Abstract

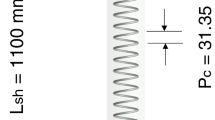

Single-walled carbon nanotube–water nanofluids were tested in a 1–5 TEMA E shell and coil heat exchanger. Cold nanofluid, flowing inside the coil, was heated by hot water flowing in the shell side. Volumetric fraction of nanoparticles, inlet temperature of nanofluid, and mass flow rate of nanofluids ranged from 0 to 0.21%, 2.3 to 23.4 °C, and 40 to 90 g/s, respectively. For a given Reynolds number, at the coil side, pure base fluid (φ = 0%) performed better than low-concentration nanofluid samples (φ = 0.035% and 0.053%) and was nearly equivalent to the nanofluid of highest concentration, φ = 0.21%. The thermal conductivity enhancement factor of the nanofluid ranged from 0 to 0.2 and to 0.45, at inlet temperatures of 30 °C and 50 °C, respectively. It is believed to work in favor of a better performance of the nanofluid samples. On the other hand, the unusual (literature-wise) low temperature of the nanofluid further amplified the enhancement of the nanofluid viscosity, with a reduction effect on the Reynolds number. Besides, other thermal resistances of the heat exchanger work toward an attenuation of the enhancement effect that nanoparticles may have in the heat exchanger performance.

Similar content being viewed by others

Abbreviations

- \(A\) :

-

Area (m2)

- \(a_{0} ,a_{1} \,\) :

-

Coefficients of linear adjustment for thermal conductivity enhancement factor (–)

- \(B\) :

-

Coefficient of heat transfer fluid thermal resistance equation (–)

- \(\dot{C}\) :

-

Thermal capacity rate (kW/K)

- \(\dot{C}_{\min }\) :

-

Minimum thermal capacity rate (kW/K)

- \(c_{{\text{p}}}\) :

-

Specific heat at constant pressure (kJ/kg K)

- \(D\) :

-

Coil diameter (m)

- \(D_{\text{h}}\) :

-

Hydraulic diameter (m)

- \(f\) :

-

Fanning friction factor (–)

- \(F_{t} \,\) :

-

Correction factor for heat exchanger temperature difference (–)

- \(k\) :

-

Thermal conductivity (kW/m K)

- \(L\) :

-

Coil total length (m)

- \(m\) :

-

Exponent of heat transfer fluid thermal resistance equation (–)

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- \(\dot{m}_{{{\text{sf}}}}^{{}}\) :

-

Secondary fluid mass flow rate (kg/s)

- \({\text{NTU}}\) :

-

Number of transfer units (–)

- \(P\) :

-

Pressure (kPa)

- \(\dot{Q}\) :

-

Heat transfer rate (kW)

- \(R\) :

-

Thermal resistance (K/kW)

- \(R_{{{\text{nf}}}}\) :

-

Thermal resistance in the nanofluid side (K/kW)

- \(R_{{{\text{UA}}}}\) :

-

Thermal resistance due to the heat exchanger conductance (K/kW)

- \({\text{Re}}\) :

-

Reynolds number (–)

- \(T\) :

-

Temperature (°C)

- \(T_{{{\text{sf}}\_{\text{cold}}}}\) :

-

Temperature of the cold side of the secondary fluid circuit (°C)

- \(T_{{{\text{sf}}\_{\text{hot}}}}\) :

-

Temperature of the hot side of the secondary fluid circuit (°C)

- \(T_{{{\text{sf}}\_{\text{in}}}}\) :

-

Temperature of secondary fluid entering the evaporator (°C)

- \(T_{{{\text{sf}}\_{\text{out}}}}\) :

-

Temperature of the secondary fluid leaving the evaporator (°C)

- \(T_{{{\text{w}}\_{\text{in}}}}\) :

-

Water inlet temperature (°C)

- \(T_{{{\text{w}}\_{\text{out}}}}\) :

-

Water outlet temperature (°C)

- \(T_{{{1} }}\) :

-

Compressor refrigerant inlet temperature (°C)

