Abstract

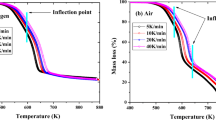

Wood waste containing halogenated compounds such as polyvinyl chloride (PVC) is in abundant supply, although the pyrolysis of such waste feedstock for energy production may cause corrosion and environmental problems due to the release of HCl gas. Hence, there is a need to understand the pyrolysis behaviour of chlorine-contaminated wood in order to develop methods that minimise the impact of chloride species on pyrolysis equipment and product quality. In literature, few studies exist on the kinetic analysis of wood and PVC co-pyrolysis. The existing models assume a single-step reaction with an n-order reaction mechanism for the entire process, which may lead to large errors in the kinetic parameters estimated. Therefore, in this paper, we develop and validate a multi-step kinetic model that predicts the pyrolysis behaviour and reaction mechanism of poplar wood (PW) pellet with different contents of PVC (0, 1, 5, 10, 100 wt%). Using data from thermogravimetric analysis of the pellets at heating rates of 5, 10 and 20 °C/min, we determined the apparent kinetic parameters by combining Fraser-Suzuki deconvolution, isoconversional methods and master plot procedures. Our model fitted the experimental data well with a deviation of less than 4.5%. Our results show that the addition of 1 wt% PVC to PW decreases the activation energy of hemicellulose and cellulose pyrolysis in PW from 136.3 to 101.6 kJ/mol and from 216.7 to 108.2 kJ/mol, respectively. This demonstrates the importance of acid hydrolysis reactions between the cellulosic fibres of PW and HCl released from PVC dehydrochlorination. Furthermore, we found that a nucleation and growth mechanism best represents the rate-limiting interactions between PVC and PW, which we linked to the formation of metal chloride crystals from acid-base reactions between HCl and PW minerals. Our kinetic model is an improvement of current models for the co-pyrolysis of wood and PVC, and can be readily used in a reactor-scale model of a pyrolyser or gasifier due to its relative simplicity.

Similar content being viewed by others

References

JRC-IPTS (2010) Study on the selection of waste streams for end-of-waste assessment. JRC Scientific and Technical Reports, EUR 24362, https://ec.europa.eu/jrc/en/publication/eur-scientific-and-technical-research-reports/study-selection-waste-streams-end-waste-assessment-final-report (Accessed August 1st, 2020).

Fail S, Diaz N, Benedikt F, Kraussler M, Hinteregger J, Bosch K, Hackel M, Rauch R, Hofbauer H (2014) Wood gas processing to generate pure hydrogen suitable for PEM fuel cells. ACS Sustain Chem Eng 2(12):2690–2698. https://doi.org/10.1021/sc500436m

Pal DB, Chand R, Upadhyay SN, Mishra PK (2018) Performance of water gas shift reaction catalysts: a review. Renew Sust Energ Rev 93:549–565. https://doi.org/10.1016/j.rser.2018.05.003

Grande CA (2016) PSA Technology for H2 Separation. In: Stolten D, Emonts B (eds) Hydrogen science and engineering: materials, processes, systems and technology. Wiley-VCH Verlag GmbH & Co. KGaA, Boschstr. 12, 69469 Weinheim, Germany.

Hale SE, Lehmann J, Rutherford D, Zimmerman AR, Bachmann RT, Shitumbanuma V, O’Toole A, Sundqvist KL, Arp HPH, Cornelissen G (2012) Quantifying the total and bioavailable polycyclic aromatic hydrocarbons and dioxins in biochars. Environ Sci Technol 46:2830–2838

Zhou H, Long Y, Meng A, Li Q, Zhang Y (2015) Interactions of three municipal solid waste components during co-pyrolysis. J Anal Appl Pyrolysis 111:265–271. https://doi.org/10.1016/j.jaap.2014.08.017

Yu J, Sun L, Ma C, Qiao Y, Yao H (2016) Thermal degradation of PVC: a review. Waste Manag 48:300–314. https://doi.org/10.1016/j.wasman.2015.11.041

Han B, Chen Y, Wu Y, Hua D, Chen Z, Feng W, Yang M, **e Q (2014) Co-pyrolysis behaviors and kinetics of plastics-biomass blends through thermogravimetric analysis. J Therm Anal Calorim 115(1):227–235. https://doi.org/10.1007/s10973-013-3228-7

Çepelioğullara Ö, Pütün AE (2013) Thermal and kinetic behaviors of biomass and plastic wastes in co-pyrolysis. Energy Convers Manag 75:263–270. https://doi.org/10.1016/j.enconman.2013.06.036

Miskolczi N, Bartha L, Angyal A (2009) Pyrolysis of polyvinyl chloride (PVC)-containing mixed plastic wastes for recovery of hydrocarbons. Energy Fuel 23:2743–2749. https://doi.org/10.1021/ef8011245

