Abstract

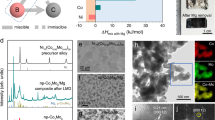

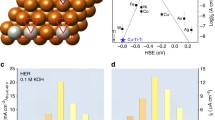

Nanoporous metals show promising performances in electrochemical catalysis. In this paper, we report a self-supporting bimetallic porous heterogeneous indium/copper structure synthesized with a eutectic gallium-indium (EGaIn) material on a copper substrate. This nanoporous copper-indium heterostructure catalyst exhibits excellent performance in the reduction of carbon dioxide to syngas. The ratio of H2/CO is tunable from 0.47 to 2.0 by changing working potentials. The catalyst is highly stable, showing 96% maintenance of the current density after a 70-h continuous test. Density functional theory calculations reveal that the indium/copper interface induces charge redistribution within the copper surface, leading to the formation of two distinct active sites, namely, Cuδ and Cu0, and enabling a high-performance generation of CO and H2. This work provides a new strategy for obtaining self-supporting nanoporous metal electrode catalysts.

摘要

纳米多孔金属作为电催化剂使用时表现出了优异的性能. 我们报道了一种利用共熔镓铟合金和铜基底制备而成的自支撑铜铟双金属多孔异质结构材料. 该多孔铜铟异质结构电催化剂具有良好的二氧化碳转化为合成气的性能. 通过调整工作电压, 可以使氢气和一氧化碳的比例控制在0.47–2.0之间. 且该催化剂非常稳定, 经过70小时连续测试后还可以保持96%的电流密度. 密度泛函理论计算表明, 得益于这种铜铟异质结构的存在, 铜表面电荷发生了转变, 形成了Cuδ和Cu0等不同位点, 从而协同作用分别增**了催化剂生成一氧化碳和氢气的能力. 本工作可为多孔金属异质结构电催化剂的设计提供新思路.

Similar content being viewed by others

References

Wittstock A, Zielasek V, Biener J, et al. Nanoporous gold catalysts for selective gas-phase oxidative coupling of methanol at low temperature. Science, 2010, 327: 319–322

Fujita T, Guan P, McKenna K, et al. Atomic origins of the high catalytic activity of nanoporous gold. Nat Mater, 2012, 11: 775–780

Lu Q, Hutchings GS, Yu W, et al. Highly porous non-precious bimetallic electrocatalysts for efficient hydrogen evolution. Nat Commun, 2015, 6: 6567

Zielasek V, Jürgens B, Schulz C, et al. Gold catalysts: Nanoporous gold foams. Angew Chem Int Ed, 2006, 45: 8241–8244

Lang X, Hirata A, Fujita T, et al. Nanoporous metal/oxide hybrid electrodes for electrochemical supercapacitors. Nat Nanotech, 2011, 6: 232–236

Han J, Lin YC, Chen L, et al. On-chip micro-pseudocapacitors for ultrahigh energy and power delivery. Adv Sci, 2015, 2: 1500067

Chen Q, Sieradzki K. Spontaneous evolution of bicontinuous nanostructures in dealloyed Li-based systems. Nat Mater, 2013, 12: 1102–1106

An Y, Tian Y, Wei C, et al. Dealloying: An effective method for scalable fabrication of 0D, 1D, 2D, 3D materials and its application in energy storage. Nano Today, 2021, 37: 101094

Wang Z, Liu P, Han J, et al. Engineering the internal surfaces of three-dimensional nanoporous catalysts by surfactant-modified dealloying. Nat Commun, 2017, 8: 1066

Snyder J, Asanithi P, Dalton AB, et al. Stabilized nanoporous metals by dealloying ternary alloy precursors. Adv Mater, 2008, 20: 4883–4886

Zhang W, Xu C, Hu Y, et al. Electronic and geometric structure engineering of bicontinuous porous Ag-Cu nanoarchitectures for realizing selectivity-tunable electrochemical CO2 reduction. Nano Energy, 2020, 73: 104796