- \(T_{3}\) :

-

Condenser refrigerant outlet temperature (°C)

- \(U\) :

-

Overall heat transfer coefficient (kW/m2 K)

- \({\text{UA}}\) :

-

Heat exchanger overall conductance (kW/K)

- \({\text{wt}}\) :

-

Mass fraction of nanoparticles (%)

- \(x_{n}\) :

-

Generic measured parameter of Eq. (18)

- EEV:

-

Electronic expansion valve

- HCT:

-

Helically coiled tube heat exchanger

- LMTD:

-

Logarithmic mean temperature difference

- MWCNT:

-

Multi-walled carbon nanotube

- SCHX:

-

Shell and coil heat exchanger

- SMWCNT:

-

Single-walled carbon nanotube

- TEMA:

-

Tubular exchanger manufacturers association

- \(\alpha\) :

-

Heat transfer coefficient (kW/m2 K)

- \(\Delta T_{a}\) :

-

Temperature difference between fluids at side a of the heat exchanger (K)

- \(\Delta T_{b}\) :

-

Temperature difference between fluids at side b of the heat exchanger (K)

- \(\overline{\Delta T}_{\ln }\) :

-

Logarithmic mean temperature difference (K)

- \(\varepsilon\) :

-

Heat exchanger effectiveness (–)

- \(\mu\) :

-

Dynamic viscosity (kg/m s)

- \(\rho\) :

-

Density (kg/m3)

- \(\varphi\) :

-

Volumetric fraction of nanoparticle (%)

- \(\eta_{\text{p}}\) :

-

Pump efficiency (–)

- \(\xi_{k}\) :

-

Nanofluid thermal conductivity enhancement factor (–)

- \(\xi_{\mu }\) :

-

Nanofluid dynamic viscosity enhancement factor (–)

- a, b:

-

Physical sides of the heat exchanger

- bf:

-

Base fluid

- HTF:

-

Heat transfer fluid

- i:

-

Inner

- in:

-

Inlet

- k:

-

Thermal conductivity

- K:

-

In Kelvin (for temperatures)

- loss:

-

Relative to heat loss across the heat exchanger shell

- min:

-

Minimum

- nf:

-

Nanofluid

- np:

-

Nanotube

- o:

-

Outer

- out:

-

Outlet

- t:

-

t

- w:

-

Water

- wt:

-

Water

- µ :

-

Viscosity

References

Cheng L, Bandarra Filho EP, Thome JR (2008) Nanofluid two-phase flow and thermal physics: a new research frontier of nanotechnology and its challenges. J Nanosci Nanotechnol 8(7):3315–3332. https://doi.org/10.1166/jnn.2008.413

Saidur R, Leong KY, Mohammad HA (2011) A review on applications and challenges of nanofluids. Renew Sustain Energy Rev 15:1646–1668. https://doi.org/10.1016/j.rser.2010.11.035

Choi SUS (1995) Developments and applications of non-Newtonian flows. ASME FED 231(66):99–103

Sidik NAC, Mohammed HA, Alawi OA, Samion S (2014) A review on preparation methods and challenges of nanofluids. Int Commun Heat Mass Transf 54:115–125. https://doi.org/10.1016/j.icheatmasstransfer.2014.03.002

Angayarkanni SA, Philip J (2015) Review on thermal properties of nanofluids: recent developments. Adv Colloid Interface Sci 225:146–176. https://doi.org/10.1016/j.cis.2015.08.0140001-8686

Vatani A, Woodfield PL, Dao DV (2015) A survey of practical equations for prediction of effective thermal conductivity of spherical–particle nanofluids. J Mol Liq 211:712–733. https://doi.org/10.1016/j.molliq.2015.07.043

Mishra PC, Mukherjee S, Nayak SK, Panda A (2014) A brief review on viscosity of nanofluids. Int Nano Lett 4:109–120. https://doi.org/10.1007/s40089-014-0126-3

