Abstract

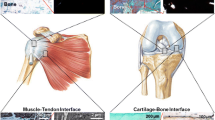

The occurrence of musculoskeletal tissue injury or disease and the subsequent functional impairment is at an alarming rate. It continues to be one of the most challenging problems in the human health care. Regenerative engineering offers a promising transdisciplinary strategy for tissues regeneration based on the convergence of tissue engineering, advanced materials science, stem cell science, developmental biology, and clinical translation. Biomaterials are emerging as extracellular-mimicking matrices designed to provide instructive cues to control cell behavior and ultimately be applied as therapies to regenerate damaged tissues. Biodegradable polymers constitute an attractive class of biomaterials for the development of scaffolds due to their flexibility in chemistry and the ability to be excreted or resorbed by the body. Herein, the focus will be on biodegradable polyphosphazene-based blend systems. The synthetic flexibility of polyphosphazene, combined with the unique inorganic backbone, has provided a springboard for more research and subsequent development of numerous novel materials that are capable of forming miscible blends with poly(lactide-co-glycolide) (PLAGA). Laurencin and co-workers have demonstrated the exploitation of the synthetic flexibility of polyphosphazene that will allow the design of novel polymers, which can form miscible blends with PLAGA for biomedical applications. These novel blends, due to their well-tuned biodegradability, and mechanical and biological properties coupled with the buffering capacity of the degradation products, constitute ideal materials for regeneration of various musculoskeletal tissues.

Lay Summary

Regenerative engineering aims to regenerate complex tissues to address the clinical challenge of organ damage. Tissue engineering has largely focused on the restoration and repair of individual tissues and organs, but over the past 25 years, scientific, engineering, and medical advances have led to the introduction of this new approach which involves the regeneration of complex tissues and biological systems such as a knee or a whole limb. While a number of excellent advanced biomaterials have been developed, the choice of biomaterials, however, has increased over the past years to include polymers that can be designed with a range of mechanical properties, degradation rates, and chemical functionality. The polyphosphazenes are one good example. Their chemical versatility and hydrogen bonding capability encourages blending with other biologically relevant polymers. The further development of polyphosphazene-based blends will present a wide spectrum of advanced biomaterials that can be used as scaffolds for regenerative engineering as well as other biomedical applications.

Similar content being viewed by others

References

Laurencin CT, Khan Y. Regenerative engineering. Sci Transl Med. 2012;4(160):160ed169.

Laurencin CT, Nair LS. Regenerative engineering: approaches to limb regeneration and other grand challenges. Regen Eng Transl Med. 2015;1(1):1–3.

Reichert WM, Ratner BD, Anderson J, Coury A, Hoffman AS, Laurencin CT, et al. 2010 Panel on the biomaterials grand challenges. J Biomed Mater Res A. 2011;96(2):275–87.

Polyphosphazenes for biomedical applications (1). Hoboken, US: Wiley; 2009.

Allcock HR, Morozowich NL. Bioerodible polyphosphazenes and their medical potential. Polym Chem. 2012;3(3):578–90.

Laurencin CT, Norman ME, Elgendy HM, El‐Amin SF, Allcock HR, Pucher SR, et al. Use of polyphosphazenes for skeletal tissue regeneration. J Biomed Mater Res. 1993;27(7):963–73.

Nair LS, Laurencin CT. Biodegradable polymers as biomaterials. Prog Polym Sci. 2007;32(8–9):762–98.

Allcock HR. The synthesis of functional polyphosphazenes and their surfaces. Appl Organomet Chem. 1998;12(10–11):659–66.

Baillargeon AL, Mequanint K. Biodegradable polyphosphazene biomaterials for tissue engineering and delivery of therapeutics. Biomed Res Int. 2014;2014:761373.

Rothemund S, Teasdale I. Preparation of polyphosphazenes: a tutorial review. Chem Soc Rev. 2016.

Borden M, Attawia M, Khan Y, El-Amin S, Laurencin C. Tissue-engineered bone formation in vivo using a novel sintered polymeric microsphere matrix. Bone Joint J. 2004;86(8):1200–8.

Cao H, Kuboyama N. A biodegradable porous composite scaffold of PGA/β-TCP for bone tissue engineering. Bone. 2010;46(2):386–95.

