Abstract

Metal additive manufacturing technologies, such as powder bed fusion process, directed energy deposition (DED) process, sheet lamination process, etc., are one of promising flexible manufacturing technologies due to direct fabrication characteristics of a metallic freeform with a three-dimensional shape from computer aided design data. DED processes can create an arbitrary shape on even and uneven substrates through line-by-line deposition of a metallic material. Theses DED processes can easily fabricate a heterogeneous material with desired properties and characteristics via successive and simultaneous depositions of different materials. In addition, a hybrid process combining DED with different manufacturing processes can be conveniently developed. Hence, researches on the DED processes have been steadily increased in recent years. This paper reviewed recent research trends of DED processes and their applications. Principles, key technologies and the state-of-the art related to the development of process and system, the optimization of deposition conditions and the application of DED process were discussed. Finally, future research issues and opportunities of the DED process were identified.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Additive manufacturing (AM) technologies produce three-dimensional (3D) physical objects from digital information through layer-by-layer, line-by-line, piece-by-piece, or surface-by-surface depositions of materials on the substrate and the previous layer [1,2,3,4,5]. The AM is defined to be “a process of joining materials to make parts from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing and formative manufacturing methodologies” by ASTM and ISO standards [1, 6, 7]. The AM is also referred to as rapid prototy** (RP), 3D printing, freeform fabrication (FF), layer manufacturing, etc. [1,2,3, 8]. The AM technologies have important features, including complexity-for-free, tool-less and less-resource intensive, from the viewpoint of sustainability effects [9,10,11,12]. The complexity-for-free feature of the AM technologies has created a new research field called design for additive manufacturing (DFAM) [2, 5, 13, 14]. Research issues related to DFAM include freeform shapes, lattice structures and porous objects, topology optimization, part consolidation, non-assembly mechanism, internal channels, segmentation, embedded components, thin and small features, surface features, material choices, multiple materials, infill modifications, process dependent design parameters, etc. [2, 5, 13,14,15,16,17,18,19,20,21,22]. As compared to conventional manufacturing (CM) processes, the AM technologies have several promising benefits: (a) decreased the production time and the amount of human intervention due to the reduction of the time-consuming multiple re-fixturing and calibration procedure through the completely automated AM process from design to fabrication of the product in a computer aided design and manufacturing (CAD and CAM) environment, (b) reduction of cost to fabricate products using expensive materials, such as titanium and nickel based super-alloys, through the improved buy-to-fly (BTF) ratio and the reduced waste, and (c) Improvement of cost-competitiveness and structural integrity through the manufacture of unified structures with arbitrary shapes [2,3,4, 6, 8, 10, 13, 23,24,25,26,27]. Due to these important features and promising advantages, the AM technologies have attracted attention as emerging technologies from academies and industries in recent years [6, 28, 29].

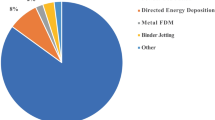

The usage of AM technologies has significantly changed in the last 30 years [6, 8, 24]. Recently, AM technologies were applied to the direct production of end-use parts and whole products (termed rapid manufacturing (RM)) [2, 6, 8, 28,29,30,31]. The AM technologies employ plastics, metals, ceramics, composites, and biological materials as deposited materials [1, 4, 8, 24,25,26,27,28, 30,31,32,33]. In order to create metallic parts using a plastic product fabricated by the plastic based AM processes, secondary processes are additionally needed [30, 31]. Metal additive manufacturing (MAM) technologies can directly fabricate a metallic part with a complex shape without an additional manufacturing process [4, 6, 24, 30,31,32,33]. The MAM technologies can reduce the lead-time and the cost to create a metallic product from CAD data through the elimination of the secondary process [30,31,32]. The MAM technologies are promising flexible manufacturing technologies to manufacture a metallic part with complex geometries, controlled properties and desired functionalities [28, 32,33,34,35]. In addition, it is very convenient to create a hybrid manufacturing process combining MAM processes with subtractive and forming processes [37,38,39]. Hence, research into novel processes and applications of the MAM significantly increased in the last decade.

Since Carl Deakard and Professor Joseph Beaman at University of Texas patented a selective laser sintering (SLS) process in 1986, various metal additive manufacturing (MAM) processes, such as a powder bed fusion (PBF) process, a directed energy deposition (DED) process, a sheet lamination (SL) process, etc., were developed [1,2,3,4,5,6,7,8, 24, 28,29,30,31,32,33, 39,40,41,42]. PBF, including selective laser sintering (SLS), direct metal laser sintering (DMLS), selective laser melting (SLM), and electron beam melting (EBM) processes, and DED processes have been widely applied to academic researches, commercialized systems and industrial applications [1,2,3,4, 6, 24, 28, 32,33,34, 39,40,41,42,43,44,45,46]. The deposition rate and the volume density of the DED processes are greater than those of the PBF process, while the layer thickness, the surface roughness and the minimum feature size of the fabricated part by the PBF processes are relatively smaller than those by the DED process [4, 24, 40, 42, 44,45,46,47,48]. The DED processes can create an arbitrary shape on even and uneven substrates through line-by-line deposition of a metallic material, unlike the PBF processes [32, 49, 50]. Because several developed DED systems include multiple powder hoppers and wire feeders to selectively supply powders and wires for different materials, the DED systems can easily fabricate a heterogeneous material with desired properties via successive and simultaneous deposition of different materials [4, 32, 51,52,53,54]. Due to the simplified system of the DED apparatus as compared to the PBF apparatus, it is convenient to develop a hybrid process combining DED with different manufacturing processes [24, 36, 38, 55,56,57]. Hence, research and application of the DED processes has steadily increased in recent years.

This paper reviews recent research trends of DED processes and their applications. Principles, key technologies and the state-of-the art related to the development of process and system, optimization of the deposition conditions and application of the DED process are discussed. In addition, future research issues and opportunities of the DED process are investigated.

2 Principle and Classification of DED Processes

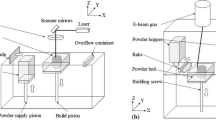

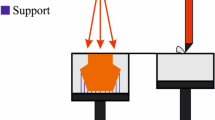

The DED process is defined as “additive manufacturing process in which focused thermal energy is used to fuse materials by melting as they are being deposited” by ISO/ASTM 52900 standard [7]. The principle of the DED process is illustrated in Figs. 1 and 2 [24, 57]. The DED process utilizes the concept of cladding and welding processes [1,2,3,4, 6, 8, 24, 32, 42,43,44,45,46,47,48,49,50,51, 56,57,58,59,60]. Thermal energy, such as a laser, electron beam, welding heat flux, etc., is focused on the previous layer, as shown in Table 1 [1,2,3,4, 6, 8, 24, 32, 42,43,44,45,46,47,48,49,50,51, 56,57,58,59,60,61,62]. Simultaneously, the feedstock with types of wires and powders is fed to the focused region of the thermal energy [40, 42, 58]. The molten pool is formed by melting of both the previous layer and the feedstock in and around the spot of the focused thermal energy [40, 42, 58]. The deposition bead is created by cooling of the molten pool. Through repetition of the above procedure, a 3D metallic part is fabricated. A typical cooling rate of the DED process ranges from 103 to 105 °C/s [58].

Powder feeding methodologies of LAM-DED processes (Redrawn and modified figures of reference 57) [57]: (a) co-axial feeding and (b) off-axis feeding

Wire feeding methodologies of DED processes (Redrawn and modified figures of reference 24) [24]: (a) co-axial feeding (WAAM) and (b) off-axis feeding (WLAM and WEAM)

The DED process can be classified into powder and wire feeding types according to the feedstock, as shown in Table 1 and Fig. 3 [1,2,3,4, 6, 8, 24, 42, 46, 56,57,58,59,60,61,62,63,64,65,66,67]. The developed powder feeding type DED processes uses a laser as a thermal energy, while the wire feeding type DED processes utilizes an electric arc, a plasma arc, a laser, and an electron beam as a thermal energy, as shown in Table 1 and Fig. 3 [1,2,3,4, 6, 8, 24, 42, 46, 56,57,58,59,60,61,62]. In order to deliver the feedstock into the molten pool, the DED process uses co-axial and lateral types of feeding technologies, as shown in Table 1 and Fig. 2 [1,2,3,4, 6, 8, 24, 42, 46, 57,58,59,60,61]. The DED process consisting of a powder feeding device and a laser is known as a laser additive manufacturing (LAM)-DED process [60]. The wire feeding type DED processes are classified into wire and arc additive manufacturing (WAAM), wire and laser additive manufacturing (WLAM), and wire and electron beam additive manufacturing (WEAM) processes according to used thermal energies [1, 4, 6, 24, 46, 58,59,60,61,62,63,64,65,66,67]. The DED process with off-axial feeding devices of the feedstock relative to the focused thermal energy is sensitive to feed orientations and deposition conditions [59]. The sensitivity greatly increases for the case of a wire laser additive manufacturing (WLAM) process [24, 59] (Figs. 4, 5, 6).