Shahrul IM, Mahbubul IM, Khaleduzzaman SS, Saidur RR, Sabri MFM (2014) A comparative review on the specific heat of nanofluids for energy perspective. Renew Sustain Energy Rev 38:88–98. https://doi.org/10.1016/j.rser.2014.05.081

Solangi KH, Kazi SN, Luhur MR, Badarudin A, Amiri A, Sadri R, Zubir MNM, Gharehkhani S, Teng KH (2015) A comprehensive review of thermo-physical properties and convective heat transfer to nanofluids. Energy 89:1065–1086. https://doi.org/10.1016/j.energy.2015.06.105

Gupta M et al (2017) A review on thermophysical properties of nanofluids and heat transfer applications. Renew Sustain Energy Rev 74:638–670. https://doi.org/10.1016/j.rser.2017.02.073

Paul G, Pal T, Manna I (2010) Thermo-physical property measurement of nano-gold dispersed water based nanofluids prepared by chemical precipitation technique. J Colloid Interface Sci 349(1):434–437. https://doi.org/10.1016/j.jcis.2010.05.086

Teng TP, Hung YH, Teng TC, Mo HE, Hsu HG (2010) The effect of alumina/water nanofluid particle size on thermal conductivity. Appl Therm Eng 30(14):2213–2218. https://doi.org/10.1016/j.applthermaleng.2010.05.036

**e H, Wang J, ** T, Liu Y, Ai F, Wu Q (2002) Thermal conductivity enhancement of suspensions containing nanosized alumina particles. J Appl Phys 91(7):4568–72. https://doi.org/10.1063/1.1454184

Li XF, Zhu DS, Wang XJ, Wang N, Gao JW, Li H (2008) Thermal conductivity enhancement dependent pH and chemical surfactant for Cu–H2O nanofluids. Thermochim Acta 469(1):98–103. https://doi.org/10.1016/j.tca.2008.01.008

Zhu D, Li X, Wang N, Wang X, Gao J, Li H (2009) Dispersion behaviour and thermal conductivity characteristics of Al2O3–H2O nanofluids. Curr Appl Phys 9(1):131–139. https://doi.org/10.1016/j.cap.2007.12.008

Keblinski P, Phillpot SR, Choi SUS, Eastman JA (2002) Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). Int J Heat Mass Transf 45(4):855–863. https://doi.org/10.1016/S0017-9310(01)00175-2

Hong KS, Hong TK, Yang HS (2006) Thermal conductivity of Fe nanofluids depending on the cluster size of nanoparticles. Appl Phys Lett 88(3):031901. https://doi.org/10.1063/1.2166199

Verma SK, Tiwari AK (2015) Progress of nanofluid application in solar collectors: a review. Energy Convers Manag 100:324–346. https://doi.org/10.1016/j.enconman.2015.04.071

Islam MR, Shabani B, Rosengarten G, Andrews J (2015) The potential of using nanofluids in PEM fuel cell cooling systems: a review. Renew Sustain Energy Rev 48:523–539. https://doi.org/10.1016/j.rser.2015.04.018

Sidik NAC, Yazid MNAWM, Mamat R (2015) A review on the application of nanofluids in vehicle engine cooling system. Int Commun Heat Mass Transf 68:85–90. https://doi.org/10.1016/j.icheatmasstransfer.2015.08.017

Hussein AM, Sharma KV, Bakar RA, Kadirgama K (2014) A review of forced convection heat transfer enhancement and hydrodynamic characteristics of a nanofluid. Renew Sustain Energy Rev 29:734–743. https://doi.org/10.1016/j.rser.2013.08.014

Pandya NS, Shah H, Molana M, Tiwari AK (2020) Heat transfer enhancement with nanofluids in plate heat exchangers: a comprehensive review. Eur J Mech B/Fluids 81:173–190. https://doi.org/10.1016/j.euromechflu.2020.02.004

Kumar H, Sokhal GS (2020) Effect of geometries and nanofluids on heat transfer and pressure drop in microchannels: a review. Mater Today Proc 28(part 3):1841–1846