Carampin P, Conconi MT, Lora S, Menti AM, Baiguera S, Bellini S, et al. Electrospun polyphosphazene nanofibers for in vitro rat endothelial cells proliferation. J Biomed Mater Res A. 2007;80(3):661–8.

Deng M, James R, Laurencin CT, Kumbar SG. Nanostructured polymeric scaffolds for orthopaedic regenerative engineering. IEEE Trans NanoBiosci. 2012;11(1):3–14.

Deng M, Kumbar SG, Wan Y, Toti US, Allcock HR, Laurencin CT. Polyphosphazene polymers for tissue engineering: an analysis of material synthesis, characterization and applications. Soft Matter. 2010;6(14):3119–32.

Jabbarzadeh E, Deng M, Lv Q, Jiang T, Khan YM, Nair LS, et al. VEGF-incorporated biomimetic poly(lactide-co-glycolide) sintered microsphere scaffolds for bone tissue engineering. J Biomed Mater Res B Appl Biomater. 2012;100B(8):2187–96.

Li W-J, Laurencin CT, Caterson EJ, Tuan RS, Ko FK. Electrospun nanofibrous structure: a novel scaffold for tissue engineering. J Biomed Mater Res. 2002;60(4):613–21.

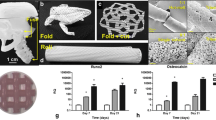

Deng M, Nair LS, Nukavarapu SP, Jiang T, Kanner WA, Li X, et al. Dipeptide-based polyphosphazene and polyester blends for bone tissue engineering. Biomaterials. 2010;31(18):4898–908.

Deng M, Nair LS, Nukavarapu SP, Kumbar SG, Brown JL, Krogman NR, et al. Biomimetic, bioactive etheric polyphosphazene-poly(lactide-co-glycolide) blends for bone tissue engineering. J Biomed Mater Res A. 2010;92(1):114–25.

Ibim SE, Ambrosio AM, Kwon MS, El-Amin SF, Allcock HR, Laurencin CT. Novel polyphosphazene/poly(lactide-co-glycolide) blends: miscibility and degradation studies. Biomaterials. 1997;18(23):1565–9.

Krogman NR, Steely L, Hindenlang MD, Nair LS, Laurencin CT, Allcock HR. Synthesis and characterization of polyphosphazene-block-polyester and polyphosphazene-block-polycarbonate macromolecules. Macromolecules. 2008;41(4):1126–30.

Krogman NR, Weikel AL, Nguyen NQ, Kristhart KA, Nukavarapu SP, Nair LS, et al. Hydrogen bonding in blends of polyesters with dipeptide‐containing polyphosphazenes. J Appl Polym Sci. 2010;115(1):431–7.

Shan D, Huang Z, Zhao Y, Cai Q, Yang X. Improving the miscibility of biodegradable polyester/polyphosphazene blends using cross-linkable polyphosphazene. Biomed Mater. 2014;9(6):061001.

Bostman O, Pihlajamaki H. Clinical biocompatibility of biodegradable orthopaedic implants for internal fixation: a review. Biomaterials. 2000;21(24):2615–21.

Landes CA, Ballon A, Roth C. Maxillary and mandibular osteosyntheses with PLGA and P (L/DL) LA implants: a 5-year inpatient biocompatibility and degradation experience. Plast Reconstr Surg. 2006;117(7):2347–60.

Conconi MT, Lora S, Menti AM, Carampin P, Parnigotto PP. In vitro evaluation of poly[bis(ethyl alanato)phosphazene] as a scaffold for bone tissue engineering. Tissue Eng. 2006;12(4):811–9.

Nair LS, Bhattacharyya S, Bender JD, Greish YE, Brown PW, Allcock HR, et al. Fabrication and optimization of methylphenoxy substituted polyphosphazene nanofibers for biomedical applications. Biomacromolecules. 2004;5(6):2212–20.

Sethuraman S, Nair LS, El-Amin S, Farrar R, Nguyen MT, Singh A, et al. In vivo biodegradability and biocompatibility evaluation of novel alanine ester based polyphosphazenes in a rat model. J Biomed Mater Res A. 2006;77(4):679–87.