Typical crossing regions of fed powders for conventional LAM-DED and HELA technology (redrawn and modified figures of reference 90) [90]: (a) conventional LAM-DED process and (b) HELA technology

Deposited region and optimal processing map for LAM-DED process: (a) typical formation of the deposited region and (b) optimal processing maps for different materials [adapted from reference 42 (Open Access)] [42]

Energy densities of the laser, the arc and the electron beam for the DED processes are on the order of 106, 104 and 108 W/mm2, respectively, as shown in Table 2 [46]. The LAM-DED, WAAM and WLAM processes use a shield gas to prevent oxidation of the molten pool during the deposition [6, 24, 34, 40, 42, 44, 56,57,58,59,60, 64,65,66,67,68]. The WEAM processes are operated in a vacuum furnace unlike the LAM-DED, WAAM and WLAM processes [4, 46, 62, 63, 69,70,71,72]. The investment cost of the WAAM process is relatively cheaper than that of the LAM-DED, WLAM and WEAM processes [24, 46]. The surface roughness (Ra) of the fabricated part by LAM-DED processes is greater than that by WLAM processes by nearly 20–30% in a plane deposition [59, 73]. The deposition rate and the layer thickness of the wire feeding type DED processes are remarkably greater than those of the powder feeding type DED processes, while the dimensional accuracy and the residual stress of the fabricated part by the wire feeding type DED processes are inferior to those by of the powder feeding type DED processes, as shown in Table 2 [4, 42, 46, 56,57,58,59,60].

3 Powder Feeding Type DED (LAM-DED) Processes: State-of-the Art

3.1 Characteristics and Principle of LAM-DED Processes

Powder feeding type DED (LAM-DED) processes use the concept of the laser cladding process, as shown in Fig. 1 and Table 1 [1, 4, 6, 32, 40, 42, 47, 48, 58,59,60, 73, 74]. Sandia National Laboratories in United States developed the first LAM-DED process. In addition, the process was patented as the laser engineered net sha** (LENS) process [4, 40, 59, 60, 75]. The LENS process was commercialized by Optomec Inc. [4, 76]. Since the LENS process was introduced, various LAM-DED processes, such as direct metal deposition (DMD) process, direct metal tooling process, laser metal deposition (LMD) process, laser consolidation (LC) process, direct light fabrication (DLF) process, laser casting process, etc., were developed [4, 58, 77,78,79,80,81,82,83]. Mazumder et al. developed the DMD process [4, 32, 58, 77]. The DMD process integrated the closed-loop control unit, including CCD (Charge coupled device) cameras, into the DMD system to maintain the deposited thickness through monitoring of the deposited region [58, 77,78,79]. The DMD process was commercialized by POM Group (DM3D Inc.) [4, 58, 77,78,79]. The DMT process with a similar process concept to the DMD process was commercialized by InssTek Inc. in Korea [4, 32, 80, 84].

The LMD process was commercialized by several companies, such as Trumpf Inc., EFESTO Inc., and RPM Inc., [4, 81, 82, 85,86,87,88,89]. The LMD process of Trumpf Inc. optionally provided an extreme high speed-laser material deposition (EHLA) technology to improve the surface creation rate and the quality of the deposited bead [81, 90]. Typical DED processes formed a crossing region of the fed powders from the feeding nozzle into the molten pool, while the EHLA technology created a focal region of the fed powders above the molten pool to melt fed powders before hitting the powders to the molten pool [81, 90]. With EHLA technology, the powder particles no longer need to be melted in the molten pool due to melting of the fed powders above the molten pool, unlike typical DED processes [81, 90]. The typical layer thickness, the minimum feature size and the maximum deposition rate of the LAM-DED are 250–500 μm, 380–1000 μm and 8.3 g/min, respectively, as shown in Table 2 [4, 40, 44, 48, 58, 76]. The maximum layer thickness of the LENS process is nearly 1000 μm [58, 76].

3.2 Development of Processes and Systems

Table 3 shows features of commercialized LAM-DED processes. The LENS process uses a fiber laser and a gantry type deposition head, as shown in Table 3 and Fig. 7a [4, 32, 59, 60, 76]. A recently developed LENS system includes a melt pool sensor with a vision camera for a feedback control through real time monitoring of the variation of the molten pool during the deposition [76]. The Optomec Inc. developed a LENS modular print engine to integrate the deposition head into a conventional CNC machine tool [76]. The modular print engine provided a promising direction related to technical progress of the LAM-DED process for a hybrid system [91]. The DMD process uses three types of laser, including diode, disc and fiber lasers, as well as gantry and robot arm types of deposition head, as shown in Table 3 [4, 32, 77, 79]. The DMT process utilizes a fiber laser and a gantry type deposition head, as shown in Table 3 and Fig. 7b [4, 32, 80]. In addition, the DMT process employs two vision cameras for a closed-loop control of the layer thickness [80]. The LMD process of Trumpf Inc. includes three types of laser, including diode, disc and fiber lasers, and a gantry type deposition head, as shown in Table 3 and Fig. 7c [81]. In addition, the LMD process of Trumpf Inc. employs a vision camera for monitoring the formation of the molten pool during the deposition. MAXROTEC Inc. in Korea developed a robot arm type DED system, as shown in Table 3 and Fig. 7d [92]. The system uses a fiber laser as a thermal energy source. In addition, the system employs an infrared (IR) camera for closed-loop control through monitoring of the width of the molten pool [92]. Most commercialized DED processes uses two or more hoppers for feeding of powders to deposit heterogeneous materials through selective mixing of different powders [93]. The feature allows the DED process to easily produce a functionally graded material and structure (FGM&S) [93].

Deposition heads for different commercialized DED process: (a) LENS process (reprinted from figure provided by Ph.D Yong Son and Ph.D Hyub Lee of KITECH with permission), (b) DMT process, (c) LMD process (Trumph Inc., reprinted from figure provided by Doosan Machine Tools Inc. with permission), and (d) DED process (MAXROTEC Inc., reprinted from figure provided by MAXROTECH Inc. with permission) [92]

3.3 Effects of Deposition Parameters

Deposition parameters of LAM-DED process can be classified into laser, feeding, material and design, and motion and path parameters, as shown in Fig. 5 [42, 57,58,59,60, 94,95,96,97]. The power of the laser, the scan speed of the laser and the feed rate (mass flow rate) of powders are major parameters affecting the bead formation, joining between successive layers, the porosity, the microstructure, and the residual stress [42, 60, 98]. Several researchers proposed a laser energy per unit length (LEL, Π) and a powder feed per unit length (PFL, Γ) to reflect the influence of the correlation between the three parameters, as shown in Eqs. (1) and (2) [42, 60, 98]. The beam diameter and the profile of the laser beam affect the minimum size of the feature and the formation of the molten pool [60, 94]. The catchment efficiency of powders generally depends on the feed rate of powders, the flow rate of carrier gas, the diameter distribution of powders, the beam profile of the laser, the scan speed of the laser, etc. [42, 72, 94]. Despite the maximum catchment efficiency of powders was reported to be nearly 90% for a specific case, the material usage efficiency of LAM-DED process is generally less than 30% [42, 57, 74]. The energy efficiency of the laser for LAM-DED process is less than 40%, as shown in Table 2 [42, 74]. A dilution layer with mixed chemical compositions is formed between successive layers, as shown in Fig. 6a [42, 57].

