Abstract

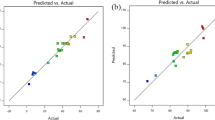

Exploring sustainable energy and chemical sources based on biomass has increased global interest. This study was focused on produce second-generation bioethanol using a new pretreatment process. The effectiveness of sodium hydroxide (NaOH) pretreatment on oil palm empty fruit bunch (OPEFB) for lignin removal, reducing sugar, and bioethanol production at low temperature and pressure was investigated using batch and continuous processes. Response surface methodology (RSM) was used to optimize the NaOH concentration and solid to liquor ratio (SL) at a maximum temperature of 100 °C and atmospheric pressure. The mathematical formula derived from RSM was based on 11 runs of the batch treatment. In the batch treatment process, 2 M NaOH, the temperature of 80 °C, and SL ratio of 8 have resulted in lignin removal of 38.7%, reducing sugars of 8.3%, and bioethanol concentration of 4.1%. The validation of formula has been calculated from calculation and experiment values. Moreover, at the same retention time, continuous pretreatment showed a reducing sugar content of 5.9% and a bioethanol concentration by 2.5%. The results show that the continuous process can be employed in effective bioethanol production from OPEFB.

Graphical abstract

Similar content being viewed by others

References

Tanaka M, Taniguchi M, Morita T, Matsuna R, Kamikubo T (1979) Effect of chemical treatment on solubilization of crystalline cellulose and cellulosic wastes with Pellicularia filamentosa cellulase. J Ferment Technol 57:186–190

Taniguchi M, Tanaka M, Matsuno R, Kamikubo T (1982) Evaluation of chemi- Microbiol., cal pretreatment for enzymatic solubilization of rice straw, Eur. J Appllied Biotechnol 14:35–39

Das AK, Nakagawa-izumi A, Ohi H (2016) Quality evaluation of dissolving pulp fabricated from banana plant stem and its potential for biorefinery. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2016.03.103

Das AK, Nakagawa-izumi A, Ohi H (2015) Evaluation of pulp quality of three non-wood species as alternative raw materials for paper production. Japan Tappi J 69(5):548–554. https://doi.org/10.2524/jtappij.1501

Mosier N et al (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96(6):673–686. https://doi.org/10.1016/j.biortech.2004.06.025

Thamsee T, Choojit S, Cheirsilp B, Yamseangsung R, Ruengpeerakul T, Sangwichien C (2019) Combination of superheated steam explosion and alkaline autoclaving pretreatment for improvement of enzymatic digestibility of the oil palm tree residues as alternative sugar sources. Waste Biomass Valori 10(10):3009–3023. https://doi.org/10.1007/s12649-018-0292-z

Li J et al (2018) Optimization of pretreatment and alkaline cooking of wheat straw on its pulpability using response surface methodology. BioResources 13(1):27–42. https://doi.org/10.15376/biores.13.1.27-42

Tang PL, Hong WL, Yue CS, Harun S (2021) Recovery of lignin and phenolics via one-pot pretreatment of oil palm empty fruit bunch fiber and palm oil mill effluent. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-021-01496-9

Fatriasari W, Raniya R, Oktaviani M, Hermiati E (2018) The improvement of sugar and bioethanol production of oil palm empty fruit bunches (Elaeis guineensis Jacq) through microwave-assisted maleic acid pretreatment. BioResources 13(2):4378–4403. https://doi.org/10.15376/biores.13.2.4378-4403

Vochozka M, Maroušková A, Váchal J, Straková J (2016) Economic and environmental aspects of steam-explosion pretreatment. Waste and Biomass Valorization 7(6):1549–1554. https://doi.org/10.1007/s12649-016-9555-8

Ibrahim Q, Kruse A (2020) Prehydrolysis and organosolv delignification process for the recovery of hemicellulose and lignin from beech wood. Bioresour Technol Reports 11:100506. https://doi.org/10.1016/j.biteb.2020.100506

Yang J, Gao C, Yang X, Su Y, Shi S, Han L (2022) Effect of combined wet alkaline mechanical pretreatment on enzymatic hydrolysis of corn stover and its mechanism. Biotechnol Biofuels Bioprod 15(1):1–11. https://doi.org/10.1186/s13068-022-02130-0