Duan S, Yang X, Mao J, Qi B, Cai Q, Shen H, et al. Osteocompatibility evaluation of poly(glycine ethyl ester-co-alanine ethyl ester)phosphazene with honeycomb-patterned surface topography. J Biomed Mater Res A. 2013;101(2):307–17.

Rothemund S, Aigner TB, Iturmendi A, Rigau M, Husar B, Hildner F, et al. Degradable glycine-based photo-polymerizable polyphosphazenes for use as scaffolds for tissue regeneration. Macromol Biosci. 2015;15(3):351–63.

Allcock HR. The expanding field of polyphosphazene high polymers. Dalton Trans. 2016;45(5):1856–62.

Allcock H. Phosphorus-nitrogen compounds: cyclic, linear, and high polymeric system. Elsevier; 2012

Allcock HR. Heteroatom ring systems and polymers. 1967.

Allcock HR. Chemistry and applications of polyphosphazenes. Wiley-Interscience; 2003.

Oredein-McCoy O, Krogman NR, Weikel AL, Hindenlang MD, Allcock HR, Laurencin CT. Novel factor-loaded polyphosphazene matrices: potential for driving angiogenesis. J Microencapsul. 2009;26(6):544–55.

Nair LS, Lee DA, Bender JD, Barrett EW, Greish YE, Brown PW, et al. Synthesis, characterization, and osteocompatibility evaluation of novel alanine-based polyphosphazenes. J Biomed Mater Res A. 2006;76(1):206–13.

Peach MS, James R, Toti US, Deng M, Morozowich NL, Allcock HR, et al. Polyphosphazene functionalized polyester fiber matrices for tendon tissue engineering: in vitro evaluation with human mesenchymal stem cells. Biomed Mater. 2012;7(4):045016.

Singh A, Krogman NR, Sethuraman S, Nair LS, Sturgeon JL, Brown PW, et al. Effect of side group chemistry on the properties of biodegradable L-alanine cosubstituted polyphosphazenes. Biomacromolecules. 2006;7(3):914–8.

Allcock HR. Inorganic–organic polymers. Adv Mater. 1994;6(2):106–15.

Sethuraman S, Nair LS, El-Amin S, Nguyen M-T, Singh A, Krogman N, et al. Mechanical properties and osteocompatibility of novel biodegradable alanine based polyphosphazenes: side group effects. Acta Biomater. 2010;6(6):1931–7.

Allcock HR, Crane CA, Morrissey CT, Nelson JM, Reeves SD, Honeyman CH. Manners I: “Living” cationic polymerization of phosphoranimines as an ambient temperature route to polyphosphazenes with controlled molecular weights. Macromolecules. 1996;29(24):7740–7.

Deng M, Kumbar SG, Nair LS, Weikel AL, Allcock HR, Laurencin CT. Biomimetic structures: biological implications of dipeptide-substituted polyphosphazene–polyester blend nanofiber matrices for load-bearing bone regeneration. Adv Funct Mater. 2011;21(14):2641–51.

Allcock H. Recent advances in phosphazene (phosphonitrilic) chemistry. Chem Rev. 1972;72(4):315–56.

Allcock H, Fuller T, Matsumura K. Hydrolysis pathways for aminophosphazenes. Inorg Chem. 1982;21(2):515–21.

Allcock HR, Pucher SR, Scopelianos AG. Poly [(amino acid ester) phosphazenes] as substrates for the controlled release of small molecules. Biomaterials. 1994;15(8):563–9.

Ulery BD, Nair LS, Laurencin CT. Biomedical applications of biodegradable polymers. J Polym Sci B Polym Phys. 2011;49(12):832–64.

Deng M, Nair LS, Nukavarapu SP, Kumbar SG, Jiang T, Krogman NR, et al. Miscibility and in vitro osteocompatibility of biodegradable blends of poly [(ethyl alanato)(p-phenyl phenoxy) phosphazene] and poly (lactic acid-glycolic acid). Biomaterials. 2008;29(3):337–49.

Heyde M, Moens M, Van Vaeck L, Shakesheff KM, Davies MC, Schacht EH. Synthesis and characterization of novel poly[(organo)phosphazenes] with cell-adhesive side groups. Biomacromolecules. 2007;8(5):1436–45.