The dilution ratio (α) is defined as given in Eq. (3) [42, 57]. Several researchers proposed the optimal range of the dilution ratio as 10–30% to obtain a proper dilution between the first layer and the substrate [42, 99]. The amount of porosity in the fabricated part was used as an important measure to estimate the optimal deposition conditions [42, 60, 98]. Dass et al. investigated the effects of the LEL and the powder feed rate on the occurrence of the porosity. In addition, they predicted optimal processing regions for different alloys, as shown in Fig. 6b. The global energy density (GED, ω) was introduced to investigate the porosity in the fabricated part by the LAM-DED process, as shown in Eq. (4) [42, 100]. Wolff et al. illustrated that interlayer and intralayer porosities were taken place for regions of low and high values of the GED, respectively [42, 100]. Dass et al. reported that the possibility of lack of fusion defect induced by less dilution increases with decreasing GED in the region of low GED, while the possibility of keyhole porosity induced by high dilution decreases with increasing GED in the region of high GED [42, 100]. In addition, they reported that the keyhole takes place when the dilution ratio exceeds 30%, while the lack of fusion occurs when the dilution ratio is under 10% [42]. The track overlap ratio affected the porosity of the fabricated part by the LAM-DED process [42, 60, 98]. The track overlap ratio of the LAM-DED process is typically 25% of the width of the deposited bead [58]. Paul et al. defined a transverse traverse index (TTL, Ω) to consider the influence of the track overlap ratio on the porosity of the fabricated part, as shown in Eq. (5) [60, 98]. They estimated an experimental equation, including LEL, PFL and TTL, to predict the porosity of the fabricated Inconel 625 specimen by the LAM-DED process [60, 98]. In addition, they reported that dense parts are fabricated when the TTI is close to 0.6, while porous structures are created when the TTL is greater than 0.7 [60, 98].

The particle diameter of the fed powders for the LAM-DED process generally ranges from 30 to 200 μm [57, 59, 95]. Spherical powders are preferred for the feedstock in terms of flowability, layer spreading, and loose powder packing [101]. The deposition path affects the residual stress distribution, the microstructure, the anisotropy, the porosity, and the mechanical properties of the fabricated part [96, 102,103,104,105]. Uni-directional, alternative directional (zig-zag), chessboard, and contour paths are used to fabricate parts using the LAM-DED process [96, 100]. Riberiro et al. [102] investigated the influence of the deposition path on the shape, the morphology, the surface roughness, the microstructure, and the microhardness of the AISI 316 deposited region. Wolff et al. examined anisotropic characteristics of a Ti–6Al–4V block fabricated by the LENS process using an alternative directional path [103]. Li and Soshi studied the effects of the deposition path on grain morphologies of the fabricated specimen by a DED coating process using a Kinetic Monte Carlo (KMC) Potts model [104]. Soshi et al. investigated the influence of a trochoidal deposition path on the preheating effect, the molten pool size, the power catchment efficiency, the material addition rate, the porosity, and the post deformation for the DED process [105]. Denlinger et al. studied the effects of inter-layer dwell time on distortion and residual stress of a wall structure fabricated by a DED process using Ti-6Al-4 V and Inconel 625 powders [97].

3.4 Applications and Fabricated Parts

Although LAM-DED processes are mainly used to fabricate metallic parts with a near-net shape in the early stage, applications of the LAM-DED processes have been expanded to repair, restoration, remanufacturing, porous coating, tailored materials, tailored structures, and thermal management in recent years, as shown in Table 4 [4, 32, 35, 50, 51, 79,80,81, 106,107,108,109,110,111,112,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127,128,129,130,131,132,133,134,135,136,137,138,139,140,141,142,143,144,145,146,147,148,149,150,151].

3.4.1 Repair, Restoration and Remanufacturing

LAM-DED processes have various advantageous characteristics, such as relatively lower heat input, less distortion, lower dilution rate, excellent metallurgical bonding, excellent mechanical performance, relatively higher geometrical accuracy, suitability for full automation, and precise thermal control, in terms of repair, restoration and remanufacturing (3R) of products as compared to welding processes [107, 109]. Therefore, research on application of the LAM-DED process to repair, restoration and remanufacturing remarkably increased for the purpose of decreasing lead time, cost and greenhouse gas (GHG) emissions through recycling of used materials and the simple modification of used parts [4, 32, 35, 50, 106,107,108,109,110,111,112]. Restoration and remanufacturing using the LAM-DED process can potentially improve the properties and the reproduction of discontinued parts [4, 32, 35, 106, 108, 109, 111, 112, 117]. Most of previous studies related to the 3R of parts using LAM-DED processes were focused on repair and remanufacturing of components of power plants and engines [4, 79,80,81, 106,107,108,109,110,111,112]. Hot sections, knife-edges, blades, and compressor seals were repaired by LAM-DEM processes to reduce cost and lead time [4, 32, 106, 107, 109,110,111]. Diaz et al. examined deposition characteristics of Stellite6 using a LAM-DED process to repair steam circuit components in thermal power stations [106, 110]. Petrat et al. [113] repaired a gas turbine burner, which was fabricated from a SLM process, using a LMD process. Kimi Inc. remanufactured four stroke marine pistons for not only the restoration of the parts but also the improvement of the wear resistance of grooves [107, 109, 114]. Willson et al. [112] reported that there was nearly a 72.5% decrease in GHG emissions and a 68.1% decrease in energy consumption as compared to the fabrication of a new replacing turbine blade when 5% volume of the turbine blade was repaired by a LAM-DED process. InssTek Inc. [80] in collaboration with Korean Air Force repaired the air seal of a jet engine.

LAM-DED processes, including LENS, DMD, DMT, and LMD processes, were used for the sake of repair, restoration and remanufacturing of molding, forming and die casting tools from the viewpoint of economic efficiency [4, 32, 35, 51, 76, 77, 79,80,81, 106, 107, 109, 115,116,117,118,119,120]. Several researchers reported that the LAM-DED process can provide sharper and smaller deposition with focused high laser energy and improved metallurgical properties as compared to traditional repair technology, such as TIG welding, plasma welding and GTAW welding, [107, 115, 116]. Bennett et al. [116] revealed that the service life of dies repaired by the LAM-DED process is longer than that by a traditional repair process by factors of 3.4–8.0 times. Research on the 3R of molding, forming and die casting tools started from only the repair of tools with different types of defects, while those extended to remanufacturing of tools with improved functionality and performance [4, 32, 35, 76, 77, 79, 80, 106, 107, 116,117,118,119,120]. Ahn et al. remanufactured several hot forging dies with the wear resistance using a selective deposition technology based on the LAM-DED process [4, 119]. They demonstrated that the wear resistance and the service life can be greatly improved when remanufacturing technology based on the LAM-DED process is applied to the hot forging die, as shown in Fig. 8a [119]. Hong et al. [120] remanufactured trimming dies with 23F858 tool steel deposited on S45C structural steel using a DMT process owing to the improved service life of the dies. InssTek Inc. [80] remanufactured the mold of a headlamp to reduce cost and lead time using the DMT process. Morrow et al. addressed that LAM-DED processes can greatly reduce energy consumption, GHG emissions and manufacturing costs for repair and remanufacturing of molds and dies [4, 106, 117].

Fabricated parts by LAM-DED processes: (a) comparison of external contours of remanufactured hot forging dies with those of conventional dies, (b) repaired weapon components (adapted from figures provided by Naval Shipyard of R.O.K and 3D Printing Center of KITECH with permission), (c) example of compositional graded interlayers (adapted from figures of reference 119 with permission) [119], (d) example of hot forging die with DDL and TL, (e) injection molds incorporating CCCs (adapted from figures reference 149 with permission) [149], and (f) hot stam** dies incorporating CCCs [adapted from figures reference 151 (Open Access)] [151]

LAM-DED processes were used to repair various industrial and military parts. Lewis et al. applied the LAM-DED process to repair rail track. They reported that the LAM-DED process is highly recommended to repair track parts with a simple geometry [107, 120]. Rooyen et al. repaired austenitic stainless steel vessels using a LAM-DED process [107]. Liu et al. applied the LMD process to repair the sprocket of a scraper conveyor [109, 122]. Oh et al. [123] applied the DMT process to repair of damaged parts, which were fabricated from a PBF process. Recently, LAM-DMD processes were widely used to repair military parts. The military parts require a long delivery time and an expensive cost. Occasionally, the military parts are discontinued by the manufacturer. Hence, the repair of military parts has attracted attention as a promising application field of the LAM-DED process. The 3D printing center of KITECH (Korea) in collaboration with Navy Shipyard of R.O.K (Republic of Korea) repaired several military parts, as shown in Fig. 8b.