Chen J, Adjallé K, Barnabé S, Perrier M, Paris J (2018) Mechanical and thermal pretreatment processes for increasing sugar production from woody biomass via enzymatic hydrolysis. Waste and Biomass Valorization. https://doi.org/10.1007/s12649-018-0217-x

Galbe M, Zacchi G (2007) Pretreatment of lignocellulosic materials for efficient bioethanol production. Adv Biochem Engin/Biotechnol 108:41–65. https://doi.org/10.1007/10_2007_070

Galbe M, Sassner P, Wingren A, Zacchi G (2007) Process engineering economics of bioethanol production. Adv Biochem Eng Biotechnol 108(June):303–327. https://doi.org/10.1007/10_2007_063

Jeon H et al (2014) Production of anhydrous ethanol using oil palm empty fruit bunch in a pilot plant. Biomass Bioenerg 67:99–107. https://doi.org/10.1016/j.biombioe.2014.04.022

Konan D, Koffi E, Ndao A, Peterson EC, Rodrigue D, Adjallé K (2022) An overview of extrusion as a pretreatment method of lignocellulosic biomass. Energies 15(9). https://doi.org/10.3390/en15093002.

Khan MU, Usman M, Ashraf MA, Dutta N, Luo G, Zhang S (2022) A review of recent advancements in pretreatment techniques of lignocellulosic materials for biogas production: opportunities and limitations. Chem Eng J Adv. 10(November 2021):100263. https://doi.org/10.1016/j.ceja.2022.100263

Karunanithy C, Muthukumarappan K (2010) Influence of extruder temperature and screw speed on pretreatment of corn stover while varying enzymes and their ratios. Appl Biochem Biotechnol 162(1):264–279. https://doi.org/10.1007/s12010-009-8757-y

Jorge M, Roberto G, Karina P, Oliva C, Benjamin R, Cuauhtemocc R (2006) The optimization of the extrusion process when using maize flour with a modified amino acid profile for making tortillas. Int J Food Sci Technol 41:727–736. https://doi.org/10.1111/j.1365-2621.2005.00997.x

Han M, Kang KE, Kim Y, Choi GW (2013) High efficiency bioethanol production from barley straw using a continuous pretreatment reactor. Process Biochem 48(3):488–495. https://doi.org/10.1016/j.procbio.2013.01.007

Zheng J, Rehmann L (2014) Extrusion pretreatment of lignocellulosic biomass: a review. Int J Mol Sci 15:18967–18984. https://doi.org/10.3390/ijms151018967

Conrad M, Häring H, Smirnova I (2021) Design of an industrial autohydrolysis pretreatment plant for annual lignocellulose. Biomass Convers Biorefinery 11(6):2293–2310. https://doi.org/10.1007/s13399-019-00479-1

Statistics I (2022) Plantation area by province (thousand hectares), 2019–2021. https://www.bps.go.id/indicator/54/131/1/luas-tanaman-perkebunan-menurut-provinsi.html.

Gapki (2021) Palm oil industry reflection 2020 and prospects 2021. https://gapki.id/news/18768/refleksi-industri-sawit-2020-prospek-2021.

Hambali E and Rivai M (2017) The potential of palm oil waste biomass in Indonesia in 2020 and 2030, in IOP Conference Series: Earth and Environmental Science. 65:1. https://doi.org/10.1088/1755-1315/65/1/012050

Maryana R et al (2022) Extraction of cellulose acetate from Cajuput (Melaleuca leucadendron) twigs and sugarcane (Saccharum officinarum) bagasse by environmentally friendly approach. Waste Biomass Valori 13(3):1535–1545. https://doi.org/10.1007/s12649-021-01610-y

Marrubini G, Papetti A, Genorini E, Ulrici A (2017) Determination of the sugar content in commercial plant milks by near infrared spectroscopy and Luff-Schoorl total glucose titration. Food Anal Methods 10(5):1556–1567. https://doi.org/10.1007/s12161-016-0713-1

