Highlights

-

A bi-service host with lithiophilic/sulfiphilic Fe2CoSe4 quantum dots embedded in three-dimensional ordered nitrogen-doped carbon skeleton is elaborately developed for both the sulfur cathode and Li anode synchronously.

-

The highly dispersed Fe2CoSe4 quantum dots can not only act as a redox accelerator to promote the bidirectional conversion of LiPSs but also regulate the uniform Li plating/strip** to mitigate the growth of Li dendrite.

-

The assembled Li-S full batteries achieve excellent long-term cyclability and a remarkable areal capacity of 8.41 mAh cm2 at high sulfur loading of 8.50 mg cm2, and the pouch full battery also displays high capacity and cycling-stability at lean electrolyte condition.

Abstract

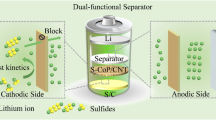

The commercial viability of lithium–sulfur batteries is still challenged by the notorious lithium polysulfides (LiPSs) shuttle effect on the sulfur cathode and uncontrollable Li dendrites growth on the Li anode. Herein, a bi-service host with Co-Fe binary-metal selenide quantum dots embedded in three-dimensional inverse opal structured nitrogen-doped carbon skeleton (3DIO FCSe-QDs@NC) is elaborately designed for both sulfur cathode and Li metal anode. The highly dispersed FCSe-QDs with superb adsorptive-catalytic properties can effectively immobilize the soluble LiPSs and improve diffusion-conversion kinetics to mitigate the polysulfide-shutting behaviors. Simultaneously, the 3D-ordered porous networks integrated with abundant lithophilic sites can accomplish uniform Li deposition and homogeneous Li-ion flux for suppressing the growth of dendrites. Taking advantage of these merits, the assembled Li–S full batteries with 3DIO FCSe-QDs@NC host exhibit excellent rate performance and stable cycling ability (a low decay rate of 0.014% over 2,000 cycles at 2C). Remarkably, a promising areal capacity of 8.41 mAh cm−2 can be achieved at the sulfur loading up to 8.50 mg cm−2 with an ultra-low electrolyte/sulfur ratio of 4.1 μL mg−1. This work paves the bi-serve host design from systematic experimental and theoretical analysis, which provides a viable avenue to solve the challenges of both sulfur and Li electrodes for practical Li–S full batteries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The surge of decarbonization has driven the rapid development of energy-storage technologies to meet the ever-expanding market and high-energy-demanding applications. Lithium-sulfur (Li–S) batteries are regarded as one of the most promising next-generation energy-storage systems owing to their high theoretical energy density and cost-effectiveness [1, 2]. Nevertheless, the commercialization of Li–S batteries is still challenged by various intractable obstacles in both sulfur cathode and Li anode. The so-called shuttle effect triggered by the dissolution of intermediate polysulfides (Li2Sx, 4 ≤ x ≤ 8) leads to sluggish sulfur redox kinetics and unavoidable sulfur loss [3, 4]. Additionally, the infinite volume expansion and uncontrollable dendrite growth on the anode side result in low Coulombic efficiency (CE), electrical short circuits, and even security risk. Moreover, the commonly used Li foil anodes have a high negative to positive electrode capacity (N/P) ratio of over 50, much higher than practical relevance applications (< 10), sacrificing the superiority of the high-energy–density of Li–S batteries.

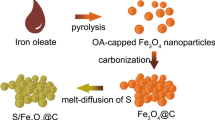

In light of these challenges, tremendous efforts have been dedicated to develo** advanced host matrices for constructing high-efficiency sulfur cathode and Li-metal anode. At the cathode side, porous carbon materials with high electrical conductivity and large specific surface area were initially employed to physically confine lithium polysulfides (LiPSs) [5]. Nevertheless, the nonpolar carbon-based materials are inadequate in suppressing the shuttle effect due to the weak affinity for polysulfides [6]. Therefore, a synergetic strategy of combining conductive carbon matrices and polar materials (such as various heteroatoms [7], metal compounds [8, a Schematic illustration for the preparation of 3DIO FCSe-QDs@NC and its application as a two-in-one host for both sulfur cathode and Li metal anode. b SEM images, c, d TEM images, and e, f HR-TEM images of 3DIO FCSe-QDs@NC. g Energy band structure of the Fe2CoSe4 crystal, h SEM image and corresponding elemental map**s of 3DIO FCSe-QDs@NC