3.4.2 Porous Materials and Coating

Porous materials and coating technologies are emerging as an important application of LAM-DED processes [42, 80, 86, 124,125,126,127,128]. Carcel et al. [86] researched the fabrication of aluminum and titanium foamed layers on Ti–6Al–4V sheet by a LMD process. Koike et al. [124] investigated the manufacture of stainless steel foam with titanium hydride using a LAM-DED process. Recently, the LAM-DED process was applied to a porous coating for implants [42]. Dass and Moridi [42] reported that the porous coating technology using LAM-DED process offers benefits to fabricate porous implants as compared to conventional casting. Xu et al. fabricated porous titanium samples for implants from a LENS process [42, 124]. They also performed in vivo biocompatibility studies using the fabricated porous titanium samples [42, 124]. Bernard et al. [126] examined the fatigue behavior of a porous NiTi alloy for implants in a cyclic compression loading. They manufactured the porous NiTi alloy from a LENS process [126]. Bandyopadhyay et al. [127, 128] applied a LENS process to fabricate porous and functionally graded structures for load bearing implants. In addition, they investigated the in vivo response of porous titanium implants [128]. InssTek Inc. [80] in collaboration with Corentec Inc. developed porous coating technologies for customized implants using a DMT process.

3.4.3 Tailored Materials and Structures

The developed LAM-DED process employs multiple hoppers for feeding of different powders [4, 32, 51,52,53,54]. The feeding of different materials enables in situ synthesizing alloys with a location-dependent chemical compositions through mixing of different powders [4, 93, 129, 130]. The in situ synthesizing characteristics of the LAM-DED process can fabricate tailored materials [42, 52, 129, 130]. In addition, inherent deposition characteristics of the LAM-DED process, including line-by-line and layer-by-layer depositions of different materials, allow the manufacture of tailored structures in the material [4, 42, 52, 129, 130]. Representative examples of tailored materials and structures using the LAM-DED process are functionally graded materials and structures (FGM&Ss) with the graded composition as a function of position [4, 42, 52, 129, 130].

Three deposition strategies, including direct joining method (DJM), gradient path method (GPM) and intermediate section method (ISM), were utilized to create the FGM&S using the LAM-DED process [129]. The DJM deposits a successive layer with heterogeneous materials on a substrate or a previous layer without any interlayer between successive layers [51, 129]. The DJM was widely used to create bimetallic materials and structures as a common technology [4, 51, 131, 132]. Yadroitsev et al. [131] applied the DJM to deposition of Stellite12 on stainless steel 316. They investigated the influence of the layer thickness on gradient transition characteristics. They have estimated that the minimum thickness of FGM is 200 μm [131]. In addition, they fabricated thin wall structures with the combination of bronze with stainless steel 430 L [131]. Park and Ahn [132] used the DJM to create bimetallic materials with a wear resistance layer through the deposition of Stellite6 and NOREM02 on SKD61 hot working tool steel. The DJM provided a key concept for restoration and remanufacturing of products through the deposition of heterogamous materials on even and uneven substrates [4, 35, 50, 51, 123, 133]. Several researchers and industries applied the DJM to the fabrication of bimetallic parts with volumetric heat sinks, wear resistance and the corrosion resistance [4, 32, 51, 77, 79, 80, 117, 120]. Cortina et al. [134] manufactured bimetallic hot stam** tools with a H13 coated layer on AISI 1045 steel from a LAM-DED process to apply a cheaper material to tools.

The DJM can cause cracking in the interface between different materials owing to the difference of lattice structures, thermal expansion coefficient and mechanical properties [4, 51, 119, 129, 132, 135]. The GPM and the ISM were used to overcome the cracking in the interface during the creation of FGM&S [4, 51, 119, 129, 130]. The GPM creates compositionally graded interlayers between different materials, as shown in Fig. 8d [51, 53, 93, 119, 130, 131, 136,137,138,139,140]. Ocylok et al. fabricated functionally graded multi-layers with mixed compositions between bottom and top layers using a LAM-DED process for the sake of improving the wear and corrosion characteristics of a die casting mold [51, 136]. Articek et al. [137] manufactured a continuously graded material consisting of H13 tool steel and Cu from a LENS process. Caroll et al. created a bulk part with compositionally graded interlayers between 304 L stainless steel and Inconel 625 using a RPM 557 laser deposition system [52, 131, 138]. Durejko et al. fabricated thin wall tubes with a Fe3Al/SS316L graded structure in the radial direction using a LENS process [129, 139]. Heer et al. developed a compositionally graded magnetic-nonmagnetic bimetallic structure consisting of 316 and 430 stainless steels using a LENS process [129, 140]. Ahn et al. [119] investigated the influence of the design of compositionally graded interlayers on wear characteristics, as shown in Fig. 8c. In addition, they manufactured hot working dies with a compositionally graded interlayer between SKD61 substrate and Stellite21 deposited layer for the purpose of improving wear characteristics and service life of the die [119].

The ISM creates an intermediate bonding layer, including additional materials, between different materials to avoid undesirable phases, which may be easily formed in the GPM [129]. A brittle intermetallic layer was formed in the interface when the titanium alloys is deposited on stainless steel and Inconel alloy [129, 141, 142]. An intermediate bonding layer with additional materials was required to improve joining characteristics through the elimination of a brittle intermetallic layer [129, 141, 142]. Saharabudhe et al. [141] fabricated a metallic structure with an intermediate bonding layer of NiCr to prevent delamination and cracks via the deposition of Ti–6Al–4V on 410 stainless steel. Several studies used graded vanadium, vanadium, chromium, and iron as materials of the intermediate bonding layer to deposit Ti–6Al–4V on stainless steel [129]. Onuike et al. [142] successfully deposited Ti–6Al–4V on an Inconel 718 substrate through the creation of an intermediate bonding layer with vanadium using a LENS process. Ahn and Kim [143] applied an intermediate bonding layer with Monel 400 between P21 and ampcoloy 940 to the fabrication of a thermal management mould using a DMT process. Kim et al. [144] adopted a damage diminution layer (DDL) between successive layers to improve the ductility of the deposited region. They also used transition layers (TLs) with graded compositions between successive layers to prevent cracking induced by the differences in thermal and mechanical properties [144]. Figure 8d shows an example of a hot forging die with DDL and TL.

3.4.4 Thermal Management

Various studies on applications of the LAM-DED process to the development of structures and parts related to a thermal management are performed. Representative applications of the LAM-DED process to the thermal management are the fabrication of conformal cooling channels (CCCs) and heat sinks for molding, forming and die casting tools [4, 32, 76,77,78,79,80, 84, 117, 143, 145,146,147,148,149,150,151]. Mazumder et al. and DM3D Inc. manufactured various injection molds with CCCs and volumetric heat sinks from a DMD process to reduce cooling and cycle times through improvement of the cooling rate [4, 32, 77, 79, 117]. Kolleck et al. [145] fabricated hot stam** dies incorporating CCCs using a DMD process. Vollmer et al. manufactured press-hardening tools with CCCs from a LMD process of Trumpf Inc. for the sake of reducing the tool temperature and the elimination of hot spots in the tools [147]. Ahn et al. developed thermal management molds with volumetric heat sinks using a DMT process for the purpose of uniform and rapid cooling of the molds [32, 143]. Ahn et al. in collaboration with Woosung Inc. developed several injection molds incorporating CCCs, including molds for a fan of a refrigerator, a window button of a car, a drawer of a refrigerator, etc., using a DMT process for the sake of improving the production efficiency and the product quality together [4, 32, 147]. They reported that injection molds incorporating CCCs can greatly enhance the production efficiency and the product quality [4, 32, 147]. Ahn et al. [147] patented design and fabrication technologies related to CCCs on curved surfaces. Soshi et al. [148] developed an injection mold incorporating a coolant grid using a DMG Mori LASERTEC 65 3D. They revealed that the injection mold incorporating a coolant grid can improve cooling efficiency [148]. Extreme Fabrication Technology Group (EFTG) of KITECH manufactured various injection and blow molding molds, including molds for a TPE boot, a wheel hub cap, etc., to reduce cooling and cycle times, as shown in Fig. 8e [149]. In addition, the EFTG developed a direct metal tooling process for injection mold with curved CCCs [150]. Cortina et al. [151] have fabricated hot stam** dies incorporating CCCs using a LMD process, as shown in Fig. 8f.