Veronese F, Marsilio F, Caliceti P, De Filippis P, Giunchedi P, Lora S. Polyorganophosphazene microspheres for drug release: polymer synthesis, microsphere preparation, in vitro and in vivo naproxen release. J Control Release. 1998;52(3):227–37.

Deng M, Nair LS, Nukavarapu SP, Kumbar SG, Jiang T, Weikel AL, et al. In situ porous structures: a unique polymer erosion mechanism in biodegradable dipeptide-based polyphosphazene and polyester blends producing matrices for regenerative engineering. Adv Funct Mater. 2010;20(17):2743–957.

Ramani R, Alam S. Composition optimization of PEEK/PEI blend using model-free kinetics analysis. Thermochim Acta. 2010;511(1–2):179–88.

Utracki L, Favis B. Polymer alloys and blends, vol. 4. New York: Marcel Dekker; 1989.

Parameswaranpillai J, Thomas S, Grohens Y. Polymer blends: state of the art, new challenges, and opportunities. Characterization of polymer blends: miscibility, morphology and interfaces. 2014. p. 1–6.

Zhang QS, Yan YH, Li SP, Feng T. Synthesis of a novel biodegradable and electroactive polyphosphazene for biomedical application. Biomed Mater. 2009;4(3):035008.

Deng M. Novel biocompatible polymeric blends for bone regeneration: material and matrix design and development. 2010.

Allcock HR. Polyphosphazenes: new polymers with inorganic backbone atoms. Science (New York, NY). 1976;193(4259):1214–9.

Allcock HR, Ambrosio AM. Synthesis and characterization of pH-sensitive poly (organophosphazene) hydrogels. Biomaterials. 1996;17(23):2295–302.

Chaubal MV, Gupta AS, Lopina ST, Bruley DF. Polyphosphates and other phosphorus-containing polymers for drug delivery applications. Crit Rev Ther Drug Carrier Syst. 2003;20(4):295–315.

Morozowich NL, Modzelewski T, Allcock HR. Synthesis of phosphonated polyphosphazenes via two synthetic routes. Macromolecules. 2012;45(19):7684–91.

Kumbar S, Laurencin C, Deng M. Natural and synthetic biomedical polymers. Newnes; 2014.

Allcock HR. Recent developments in polyphosphazene materials science. Curr Opinion Solid State Mater Sci. 2006;10(5–6):231–40.

Allcock HR. Expanding options in polyphosphazene biomedical research. In: Polyphosphazenes for biomedical applications. Wiley; 2008. p. 15–43.

Henke H, Wilfert S, Iturmendi A, Brüggemann O, Teasdale I. Branched polyphosphazenes with controlled dimensions. J Polym Sci A Polym Chem. 2013;51(20):4467–73.

Krogman NR, Weikel AL, Kristhart KA, Nukavarapu SP, Deng M, Nair LS, et al. The influence of side group modification in polyphosphazenes on hydrolysis and cell adhesion of blends with PLGA. Biomaterials. 2009;30(17):3035–41.

Tian Z, Zhang Y, Liu X, Chen C, Guiltinan MJ, Allcock HR. Biodegradable polyphosphazenes containing antibiotics: synthesis, characterization, and hydrolytic release behavior. Polym Chem. 2013;4(6):1826–35.

Andrianov AK, Svirkin YY, LeGolvan MP. Synthesis and biologically relevant properties of polyphosphazene polyacids. Biomacromolecules. 2004;5(5):1999–2006.

Cohen S, Bano MC, Cima LG, Allcock HR, Vacanti JP, Vacanti CA, et al. Design of synthetic polymeric structures for cell transplantation and tissue engineering. Clin Mater. 1993;13(1–4):3–10.

Deng M, Nair LS, Krogman NR, Allcock HR, Laurencin CT. Biodegradable polyphosphazene blends for biomedical applications. In: Polyphosphazenes for biomedical applications. Wiley; 2008. p. 139–154.

Stone DA, Allcock HR. A new polymeric intermediate for the synthesis of hybrid inorganic–organic polymers. Macromolecules. 2006;39(15):4935–7.

Ambrosio AMA, Allcock HR, Katti DS, Laurencin CT. Degradable polyphosphazene/poly(α-hydroxyester) blends: degradation studies. Biomaterials. 2002;23(7):1667–72.

