Abstract

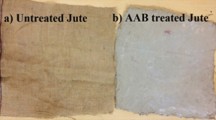

The application of natural fibers for improving the strength of soft soil is gaining recent global popularity to achieve sustainable development. However, the biodegradability of natural fibers within 6–12 months is the main source of a hindrance towards its practical implementation. Treatment of natural fibers with antimicrobial chemicals, plant-derived oils, acetylation, and bitumen coating results in improving the durability of natural fibers, but these methods are costly and may cause leaching. The current work suggests a unique treatment approach for natural jute geotextiles that involves treating these geotextiles with an alkali-activated binder (AAB) to improve their strength and durability. Fly ash, an aluminosilicate-rich industrial waste, reacts with a sodium silicate and sodium hydroxide-based activator solution to form AAB. The water-to-solids ratios (w/s) are maintained at 0.30, 0.35, 0.4, 0.45, and 0.50 for treatment of the fibers. The untreated and treated natural geotextiles are subjected to different durability tests including soil burial, compost burial, exposure to acids and alkalis, and hydrolysis of water for three different periods of 30, 60, and 90 days. The durability performance is assessed by analyzing the surface texture, surface morphology, change in chemical bonds, weight loss, tensile strength, and elongation at failure (fiber breaking). It is observed from the durability studies that the AAB treatment makes the jute geotextile harder and more resistant to exposure to different chemicals. It is also been determined that jute coated with an AAB of 0.35 w/s ratio degrades the least.

Similar content being viewed by others

Data Availability Statement

Some or all data, models, or codes that support the findings of this study are available from the corresponding author upon reasonable request.

References

Muthukumar S, Sakthivelu A, Shanmugasundaram K, Mahendran N, Ravichandran V (2019) Performance assessment of square footing on jute geocell-reinforced sand. Int J Geosynth Ground Eng 5(3):1–10

Kiffle ZB, Steele SE, Bhatia SK, Smith JL (2017) Use of jute as a sustainable alternative for PP in geotextile tubes. In: Brandon TL, Valentine RJ (eds) Geotechnical frontiers 2017: waste containment, barriers, remediation, and sustainable geoengineering. ASCE, Reston, pp 369–378

Calvarano LS, Palamara R, Leonardi G, Moraci N (2016) Reinforced unpaved roads: parametrical analysis of design procedures. In: 6th European Geosynthetics Congress EUROGEO6

Rawal A, Sayeed MMA (2013) Mechanical properties and damage analysis of jute/polypropylene hybrid nonwoven geotextiles. Geotext Geomembr 37:54–60

Mishra SR, Mohapatra S, Sudarsanan N, Rajagopal K, Robinson RG (2017) A simple image-based deformation measurement technique in tensile testing of geotextiles. Geosynth Int 24(3):306–320

Broda J, Gawłowski A, Przybyło S, Biniaś D, Rom M, Grzybowska-Pietras J, Laszczak R (2018) Innovative wool geotextiles designed for erosion protection. J Ind Text 48(3):599–611

Kumar N, Das D (2018) Nonwoven geotextiles from nettle and poly (lactic acid) fibers for slope stabilization using bioengineering approach. Geotext Geomembr 46(2):206–213

Prambauer M, Wendeler C, Weitzenböck J, Burgstaller C (2019) Biodegradable geotextiles–An overview of existing and potential materials. Geotext Geomembr 47(1):48–59

Ghosh M, Saha R, Das M (2021) Application of jute-polypropylene blended geotextile in black cotton soil subgrade for low volume road construction. Int J Geosynth Ground Eng 7(3):1–18

Menon AR, Konnur S, Bhasi A (2021) Model tests on coir geotextile-encased stone columns with tyre crumb-infilled basal coir geocell. Int J Geosynth Ground Eng 7(2):1–13

Buragadda V, Thyagaraj T (2019) Bearing capacity of jute geotextile-reinforced sand bed. Int J Geosynth Ground Eng 5(4):1–14

Kolathayar S, Sowmya S, Priyanka E (2020) Comparative study for performance of soil bed reinforced with jute and sisal geocells as alternatives to HDPE Geocells. Int J Geosynth Ground Eng 6(4):1–8

Shukla SK (2021) Geosynthetics and ground engineering: sustainability considerations. Int J Geosynth Ground Eng. https://doi.org/10.1007/s40891-021-00256-z

Gupta S, GuhaRay A, Kar A, Komaravolu VP (2018) Performance of alkali-activated binder treated jute geotextile as reinforcement for subgrade stabilization. Int J Geotechn Eng. https://doi.org/10.1080/19386362.2018.1464272