Figures 1b and S2 display the typical scanning electron microscopy (SEM) images of 3DIO FCSe-QDs@NC at different resolutions, in which the 3D cross-linked porous morphology is observed clearly, and holes are arranged in a regular inverse opal structure with no particle agglomeration on the surface. Transmission electron microscopy (TEM) images further verify the hollow-ordered macroporous structure with cross-linked nanocages and the pore size is about 220 nm (Fig. 1c, d). This unique morphology would attribute to the strong binding affinity between metal-oleate molecules and silica surfaces. Such interconnected porous architecture can not only ensure sufficient sulfur loading and expose interface active sites for surface electrochemical reactions, but also can serve as conductive scaffolds for expediting electron transfer. HRTEM images in Fig. 1e suggest that the punctate FCSe-QDs are homogeneously implanted into the carbon skeleton with an average diameter size of about 3 nm, and the lattice fringes of 0.207 and 0.272 nm are assigned to the (-202) and (004) lattice planes of the Fe2CoSe4 phase, respectively (Figs. 1f and S2).

X-ray diffraction (XRD) pattern shows that all the diffraction peaks are well indexed to the Fe2CoSe4 phase (JCPDS No. 89–1967) after removing the SiO2 templates, demonstrating the successful evolution of the metal-oleate in the hydrogen selenide atmosphere (Fig. S2a). Thermogravimetric analysis (TGA) was performed in the air to estimate the weight ratio of Fe2CoSe4 in 3DIO FCSe-QDs@NC and the large weight decrease in the range from 600 to 800 °C is related to the conversion of the selenide into oxides (Fig. S3). Therefore, the weight ratio of Fe2CoSe4 is calculated to be about 81 wt%. Moreover, the heteroatom nitrogen-do** can serve as a Lewis-base site to interact with the Lewis acid site of LiPSs, which is favorable for LiPSs immobilization (Fig. S4). Additionally, it is worth mentioning that the phase composition is closely related to the feed ratio, when the Fe-OL alone was utilized as the starting precursor, the pure iron selenide (JCPDS No. 75–0608) phase was obtained (Fig. S5). By introducing a moderate amount of Co precursor (Co: Fe = 1:2), in addition to the diffraction peaks of Fe2CoSe4, the diffraction peaks of selenide cobalt (CoSe2: JCPDS No. 53–0449 and No. 09–0234) appear. As increasing the concentration of Co to 100%, the final product contains only the CoSe2 phase. These results evidence the success of our proposed strategy to produce binary-metal selenide QDs in a simplistic way. Figure 1h shows the energy-dispersive X-ray spectroscopy (EDS) elemental map**s of 3DIO FCSe-QDs@NC, wherein C, Fe, Co, Se, and N elements are distributed homogeneously, certifying the good dispersion of FCSe-QD, and successful do** of nitrogen in the inverse opal carbon frameworks, which are helpful for the LiPSs immobilization [6]. In addition, the electronic structure is presented to gain insight into the catalytic properties of 3DIO FCSe-QDs@NC. As shown in Fig. 1g, peaks corresponding to the calculated density of states of FCSe/NC are absent near the Fermi energy, demonstrating that the decoration of FCSe with metallic-like property can greatly improve the intrinsic conductivity of 3DIO carbon matrices and favor electron transfer during redox reactions. For comparison, the bulk FCSe-QDs@NC and 3DIO NC without FCSe-QDs loading were also synthesized as reference samples (Figs. S6 and S7). Note that the QDs of FCSe-QDs@NC are embedded in the interior and densely packed, which might not conducive to the exposure and full utilization of active sites.

Figure S8 displays the Raman spectra of the prepared host matrix, in which two strong Raman peaks at 1338 and 1590 cm–1 are assigned to the sp3-type disordered carbon form (D band) and sp2-type graphitized carbon form (G band), respectively. The 3DIO FCSe-QDs@NC shows a higher G/D ratio than that of FCSe-QDs@NC and FCSe-QDs@NC, indicating its higher graphitization degree in the carbon layer. Besides, the 3DIO FCSe-QDs@NC exhibits a high Brunauer–Emmett–Teller (BET) surface area and pore volume of 326 m2 g–1 and 0.441 cm3 g–1, respectively (Fig. S9). From the pore size distribution, the hierarchical porous structure consists of micropores, mesopores, and macropores, and pore size is mainly concentrated at 1 ~ 10 nm. Such a large specific surface area and hierarchical porous characteristics are favorable for sulfur loading and volume change mitigation upon cycling.

