Abstract

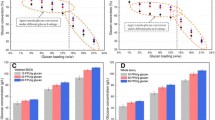

The pretreatment step has a major role in ethanol production as it breaks the lignocellulosic material structure, which improves the digestibility in the enzymatic hydrolysis and increases the ethanol yield during fermentation. The purpose in this study was to pretreat green coconut fiber (GCF) with steam explosion (SE) to produce ethanol. Different severity factors (ranging between 2.18 and 4.24) were performed and the humidification process of the raw material before pretreatment was also evaluated. Considering that SE did not provide lignin removal nor significant improvement in enzymatic digestibility, a subsequent alkaline pretreatment was carried out to overcome these challenges. The alkaline pretreatment using NaOH increased delignification, either as a stand-alone or in the sequential pretreatment. The sequential SE/alkaline pretreatment provided higher values of hydrolysis yield (54.74%), total reducing sugars (29.17 ± 1.21 g/L), and glucose production (16.65 ± 0.82 g/L) when compared to the separated pretreatments. Thereafter, simultaneous saccharification and fermentation (SSF) and semi-simultaneous saccharification and fermentation (SSSF) strategies were evaluated using Saccharomyces cerevisiae PE2, Saccharomyces cerevisiae CAT-1, and Kluyveromyces marxianus ATCC 36,907 yeasts with different solid loadings (5, 10, and 15% w/v). The pre-saccharification step increased ethanol yield and ethanol concentration in all experiments. The highest ethanol concentration (24.88 ± 1.04 g/L) was achieved using SSSF with 15% (w/w) solid loading, while the ethanol obtained in SSF experiments was equal to 21.62 ± 0.87 g/L using the same solid loading. The sequential SE/alkaline pretreatment was a successful combination, improving sugars’ production and leading to a high ethanol concentration.

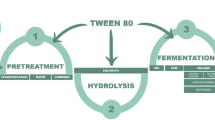

Graphical abstract

Similar content being viewed by others

References

STATISTA (2020) Coconut production worldwide from 2000 to 2020. https://www.statista.com/statistics/577497/world-coconut-production/. Accessed 08 June 2022

Santos MMS, Lacerda CF, Neves ALR, de Sousa CHC, Ribeiro AA, Bezerra MA, Araújo ICS, Gheyi HR (2020) Ecophysiology of the tall coconut growing under different coastal areas of northeastern Brazil. Agri Water Manag 232:106047. https://doi.org/10.1016/j.agwat.2020.106047

Nunes LA, Silva MLS, Gerber JZ, Kalid RA (2020) Waste green coconut shells: diagnosis of the disposal and applications for use in other products. J Clean Prod 255:120169. https://doi.org/10.1016/j.jclepro.2020.120169

Padilha CEA, Nogueira CC, Souza DFS, de Oliveira JA, dos Santos ES (2020) Organosolv lignin/Fe3O4 nanoparticles applied as a β-glucosidase immobilization support and adsorbent for textile dye removal. Ind Crops Prod 146:112167. https://doi.org/10.1016/j.indcrop.2020.112167

Endut A, Abdullah SHYS, Hanapi NHM, Hamid SHA, Lananan F, Kamarudin MKA, Umar R, Juahir H, Khatoon H (2017) Optimization of biodiesel production by solid acid catalyst derived from coconut shell via response surface methodology. Int Biodeterior Biodegrad 124:250–257. https://doi.org/10.1016/j.ibiod.2017.06.008

Gonçalves FA, Ruiz HA, dos Santos ES, Teixeira JA, de Macedo GR (2015) Bioethanol production from coconuts and cactus pretreated by autohydrolysis. Ind Crops Prod 77:1–12. https://doi.org/10.1016/j.indcrop.2015.06.041

Nogueira CC, Padilha CEA, de Jesus AA, Souza DFS, de Assis CF, Junior FCS, dos Santos ES (2019) Pressurized pretreatment and simultaneous saccharification and fermentation with in situ detoxification to increase bioethanol production from green coconut fibers. Ind Crops Prod 130:259–266. https://doi.org/10.1016/j.indcrop.2018.12.091