4 Wire Feeding Type DED Processes: State-of-the Art

Wire feeding type DED processes are essentially the extension of welding and cladding processes, as shown in Fig. 2 and Table 1 [1, 4, 24, 40, 46, 58,59,60, 62,63,64,65,66,67,68,69,70,71,72,73]. The capture efficiency of the feedstock for the wire feeding type DED processes is nearly 100%, as shown in Table 2 [24, 57,58,59, 152]. The material usage efficiency of the wire feeding type DED process is extremely greater than that of the LAM-DED process [152]. In addition, wires are cheaper than powders [152]. Due to a higher deposition rate and the ability to fabricate larger structures, the wire feeding type DED process is proper to fabricate a part with a large volume [24, 42, 65, 152, 153]. The wire feeding type DED process is effective for simple geometries and a surface coating [58].

4.1 Wire and Arc Additive Manufacturing (WAAM) Process

4.1.1 Characteristics and Principle of WAAM Processes

The WAAM combines an arc, including electric and plasma arcs, as heat energy and a wire as a feed stock [4, 24, 42, 43, 59, 65, 154]. The WAAM process can be classified into three types according to the principle of the welding process: (a) gas metal arc welding (GMAW), (b) gas tungsten arc welding (GTAW) and (c) plasma arc welding (PAW) [24, 42, 43, 65, 154,155,156,157]. Table 5 shows merits and demerits for different WAAM processes [24, 65, 165]. Because the feeding direction of the wire is co-axial with the welding torch, the deposition path is easily created, as shown in Table 5 [24, 65, 157]. The set-up cost of the GMAW is cheaper than that of the GTAW and the PAW [165]. However, the GMAW includes several disadvantages, including residual stress, distortion and deterioration induced by an excessive heat input, [158]. Cold metal transfer (CMT) technology is the modified GMAW using the controlled dip transference [24, 65, 157]. The CMT technology can provide several advantages, such as a very low heat input, spatter-free metal transference, extremely stable electric arc, and sound welds, [24, 65, 157, 165]. In addition, the CMT technology can control the arc length on its own [157]. The GTAW and the PAW are more stable and reliable process than the GMAW [157].

The WAAM process based on GTAW can fabricate metallic parts with relatively smooth surface and high strength [54, 165]. The GTAW can greatly reduce porosity as compared to the GMAW [158]. The high temperature region of the arc of the PAW is narrower than that of GTAW. Hence, the WAAM based on PAW can create relatively narrower deposition bead [24]. WAAM processes based on GTAW and PAW are used to deposit titanium due to the arc wandering problem of the WAAM process based on GMAW [65]. Unlike the WAAM process based on GMAW, WAAM processes based on GTAW and PAW off-axially feed the wire [4, 24, 65, 152,153,154,155,156,157]. The off-axial feeding of wire leads to a change of the welding direction and excessive sensitivity of the arc length [157]. The WAAM processes based on GTAW and PAW require rotation of the torch to maintain an identical feeding direction of the wire [65, 159]. The WAAM processes based on GTAW and PAW need a complicated path program [65, 157].

The WAAM process employs CNC gantries and robot systems for manipulating the motion of the welding torch and the wire feeder [65]. A typical layer thickness and the minimum feature size ranges from 1000 to 2000 μm together, as shown in Table 2 [24, 65, 154]. The energy efficiency of WAAM is less than 90%, as shown in Table 2 [4, 24]. The BTF ratio of WAAM can be reduced to 1.2 [65, 154]. The WAAM process can greatly reduce the waste of material due to a low BTF ratio as compared to conventional subtractive manufacturing (SM) processes [65, 154, 155, 157, 159]. The deposition rate of the WAAM process typically ranges from 16.7 to 66.7 g/min [24, 65]. The surface roughness of the fabricated part by the WAAM process is nearly 200 μm of Ra [59]. Deposition rates of WAAM processes based on GMAW, GTAW and PAW lie in ranges of 3–4 kg/h, 1–2 kg/h and 2–4 kg/h, respectively, as shown in Table 5 [160]. Wu et al. [160] summarized materials used in WAAM processes, as shown in Table 6.

4.1.2 Development of Processes and Systems

Table 7 summarizes representative research groups and used thermal energy sources for WAAM processes. Cranfield University (U.K), University of Sheffield (U.K), University of Wollongong (Australia), Tennessee Technological University (U.S.A), Oak Ridge National Laboratory (U.S.A), Indian Institute of Technology (India), and Harbin Institute of Technology (China) are representative active research groups working on WAAM processes, as shown in Table 7 [24, 44, 65, 161, 165]. Oak Ridge National Laboratory (ORNL) in collaboration with Wolf Robotics and Lincoln Electric developed a robot WAAM process based on the GMAW for a metal big area additive manufacturing (MBAAM), as shown in Fig. 10b [162, 163]. Rodriguez et al. [157] developed WAAM processes based on CMT and TopTIG for stainless steel. Norsk Titanium commercialized a WAAM process based on PAW, which is a Rapid Plasma Deposition (RPD) process, to fabricate a large part using titanium alloys [42, 57, 169]. Several WAAM machines, such as GTarc300-3 WAAM machine (Gefertec GmbH, Germany), VARIAXISj-600 AM (Mazak, Japan), Addilan V0.1 (Addilan, Spain), ArcMan-600 (Nan**g Enigma Automation, China), RC-WAAM-3000 (Nan**g Zhongke Raycham Laser Technology, China), etc., were commercialized [162, 169].

4.1.3 Effects of Deposition Parameters

Representative deposition parameters of the WAAM process are arc current, arc voltage, working distance, travel speed, feed rate of wire, flow rate of shielding gas, deposition path, interpass time, dwell time between successive layers, material of wire, diameter of wire, etc., as shown in Fig. 9 [58, 152,153,154,155,156,157,158,159,160,161, 168, 171,172,173,174,175,176,177,178,179,180,46, 58, 66,67,68, 71, 73, 152, 154,155,156,157,158,159,160,161,162,163,164,165, 168, 180,194, 200, 203, 204, 212, 217,218,219, 221,222,223,224]

Yehorov et al. [176] studied on the effects of the travel speed, the deposition rate, and the wire feed rate on the surface quality of a thin wall part fabricated by a WAAM process based on GMAW. Shen et al. [177] examined the influence of the arc current and the interpass temperature on the morphology, the phase change, the hardness, the chemical composition, and the tensile property of a Fe3Al-based iron aluminide part fabricated by a WAAM process based on GTAW. Wu et al. [178] examined the influence of the heat accumulation on arc characteristics and metal transfer behavior during deposition in WAAM of Ti–6Al–4V parts. Gokhale et al. investigated the effects of the arc current, the torch speed, the wire feed rate, and the torch angle on the formation of the bead to fabricate a thin wall structure using a WAAM process based GTAW [158, 179]. They reported that the torch angle is a dominant parameter to determine the formation of the bead. Martina et al. [159] investigated the influence of the wire feed rate, the arc current and the travel speed on the bead formation and the surface waviness of the deposited part to obtain a processing map for a WAAM process based on PAW. Jhavar et al. [175] examined the effects of the plasma power, the travel speed and the wire feed rate on the formation and the quality of the deposited bead by a WAAM process based on a micro PTA.

Rodrigues et al. [172] reported that the deposition path greatly affects defects, including the porosity, the surface waviness, the hump, recurrent macrostructural problems, etc., and residual stress distributions of the fabricated part by a WAAM process. Li et al. [168] investigated the influence of the overlap ratio of in-plane and out-of-plane and the deposition path of out-of-plane on the surface profile of the fabricated part by a robot WAAM process based on GMAW. Ding et al. [180] proposed a tangent overlap model to improve the surface profile and roughness of the fabricated part by a robotic WAAM process. Ma et al. [165]. Kim et al. deposited different materials in bottom and top regions to create a BAMS. Wu et al. [156] manufactured a different type BAMS, in which a Ni deposited region is parallel to a steel deposited region in the horizontal direction, from a WAAM process based on GTAW.