Wen D, Ding Y (2004) Experimental investigation into convective heat transfer of nanofluids at the entrance region under laminar flow conditions. Int J Heat Mass Transf 47(24):5181–5518. https://doi.org/10.1016/j.ijheatmasstransfer.2004.07.012

Sozen A, Variyenli HI, Ozdemir MB, Gürü M (2016) Improving the thermal performance of parallel and cross-flow concentric tube heat exchangers using fly-ash nanofluid. Heat Transf Eng 37:805–813. https://doi.org/10.1080/01457632.2015.1080574

Shahrul IM, Mahbubul IM, Saidur R, Sabri MFM (2016) Experimental investigation on Al2O3–W, SiO2–W and ZnO–W nanofluids and their application in a shell and tube heat exchanger. Int J Heat Mass Transf 97:547–558. https://doi.org/10.1016/j.ijheatmasstransfer.2016.02.016

Elshazly KM, Sakr RY, Ali RK, Salem MR (2017) Effect of γ-Al2O3/water nanofluid on the thermal performance of shell and coil heat exchanger with different coil torsions. Heat Mass Transf 53:1893–1903. https://doi.org/10.1007/s00231-016-1949-4

Shahrul IM, Mahbubul IM, Saidur R, Khaleduzzaman SS, Sabri MFM (2016) Performance evaluation of a shell and tube heat exchanger operated with oxide based nanofluids. Heat Mass Transf 52:1425–1433. https://doi.org/10.1007/s00231-015-1664-6

Barzegarian R, Aloueyan A, Yousefi T (2017) Thermal performance augmentation using water based Al2O3-gamma nanofluid in a horizontal shell and tube heat exchanger under forced circulation. Int Commun Heat Mass Transf 86:52–59. https://doi.org/10.1016/j.icheatmasstransfer.2017.05.021

Farajollahi B, Etemad SG, Hojjat M (2010) Heat transfer of nanofluids in a shell and tube heat exchanger. Int J Heat Mass Transf 53:12–17. https://doi.org/10.1016/j.ijheatmasstransfer.2009.10.019

Leong KY, Saidur R, Mahlia TMI, Yau YH (2012) Modeling of shell and tube heat recovery exchanger operated with nanofluid based coolants. Int J Heat Mass Transf 55:808–816. https://doi.org/10.1016/j.ijheatmasstransfer.2011.10.027

Raja M, Arunachalam RM, Suresh S (2012) Experimental studies on heat transfer of alumina/water nanofluid in a shell and tube heat exchanger with wire coil insert. Int J Mech Mater Eng 7:16–23

Akhtari M, Haghshenasfard M, Talaie MR (2013) Numerical and experimental investigation of heat transfer of γ-Al2O3/water nanofluid in double pipe and shell and tube heat exchangers. J Numer Heat Transf A 63:941–958. https://doi.org/10.1080/10407782.2013.772855

Elias MM, Miqdad M, Mahbubul IM, Saidur R, Kamalisarvestani M, Sohel MR, Hepbasli A, Rahim NA, Amalina MA (2013) Effect of nanoparticle shape on the heat transfer and thermo-dynamic performance of a shell and tube heat exchanger. Int Commun Heat Mass Transf 44:93–99. https://doi.org/10.1016/j.icheatmasstransfer.2013.03.014

Godson L, Deepak K, Enoch C, Jefferson B, Raja B (2014) Heat transfer characteristics of silver/water nanofluids in a shell and tube heat exchanger. Arch Civ Mech Eng 14:489–496. https://doi.org/10.1016/j.acme.2013.08.002

Dharmalingam R, Sivagnanaprabhu KK, Yogaraja J, Gunasekaran S, Mohan R (2015) Experimental investigation of heat transfer characteristics of nanofluid using parallel flow, counter flow and shell and tube heat exchanger. Arch Mech Eng LXII:509–522. https://doi.org/10.1515/meceng-2015-0028