Yao R, Lang X, Jiang Q. Recent advances of nanoporous metal-based catalyst: Synthesis, application and perspectives. J Iron Steel Res Int, 2019, 26: 779–795

Lu Z, Li C, Han J, et al. Three-dimensional bicontinuous nanoporous materials by vapor phase dealloying. Nat Commun, 2018, 9: 276

McCue I, Ryan S, Hemker K, et al. Size effects in the mechanical properties of bulk bicontinuous Ta/Cu nanocomposites made by liquid metal dealloying. Adv Eng Mater, 2016, 18: 46–50

Geslin PA, McCue I, Gaskey B, et al. Topology-generating interfacial pattern formation during liquid metal dealloying. Nat Commun, 2015, 6: 8887

Wada T, Geslin PA, Kato H. Preparation of hierarchical porous metals by two-step liquid metal dealloying. Scripta Mater, 2018, 142: 101–105

Ellis PR, Enache DI, James DW, et al. A robust and precious metal-free high performance cobalt Fischer-Tropsch catalyst. Nat Catal, 2019, 2: 623–631

AlNouss A, McKay G, Al-Ansari T. Production of syngas via gasification using optimum blends of biomass. J Clean Prod, 2020, 242: 118499

Hernández S, Amin Farkhondehfal M, Sastre F, et al. Syngas production from electrochemical reduction of CO2: Current status and prospective implementation. Green Chem, 2017, 19: 2326–2346

Leverett J, Daiyan R, Gong L, et al. Designing undercoordinated Ni-Nx and Fe-Nx on holey graphene for electrochemical CO2 conversion to syngas. ACS Nano, 2021, 15: 12006–12018

Daiyan R, Lovell EC, Huang B, et al. Uncovering atomic-scale stability and reactivity in engineered zinc oxide electrocatalysts for controllable syngas production. Adv Energy Mater, 2020, 10: 2001381

Daiyan R, Chen R, Kumar P, et al. Tunable syngas production through CO2 electroreduction on cobalt-carbon composite electrocatalyst. ACS Appl Mater Interfaces, 2020, 12: 9307–9315

Ross MB, Dinh CT, Li Y, et al. Tunable Cu enrichment enables designer syngas electrosynthesis from CO2. J Am Chem Soc, 2017, 139: 9359–9363

Kumar B, Brian JP, Atla V, et al. Controlling the product syngas H2:CO ratio through pulsed-bias electrochemical reduction of CO2 on copper. ACS Catal, 2016, 6: 4739–4745

Mascaretti L, Niorettini A, Bricchi BR, et al. Syngas evolution from CO2 electroreduction by porous Au nanostructures. ACS Appl Energy Mater, 2020, 3: 4658–4668

Lamaison S, Wakerley D, Montero D, et al. Zn-Cu alloy nanofoams as efficient catalysts for the reduction of CO2 to syngas mixtures with a potential-independent H2/CO ratio. ChemSusChem, 2019, 12: 511–517

Kim H, Lee H, Lim T, et al. Facile fabrication of porous Sn-based catalysts for electrochemical CO2 reduction to HCOOH and syngas. J Industrial Eng Chem, 2018, 66: 248–253

Ross MB, Li Y, De Luna P, et al. Electrocatalytic rate alignment enhances syngas generation. Joule, 2019, 3: 257–264

Li H, Wen P, Itanze DS, et al. Colloidal silver diphosphide (AgP2) nanocrystals as low overpotential catalysts for CO2 reduction to tunable syngas. Nat Commun, 2019, 10: 5724

Lee JH, Kattel S, Jiang Z, et al. Tuning the activity and selectivity of electroreduction of CO2 to synthesis gas using bimetallic catalysts. Nat Commun, 2019, 10: 3724