Morozowich NL, Weikel AL, Nichol JL, Chen C, Nair LS, Laurencin CT, et al. Polyphosphazenes containing vitamin substituents: synthesis, characterization, and hydrolytic sensitivity. Macromolecules. 2011;44(6):1355–64.

O’Brien FJ. Biomaterials & scaffolds for tissue engineering. Mater Today. 2011;14(3):88–95.

Andrianov AK. Water-soluble polyphosphazenes for biomedical applications. J Inorg Organomet Polym Mater. 2006;16(4):397–406.

Lakshmi S, Katti DS, Laurencin CT. Biodegradable polyphosphazenes for drug delivery applications. Adv Drug Deliv Rev. 2003;55(4):467–82.

Nukavarapu SP, Kumbar SG, Allcock HR, Laurencin CT. Biodegradable polyphosphazene scaffolds for tissue engineering. In: Polyphosphazenes for biomedical applications. Wiley; 2008. p. 117–138.

Allcock H, Fuller T, Mack D, Matsumura K, Smeltz KM. Synthesis of poly[(amino acid alkyl ester) phosphazenes]. Macromolecules. 1977;10(4):824–30.

Allcock HR, Pucher SR. Polyphosphazenes with glucosyl and methylamino, trifluoroethoxy, phenoxy, or (methoxyethoxy) ethoxy side groups. Macromolecules. 1991;24(1):23–34.

Laurencin CT, El‐Amin SF, Ibim SE, Willoughby DA, Attawia M, Allcock HR, et al. A highly porous 3‐dimensional polyphosphazene polymer matrix for skeletal tissue regeneration. J Biomed Mater Res. 1996;30(2):133–8.

Modzelewski T, Wonderling NM, Allcock HR. Polyphosphazene elastomers containing interdigitated oligo-p-phenyleneoxy side groups: synthesis, mechanical properties, and x-ray scattering studies. Macromolecules. 2015;48(14):4882–90.

Weikel AL, Krogman NR, Nguyen NQ, Nair LS, Laurencin CT, Allcock HR. Polyphosphazenes that contain dipeptide side groups: synthesis, characterization, and sensitivity to hydrolysis. Macromolecules. 2009;42(3):636–9.

Weikel AL, Owens SG, Morozowich NL, Deng M, Nair LS, Laurencin CT, et al. Miscibility of choline-substituted polyphosphazenes with PLGA and osteoblast activity on resulting blends. Biomaterials. 2010;31(33):8507–15.

Adibi S. Glycyl-dipeptides: new substrates for protein nutrition. J Lab Clin Med. 1989;113(6):665–73.

El-Amin SF, Kwon MS, Starnes T, Allcock HR, Laurencin CT. The biocompatibility of biodegradable glycine containing polyphosphazenes: a comparative study in bone. J Inorg Organomet Polym Mater. 2006;16(4):387–96.

Kumbar SG, Bhattacharyya S, Nukavarapu SP, Khan YM, Nair LS, Laurencin CT. In vitro and in vivo characterization of biodegradable poly(organophosphazenes) for biomedical applications. J Inorg Organomet Polym Mater. 2006;16(4):365–85.

Allcock HR, Pucher SR, Scopelianos AG. Poly[(amino acid ester) phosphazenes]: synthesis, crystallinity, and hydrolytic sensitivity in solution and the solid state. Macromolecules. 1994;27(5):1071–5.

Krogman NR, Singh A, Nair LS, Laurencin CT, Allcock HR. Miscibility of bioerodible polyphosphazene/poly(lactide-co-glycolide) blends. Biomacromolecules. 2007;8(4):1306–12.

Laurencin C, Morris C, Pieere-Jaques H, Schwartz E, Zou L. The development of bone bioerodible polymer composites for skeletal tissue regeneration: studies of initial cell adhesion and spread. Tran Orthop Res Soc. 1990;36:383.

Nair LS, Bender JD, Singh A, Sethuraman S, Greish YE, Brown PW, et al. Biodegradable poly[bis (ethyl alanato) phosphazene]-poly (lactide-co-glycolide) blends: miscibility and osteocompatibility evaluations. In: MRS Proceedings. Cambridge Univ Press; 2004. Y9. 7.