Aghabozorg MH, Rashidi A, Mohammadi S (2016) Experimental investigation of heat transfer enhancement of Fe2O3–CNT/water magnetic nanofluids under laminar, transient and turbulent flow inside a horizontal shell and tube heat exchanger. Exp Therm Fluid Sci 72:182–189. https://doi.org/10.1016/j.expthermflusci.2015.11.011

Kumar N, Sonawane SS (2016) Experimental study of Fe2O3/water and Fe2O3/ethylene glycol nanofluid heat transfer enhancement in a shell and tube heat exchanger. Int Commun Heat Mass Transf 78:277–284. https://doi.org/10.1016/j.icheatmasstransfer.2016.09.009

Hosseini SM, Vafajoo L, Salman BH (2016) Performance of CNT–water nanofluid as coolant fluid in shell and tube intercooler of a LPG absorber tower. Int J Heat Mass Transf 102:45–53. https://doi.org/10.1016/j.ijheatmasstransfer.2016.05.071

Nallusamy S, Prabu NM (2017) Heat transfer enhancement analysis of Al2O3–water nanofluid through parallel and counter flow in shell and tube heat exchangers. Int J Nanosci 16:1750020. https://doi.org/10.1142/S0219581X1750020X

Haque AKMM, Kim S, Kim J, Noh J, Huh S, Choi B, Chung H, Jeong H (2018) Forced convective heat transfer of aqueous Al2O3 nanofluid through shell and tube heat exchanger. J Nanosci Nanotechnol 18(3):1730–1740. https://doi.org/10.1166/jnn.2018.14216

Said Z, Rahman SMA, Assad MEH, Alami AH (2019) Heat transfer enhancement and life cycle analysis of a shell-and-tube heat exchanger using stable CuO/water nanofluid. Sustain Energy Technol Assess 31:306–317. https://doi.org/10.1016/j.seta.2018.12.020

Albadr J, Tayal S, Alasadi M (2013) Heat transfer through heat exchanger using Al2O3 nanofluid at different concentrations. Case Stud Therm Eng 1:38–44. https://doi.org/10.1016/j.csite.2013.08.004

Anoop K, Cox J, Sadr R (2013) Thermal evaluation of nanofluids in heat exchangers. Int Commun Heat Mass Transf 49:5–9. https://doi.org/10.1016/j.icheatmasstransfer.2013.10.002

Singh SK, Sarkar J (2020) Improvement in energy performance of tubular heat exchangers using nanofluids: a review. Curr Nanosci 16(2):136–156. https://doi.org/10.2174/1573413715666190715101044

Sonawane SS, Khedkar RS, Wasewar KL (2013) Study on concentric tube heat exchanger heat transfer performance using Al2O3–water based nanofluids. Int Commun Heat Mass Transf 49:60–68. https://doi.org/10.1016/j.icheatmasstransfer.2013.10.001

El-Maghlany WM, Hanafy AA, Hassan AA, El-Magid MA (2016) Experimental study of Cu–water nanofluid heat transfer and pressure drop in a horizontal double-tube heat exchanger. Exp Therm Fluid Sci 78:100–111. https://doi.org/10.1016/j.expthermflusci.2016.05.015

Sozen A, Variyenli HI, Ozdemir MB, Gürü M, Aytaç I (2016) Heat transfer enhancement using alumina and fly ash nanofluids in parallel and cross-flow concentric tube heat exchangers. J Eng Inst 89:414–424. https://doi.org/10.1016/j.joei.2015.02.012

Maddhah H, Aghayari R, Mirzaee M, Ahmadi MH, Sadeghzadeh M, Chamkha AJ (2018) Factorial experimental design for the thermal performance of a double pipe heat exchanger using Al2O3–TiO2 hybrid nanofluid. Int Commun Heat Mass Transf 97:92–102. https://doi.org/10.1016/j.icheatmasstransfer.2018.07.002

Kumar NTR, Bhramara P, Addis BM, Sundar LS, Singh MK, Sousa ACM (2017) Heat transfer, friction factor and effectiveness analysis of Fe3O4/water nanofluid flow in a double pipe heat exchanger with return bend. Int Commun Heat Mass Transf 81:155–163. https://doi.org/10.1016/j.icheatmasstransfer.2016.12.019

