Abstract

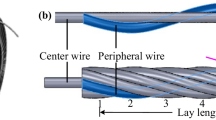

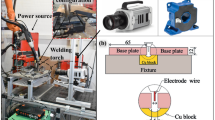

This article evaluates the performance of the cold-wire gas metal arc welding (CW-GMAW) process for narrow gap girth welding. The CW-GMAW process is characterized by the introduction of a continuously fed non-energized wire (cold-wire) into the electric arc/weld pool region. The cold-wire is melted by using the surplus heat available at the arc and molten metal at the weld pool. Narrow grooves 5 mm wide were prepared in 16 mm thick ASTM A131 grade A steel plates and filled using the CW-GMAW process. The feasibility of the process for narrow gap welding was assessed by analysing the joint cross section, microstructure and Vickers hardness. The mechanism by which the cold-wire prevents groove sidewall erosion is identified by using high speed imaging. It was found that for the CW-GMAW, the electric arc attaches to the cold-wire instead of the weld pool leading to a more stable arc, preventing the arc from attaching to the groove sidewall. The additional weld metal deposited by the cold wire, allowed complete filling of the groove with only three passes, demonstrating the productivity potential of the CW-GMAW process for narrow groove welding.

Similar content being viewed by others

References

Norrish J (2006) Narrow-gap welding techniques. in advanced welding processes, Chapter 9, vol 1. Woodhead Publishing Limited, Cambridge, pp 165–178

Nakamura T, Hiraoka K (2001) Ultranarrow GMAW process with newly developed wire melting control system. Sci Technol Weld Join 6(6):355–362

Liu L, Fang D, Song G (2015) Experimental investigation of wire arrangements for Narrow-Gap Triple-Wire gas indirect arc welding. Mater Manuf Process 6914(2016):1–7

Phaonaim R, Yamamoto M, Shinozaki K, Yamamoto M, Kadoi K (2013) Development of a heat source model for narrow-gap hot-wire laser welding. Yosetsu Gakkai Ronbunshu/Quarterly Journal of the Japan Welding Society 31(4):3–6

Malin VY (1987) Monograph on Narrow-Gap Welding technology. Technical report, Welding Research Council (WRC), New York

Li R, Yue J, Sun R, Mi G, Wang C, Shao X (2016) A study of droplet transfer behavior in ultra-narrow gap laser arc hybrid welding. Int J Adv Manuf Technol 87(9):2997–3008

Ribeiro RA, Santos EBF, Assunção PDC, Maciel RR, Braga EM (2015) Predicting weld bead geometry in the novel CW-GMAW process. Weld J 94(September):301s–311s

Cabral TS, Braga EM, Mendonça EAM, Scotti A (2015) Influence of procedures and transfer modes in MAG welding in the reduction of deformations on marine structure panels. Weld Int 29(12):928–936

Marques LFN, Dos Santos EBF, Braga EM, Gerlich AP (2017) Fatigue life assessment of weld joints manufactured by GMAW and CW-GMAW processes. Sci Technol Weld Join 22(2):87– 96

AWS (2005) Specification for carbon steel electrodes and rods for gas shielded arc welding. American Welding Society (AWS) , Miami

Häßler M, Rose S, Füssel U (2016) The influence of arc interactions and a central filler wire on shielding gas flow in tandem GMAW. Welding in the World 60(4):713–718

**ang T, Li H, Wei HL, Gao Y (2016) Effects of filling status of cold wire on the welding process stability in twin-arc integrated cold wire hybrid welding. Int J Adv Manuf Technol 83(9–12):1583–1593

Acknowledgments

The authors would like to acknowledge Natural Science and Engineering Research Council of Canada (NSERC) and TransCanada Pipelines Ltd. for the financial support. E.M. Braga and P.D.C. Assunção would like to thank the Brazilian National Council for Scientific and Technological Development (CNPq) for the financial support through the grant number 01.11.0024.00.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission II - Arc Welding and Filler Metals

This work was supported by the Brazilian National Council for Scientific and Technological Development (CNPq) through the grant number 01.11.0024.00.

Rights and permissions

About this article

Cite this article

Costa Assunção, P.D., Ribeiro, R.A., F. Dos Santos, E.B. et al. Feasibility of narrow gap welding using the cold-wire gas metal arc welding (CW-GMAW) process. Weld World 61, 659–666 (2017). https://doi.org/10.1007/s40194-017-0466-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-017-0466-5