3.2 Chemisorption and Electrocatalytic Effects of 3DIO FCSe-QDs@NC

On the cathode side, preventing the soluble polysulfides from diffusing is the first step to suppress the shuttle effect, thus the adsorption capability of host materials plays a vital role in immobilizing LiPSs. In this respect, the Li2S6 visualization adsorption tests were conducted to probe the chemical affinity toward with LiPSs. As observed from the inset optical images in Fig. 2a, the Li2S6 solution containing FCSe-QDs@NC and 3DIO NC adsorbent shows light yellow color after soaking for 6 h, while the Li2S6 solution mixed with 3DIO FCSe-QDs@NC is fully decolored, intuitively testifying the stronger affinity for polysulfides. The adsorption effects are also confirmed by UV–vis spectra, in which 3DIO FCSe-QDs@NC shows the weakest polysulfides characteristic peaks, corresponding to the hardly amount of polysulfides ions in the solution and thus the greatest LiPS adsorbability. Besides, according to the X-ray photoelectron spectroscopy (XPS) analyses in Fig. 2b, c, both Co 2p and Fe 2p peaks of 3DIO FCSe-QDs@NC-Li2S6 shift to lower binding energies than those of pristine 3DIO FCSe-QDs@NC, confirming the increased electron density located at the metal center. Conversely, the Se 3d XPS spectrum of 3DIO FCSe-QDs@NC-Li2S6 shifts to higher binding energies, which indicates an increase of the chemical environment electronegativity during the LiPS adsorption. These observations convincingly verify the existence of obvious chemical interaction between 3DIO FCSe-QDs@NC-Li2S6 and LiPSs, viz. the strong anchoring ability of 3DIO FCSe-QDs@NC-Li2S6 for LiPSs [23, 34].

a Optical photograph and UV–vis spectra of Li2S6 solutions containing different adsorbents after resting for 6 h. High-resolution XPS spectra of b Co 2p, c Fe 2p, and d Se 3d of 3DIO FCSe-QDs@NC before and after Li2S6 adsorption. e Calculated binding energies of S8 and LiPSs (Li2S8, Li2S6, Li2S4, and Li2S2) and f, g corresponding optional binding structures of Li2S8 adsorped on 3DIO FCSe-QDs@NC and 3DIO NC surfaces. h Visual illustration of polysulfide entrapment at different discharge stages in bottle-assembled batteries of 3DIO FCSe-QDs@NC (top) and 3DIO NC (bottom)

Density functional theory (DFT) calculations were performed to investigate the intrinsic interfacial interaction mechanism between adsorbent and LiPSs at the atomic level. The binding energies and atomic structures between LiPSs and FCSe and bare NC were calculated. As summarized in Fig. 2e, the FCSe possesses higher binding energies (Eb) at all lithiation stages than those on bare NC. Especially, the FCSe delivers an extremely high Eb of -8.54 eV for Li2S8 on the (001) lattice plane, which is more than three times that on unadorned NC (-2.42 eV) (Fig. 2f, g). Additionally, Figs. S10 and S11 display the optimized LiPSs adsorption configuration at different lithiation stages (Li2S, Li2S2, Li2S4, Li2S6, Li2S8, and S8). The coexistence of multiple adsorption sites to strongly capture the LiPSs by Fe/Co-S and Li-Se bonds endow the great potential of 3DIO FCSe-QDs@NC composite as high-efficiency sulfur host [35]. And, the strong adsorbability is favorable for the smooth progress of subsequent complex electrocatalytic reactions on the 3DIO FCSe-QDs@NC electrode [36].

Sulfur was infiltrated into 3DIO FCSe-QDs@NC nanoarchitecture by a typical melt-diffusion method, and the loaded mass of sulfur is about 70.2 wt% from thermogravimetry analysis (Fig. S12a). Notably, the 3D-ordered porous structure is well maintained after sulfur loading and EDS elemental map**s display homogeneous distribution of sulfur with no apparent particle agglomeration (Fig. S12b-i). To observe the dissolution and diffusion behavior of soluble LiPSs in real time, the optically transparent bottle cells were assembled with different cathode and Li foil anode in a clear electrolyte and connected to an external light bulb to discharge. As exhibited in Fig. 2h, the transparent electrolyte quickly turned to yellow for the S/FCSe-QDs@NC and S/3DIO NC electrode (less than 30 min), owing to the overflow of LiPSs from the electrode surface and diffuse into the electrolyte. In stark contrast, one can clearly observe that the electrolyte color of the S/3DIO FCSe-QDs@NC-based bottle cell remains transparent during the whole discharge process even lasting for 60 min, indicating the strong immobilization ability toward LiPSs owing to the customized porous structure and abundant adsorption sites [37].