Awoyale AA, Lokhat D (2018) Harnessing the potential of bio-ethanol production from lignocellulosic biomass in Nigeria – a review. Biofuel Bioprod Biorefin 13:192–207. https://doi.org/10.1002/bbb.1943

Gonçalves FA, Ruiz HA, dos Santos ES, Teixeira JA, de Macedo GR (2019) Valorization, comparison and characterization of coconuts waste and cactus in a biorefinery context using NaClO2-C2H4O2 and sequential NaClO2-C2H4O2/autohydrolysis pretreatment. Waste Biomass Valor 10:2249–2262. https://doi.org/10.1007/s12649-018-0229-6

Thamsee T, Choojit S, Cheirsilp B, Yamseangsung R, Ruengpeerakul T, Sangwichien C (2018) Combination of superheated steam explosion and alkaline autoclaving pretreatment for improvement of enzymatic digestibility of the oil palm tree residues as alternative sugar sources. Waste Biomass Valor 10:3009–3023. https://doi.org/10.1007/s12649-018-0292-z

Cotana F, Cavalaglio G, Gelosia M, Coccia V, Petrozzi A, Ingles D, Pompili E (2015) A comparison between SHF and SSSF processes from cardoon for ethanol production. Ind Crops Prod 69:424–432. https://doi.org/10.1016/j.indcrop.2015.02.064

Ruiz HA, Conrad M, Sun S, Sanchez A, Rocha GJM, Romaní A, Castro E, Torres A, Rodríguez-Jasso RM, Andrade LP, Smirnova I, Sun R, Meyer AS (2020) Engineering aspects of hydrothermal pretreatment: from batch to continuous operation, scale-up and pilot reactor under biorefinery concept. Bioresour Technol 299:122685. https://doi.org/10.1016/j.biortech.2019.122685

Li W, Zhang X, He X, Li F, Zhao J, Yin R, Ming J (2020) Effects of steam explosion pretreatment on the composition and biological activities of tartary buckwheat bran phenolics. Food Funct 11:4648–4658. https://doi.org/10.1039/d0fo00493f

Liu Y, Ren X, Wu H, Meng Q, Zhou Z (2019) Steam explosion treatment of byproduct feedstuffs for potential use as ruminant feed. Animals 9:688. https://doi.org/10.3390/ani9090688

Ruiz HA, Galbe M, Garrote G, Ramirez-Gutierrez DM, **menes E, Sun S, Lachos-Perez D, Rodríguez-Jasso RM, Sun R, Yang B, Ladisch MR (2021) Severity factor kinetic model as a strategic parameter of hydrothermal processing (steam explosion and liquid hot water) for biomass fractionation under biorefinery concept. Bioresour Technol 342:125961. https://doi.org/10.1016/j.biortech.2021.125961

Tomás-Pejó E, Alvira P, Ballesteros M, Negro MJ (2011) Chapter 7 – Pretreatment technologies for lignocellulose-to-bioethanol conversion. Biofuels. 2011, 149–176. https://doi.org/10.1016/B978-0-12-385099-7.00007-3

Park J, Kang M, Kim JS, Lee J, Choi W, Lee J (2012) Enhancement of enzymatic digestibility of Eucalyptus grandis pretreated by NaOH catalyzed steam explosion. Bioresour Technol 123:707–712. https://doi.org/10.1016/j.biortech.2012.07.091

Wang W, Ling H, Zhao H (2015) Steam explosion pretreatment of corn straw on xylose recovery and xylitol production using hydrolysate without detoxification. Process Biochem 50:1623–1628. https://doi.org/10.1016/j.procbio.2015.06.001

Lourenço A, Gominho J, Curt MD, Revilla E, Villar JC, Pereira H (2016) Steam explosion as a pretreatment of Cynara cardunculus prior to delignification. Ind Eng Chem Res 56:424–433. https://doi.org/10.1021/acs.iecr.6b03854

Gonçalves FA, Ruiz HA, dos Santos ES, Teixeira JA, de Macedo GR (2016) Bioethanol production by Saccharomyces cerevisiae, Pichia stipitis and Zymomonas mobilis from delignified coconut fibre mature and lignin extraction according to biorefinery concept. Renew Energy 94:353–365. https://doi.org/10.1016/j.renene.2016.03.045

