M.: A theory of large elastic deformation. J. Appl. Phys. 11(9), 582–592 (1940). https://doi.org/10.1063/1.1712836

Nelder, J.A.: Inverse polynomials, a useful group of multi-factor response functions. Biometrics 22(1), 128–141 (1966)

Ogden, R.: Large deformation isotropic elasticity: on the correlation of theory and experiment for compressible rubberlike solids. Proc. R. Soc. Lond A Math. Phys. Eng. Sci. 328(1575), 567–583 (1972). https://doi.org/10.1098/rspa.1972.0096

Ogden, R., Saccomandi, G., Sgura, I.: Fitting hyperelastic models to experimental data. Comput. Mech. 34(6), 484–502 (2004)

Overend, M.: Optimising connections in structural glass. In: Proceedings of 2nd International conference on Glass in Buildings (2005)

Pacheco, C.C., Dulikravich, G.S., Vesenjak, M.: Inverse parameter identification in solid mechanics using bayesian statistics, response surfaces and minimization. Technische Mechanik 36(1–2), 110–121 (2016)

Pagnacco, E., Lemosse, D., Hild, F., Amiot, F.: Inverse strategy from displacement field measurement and distributed forces using fea. In: SEM Annual Conference and Exposition on Experimental and Applied Mechanics (2005)

Rivlin, R.S.: Large elastic deformations of isotropic materials. iv. Further developments of the general theory. Philos. Trans. R. Soc. Lond. A Math. Phys. Sci. 241(835), 379–397 (1948)

Santarsiero, M., Louter, C., Nussbaumer, A.: The mechanical behaviour of sentryglas ionomer and tssa silicon bulk materials at different temperatures and strain rates under uniaxial tensile stress state. Glass Struct. Eng. (2016). https://doi.org/10.1007/s40940-016-0018-1

Schwarz, C., Ackert, P., Rössinger, M., Hofmann, A., Mauermann, R., Landgreber, D.: Mathematical optimization of clam** processes in car-body production. In: 12. Weimarer Optimierungs- und Stochastiktage (2015)

Shkarayev, S., Krashanitsa, R., Tessler, A.: An inverse interpolation method utilizing in-flight strain measurements for determining loads and structural response of aerospace vehicles. Technical Report, NASA (2001)

Shutov, A., Kreißig, R.: Regularized strategies for material parameter identification in the context of finite strain plasticity. Technische Mechanik 30(1–3), 280–295 (2010)

Sitte, S., Brasseur, M., Carbary, L., Wolf, A.: Preliminary evaluation of the mechanical properties and durability of transparent structural silicone adhesive (tssa) for point fixing in glazing. J. ASTM Int. 10(8), 1–27 (2011). https://doi.org/10.1520/JAI104084

Tessler, A., Spangler, J.L.: Inverse fem for full-field reconstruction of elastic deformations in shear deformable plates and shells. In: Proceedings of Second European Workshop on Structural Health Monitoring, pp. 83–90 (2004)

Treloar, L.: The Physics of Rubber Elasticity. Oxford University Press, Oxford (1975)

Wineman, A.: Some results for generalized neo-hookean elastic materials. Int. J. Non-Linear Mech. 40(2), 271–279 (2005). https://doi.org/10.1016/j.ijnonlinmec.2004.05.007

Yeoh, O.H., Fleming, P.: A new attempt to reconcile the statistical and phenomenological theories of rubber elasticity. J. Polym. Sci. B Polym. Phys. 35(12), 1919–1931 (1997)

Acknowledgements

We would like to thank Dow Corning Inc. and Interpane Glas Industrie AG gratefully for their support during our studies by providing us testing material.

Author information

Authors and Affiliations

Corresponding author

Additional information

The original article has been revised: the name of the second author has been corrected.

A correction to this article is available online at https://doi.org/10.1007/s40940-017-0054-5.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix-A

A data package of the presented experimental raw data including the engineering stress strain responses for UT, UC, BT, SPC experiments based on mean values can be granted upon e-mail request to the authors. Table 2 gives an overview of the testing data and the utilized fitting algorithm.

Appendix-B

In this appendix, the determined constitutive material parameters for thin structural silicone will be provided based on the applied two methodologies - direct/inverse method. The constitutive parameters are listed with respect to the applied constitutive model (Table 3).

Appendix-C

For the sake of completeness, in the following graphs the comparison for the conventional and unconventional MPI will be illustrated for the material models NH, ExtTube and MD (see Fig. 10) in accordance to Fig. 8.

Rights and permissions

About this article

Cite this article

Drass, M., Schwind, G., Schneider, J. et al. Adhesive connections in glass structures—part II: material parameter identification on thin structural silicone. Glass Struct Eng 3, 55–74 (2018). https://doi.org/10.1007/s40940-017-0048-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40940-017-0048-3