To evaluate the ability of host materials to catalytically accelerate the kinetics of polysulfide conversion, cyclic voltammetry (CV) profiles of Li2S6 symmetrical cells were collected in the voltage window of –1.0 to 1.0 V (Fig. 3a). All the symmetrical cells exhibit two pairs of redox peaks, corresponding to the conversion of S8 to Li2S6 and then to Li2S, respectively, and vice versa [3]. Among them, the 3DIO FCSe-QDs@NC harvests the sharpest redox peaks and smallest voltage polarization compared with other symmetric cells, indicative of accelerated redox kinetics and enhanced catalytic activity [38]. Notably, the 3DIO FCSe-QDs@NC-based symmetrical cell still maintains two obvious redox peaks as the sweep rate up to 50 mV s−1, implying rapid charge transfer and low electrochemical polarization, and electrochemical impedance spectroscopy (EIS) results collectively verify the lowest impedance for 3DIO FCSe-QDs@NC electrode (Fig. S14). Additionally, the enhanced reaction kinetics and electrocatalytic activity were further investigated by Tafel plots in Fig. 3b, wherein the uppermost response current is obtained for 3DIO FCSe-QDs@NC in both anodic and cathodic processes. And the highest exchange current density of 0.14 mA cm−2 vs. FCSe-QDs@NC (0.064 mA cm−2) and 3DIO NC (0.041 mA cm−2) further reveals the fast electron transfer on the electrode-LiPSs interface in 3DIO FCSe-QDs@NC electrode.

a CV curves of symmetric cells assembled with 3DIO FCSe-QDs@NC, FCSe-QDs@NC, and 3DIO NC electrodes at 5 mV s−1. b Tafel plots of symmetric cells. c CV curves of different Li–S cells at 0.1 mV s–1. d The corresponding peak voltages and onset potentials from CV curves. e CV curves tested at different scanning rates of 3DIO FCSe-QDs@NC and f peak current for the second electrochemical processes (II: Li2Sx → Li2S2/Li2S) versus the square root of the scan rates. g–i Li2S nucleation tests based on different electrodes for evaluating the nucleation kinetics. j–l Dimensionless current–time transient to perform peak fitting according to theoretical 2D and 3D models, Im (peak current) and tm (time needed to achieve the peak current) detected from the current–time transients

Figure 3c shows the CV curves obtained from S/3DIO FCSe-QDs@NC, S/FCSe-QDs@NC, and S/3DIO NC electrodes. All curves exhibit two well-defined cathodic peaks, which are associated with the conversion of active sulfur to long-chain LiPSs (Li2Sx, 4 ≤ x ≤ 8, peak A) and the subsequent conversion to insoluble Li2S2/Li2S (peak B). In turn, the anodic peaks correspond to the reverse oxidation conversion from Li2S to sulfur [6b, in stark contrast to the violent fluctuations for FCSe-QDs@NC, 3DIO NC, and bare Cu electrodes, a stable Coulombic efficiency of > 99.1% is achieved for the 3DIO FCSe-QDs@NC within 200 cycles at 2 mA cm–2 and 2 mAh cm−2, certifying the significant synergistic effect of mixed ion–electron conductive interphase. Beyond that, the surface morphology evolution was investigated by ex-SEM to clarify the Li deposition behavior. The 3DIO FCSe-QDs@NC electrode exhibits an ultrafine and smooth Li nucleation morphology during the progressive plating progress, which is in vast contrast to the cavities and dendrites morphology on bulk FCSe-QDs@NC and Cu foil electrodes (Figs. S27-S30). Notably, even under an ultrahigh plating capacity of 10 mAh cm–2, a dense, smooth Li deposition layer with large grains of Li bulk is formed on the surface of 3DIO FCSe-QDs@NC electrode without obvious Li dendrites formation (Fig. 6c).

a The voltage–capacity profiles and b Coulombic efficiency of the Li plating-strip** progress on 3DIO FCSe-QDs@NC, FCSe-QDs@NC, 3DIO NC, and bare Cu foil hosts. c SEM images of Li deposition morphologies on 3DIO FCSe-QDs@NC host with a capacity of 10 mAh cm−2. d, e Calculated electron density differences of Li atom absorbed on 3DIO FCSe-QDs and 3DIO NC. f Galvanostatic cycling of symmetric cells based on Li/Cu, Li/3DIO FCSe-QDs@NC and Li/FCSe-QDs@NC, and Li/3DIO NC electrodes at 1 mA cm−2 for 1 mAh cm−2. Galvanostatic cycling of Li/3DIO FCSe-QDs@NC symmetric cells at g 3 mA cm−2 for 3 mAh cm−2 and h 5 mA cm−2 for 5 mAh cm−2