4.2 Wire and Laser Additive Manufacturing (WLAM) Process

4.2.1 Characteristics and Principle of WLAM Processes

The WLAM process is one of the MAM processes to produce metallic parts without porosity using a laser, such as diode, disc, Nd:YAG, CO2, and fiber lasers, as a thermal energy source and an metallic wire [4, 24, 61, 67, 73, 153, 185,186,187,188,189,190,191,192,193,194,195,73, 185]. The travel speed of the laser commonly lies in the range of 0.05–2.4 m/min in the WLAM process [24]. Unlike the WAAM process, a hardness gradient within the top region of the deposited part by the WLAM process manifests due to repeated rapid heating, melting, solidification, and cooling cycles during the deposition process [153, 187, 193]. The hardness gradients affect the increased tensile strength of the top region [153, 187]. The tensile strength in the deposition direction is greater than that in the building direction [153, 187, 193]. Anisotropic characteristics with different mechanical properties in the deposition and building direction appear in the fabricated part by the WLAM process [153, 187, 191, 193].

4.2.2 Development of Processes and Systems

Various types of WLAM processes and systems have been developed [24, 61, 66, 153, 187,188,189,190,191,192,193]. The WLAM process can be classified into lateral and co-axial types according to the feeding type of the wire [24, 59, 61, 153, 185, 188,189,190,191,192,193,194,195, 198]. Lateral feeding of the wire is a common method to deliver the wire to the molten pool in the WLAM process [24, 59, 66, 73, 185, 194,195,194] developed a WLAM set-up for rapid prototy** using a Ti–6Al–4V wire. The system included a Yb fiber laser with a maximum power of 8 kW, a fiber coupler and a five axis rig [194]. EDAS Innovation Works Inc. devised an experimental set-up consisting of a lateral wire feeder (Weldaix Inc.), Nd:YAG laser with a maximum power of 3.5 kW, a high accuracy 6-axis robot (KR 100, KUKA Inc.), a COMS camera, and a thermography camera for the WLAM process [153, 187]. Research Center for Advanced Manufacturing at Southern Methodist University developed a robotized laser-wire direct metal deposition system, including a 6-axis robot (KR-60) with a 2-axis rotary table, an fiber laser with a maximum power of 4 kW (IPG Inc.), a wire feeding system (Binzel Inc.), and a CMOS camera (Prosilica GC640), as shown in Fig. 11a [191].

Developed WLAM systems: (a) robotized laser-wire direct metal deposition system (reprinted from figure of reference 191 with permission) [191], (b) WLAM system with a rotating wire feeder (reprinted from figure provided by Ph.D Jae Gu Kim of KIMM with permission) and (c) LMWD system with a coaxial wire deposition head (reprinted from figure reference 61 with permission) [61]

ORNL in cooperation with GKN aerospace Inc. developed a WLAM system, including a laser with a maximum power of 20 kW, a lateral wire feeder, and an online monitoring camera, for mBAAM using a titanium alloy [190, 191]. Su et al. [197]. The LHS system offered potential for a high deposition rate using a low laser power owing to resistive preheating of the wire [197, 198]. In addition, the LHS could provide several advantages, including low melt-back of the diluted region, thermal stability and metallurgical control, for additive manufacturing of metals [194]. Kim and Lee [195] developed a novel WLAM process with a rotating metal wire feeder to ensure front feeding of the wire irrespective of the deposition path, as shown in Fig. 11b. Demir [186] investigated a micro laser metal wire deposition (MLMWD) process for additive manufacturing of thin-wall structure. The MLMWD process employed a pulsed Nd:YAG laser and an in-house built wire feeder for precise control of the deposited region [186]. In the MLMWD process, the beam diameter was comparable to that of the wire to allow correct positioning of the laser over the deposited wire unlike a conventional WLAM process [186].

Although the lateral feeding type easily implements the concept of the designed WLAM process, the lateral feeding type of WLAM process is greatly sensitive to wire feeding and deposition conditions [24, 59, 73, 153, 189, 195]. With the lateral feeding type WLAM process, it is difficult to create the deposition path considering the proper feeding direction and location of the wire during the deposition of a complex shape as compared to the co-axial feeding type [191]. In addition, the lateral feeding of the wire causes anisotropic deposition problems, limited mobility of the deposition head and reduced flexibility of the deposition geometry [61, 153]. In order to overcome disadvantages of the lateral feeding type WLAM process, several co-axial feeding type WLAM processes with vertical feeding of the wire have been introduced [61, 199,200,201,202,203]. The wire is vertically fed to the laser focus for the case of the co-axial wire feeder. Several split separate beams and an axisymmetric multi-laser beam source are focused on a focal point through lateral irradiation of the laser beam for the case of the laser cladding head with a co-axial wire feeder [191, 201]. The co-axial feeding type WLAM process allows omni-directional deposition [191, 201]. Wang et al. [200] devised a co-axial feeding type of directed laser deposition (DL) system with vertical wire feeding inside of an annular laser beam.

Fraunhofer Institute for Material and Beam Technology (IWS) commercialized a novel laser cladding head with a co-axial wire feeder (COAXwire) [191, 201]. ORNL in collaboration with GKN aerospace developed a WLAM process using a COAX laser wire feeding system [190]. Brueckner et al. [201] employed a COAXwire cladding head consisting of an IPG fiber laser with maximum power of 400 W and a modified DINSE wire feeding system for fabricating a small-sized part. Motta et al. [61] developed a laser metal wire deposition (LMWD) system. The system consisted of a coaxial wire deposition head (CoaxPrinter) a multi-mode active fiber laser with a maximum power of 3 kW (YLS-300), a 6 axis anthropomorphic robot with a rotary table (ABB IRB 2400-10), and a high speed imaging system (Fastcam Mini AX200), as shown in Fig. 11c [61]. Kotar et al. [202] devised an experimental set-up to investigate the initial transient phase and the stability of the annular laser beam direct wire deposition (ALB-DWD) process. Fu et al. [199] developed a WLAM process using an axisymmetric multi-laser source and vertical wire feeding. They used three laser beams and a coaxial wire feeder [199].

4.2.3 Effects of Deposition Parameters

The quality and the properties of parts fabricated by the WLAM process are dependent on the laser power, the travel speed, the beam diameter, the track overlap ratio, the deposition path, the interpass time, the interlayer dwell time, the wire feeding direction, the feeding angle, the wire tip position, etc., as shown in Fig. 9 [24, 66,67,68, 73, 185, 188, 189, 191, 193, 200, 201, 204]. Several researchers reported that the wire tip should be immersed in the molten pool to create continuous and smooth beads with a uniform surface aspect [66, 194]. The combination of the wire feeding direction and the wire tip position in the molten pool remarkably affected the droplet transfer and the bead quality [24, 61, 67, 73, 185, 189, 199, 205]. Most previous research works revealed that front and side feeding can fabricate a good deposition bead as compared to back feeding [24, 67, 73, 185, 199, 205]. In addition, it was suggested that the proper feeding angle of the wire ranges from 20 o to 60 o [67, 73, 185]. Syed and Li [205] reported that pores hardly appear in the multi-layer deposited part when front feeding of the wire is adopted. ** with high power fiber lasers. Materials and Design, 29(10), 20207-2074." href="/article/10.1007/s40684-020-00302-7#ref-CR194" id="ref-link-section-d24044222e7400">194]. The feed rate of the wire is limited by the LEL [24, 188, 189]. The intermittent drip** phenomenon in the deposited bead occurs when the feed rate of the wire is very low for a high LEL, while a stubbing phenomenon in the deposited bead takes place when the feed rate of the wire is excessively high for a low LEL [24, 61, 188, 189]. Motta et al. [61] predicted the process feasibility map to estimate an appropriate LEL for the deposition of AISI 308 stainless steel using the LMWD process with a coaxial wire deposition head. In addition, they reported that power decay strategies or close-loop temperature control is needed to maintain a stable molten pool size through the prevention of heat accumulation during multi-layer deposition [61]. Kotar et al. [202] developed process-stability windows to predict an appropriate combination of initial laser power and workpiece irradiation proportion (WIP) of each wire feed rate for the deposition of SS 316 wire on a SS 304 substrate using the ALB-DWD process. Deposition rate and area can be estimated by the ratio of the wire feed rate to the travel speed when the diameter of the wire is fixed [24, 186, 194]. Demir [186] defined equations to predict the deposited volume of the wire, the delivered volume of the wire and the material use efficiency for the deposition of single and multiple layers. Chua et al. [203] investigated the influence of the laser power, the travel speed and the bead length on the temperature distribution and the residual stress. Caiazzo [206] derived an equation to estimate the deposition rate of wire. The porosity of the deposited region was considered in the equation [206].