Lv K, Teng C, Shi M, et al. Hydrophobic and electronic properties of the E-MoS2 nanosheets induced by FAS for the CO2 electroreduction to syngas with a wide range of CO/H2 ratios. Adv Funct Mater, 2018, 28: 1802339

He R, Zhang A, Ding Y, et al. Achieving the widest range of syngas proportions at high current density over cadmium sulfoselenide nanorods in CO2 electroreduction. Adv Mater, 2018, 30: 1705872

**e Q, Larrazábal GO, Ma M, et al. Copper-indium hydroxides derived electrocatalysts with tunable compositions for electrochemical CO2 reduction. J Energy Chem, 2021, 63: 278–284

Liang Z, Song L, Sun M, et al. Tunable CO/H2 ratios of electrochemical reduction of CO2 through the Zn-Ln dual atomic catalysts. Sci Adv, 2021, 7: eabl4915

Zhong H, Ghorbani-Asl M, Ly KH, et al. Synergistic electroreduction of carbon dioxide to carbon monoxide on bimetallic layered conjugated metal-organic frameworks. Nat Commun, 2020, 11: 1409

Hoffman ZB, Gray TS, Moraveck KB, et al. Electrochemical reduction of carbon dioxide to syngas and formate at dendritic copper-indium electrocatalysts. ACS Catal, 2017, 7: 5381–5390

**ang H, Rasul S, Hou B, et al. Copper-indium binary catalyst on a gas diffusion electrode for high-performance CO2 electrochemical reduction with record CO production efficiency. ACS Appl Mater Interfaces, 2020, 12: 601–608

**e H, Chen S, Ma F, et al. Boosting tunable syngas formation via electrochemical CO2 reduction on Cu/In2O3 core/shell nanoparticles. ACS Appl Mater Interfaces, 2018, 10: 36996–37004

Daeneke T, Khoshmanesh K, Mahmood N, et al. Liquid metals: Fundamentals and applications in chemistry. Chem Soc Rev, 2018, 47: 4073–4111

Khoshmanesh K, Tang SY, Zhu JY, et al. Liquid metal enabled microfluidics. Lab Chip, 2017, 17: 974–993

Liu H, **a J, Zhang N, et al. Solid-liquid phase transition induced electrocatalytic switching from hydrogen evolution to highly selective CO2 reduction. Nat Catal, 2021, 4: 202–211

Esrafilzadeh D, Zavabeti A, Jalili R, et al. Room temperature CO2 reduction to solid carbon species on liquid metals featuring atomically thin ceria interfaces. Nat Commun, 2019, 10: 865

Jedidi A, Rasul S, Masih D, et al. Generation of Cu-In alloy surfaces from CuInO2 as selective catalytic sites for CO2 electroreduction. J Mater Chem A, 2015, 3: 19085–19092

Barasa GO, Yu T, Lu X, et al. Electrochemical training of nanoporous Cu-In catalysts for efficient CO2-to-CO conversion and high durability. Electrochim Acta, 2019, 295: 584–590

Tang J, Zhao X, Li J, et al. Gallium-based liquid metal amalgams: Transitional-state metallic mixtures (TransM2ixes) with enhanced and tunable electrical, thermal, and mechanical properties. ACS Appl Mater Interfaces, 2017, 9: 35977–35987

Kresse G, Hafner J. Ab initio molecular dynamics for liquid metals. Phys Rev B, 1993, 47: 558–561

Kresse G, Furthmüller J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B, 1996, 54: 11169–11186

Blöchl PE. Projector augmented-wave method. Phys Rev B, 1994, 50: 17953–17979

Kresse G, Joubert D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys Rev B, 1999, 59: 1758–1775

Perdew JP, Burke K, Ernzerhof M. Generalized gradient approximation made simple. Phys Rev Lett, 1996, 77: 3865–3868

Grimme S. Semiempirical GGA-type density functional constructed with a long-range dispersion correction. J Comput Chem, 2006, 27: 1787–1799