Based on the above results, to get insight into the Li adsorption ability. DFT calculations are carried out to determine the binding energies between Li atoms and different substrates. According to the calculation results in Fig. S31, the FCSe manifests a stronger interaction (−5.17 eV) than unadorned NC (-1.65 eV), indicating that FCSe is more lithiophilic and benefits the decrease of the nucleation overpotential of Li, which is consistent well with the aforementioned Li plating process. Moreover, the charge density difference was performed to understand the chemical origin of the above different binding energies (Fig. 6d, e), wherein the light blue and yellow colors indicate the regions of charge accumulation and depletion, respectively. Notably, there is strong electron density accumulation between Li and FCSe and reduced charge density around Li, implying that electrons are transferred from Li ions to neighboring FCSe atoms [53]. That is, Li ions tend to react with FCSe and prefer to nucleate around the QDs edges. Reversely, there is indeed an opposite display scene for unadorned NC.

Given that the plating/strip** stability of Li metal anodes plays a significant role in overall battery performance. Li symmetrical cells with different hosts were assembled and cycled with various current densities and capacities. As shown in Fig. 6f, the 3DIO FCSe-QDs@NC symmetric cell inherits the smallest overpotential of around 13 mV at 1 mA cm–2 and harvests impressive stability of more than 1,400 h with a small capacity of 1 mAh cm–2, while the other three cells behave in limited cycle lives with random voltage oscillations and increased polarization (Li/FCSe-QDs@NC: 685 h; Li/3DIO NC: 417 h; bare Cu: 256 h). Besides, Li/3DIO FCSe-QDs@NC electrode also delivers the lowest Rct of 38.5 Ω, pointing to the formation of stable and high ion-conducing SEI film (Fig. S32 and Table S4). Admittedly, Li dendrites growth is usually caused by the large current density since the uniformity of Li+ ions flux strongly depends on the magnitude of current density [54, 55]. The electrochemistry stability of Li/3DIO FCSe-QDs@NC anode is further investigated under high current densities. As delivered in Fig. 6g, a long lifespan of over 800 h with a low voltage hysteresis of about 28 mV is obtained at 3 mA cm−2 and 3 mAh cm−2. More impressively, even rising to 5 mA cm–2 and 5 mAh cm−2, an outstanding Li strip**/plating stability is achieved with long-stable life of over 500 h, which is super to most of the state-of-the-art Li symmetrical cells reported previously (Table S5). Collectively, these satisfactory improvements testify that 3DIO FCSe-QDs@NC shows great potential for dendritic-free anodes by means of the unique 3DIO architecture and embedded lithiophilic FCSe-QDs.

3.4 Performance of S/3DIO FCSe-QDs@NC||Li/3DIO FCSe-QDs@NC Full Batteries

Encouraged by the excellent dual-functional properties of 3DIO FCSe-QDs@NC on both sulfur cathode and Li anode, the full cells coupling the S/3DIO FCSe-QDs@NC cathode and Li/3DIO FCSe-QDs@NC anode were established, as schematized in Fig. 7a. Since the self-discharge phenomenon caused by the shuttle effect is still a bottleneck for Li–S batteries, the self-discharge behaviors of the as-prepared full cells were firstly investigated by the open-circuit voltage profile (Fig. 7b). After resting for 200 h, the 3DIO FCSe-QDs@NC-based full cell exhibits an almost horizontal voltage curve with the highest voltage retention of 96.7% vs. FCSe-QDs@NC- (84.6%), 3DIO NC-based full cell (82.5%), and S/3DIO FCSe-QDs@NC||Li/Cu full cells (95.4%), revealing the effectively suppressed shuttle effect. Moreover, the long-term cycling performances are compared in Fig. 7d, an ultralow dam** rate of 0.014% per cycle is harvested for 3DIO FCSe-QDs@NC-based full cell within 2,000 cycles at 2C, that is outperforming the state-of-the-art Li–S batteries (Fig. 7c and Table S6). Noticeably, the 3DIO FCSe-QDs@NC host from the disassembled cell displays the 3D ordered porous morphology without obvious structural degradation, indicating its excellent mechanical stability (see details in Fig. S33).

