Abstract

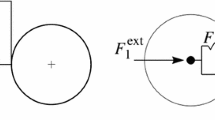

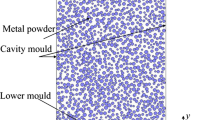

Multi-scale mechanical theory of powder compacting is the foundation for improving the quality of the product made by powder metallurgy. Aimed at powder compacting process, a 2D numerical model of the single-direction granular compacting system is established by the discrete element method. Using this DEM numerical model, the stress–strain responses, directional distributions of velocity vector and distributions of force chains in the compacting stage are studied. Research results show that powder granules successively go through the phase transformation processes of flow state, quasi-static and jamming state in the compacting process. Clearly, it is noted that velocity direction distribution of powder granule is closely related to the granule flow state, and dilatancy behavior of powder granule is a main reason for influencing the velocity direction distribution of powder granules under the quasi-static. The contact normal force, contact tangential force and contact force all comply with a power law forms, and the strength of force chains between powder granules increases with increased inter-granule friction coefficient.

Similar content being viewed by others

References

Bi ZW, Sun QC, Liu JG, ** F, Zhang CH (2011) Development of shear band in a granular material in biaxial tests. Acta Phys Sin 60(3):366–375

Tordesillas A, Lin Q, Zhang J, Behringer RP, Shi JY (2011) Structural stability and jamming of self-organized cluster conformations in dense granular materials. J Mech Phys Solids 59(2):265–296

Elkholy KN, Khonsari MM (2008) Experimental investigation on the stick–slip phenomenon in granular collision lubrication. J Tribol 130(2):319–320

Heshmat H, Brewe D (1995) Performance of powder-lubricated journal bearings with MoS2 powder—experimental study of thermal phenomena. J Tribol 117(3):506–512

Jang JY, Khonsari MM (2006) On the role of enduring contact in powder lubrication. J Tribol 128(1):168–175

Meng FJ, Liu K (2014) Velocity fluctuation and self diffusion character in a dense granular sheared flow studied by discrete element method. Acta Phys Sin 63(13):134502

Hsiau SS, ShiehY M (1999) Fluctuations and self-diffusion of sheared granular material flows. J Rheol 43(5):1049–1066

Zhou L, Khonsari MM (2000) Flow characteristics of a powder lubricant sheared between parallel plates. J Tribol 122(1):147–155

Iordanoff I, Khonsari MM (2004) Granular lubrication: towards an understanding of the transition between kinetic and quasi-fluid regime. J Tribol 126(1):137–145

Kabir MA, Lovell MR, Higgs CF (2008) Utilizing the explicit finite element method for studying granular flows. Tribol Lett 29(2):85–94

Wang W, Liu XJ, Liu K (2012) Experimental research on force transmission of dense granular assembly under shearing in Taylor–Couette geometry. Tribol Lett 48(2):229–236

Nasuno S, Kudrolli A, Bak A, Gollur JP (1998) Time-resolved studies of stick-slip friction in sheared granular layers. Phys Rev E 58(2):2161–2171

AlbertA Tegzes P, Albert R, Sample JG (2001) Stick-slip fluctuations in granular drag. Phys Rev E 64(3):166–168

Fang L, Zhao J, Li B, Sun K (2009) Movement patterns of ellipsoidal particle in abrasive flow machining. J Mater Process Technol 209(20):6048–6056

Jop P, Forterre Y, Pouliquen O (2006) A constitutive law for dense granular flows. Nature 441(7094):727–730

Geng J, Howell D, Longhi E, Behringer RP, Reydellet G (2001) Footprints in sand: the response of a granular material to local perturbations. Phys Rev Lett 87(3):035506

Wang W, Gu W, Liu K (2015) Force chain evolution and force characteristics of shearing granular media in Taylor–Couette geometry by DEM. Tribol Trans 58(2):197–206

Majumdar TS, Behringer RP (2005) Contact force measurements and stress-induced anisotropy in granular materials. Nature 435(7045):1079–1082

Teeentjev EM (2002) Soft matter dynamics-searching for equilibrium. Nat Mater 1(3):149–150

Cundall PA, Strack A (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65

Gu XQ, Yang J, Huang MS (2013) DEM simulations of the small strain stiffness of granular soils: effect of stress ratio. Granular Matter 15(3):287–298

Lu LS, Hsiau SS (2008) DEM simulation of particle mixing in a sheared granular flow. Particuology 7(6):445–454

Radjai F, Jean M, Mroeau JJ, Rous S (1996) Force distributions in dense two-dimensional granular systems. Phys Rev Lett 77(2):274–277

Tao Ma, Zhang DY, Zhang G, Zhao YL, Huang XM (2016) Microstructure modeling and virtual test of asphalt mixture based on three-dimensional discrete element method. J Cent South Univ 23(6):1525–1534

Cao MY, Peng YX, Zhao CC, Dong GJ, Du B (2016) Frictional characteristics of granular system under high pressure. J Cent South Univ 23(5):1132–1141

Giulio B (2007) Jamming-a new kind of phase transition. Nat Phys 3(4):222–223

Campbell CS (2006) Granular material flows—an overview. Powder Technol 162(3):208–229

Meng FJ, Liu K, Wang W (2015) The force chains and dynamic states of granular flow lubrication. Tribol Trans 58(1):70–78

Wang F, Liu K, Wang W (2014) Simulation of jamming phenomenon of granular matter under single-direction pressing process. Chin J Appl Mech 31(3):400–406

Mehmet BC, Khalid AA (2014) 3D analysis of kinematic behavior of granular materials in triaxial testing using DEM with flexible membrane boundary. Acta Geotech 9(2):287–298

Wang F (2014) Research on jamming phenomenon in powder material compaction. Hefei University of Technology, Hefei

Jasti V, Fred HC (2008) Experimental study of granular flows in a rough annular shear cell. Phys Rev E 78(4 Pt 1):041306

Bi ZW, Sun QC, Liu JG, ** F, Zhang CH (2011) Development of shear band in a granular material in biaxial tests. Acta Phys Sin 60(3):366–375

Meng FJ, Liu K, Tang ZQ, Wang W, Liu XJ (2014) Multiscale mechanical research in a dense granular system between sheared parallel plates. Phys Scr 89(10):105702

Yang ZX, Yang J, Wang LZ (2012) On the influence of inter-particle friction and dilatancy in granular materials: a numerical analysis. Granular Matter 14(3):433–447

Majmudar TS, Behringer RP (2005) Contact force measurements and stress-induced anisotropy in granular materials. Nature 435(23):1079–1082

Acknowledgements

The authors wish to thank the financial support from the National Natural Science Foundation of China under Grant No. 51605150 and Grant No. 11472096.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Paulo de Tarso Rocha de Mendonça.

Rights and permissions

About this article

Cite this article

Meng, F., Liu, K. & Qin, T. Numerical analysis of multi-scale mechanical theory of densified powder compaction. J Braz. Soc. Mech. Sci. Eng. 40, 430 (2018). https://doi.org/10.1007/s40430-018-1337-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1337-8