Chin SX et al (2016) Catalytic conversion of empty fruit bunch (EFB) fibres into lactic acid by lead (II) ions. BioResources 11(1):2186–2201. https://doi.org/10.15376/BIORES.11.1.2186-2201

de Marçal AF, de França LF, Corrêa NCF (2019) Hydrothermal treatment of empty fruit buncH (EFB) aimed at increased production of reducing sugars. BioResources 3:6911–6921. https://doi.org/10.15376/biores.13.3.6911-6921

Wyman CE (1996) Handbook on bioethanol : production and utilization, 1st edn. CRC Press, Boca Raton, pp 444

Isci A, Himmelsbach JN, Pometto AL, Raman DR, Anex RP (2008) Aqueous ammonia soaking of switchgrass followed by simultaneous saccharification and fermentation. Appl Biochem Biotechnol 144(1):69–77. https://doi.org/10.1007/s12010-007-8008-z

Fatriasari W et al (2021) Optimization of maleic acid pretreatment of oil palm empty fruit bunches (OPEFB) using response surface methodology to produce reducing sugars. Ind Crops Prod 171(1):113971. https://doi.org/10.1016/j.indcrop.2021.113971

Kim S, Holtzapple MT (2006) Delignification kinetics of corn stover in lime pretreatment. Bioresour Technol 97(5):778–785. https://doi.org/10.1016/j.biortech.2005.04.002

Shatalov AA, Pereira H (2005) Kinetics of organosolv delignification of fibre crop Arundo donax L. Ind Crops Prod 21(2):203–210. https://doi.org/10.1016/j.indcrop.2004.04.010

Wertz JL, Bedue O, Mercier JP (2010) Cellulose science and technology, 1st edn. EPFL Press, Lausanne, pp 350

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. A J Ger Chem Soc. 3358–3393. https://doi.org/10.1002/anie.200460587

Mansfield SD, Mooney C, Saddler JN (1999) Substrate and enzyme characteristics that limit cellulose hydrolysis. Biotechnol Prog 15(5):804–816. https://doi.org/10.1021/bp9900864

Zhu L, O’Dwyer JP, Chang VS, Granda C (2008) Structural features affecting biomass enzymatic digestibility. Bioresour Technol 99(9):3817–3828. https://doi.org/10.1016/j.biortech.2007.07.033

Antczak A, Szadkowski J, Szadkowska D, Zawadzki J (2022) Assessment of the effectiveness of liquid hot water and steam explosion pretreatments of fast-growing poplar (Populus trichocarpa) wood. Wood Sci Technol 56(1):87–109. https://doi.org/10.1007/s00226-021-01350-1

Il Choi W, Oh KK, Park JY, Lee JS (2014) Continuous sodium hydroxide-catalyzed pretreatment of empty fruit bunches (EFB) by continuous twin-screw-driven reactor (CTSR). J Chem Technol Biotechnol 89(2):290–296. https://doi.org/10.1002/jctb.4119

Han M, Choi SMG (2014) Pretreatment solution recycling and high-concentration output for economical production of bioethanol 2205–2213. https://doi.org/10.1007/s00449-014-1198-1

Duque A, Manzanares P, González A, Ballesteros M (2018) Study of the application of alkaline extrusion to the pretreatment of eucalyptus biomass as first step in a bioethanol production process. Energies 11:(11). https://doi.org/10.3390/en11112961.

Funding

The Indonesia Endowment Funds for Education (LPDP) – Ministry of Finance of the Republic of Indonesia provided research grant no. KEP-02/LPDP/LPDP.4/2022 of 2022.

Author information

Authors and Affiliations

Contributions

R.M. and TBB are the main contributors who conceptualized the study and performed pretreatment and study analysis result for XRD. Meanwhile, ARIU prepared the system control. YI and WAR designed the continuous reactor. DMI, ET, and M performed pretreatment and the other experiments. A.K.D. revised and finalized the manuscript. Finally, YS supervised the study.

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human or animal participants.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maryana, R., Bardant, T.B., Ihsan, D.M. et al. Reducing sugars and bioethanol production from oil palm empty fruit bunch by applying a batch and continuous pretreatment process with low temperature and pressure. Biomass Conv. Bioref. 14, 11155–11164 (2024). https://doi.org/10.1007/s13399-022-03138-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03138-0