Sanyal T, Chakraborty K (1994) Application of a bitumen-coated jute geotextile in bank-protection works in the hooghly estuary. Geotext Geomembr 13(2):127–132

Teli MD, Valia SP (2013) Acetylation of jute fiber to improve oil absorbency. Fibers Polym 14(6):915–919

Andersson M, Tillman AM (1989) Acetylation of jute: effects on strength, rot resistance, and hydrophobicity. J Appl Polym Sci 37(12):3437–3447

Sanyal T (2017) Jute geotextiles and their applications in civil engineering. Springer, Singapore

Anggraini V, Asadi A, Huat BBK, Nahazanan H (2015) Performance of chemically treated natural fibres and lime in soft soil for the utilisation as pile-supported earth platform. Int J Geosynth Ground Eng 1:28. https://doi.org/10.1007/s40891-015-0031-5

Duan J, Han C, Liu L, Jiang J, Li J, Li Y (2015) Binding cellulose and chitosan via intermolecular inclusion interaction: Synthesis and characterisation of gel. J Spectrosc. https://doi.org/10.1155/2015/179258

Wahit MU, Akos NI, Laftah WA (2012) Influence of natural fibers on the mechanical properties and biodegradation of poly (lactic acid) and poly (ε-caprolactone) composites. A review. Polym Compos 33(7):1045–1053

Nam S, Netravali AN (2006) Green composites. I. Physical properties of ramie fibers for environment-friendly green composites. Fibers Polym 7:372–379

Batista KC, Silva DAK, Coelho LAF, Pezzin SH, Pezzin APT (2010) Soil biodegradation o PHBV/peach palm particles biocomposites. J Polym Environ 18(3):346–354

Siakeng R, Jawaid M, Asim M, Siengchin S (2020) Accelerated weathering and soil burial effect on biodegradability, colour and texture of coir/pineapple leaf fibres/PLA biocomposites. Polymers 12:458. https://doi.org/10.3390/polym12020458

Akter N, Saha J, Das SC, Khan MA (2018) Effect of bitumen and polyester resin mixture on the physico-mechanical and degradable properties of jute fabrics. Fibers 6:44. https://doi.org/10.3390/fib6030044

Schurholz H (1992) Use of woven coir geotextiles in Europe. In: Proceedings of the United Kingdom Coir Geotextile Seminar, West Midlands

Balan K (1995) Studies on engineering behaviour and uses of geotextile with natural fibres. Ph.D. Thesis (Doctor of Philosophy). Indian Institute of Technology, Delhi, India

Lekha KR (2004) Field instrumentation and monitoring of soil erosion in coir geotextile stabilized slopes: a case study. Geotext Geomembr 22(5):399–413

Marques AR, de Oliveira S, Patrício P, Soares dos Santos F, Monteiro ML, de Carvalho UD, de Souza RC (2014) Effects of the climatic conditions of the southeastern Brazil on degradation the fibers of coir-geotextile: evaluation of mechanical and structural properties. Geotext Geomembr 42(1):76–82

Dittenber DB (2012) Effect of alkalization on flexural properties and moisture absorption of kenaf fiber reinforced composites. In: International SAMPE Technical Conference

Das BR, Banerjee PK (2013) Interface bond and compatibility of jute with asphalt. Composites 53:69–75. https://doi.org/10.1016/j.compositesb.2013.04.011

Ghosh M, Banerjee PK, Rao GV (2010) Development of asphalt overlay fabric from jute. J Text Inst 101(5):431–442

Banerjee PK, Ghosh M (2008) Studies on jute-asphalt composites. J Appl Polym Sci 109:3165–3172

Midha VK, Joshi S, Kumar SS (2017) Performance of chemically treated jute geotextile in unpaved roads at different in situ conditions. J Inst Eng (India) 98(1):47–54

Rosa MF, Chiou BS, Medeiros ES, Wood DF, Williams TG, Mattoso LH, Imam SH (2009) Effect of fiber treatments on tensile and thermal properties of starch/ethylene vinyl alcohol copolymers/ coir biocomposites. Bioresour Technol 100(21):5196–5202

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Environ Polym Degrad 15(1):25–33. https://doi.org/10.1007/s10924-006-0042-3

Kabir MM, Wang H, Lau KT, Cardona F (2012) Chemical treatments on plant-based natural fibre reinforced polymer composites: an overview. Compos B 43(7):2883–2892

Wang WM, Cai ZS, Yu JY, **a ZP (2009) Changes in composition, structure, and properties of jute fibers after chemical treatments. Fibers Polym 10(6):776–778

Saha P, Manna S, Chowdhury SR, Sen R, Roy D, Adhikari B (2010) Enhancement of tensile strength of lignocellu-losic jute fibers by alkali-steam treatment. Bioresour Technol 101(9):3182–3187