Nørskov JK, Rossmeisl J, Logadottir A, et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J Phys Chem B, 2004, 108: 17886–17892

Rossmeisl J, Logadottir A, Nørskov JK. Electrolysis of water on (oxidized) metal surfaces. Chem Phys, 2005, 319: 178–184

Guo R, Wang X, Chang H, et al. Ni-GaIn amalgams enabled rapid and customizable fabrication of wearable and wireless healthcare electronics. Adv Eng Mater, 2018, 20: 1800054

Ma JL, Dong HX, He ZZ. Electrochemically enabled manipulation of gallium-based liquid metals within porous copper. Mater Horiz, 2018, 5: 675–682

Wang H, Yuan B, Liang S, et al. PLUS-M: A porous liquid-metal enabled ubiquitous soft material. Mater Horiz, 2018, 5: 222–229

Larrazábal GO, Martín AJ, Mitchell S, et al. Enhanced reduction of CO2 to CO over Cu-In electrocatalysts: Catalyst evolution is the key. ACS Catal, 2016, 6: 6265–6274

Chou TC, Chang CC, Yu HL, et al. Controlling the oxidation state of the Cu electrode and reaction intermediates for electrochemical CO2 reduction to ethylene. J Am Chem Soc, 2020, 142: 2857–2867

**ao H, Goddard III WA, Cheng T, et al. Cu metal embedded in oxidized matrix catalyst to promote CO2 activation and CO dimerization for electrochemical reduction of CO2. Proc Natl Acad Sci USA, 2017, 114: 6685–6688

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (51872116 and 12034002), the Project for Self-Innovation Capability Construction of Jilin Province Development and Reform Commission (2021C026), the Program for JLU Science and Technology Innovative Research Team (JLUSTIRT-2017TD-09), the Science and Technology Development Program of Jilin Province (20190201233JC), and the Fundamental Research Funds for the Central Universities. The work was carried out at LvLiang Cloud Computing Center of China, and the calculations were performed on TianHe-2.

Author information

Authors and Affiliations

Contributions

Author contributions Ma X designed, engineered, and characterized the samples with support from Wang F and Cui X; Ma X and Cui X analyzed the data and wrote the paper with support from Singh DJ, Zhao X, Zheng W, and Zhao J; Zhang D and Jiao D conceived the models; Jiao D and Zhao J contributed to the first-principles calculations. All authors contributed to the general discussion.

Corresponding authors

Additional information

Conflict of interest The authors declare that they have no conflict of interest.

**ngcheng Ma is currently doing his research at the School of Materials Science and Engineering, Jilin University, under the supervision of Prof. **aoqiang Cui. His research interest mainly focuses on the design of new heterogeneous electrocatalysts for carbon dioxide reduction.

**aoqiang Cui is a professor at Jilin University. He obtained his PhD degree from Changchun Institute of Applied Chemistry, Chinese Academy of Sciences, in 2002. His research interests include the interface regulation of low-dimensional materials, and electrocatalysts and photocatalysts for energy conversion and storage.

**gxiang Zhao is a professor at Harbin Normal University. He obtained his PhD degree from Jilin University in 2009. His research interests include the theoretical study of structure, properties, and applications of low-dimensional materials.

Supplementary information Supporting data are available in the online version of the paper.

Supporting Information

40843_2022_2058_MOESM1_ESM.pdf

Room Temperature Liquid Metal Synthesis of Nanoporous Copper-Indium Heterostructures Yields Efficient Carbon Dioxide Reduction to Syngas

Rights and permissions

About this article

Cite this article

Ma, X., Wang, F., Jiao, D. et al. Room-temperature liquid metal synthesis of nanoporous copper-indium heterostructures for efficient carbon dioxide reduction to syngas. Sci. China Mater. 65, 3504–3512 (2022). https://doi.org/10.1007/s40843-022-2058-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-022-2058-5