a Schematic illustration of the full cell constructed by S/3DIO FCSe-QDs@NC cathode and Li/3DIO FCSe-QDs@NC anode. b Time-dependent open circuit voltage evolution within 200 h. c Comparison of cycling performance of 3DIO FCSe-QDs@NC-based full cell with other previously reported Li–S batteries. d Prolonged cycle life of different assembled full cells. e Rate capability and f high sulfur loading measurements at 0.2 C. g Cycling stability of the pouch cell (size: 7 cm × 10 cm), inset shows the mobile phone charged by a pouch full cell

Nowadays, the pursuit of high-energy–density Li–S full batteries is strongly associated with high sulfur loading and low electrolyte dosage [56]. As depicted in Fig. 7f, the 3DIO FCSe-QDs@NC-based full cell presents an outstanding area rate performance with a superb discharge capacity of 4.56 mAh cm–2 at 0.2C under sulfur loading of about 3.5 mg cm−2, and a high reversible capacity of 2.61 mAh cm−2 is retained with the current rate up to 5C. And the galvanostatic charge/discharge profiles display distinct discharge plateaus even at high rates (Fig. S34), demonstrating the fast Li electrochemistry kinetics and sulfur conversion. Additionally, as the sulfur loading increases to 4.5 mg cm–2, the S/3DIO FCSe-QDs@NC-based full cell maintains a high areal capacity of 3.91 mAh cm−2 after 100 cycles at 0.2 C, which is well comparable to the commercial Li-ion batteries. More surprisingly, an ultrahigh initial capacity of 8.41 mAh cm–2 is acquired under sulfur loading of 8.5 mg cm–2, corresponding to a low E/S of 4.1 μL mg–1 and N/P ratio of 2.1:1. And a desirable reversible capacity of 6.53 mAh cm–2 is ultimately retained after cycling (as summarized in Table S7) [57]. To further explore the feasibility of 3DIO FCSe-QDs@NC in practice, the pouch cell based on the 3DIO FCSe-QDs@NC hosts was fabricated. As exhibited in Fig. 7g, after pre-cycling at 0.05C for three cycles, the pouch cell delivers a high initial capacity of 985 mAh g–1 at 0.3C and shows excellent cycling stability as well as mitigatory polarization in charge/discharge curves. Moreover, the pouch cell can charge a mobile phone and also light a “Li–S” panel composed of 31 LED bulbs easily (Fig. S35 and Video S1).

Overall, these outstanding results collectively demonstrate the great benefits of the 3DIO FCSe-QDs@NC in promoting the high-efficiency synergy between the cathode and anode. Summarize from the aspect of material design, such multifunctional nanocomposites provide multiple advantages: (1) The highly dispersed FCSe-QDs with excellent sulfiphilic/lithiophilic properties can not only immobilize the LiPSs effectively but also regulate the Li deposition behaviors to stable Li anode. (2) The ordered interconnected conductive skeletons provide homogeneous electric field distribution and Li+ ion flow as well as smooth transportation pathways for electrons/ions to improve the redox kinetics. (3) Such hierarchical porous skeleton endows hosts with excellent capability for sulfur loading and exposure of active QDs sites for redox reactions and further mitigates the volume change of the sulfur and Li upon cycling.

4 Conclusions

In summary, a 3DIO-ordered porous carbon matrix anchored with highly dispersed FCSe QDs was designed and employed as bi-served hosts for advanced sulfur cathode and dendrite-free Li anode. Experimental results together with theoretical calculations unveil that the abundant FCSe QDs possess a strong chemical affinity with LiPSs that can effectively capture soluble sulfur species, and the smooth diffusion-conversion of LiPSs is synchronously accelerated owing to the excellent catalytic activity. Additionally, the ordered 3DIO networks with sufficient void space and favorable lithiophilic features could regulate the Li nucleation/deposition behavior, thus suppressing the uncontrolled dendrites growth. As a consequence, the full cell constructed by the 3DIO FCSe-QDs@NC dual-functional host shows impressive electrochemical performances including the stable long cyclic ability (decay rate of 0.014% per cycle within 2,000 cycles at 2C), superior rate capability (2.61 mAh cm–2 at 5C with sulfur loading of 3.6 mg cm–2) and remarkable area capacity of 8.41 mAh cm–2 at 8.5 mg cm–2 with a low N/P of 2.1:1. Overall, this work provides a new perspective on the design of “two-in-one” host from systematic theoretical and experimental analysis, which can concurrently tackle the obstacles in both sulfur cathode and Li anode and propel the practical application of Li–S batteries.