Qi C, Luo T, Liu M, Fan F, Yan Y (2019) Experimental study on the flow and heat transfer characteristics of nanofluids in double-tube heat exchangers based on thermal efficiency assessment. Energy Convers Manag 197:111877. https://doi.org/10.1016/j.enconman.2019.111877

Singh SK, Sarkar J (2020) Improving hydrothermal performance of double-tube heat exchanger with modified twisted tape inserts using hybrid nanofluid. J Therm Anal Calorim. https://doi.org/10.1007/s10973-020-09380-w

Chun BH, Kang HU, Kim SH (2008) Effect of alumina nanoparticles in the fluid on heat transfer in double-pipe heat exchanger system. Korean J Chem Eng 25:966–971. https://doi.org/10.1007/s11814-008-0156-5

Huminic G, Huminic A (2011) Heat transfer characteristics in double tube helical heat exchangers using nanofluids. Int J Heat Mass Transf 54:4280–4287. https://doi.org/10.1016/j.ijheatmasstransfer.2011.05.017

Zamzamian A, Oskouie SN, Doosthoseini A, Joneidi A, Pazouki M (2011) Experimental investigation of forced convective heat transfer coefficient in nanofluids of Al2O3/EG and CuO/EG in a double pipe and plate heat exchangers under turbulent flow. Exp Therm Fluid Sci 35:495–502. https://doi.org/10.1016/j.expthermflusci.2010.11.013

Wu Z, Wang L, Sundén B (2013) Pressure drop and convective heat transfer of water and nanofluids in a double-pipe helical heat exchanger. Appl Therm Eng 60:266–274. https://doi.org/10.1016/j.applthermaleng.2013.06.051

Darzi AAR, Farhadi M, Sedighi K (2013) Heat transfer and flow characteristics of Al2O3–water nanofluid in a double tube heat exchanger. Int Commun Heat Mass Transf 47:105–112. https://doi.org/10.1016/j.icheatmasstransfer.2013.06.003

Mohammed HA, Hasan HA, Wahid MA (2013) Heat transfer enhancement of nanofluids in a double pipe heat exchanger with louvered strip insert. Int Commun Heat Mass Transf 40:36–46. https://doi.org/10.1016/j.icheatmasstransfer.2012.10.023

Maddah H, Alizadeh M, Ghasemi N, Alwi SRW (2014) Experimental study of Al2O3/water nanofluid turbulent heat transfer enhancement in the horizontal double pipes fitted with modified twisted tapes. Int J Heat Mass Transf 78:1042–1054. https://doi.org/10.1016/j.ijheatmasstransfer.2014.07.059

Rao VV, Reddy MC (2014) Experimental investigation of heat transfer coefficient and friction factor of ethylene glycol water based TiO2 nanofluid in double pipe heat exchanger with and without helical coil inserts. Int Commun Heat Mass Transf 50:68–76. https://doi.org/10.1016/j.icheatmasstransfer.2013.11.002

Sarafraz MM, Hormozi F (2015) Intensification of forced convection heat transfer using biological nanofluid in a double-pipe heat exchanger. Exp Therm Fluid Sci 66:279–289. https://doi.org/10.1016/j.expthermflusci.2015.03.028

Jafarimoghaddam A, Aberoumand S, Aberoumand H, Javaherdeh K (2017) Experimental study on Cu/oil nanofluids through concentric annular tube: a correlation. Heat Trans Asian Res 46:251–260. https://doi.org/10.1002/htj.21210

Kumar NTR, Bhramara P, Sundar LS, Singh MK, Sousa ACM (2017) Heat transfer, friction factor and effectiveness of Fe3O4 nanofluid flow in an inner tube of double pipe U-bend heat exchanger with and without longitudinal strip inserts. Exp Therm Fluid Sci 85:331–343. https://doi.org/10.1016/j.expthermflusci.2017.03.019