Characteristic dimensions of the deposited region, the diluted region and the HAZ for the WLAM process are greatly influenced by the three major deposition parameters [24, 67, 186, 188, 189, 197, 200, 206]. Mok et al. reported that the height of the bead is mainly influenced by the travel speed, whereas the width of the bead is significantly dependent on the laser power [24, 67]. Demir [186] estimated empirical equations related to relationships between process parameters, including the laser energy, the pulse duration and travel speed, on characteristics dimensions of the deposited bead and the diluted region for the deposition of AISI 301 wire on the AISI 316 substrate using the pulsed Nd:YAG laser. Kottman et al. [197] estimated process maps for dilution as a function of the laser power and the hot wire power when the Ti–6Al–4V wire is deposited by the laser hot wire process. Caiazzo [206] examined the effects of the laser power, the travel speed, and the wire feed rate on the formation of the bead, the fusion zone and the pores in the vicinity of the deposited region. Brandl et al. [207] extensively investigated the influence of the laser power, the travel speed, and the wire feed rate to the travel on dimensions and hardness of the bead, the fusion zone and the HAZ for the deposition of Ti–6Al–4V using a Nd:YAG laser.

The deposition path, the interpass time and the interlayer dwell time (interlayer cooling time and interlayer time interval) greatly affected residual stress distributions, mechanical properties and microstructures in the vicinity of the deposited region [191, 193, 203, 204]. Akbari and Kovacevic [191] examined the effects of the interlayer time interval on the thermal history, the microstructure and the mechanical properties of the fabricated part by the robotized LWDMD process. Bandari et al. investigated the influence of the interlayer cooling time on distortion and mechanical properties in the WLAM process to deposit Ti–6Al–4V [193, 208]. They reported that a longer interlayer cooling time increases the distortion of the fabricated part, while the interlayer cooling time hardly affects the mechanical properties of a large scale part [193]. Chua et al. [204] examined the effects of the deposition path, the deposition direction, and the interpass time on thermo-mechanical characteristics for Ti–6Al–4V thin wall deposition through a three-dimensional finite element analysis (FEA). Chua [209] proposed a control scheme of the interpass time to make a uniform interpass temperature during successive deposition of the bead in a plane using FEAs. Ding et al. [210] developed a path planning program based on Matlab software to deposit a complex part using an 8-axis robotized WLAM system.

4.2.4 Applications and Fabricated Parts

The WLAM process is not actively applied to industrial parts yet. Feasibility studies are in progress to fabricate metallic parts using developed WLAM systems. Brandl et al. [153] fabricated a Ta-200 cylinder and Ti–6Al–4V thruster using a laser beam based deposition process. Akbari and Kovacevic [191] created several thin wall structures with a medium volume, such as a ball structure, a helical screw structure, a propeller structure, etc., on thin plates and cylindrical bar from a robotized laser-wire direct metal deposition system, as shown in Fig. 12a. Kim and Lee [195] deposited several Ti–6Al–4V structures on flat and curved surfaces using a WLAM process with a rotary wire feeder, as shown in Fig. 12b. Kottman et al. [197] applied a WLAM process using a hot wire to repair of a shot block for die casting. Fu et al. [199] fabricated several test parts using a WLAM process with a vertical wire feeder. WLAM processes with a coaxial wire feeder frequently used to fabricate small metallic parts with a thin wall structure. Motta et al. [61] manufactured a cylindrical thin wall structure with a small volume from a LMWD system, as shown in Fig. 12c. Demir [186] created a small-sized thin wall structure with an aspect ratio of up to 20 on an AISI 316 substrate using the μLMWD process. Brueckner et al. [201] fabricated a near-net-shape pin structure with an extremely small volume.

Fabricated parts by the developed WLAM systems: (a) helical screw and propeller fabricated by the robotized laser-wire direct metal deposition system (reprinted from figures of reference 191 with permission) [191], (b) Ti–6AL–4V structures on curved surfaces fabricated by the WLAM process with a rotary wire feeder (reprinted from figure provided by Ph.D. Jae Gu Kim of KIMM with permission) and (c) cylindrical thin wall structure with a small volume fabricated by a LMWD system with a coaxial wire deposition head (reprinted from figure of reference 61 with permission) [61]

4.3 Wire and Electron Beam Additive Manufacturing (WEAM) Process

4.3.1 Characteristics and Principle of WEAM Processes

The WEAM process uses an electron beam (ebeam) as a thermal energy source. The ebeam is a stream of accelerated electrons with kinetic energy unlike the laser [211]. A thermal energy is generated by a collision between electrons and materials when the ebeam is applied to the material processing [211]. The ebeam is applicable to highly reflective and conductive materials, such as copper, aluminum, etc., [41, 46, 212]. The energy density, the energy efficiency, the scan speed, the penetration depth, and the deposition rate of the ebeam are significantly greater than those of the laser, as shown in Table 2 [24, 46, 62, 63, 69,70,71, 213, 214]. The deposition rate and the layer thickness of the WEAM process are less than 330 g/min and 3000 μm, respectively, as shown in Table 2 [24, 40, 69,70,71]. The WEAM process is also suitable for the fabrication of parts with a large volume. The ebeam gun included a vacuum environment to prevent electron scattering induced by the collisions between electrons and molecules of elements of air [46, 63, 69,70,71,72, 211]. In addition, a vacuum furnace with a protective environment is needed to prevent both electron scattering in the furnace and X-ray irradiation to the operator [46, 63, 69,70,71,72, 211, 214]. The deposition of the material in a vacuum environment ensures clean operation without a consumable shield gas [212]. The vacuum environment can reduce impurities [215].

Two types of ebeam gun, including thermionic and plasma Ebeam guns, are adopted for the WEAM process. Table 9 shows features of a thermionic ebeam (T-ebeam) and a plasma ebeam (P-ebeam). The T-ebeam and the P-ebeam use hot and cold cathodes to generate a stream of free electrons, respectively, as shown in Table 9 [41, 46, 211, 212]. Free electrons are emitted by heating of the filament in the T-ebeam gun, while they are emitted by the collision of the activated ions from the plasma gas into the cold cathode [41, 211, 212]. The emission temperature of the hot cathode is greater than 2200 °C, while that of the cold cathode is nearly room temperature [211]. Hence, the service life of the hot cathode is remarkably short than that of the cold cathode due to evaporation and erosion of the hot cathode, as shown in Table 9 [41, 46, 211, 212]. The T-ebeam gun requires a high level vacuum environment in the range of 10−4 to 10−6 Torrs to avoid oxidation of the cathode material, while the P-ebeam gun needs a low level vacuum environment in the range 10−2 to 10−4 Torrs, as shown in Table 9 [41, 46, 211, 212]. The WEAM system using P-ebeam is cheaper than that using T-ebeam [46]. The typical diameter of the wire for the WEAM ranges from 0.5 mm to 3.0 mm [46]. A coating of the wire using a corrosion-resistive material is needed to prevent oxidation of the wire [46].

4.3.2 Development of Process and System

Research on the WEAM process was initiated by Dave et al. of MIT in U.S.A. [213, 216]. NASA Langley Research Center (LaRC, U.S.A) patented the electron beam freeform fabrication (EBF3) process [24, 46, 69, 212, 214]. The EBF3 process used a T-ebeam gun to weld materials [46, 214, 217]. NASA LaRC developed two types of EBF3 system, including ground-based and portable systems [46, 217]. The ground-based consisted of T-ebeam guns with a maximum acceleration voltage of 60 keV and a dual wire feeder, respectively [46, 217]. The dual wire feeder of the ground-based EBF3 system used to feed either fine or coarse wires to fabricate parts with different feature sizes or two different alloys to create the product with gradient properties [217]. The portable EBF3 system, including a maximum acceleration voltage of 20–30 keV and a single wire feeder, was developed to investigate the influence of the microgravity on the fabrication characteristics [217, 218]. The EBF3 process used an off-axis feeding method of the wire [46, 218]. The EBF3 process has been applied to the deposition of Ni, Ti, Cu, and Al alloys for aerospace application [218].