Deng M, Nair LS, Nukavarapu SP, Kumbar SG, Jiang T, Weikel AL, et al. In situ porous structures: a unique polymer erosion mechanism in biodegradable dipeptide‐based polyphosphazene and polyester blends producing matrices for regenerative engineering. Adv Funct Mater. 2010;20(17):2794–806.

Borden M, Attawia M, Khan Y, Laurencin CT. Tissue engineered microsphere-based matrices for bone repair: design and evaluation. Biomaterials. 2002;23(2):551–9.

Borden M, El-Amin SF, Attawia M, Laurencin CT. Structural and human cellular assessment of a novel microsphere-based tissue engineered scaffold for bone repair. Biomaterials. 2003;24(4):597–609.

Thavornyutikarn B, Chantarapanich N, Sitthiseripratip K, Thouas GA, Chen Q. Bone tissue engineering scaffolding: computer-aided scaffolding techniques. Prog Biomater. 2014;3(2):61–102.

Qiu LY. In vitro and in vivo degradation study on novel blends composed of polyphosphazene and polyester or polyanhydride. Polym Int. 2002;51(6):481–7.

Qiu LY, Zhu KJ. Novel blends of poly[bis (glycine ethyl ester) phosphazene] and polyesters or polyanhydrides: compatibility and degradation characteristics in vitro. Polym Int. 2000;49(11):1283–8.

Ambrosio AM, Sahota JS, Runge C, Kurtz SM, Lakshmi S, Allcock HR, et al. Novel polyphosphazene-hydroxyapatite composites as biomaterials. IEEE Eng Med Biol Mag. 2003;22(5):18–26.

Peach MS, Kumbar SG, James R, Toti US, Balasubramaniam D, Deng M, et al. Design and optimization of polyphosphazene functionalized fiber matrices for soft tissue regeneration. J Biomed Nanotechnol. 2012;8(1):107–24.

Nichol JL, Morozowich NL, Allcock HR. Biodegradable alanine and phenylalanine alkyl ester polyphosphazenes as potential ligament and tendon tissue scaffolds. Polym Chem. 2013;4(3):600–6.

Langone F, Lora S, Veronese FM, Caliceti P, Parnigotto PP, Valenti F, et al. Peripheral nerve repair using a poly (organo) phosphazene tubular prosthesis. Biomaterials. 1995;16(5):347–53.

Zhang Q, Yan Y, Li S, Feng T. The synthesis and characterization of a novel biodegradable and electroactive polyphosphazene for nerve regeneration. Mater Sci Eng C. 2010;30(1):160–6.

Modzelewski T, Wilts E, Allcock HR. Elastomeric polyphosphazenes with phenoxy-cyclotriphosphazene side groups. Macromolecules. 2015;48(20):7543–9.

Xu J, Zhu X, Qiu L. Polyphosphazene vesicles for co-delivery of doxorubicin and chloroquine with enhanced anticancer efficacy by drug resistance reversal. Int J Pharm. 2016;498(1–2):70–81.

Veronese FM, Marsilio F, Lora S, Caliceti P, Passi P, Orsolini P. Polyphosphazene membranes and microspheres in periodontal diseases and implant surgery. Biomaterials. 1999;20(1):91–8.

Ibim SM, El-Amin SF, Goad ME, Ambrosio AM, Allcock HR, Laurencin CT. In vitro release of colchicine using poly(phosphazenes): the development of delivery systems for musculoskeletal use. Pharm Dev Technol. 1998;3(1):55–62.

Schacht E, Vandorpe J, Lemmouchi Y, Dejardin S, Seymour L. Degradable polyphosphazenes for biomedical applications. Frontiers in biomedical polymer applications of polymers. Lancaster PA: Technomic; 1998. p. 7–42.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/s40883-017-0026-y.

Rights and permissions

About this article

Cite this article

Ogueri, K.S., Ivirico, J.L.E., Nair, L.S. et al. Biodegradable Polyphosphazene-Based Blends for Regenerative Engineering. Regen. Eng. Transl. Med. 3, 15–31 (2017). https://doi.org/10.1007/s40883-016-0022-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40883-016-0022-7