Hussein AM (2017) Thermal performance and thermal properties of hybrid nanofluid laminar flow in a double pipe heat exchanger. Exp Therm Fluid Sci 88:37–45. https://doi.org/10.1016/j.expthermflusci.2017.05.015

Akyurek EF, Gelis K, Sahin B, Manay E (2018) Experimental analysis for heat transfer of nanofluid with wire coil turbulators in a concentric tube heat exchanger. Results Phys 9:376–389. https://doi.org/10.1016/j.rinp.2018.02.067

Bahiraei M, Jamshidmofid M, Heshmatian S (2017) Entropy generation in a heat exchanger working with a biological nanofluid considering heterogeneous particle distribution. Adv Powder Technol 28:2380–2392. https://doi.org/10.1016/j.apt.2017.06.021

Fakoor-Pakdaman M, Akhavan-Behabadi MA, Razi P (2013) An empirical study on the pressure drop characteristics of nanofluid flow inside helically coiled tubes. Int J Therm Sci 65:206–213. https://doi.org/10.1016/j.ijthermalsci.2012.10.014

Kumar PCM, Kumar J, Tamilarasan R, Nathan SS, Suresh S (2014) Heat transfer enhancement and pressure drop analysis in a helically coiled tube using Al2O3/water nanofluid. J Mech Sci Technol 28:1841–1847. https://doi.org/10.1007/s12206-014-0331-z

Salem MR, Ali RK, Sakr RY, Elshazly KM (2015) Effect of γ-Al2O3/water nanofluid on heat transfer and pressure drop characteristics of shell and coil heat exchanger with different coil curvatures. J Therm Sci Eng Appl 7:1–9. https://doi.org/10.1115/1.4030635

Srinivas T, Vinod AV (2016) Heat transfer intensification in a shell and helical coil heat exchanger using water-based nanofluids. Chem Eng Process 102:1–8. https://doi.org/10.1016/j.cep.2016.01.005

Naik BAK, Vinod AV (2018) Heat transfer enhancement using non-Newtonian nanofluids in a shell and helical coil heat exchanger. Exp Therm Fluid Sci 90:132–142. https://doi.org/10.1016/j.expthermflusci.2017.09.013

Sarafraz MM, Hormozi F, Nikkhah V (2016) Thermal performance of a counter-current double pipe heat exchanger working with COOH–CNT/water nanofluids. Exp Therm Fluid Sci 78:41–49. https://doi.org/10.1016/j.expthermflusci.2016.05.014

Goodarzi M, Kherbeet AS, Afrand M, Sadeghinezhad E, Mehrali M, Zahedi P, Wongwises S, Dahari M (2016) Investigation of heat transfer performance and friction factor of a counter-flow double-pipe heat exchanger using nitrogen-doped, graphene-based nanofluids. Int Commun Heat Mass Transf 76:16–23. https://doi.org/10.1016/j.icheatmasstransfer.2016.05.018

Hosseinian A, Isfahani AHM, Shiran E (2018) Experimental investigation of surface vibration effects on increasing the stability and heat transfer coefficient of MWCNTs–water nanofluid in a flexible double pipe heat exchanger. Exp Therm Fluid Sci 90:275–285. https://doi.org/10.1016/j.expthermflusci.2017.09.018

Kumaresan V, Velraj R, Das SK (2012) Convective heat transfer characteristics of secondary refrigerant based CNT nanofluids in a tubular heat exchanger. Int J Refrig 35:2287–2296. https://doi.org/10.1016/j.ijrefrig.2012.08.009

Lotfi R, Rashidi AM, Amrollahi A (2012) Experimental study on the heat transfer enhancement of MWNT–water nanofluid in a shell and tube heat exchanger. Int Commun Heat Mass Transf 39(1):108–111. https://doi.org/10.1016/j.icheatmasstransfer.2011.10.002

Esfahani MR, Languri EM (2017) Exergy analysis of a shell-and-tube heat exchanger using graphene oxide nanofluids. Exp Therm Fluid Sci 83:100–106. https://doi.org/10.1016/j.expthermflusci.2016.12.004