Sciaky Inc. (U.S.A) patented an electron beam additive manufacturing (EBAM) process using a T-ebeam gun, as shown in Table 10 [46, 69]. Sciaky Inc. collaborated with NASA LaRC to develop the EBAM system [69, 218]. Sciaky Inc. developed several EBAM systems with different deposition volumes to fabricate parts with medium, large and mega scales, as shown in Fig. 13a [46, 69, 215]. The maximum acceleration voltage was more than 60 keV [46, 69, 214]. The maximum power of the EBAM system ranged from 15 kW to 42 kW, as shown in Table 10 [46, 69]. The EBAM systems included a dual wire feeder to create a functionally graded material (FGM) [46, 215]. The structure and the configuration of the EBAM system of Sciaky Inc. were similar to those of the EBF3 system. Sciaky Inc. developed five types of EBAM systems, as shown in Table 10 [46, 69].

Nuclear Advanced Manufacturing Research Center (Nuclear AMRC) of University of Sheffield (U.K) in collaboration with Pro-beam Inc. developed EBAM systems based on the K2000 T-ebeam welding facility [46, 71, 219]. A T-ebeam gun with an acceleration voltage of 80 keV and a maximum power of 40 kW was mounted on a 3-axis CNC controlled gantry system [46, 71, 219]. In addition, a 2-axis rotation table, including turn and tilt table, was installed in the K2000 facility [71, 219]. The deposition rate and the layer thickness of the EBAM system lay in ranges of 0.6–5.7 kg/h and 0.4–1.7 mm, respectively [71, 219]. An off-axis wire feeding method was applied to the EBAM system [71, 219].

NVO Chervona Hvilya Inc. in Ukraine patented a method and a system for manufacturing of three-dimensional objects, referred to as the xbeam process, [46, 63, 70, 220]. Figure 13b illustrates the deposition concept of xBEAM systems [70]. The xbeam system had two key features: (a) a voltage P-ebeam with a hollow conical cathode and (b) a coaxial wire feeding system [46, 63, 70, 214, 220]. The voltage P-ebeam with a conical cathode could reduce vacuum levels of the furnace, X-rays during the deposition, protective facilities for the X-rays, and system costs, while that could improve the service life of the cathode [63, 70, 214]. The coaxial wire feeding system overcame disadvantages of the off-axis feeding system, including porosity in the deposited region and forming of non-uniform metal structures induced by an asymmetrical thermal field as well as difficulties in accurate and stable feeding of the wire caused by internal thermal stress, through omni-directional deposition [63, 214]. The coaxial wire feeding allowed the metal to continuously transfer from the fused end of the wire to the molten pool [214]. The acceleration voltage of the P-ebeam gun for the xBeam system lay in the range of 10–15 keV [214]. The spot diameter of the P-ebeam for the xBeam process was nearly 1 mm [214]. Kovalchuk et al. reported that the service life of the cathode is greater than 1000 h [214]. A low acceleration voltage of the P-ebeam gun created a rather shallow molten pool on the substrate [214]. A low specific power input of the xBeam process greatly decreased residual stresses of fabricated parts [214]. The deposition rate and the surface roughness of the xBeam process were less than 2000 cm3/h and 1 mm, respectively [63, 70]. The minimum wall thickness of the fabricated part by the xBeam process was nearly 1.5 mm [70]. The xBeam process focused on the application of titanium alloy [63, 70, 214]. Kang’s research group of Korea Institute of Industrial Technology (KITECH in Korea) performed fundamental research into the development of a WEAM process using a P-ebeam system.

4.3.3 Effects of Deposition Parameters

The product quality of the WEAM process is influenced by the acceleration voltage, the beam current, the travel speed, the beam diameter, the track overlap ratio, the deposition path, the interpass time, the interlayer dwell time, the wire feeding direction, the feeding angle, the wire tip position, etc., as shown in Fig. 9 [24, 46, 62, 71, 72, 218, 219, 221,222,223,224]. However, so far a few research works on the effects of deposition parameters have been carried out to improve the product quality and the deposition efficiency for WEAM. Taminger et al. investigated the effects of the beam power, the travel speed and the wire feed rate on microstructures and tensile properties of 2219 Al and Ti–6Al–4V parts fabricated by the EBF3 process [212, 217, 218]. They performed feasibility studies on the ability to carry out a post finishing process of parts deposited by the EBF3 process [212, 217, 218]. Wanjara et al. [221] examined the influence of the travel speed and a consecutive re-melting pass on the porosity of the deposited region, the efficient growth rate of the buildup and the height to width ratio of the buildup for the deposition of BNi-2 brazing paste on a stainless steel type 321 substrate using a Sciaky EBAM system. Węglowski et al. [72] studied the effects of the beam current, the acceleration voltage, the travel speed, and the wire feed rate on the width and the height of reinforcement for an EBAM process. Baufeld et al. obtained proper deposition conditions for different materials and shapes using an EBAM process based on K2000 [71, 219]. Kovalchuk and Ivaishin [63] investigated the influence of the deposition length on the residual distortion for the xBeam process. Tarasov et al. [222] examined the effects of the deposition path on microstructure, crystalline lattice parameter and residual strain for the deposition of 304 stainless steel using an experimental EBAM machine. Denlinger et al. [223] developed a thermo-mechanical analysis method based on a finite element analysis to estimate residual stress and distortion of the EBAM process for Ti–6Al–4V. They proposed a reset scheme of the stress and strain to account for stress relaxation during the deposition [223]. They also carried out an inverse simulation to determine the absorption efficiency, the emissivity and the stress relaxation temperature through the comparison of experimental results using a Sciaky system and analytical results [223]. Chen et al. [224] investigate the deposition path in the building direction and the beam current on temperature, distortion and residual stress distributions of a thin-walled Ti–6A–4V part fabricated by the EBF3 process.

4.3.4 Applications and Fabricated Parts

NASA LaRC fabricated aluminum, titanium and nickel alloys parts using the EBF3 process for aerospace applications [212, 217, 218]. Brice et al. [213] successfully produced a Ti–6Al–4V F-22 AMAD bracket using the EBF3 process. NASA LaRC manufactured several generic rocket nozzles with a thin wall, a gradual transition angle and a large volume using the EBF3 process [218]. NASA LaRC produced three types of generic rocket nozzles with a near-net shape, including an In 718 rocket nozzle with a height of 457 mm, a Ti–6Al–4V rocket nozzle with a height of 360 mm, and a Cu–Ni bimetallic nozzle with a height of 460 mm, [218]. In addition, in order to improve the energy efficiency, the stiffness and the acoustic dam**, NASA LaRC created Al 2219 stiffened panels with linear and curvilinear stiffeners for aircraft structures and launch vehicles using the EBF3 process [218].

Sciaky Inc. fabricated various large sized titanium parts using an EBAM system [69, 225]. Sciaky Inc. cooperated with Lockheed Martin Aeronautics and Airbus to fabricate titanium components for US Air Force [46, 69, 225]. Lockheed Martin Aeronautics Inc. in collaboration with Sciaky Inc. developed titanium propellant tanks with a thin wall structure using an EBAM system of Sciaky, as shown in Fig. 14a [69]. They reported that the lead time, the cost and the waste to produce the titanium propellant tanks can be reduced by 80%, 55% and 75%, respectively, when the EBAM system is used [69]. Sciaky Inc. in collaboration with Lockheed Martin Aeronautics Inc. fabricated a F-35 flaperon spar using an EBAM system, as shown in Fig. 14a [69]. Sciaky Inc. forecasted that the manufacturing cost of the flaperon spar can be greatly reduced as compared to the traditional manufacturing process when the EBAM process is adopted [69]. Sciaky Inc in collaboration with Airbus produced a large sized titanium rear upper spar to reduce the lead time and the cost [225]. Nuclear AMRC applied the developed EBAM system to fabricate Ti–6Al–4V, high strength corrosion resistance steel and stainless steel 316L parts [71, 219]. Nuclear AMRC produced several Ti–6Al–4V ducts, a Ti–6Al–4V bowl, a HSCR (High strength corrosion resistant) steel duct, a stainless steel trefoil, etc. using the developed EBAM system [71, 219]. In addition, Nuclear AMRC created steel features on a cylinder [219]. xBeam Inc. fabricated several examples, such as Ti–6Al–4V honeycomb structure, Ti–6Al–4V frame structure, titanium stiffened structure, titanium bracket, etc., using an xBeam system, as shown in Fig. 14b [63, 70, 214]. xBeam Inc. began to develop industrial applications in recent years [70].