Israni N, Shivakumar S (2018) 17 – Interface influence of materials and surface modifications. Fund Biomaterials Metals 2018:371–409. https://doi.org/10.1016/B978-0-08-102205-4.00021-0

Soares J, Demeke MM, Velde MV, Foulquié-Moreno MR, Kerstens D, Sels BF, Verplaetse A, Fernandes AAR, Thevelein JM, Fernandes PMB (2017) Fed-batch production of green coconut hydrolysates for high-gravity second-generation bioethanol fermentation with cellulosic yeast. Bioresour Technol 244:234–242. https://doi.org/10.1016/j.biortech.2017.07.140

Padilha CEA, Nogueira CC, Souza DFS, de Oliveira JA, dos Santos ES (2019) Valorization of green coconut fibre: use of the black liquor of organosolv pretreatment for ethanol production and the washing water for production of rhamnolipids by Pseudomonas aeruginosa ATCC 27583. Ind Crops Prod 140:111604. https://doi.org/10.1016/j.indcrop.2019.111604

Nogueira CC, Padilha CEA, dos Santos ES (2021) Boosting second-generation ethanol titers from green coconut fiber by using high-concentration polyethylene glycol. Ind Crops Prod 166:113494. https://doi.org/10.1016/j.indcrop.2021.113494

Nogueira CC, Padilha CEA, Leitão ALS, Rocha PM, Macedo GR, dos Santos ES (2018) Enhancing enzymatic hydrolysis of green coconut fiber – pretreatment assisted by tween 80 and water effect on the post-washing. Ind Crops Prod 112:734–740. https://doi.org/10.1016/j.indcrop.2017.12.047

Sluiter A, Ruiz R, Scarlata C, Sluiter J, Templeton D (2005) Determination of extractives in biomass, Technical Report NREL/TP-510–42619. National Renewable Energy Laboratory, Golden CO

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2005) Determination of ash in biomass, Technical Report NREL/TP-510–42622. National Renewable Energy Laboratory, Golden CO

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2008) Determination of structural carbohydrates and lignin in biomass, Technical Report NREL/TP-510–42618. National Renewable Energy Laboratory, Golden CO

Sluiter A, Hames B, Hyman D, Payne C, Ruiz R, Scarlata C, Sluiter J, Templeton D, Wolfe J (2008) Determination of total solids in biomass and total dissolved solids in liquid pro, Technical Report NREL/TP-510–42621. National Renewable Energy Laboratory, Golden CO

Miller GL (1959) Use of dinitrosalicylic reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Ghose TK (1987) Measurement of cellulose activities (recommendation of commission on biotechnology IUPAC). Pure Appl Chem 59:257–268

Padilha CEA, Nogueira CC, Filho MAO, Júnior FCS, Assis CF, Souza DFS, de Oliveira JA, dos Santos ES (2019) Fractionation of green coconut fiber using sequential hydrothermal/alkaline pretreatments and Amberlite XAD-7HP resin. J Environ Chem Eng 7:103474. https://doi.org/10.1016/j.jece.2019.103474

Nogueira CC, Padilha CEA, dos Santos ES (2021) Enzymatic hydrolysis and simultaneous saccharification and fermentation of green coconut fiber under high concentrations of ethylene oxide-based polymers. Renew Energy 163:1536–1547. https://doi.org/10.1016/j.renene.2020.10.050

Brienzo M, Fikizolo S, Benjamin Y, Tyhoda L (2017) Influence of pretreatment severity on structural changes, lignin content and enzymatic hydrolysis of sugarcane bagasse samples. Renew Energy 104:271–280. https://doi.org/10.1016/j.renene.2016.12.037

Pielhop T, Amgarten J, von Rohr PR, Studer MH (2016) Steam explosion pretreatment of softwood: the effect of the explosive decompression on enzymatic digestibility. Biotechnol Bioefuls 9:152. https://doi.org/10.1186/s13068-016-0567-1

Alvira P, Negro MJ, Ballesteros I, González A, Ballesteros M (2016) Steam explosion for wheat straw pretreatment for sugars production. Bioethanol 2:66–75. https://doi.org/10.1515/bioeth-2016-0003