Fares M, Mohammad AL-M, Mohammed AL-S (2020) Heat transfer analysis of a shell and tube heat exchanger operated with graphene nanofluids. Case Stud Therm Eng 18:100584. https://doi.org/10.1016/j.csite.2020.100584

Lotfi R, Rashidi AM, Amrollahi A (2012) Experimental study on the heat transfer enhancement of MWNT–water nanofluid in a shell and tube heat exchanger. Int Commun Heat Mass Transf 39:108–111. https://doi.org/10.1016/j.icheatmasstransfer.2011.10.002

Ghozatloo A, Rashidi A, Niassar MS (2014) Convective heat transfer enhancement of graphene nanofluids in shell and tube heat exchanger. Exp Therm Fluid Sci 53:136–141. https://doi.org/10.1016/j.expthermflusci.2013.11.018

Raveendran PS, Sekhar SJ (2019) Investigation on the energy and exergy efficiencies of a domestic refrigerator retrofitted with water-cooled condensers of shell-and-coil and brazed-plate heat exchangers. J Therm Anal Calorim 136(1):381–388. https://doi.org/10.1007/s10973-018-7742-5

Said Z (2016) Thermophysical and optical properties of SWCNTs nanofluids. Int Commun Heat Mass Transf 78:207–213

Iijima S, Ichihashi T (1993) Single-shell carbon nanotubes of 1-nm diameter. Nature 363:603–605

Choi S, Zhang Z, Yu W, Lockwood F, Grulke E (2001) Anomalous thermal conductivity enhancement in nanotube suspensions. Appl Phys Lett 79(14):2252–2254

Gómez AOC, Alegrias JGP, Bandarra Filho EP (2017) Experimental analysis of the thermal-hydraulic performance of water based silver and SWCNT nanofluids in single-phase flow. Appl Therm Eng 124:1176–1188. https://doi.org/10.1016/j.applthermaleng.2017.06.090

Vasconcelos AA, Gómez AOC, Bandarra Filho EP, Parise JAR (2017) Experimental evaluation of SWCNT–water nanofluid as a secondary fluid in a refrigeration system. Appl Therm Eng 111:1487–1492. https://doi.org/10.1016/j.applthermaleng.2016.06.126

Kern DK (1950) Process heat transfer. McGraw-Hill Kogakusha Ltd., Tokyo

Kline SJ, McClintock FA (1953) Describing uncertainties in single-sample experiments. Mech Eng 75:3–8

Bryning MB, Milkie DE, Islam MF, Kikkawa JM, Yodh AG (2005) Thermal conductivity and interfacial resistance in single-wall carbon nanotube epoxy composites. Appl Phys Lett 87(161909):1–3. https://doi.org/10.1063/1.2103398

**ng M, Yu J, Wang R (2015) Thermo-physical properties of water-based single-walled carbon nanotube nanofluid as advanced coolant. Appl Therm Eng 87:344–351. https://doi.org/10.1016/j.applthermaleng.2015.05.033

Sabiha MA, Saidur R, Hassani S, Said Z, Mekhilef S (2015) Energy performance of an evacuated tube solar collector using single walled carbon nanotubes nanofluids. Energy Convers Manag 105:1377–1388. https://doi.org/10.1016/j.enconman.2015.09.009

Acknowledgements

The authors are indebted to CNPq, CAPES, FAPERJ, and FAPEMIG for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article has been selected for a Topical Issue of this journal on Nanoparticles and Passive-Enhancement Methods in Energy.

Rights and permissions

About this article

Cite this article

Sica, L.U.R., Vasconcelos, A.A., Parise, J.A.R. et al. Thermal performance analysis of a 1–5 TEMA E shell and coil heat exchanger operating with SWCNT–water nanofluid with varied nanoparticle concentration. J Braz. Soc. Mech. Sci. Eng. 43, 122 (2021). https://doi.org/10.1007/s40430-021-02833-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-02833-9