Saha P, Roy D, Manna S, Adhikari B, Sen R, Roy S (2012) Durability of transesterified jute geotextiles. Geotext Geomembr 35:69–75

Tiwari N, Satyam N (2020) An experimental study on the behavior of lime and silica fume treated coir geotextile reinforced expansive soil subgrade. Eng Sci Technol Int J 23(5):1214–1222

Basu G, Roy AN, Bhattacharyya SK, Ghosh SK (2009) Construction of unpaved rural road using jute-synthetic blended woven geotextiles e a case study. Geotext Geomembr 27:506e512

Sumi S, Unnikrishnan N, Mathew L (2016) Experimental investigations on biological resistance of surface modified coir geotextiles. Int J Geosynth Ground Eng 2(4):1–9

Chakrabarti SK, Saha SG, Paul P, Dewan AR, Das K, Chowdhury PK, Gon DP, Ray P (2016) Specially treated woven jute geotextiles for riverbank protection. Indian J Fibre Text Res (IJFTR) 41(2):207–211

Uddin MK, Khan MA, Ali KI (1997) Degradable jute plastic composites. Polym Degrad Stab 55(1):1–7

Ramakrishna G, Thirumalai S (2005) Studies on the durability of natural fibres and the effect of corroded fibres on the strength of mortar. Cem Concr Compos 27(5):575–582. https://doi.org/10.1016/j.cemconcomp.2004.09.008

ASTM D5199–12 (2019) Standard test method for measuring the nominal thickness of geosynthetics. ASTM, West Conshohocken

ASTM D4751-20b (2021) Standard test methods for determining apparent opening size of a geotextile. ASTM, West Conshohocken

ASTM D5261-10 (2018) Standard test method for measuring mass per unit area of geotextiles. ASTM, West Conshohocken

ASTM D4595-17 (2021) Standard test method for tensile properties of geotextiles by the wide-width strip method. ASTM, West Conshohocken

ISO 11058:2010 (2010) Geotextiles and geotextile-related products. Determination of water permeability characteristics normal to the plane, without load. ISO, Geneva

Kar A, Ray I, Halabe UB, Unnikrishnan A, Dawson-Andoh B (2014) Characterizations and estimation of alkali-activated binder paste from microstructures. Int J Concr Struct Mater 8(3):213–228

ASTM G160-12 (2019) Standard practice for evaluating microbial susceptibility of nonmetallic materials by laboratory soil burial. ASTM, West Conshohocken

BS EN 14030:2001 Geotextiles and geotextile-related products. Screening test method for determining the resistance to acid and alkaline liquids (ISO/TR 12960:1998, modified)

BS EN 12447:2021 Geotextiles and geotextile-related products - screening test method for determining the resistance to hydrolysis in water

ISO 13934–1:1999 (1999) Textiles. Tensile properties of fibers–part 1: determination of maximum force and elongation at maximum force using the strip method. ISO, Geneva

ISO 527–1:2019 (2019) Plastics. Determination of tensile properties– Part 1: general principles. ISO, Geneva

Ramagiri KK, Kar A (2019) Effect of precursor combination and elevated temperatures on the microstructure of alkali-activated binder. Indian Concr J 93(10):34–43

Chakravarthy GS, GuhaRay A, Kar A (2021) Effect of soil burial exposure on durability of alkali-activated binder-treated jute geotextile. Innov Infrastruct Solut 6(2):1–10

Abderrahim B, Abderrahman E, Mohamed A, Fatima T, Abdesselam T, Krim O (2015) Kinetic thermal degradation of cellulose, polybutylene succinate and a green composite: comparative study. World J Environ Eng 3:95–110

Imamura Y, Nishimoto K (1986) Resistance of acetylated wood to attack by subterranean termites. Wood Res No 72:37–44

Funding

This research is supported by the Department of Science and Technology (DST), International Bilateral Cooperation Division, Govt. of India through Indo-Austria bilateral grant (Project ID: INT/AUSTRIA/BMWF/P-22/2018).

Author information

Authors and Affiliations

Contributions

SGC: Main author, conceptualisation, carrying out all experiments, overall analysis, drafting of the manuscript; AG: Conceptualisation, detailed review and editing; AK: Detailed review and editing;

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sachin Chakravarthy, G., GuhaRay, A. & Kar, A. Experimental Investigations on Strength and Durability of Alkali-Activated Binder-Treated Natural Jute Geotextile. Int. J. of Geosynth. and Ground Eng. 7, 97 (2021). https://doi.org/10.1007/s40891-021-00341-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40891-021-00341-3