Mokomele T, Sousa LC, Balan V, Rensburg E, Dale BE, Gorgens JF (2018) Ethanol production potential from AFEX™ and steam-exploded sugarcane residues for sugarcane biorefineries. Biotechnol Biofuels 11:127. https://doi.org/10.1186/s13068-018-1130-z

Sulzenbacher D, Atzmuller D, Hawe F, Richter M, Cristobal-Sarramian A, Zwirzitz A (2021) Optimization of steam explosion parameters for improved biotechnological use of wheat straw. Biomass Conv Bioref. https://doi.org/10.1007/s13399-020-01266-z

Liu LY, Qin JC, Li K, Mehmood MA, Liu CC (2017) Impact of moisture content on instant catapult steam explosion pretreatment of sweet potato vine. Bioresour Bioprocess 4:49. https://doi.org/10.1186/s40643-017-0179-z

Liu ZH, Qin L, Pang F, ** MJ, Li BZ, Kang Y, Dale BE, Yuan YJ (2013) Effects of biomass particle size on steam explosion pretreatment performance for improving the enzyme digestibility of corn stover. Ind Crops Prod 44:176–184. https://doi.org/10.1016/j.indcrop.2012.11.009

Simangunsong E, Ziegler-Devin I, Chrusciel L, Girods P, Wistara NJ, Brosse N (2020) Steam explosion of beech wood: effect of the particle size on the xylans recovery. Waste Biomass Valor 11:625–633. https://doi.org/10.1007/s12649-018-0522-4

Zhao S, Li G, Zheng N, Wang J, Yu Z (2018) Steam explosion enhances digestibility and fermentation of corn stover by facilitating ruminal microbial colonization. Bioresour Technol 253:244–251. https://doi.org/10.1016/j.biortech.2018.01.024

Monavari S, Galbe M, Zacchi G (2009) Impact of impregnation time and chip size on sugar yield in pretreatment of softwood for ethanol production. Bioresour Technol 100:6312–6316. https://doi.org/10.1016/j.biortech.2009.06.097

Gonçalves FA, Ruiz HA, Nogueira CC, dos Santos ES, Teixeira JA, Macedo GR (2014) Comparison of delignified coconuts waste and cactus for fuel-ethanol production by the simultaneous and semi-simultaneous saccharification and fermentation strategies. Fuel 131:66–76. https://doi.org/10.1016/j.fuel.2014.04.021

Marques FP, Soares AKL, Lomonaco D, Silva LMA, Santaella ST, Rosa MFR, Leitão RC (2021) Steam explosion pretreatment improves acetic acid organosolv delignification of oil palm mesocarp fibers and sugarcane bagasse. Int J Biol Macromol 175:304–312. https://doi.org/10.1016/j.ijbiomac.2021.01.174

Brígida AIS, Calado VMA, Gonçalves LRB, Coelho MAZ (2010) Effect of chemical treatments on properties of green coconut fiber. Carbohydr Polym 79:832–838. https://doi.org/10.1016/j.carbpol.2009.10.005

Wang Z, Ning P, Hu L, Nie Q, Liu Y, Zhou Y, Yang J (2020) Efficient ethanol production from paper mulberry pretreated at high solid loading in Fed-nonisothermal-simultaneous saccharification and fermentation. Renew Energy 160:211–219. https://doi.org/10.1016/j.renene.2020.06.128

Acknowledgements

The authors gratefully acknowledge the Brazilian research funding agencies CNPq and CAPES for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with humans or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Steam explosion pretreatment did not influence on lignin removal.

• Higher severity factors provided higher hydrolysis yield.

• Sequential SE/alkaline pretreatment provided higher hydrolysis yield (54.74%), total reducing sugars (29.17 ± 1.21 g/L), and glucose production (16.65 ± 0.82 g/L).

• The highest ethanol concentration (24.88 ± 1.04 g/L) was achieved using SSSF with 15% w/w solid loading.

Rights and permissions

About this article

Cite this article

Ribeiro, V.T., Campolina, A.C., da Costa, W.A. et al. Ethanol production from green coconut fiber using a sequential steam explosion and alkaline pretreatment. Biomass Conv. Bioref. 14, 8579–8589 (2024). https://doi.org/10.1007/s13399-022-03100-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03100-0