Bai XY, Wang QW, Sui SJ, Zhang CS (2011) The effects of wood-flour on combustion and thermal degradation behaviors of PVC in wood-flour/poly(vinyl chloride) composites. J Therm Anal Calorim 91(1):34–39. https://doi.org/10.1016/j.jaap.2011.02.009

Sorum L, Gronli M, Hustad J (2000) Pyrolysis characteristics and kinetics of municipal solid wastes. Fuel 80(9):1217–1227. https://doi.org/10.1016/S0016-2361(00)00218-0

Matsuzawa Y, Ayabe M, Nishino J (2001) Acceleration of cellulose co-pyrolysis with polymer. Polym Degrad Stab 71(3):435–444. https://doi.org/10.1016/S0141-3910(00)00195-6

Sanchez-Jimnez PE, Prez-Maqueda LA, Perejn A, Criado JM (2013) Generalized master plots as a straightforward approach for determining the kinetic model: the case of cellulose pyrolysis. Thermochim Acta 552:54–59. https://doi.org/10.1016/j.tca.2012.11.003

Aboulkas A, El Harfi K (2009) Co-pyrolysis of olive residue with poly (vinyl chloride) using thermogravimetric analysis. J Thermal Anal Calorim 95(3):1007–1013. https://doi.org/10.1007/s10973-008-9315-5

Vyazovkin S, Burnham AK, Criado JM, Prez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520(1-2):1–19. https://doi.org/10.1016/j.tca.2011.03.034

Burnham AK, Zhou X, Broadbelt LJ (2015) Critical review of the global chemical kinetics of cellulose thermal decomposition. Energy Fuel 29(5):2906–2918. https://doi.org/10.1021/acs.energyfuels.5b00350

Sanchez-Jimnez PE, Prez-Maqueda LA, Perejn A, Criado JM (2010) Generalized kinetic master plots for the thermal degradation of polymers following a random scission mechanism. J Phys Chem A 114(30):7868–7876. https://doi.org/10.1021/jp103171h

Hu S, Jess A, Xu M (2007) Kinetic study of Chinese biomass slow pyrolysis: comparison of different kinetic models. Fuel 86(17-18):2778–2788. https://doi.org/10.1016/j.fuel.2007.02.031

Wang X, Hu M, Hu W, Chen Z, Liu S, Hu Z, **ao B (2016) Thermogravimetric kinetic study of agricultural residue biomass pyrolysis based on combined kinetics. Bioresour Technol 219:510–520. https://doi.org/10.1016/j.biortech.2016.07.136

Cagnon B, Py X, Guillot A, Stoeckli F, Chambat G (2009) Contributions of hemicellulose, cellulose and lignin to the mass and the porous properties of chars and steam activated carbons from various lignocellulosic precursors. Bioresour Technol 100:292–298. https://doi.org/10.1016/j.biortech.2008.06.009

Zhou J, Gui B, Qiao Y, Zhang J, Wang W, Yao H, Yu Y, Xu M (2016) Understanding the pyrolysis mechanism of polyvinylchloride (PVC) by characterizing the chars produced in a wire-mesh reactor. Fuel 166:526–532. https://doi.org/10.1016/j.fuel.2015.11.034

Mehl M, Marongiu A, Faravelli T, Bozzano G, Dente M, Ranzi E (2004) A kinetic modeling study of the thermal degradation of halogenated polymers. J Anal Appl Pyrolysis 72(2):253–272. https://doi.org/10.1016/j.jaap.2004.07.007

Slopiecka K, Bartocci P, Fantozzi F (2012) Thermogravimetric analysis and kinetic study of poplar wood pyrolysis. Appl Energy 97:491–497. https://doi.org/10.1016/j.apenergy.2011.12.056

Hu M, Chen Z, Wang S, Guo D, Ma C, Zhou Y, Chen J, Laghari M, Fazal S, **ao B, Zhang B, Ma S (2016) Thermogravimetric kinetics of lignocellulosic biomass slow pyrolysis using distributed activation energy model, Fraser-Suzuki deconvolution, and iso-conversional method. Energy Convers Manag 118:1–11. https://doi.org/10.1016/j.enconman.2016.03.058

Davis PJ, Rabinowitz P (2007) Methods of numerical integration, 2nd edn. Dover Publications, Inc., Meneola, New York

Marongiu A, Faravelli T, Bozzano G, Dente M, Ranzi E (2003) Thermal degradation of poly(vinyl chloride). J Anal Appl Pyrolysis 70(2):519–553. https://doi.org/10.1016/S0165-2370(03)00024-X

De Bruijn TJW, De Jong WA, Van Den Berg PJ (1981) Kinetic parameters in Avrami-Erofeev type reactions from isothermal and non-isothermal experiments. Thermochim Acta 45(3):315–325. https://doi.org/10.1016/0040-6031(81)85091-5

Anca-Couce A (2016) Reaction mechanisms and multi-scale modelling of lignocellulosic biomass pyrolysis. Prog Energy Combust Sci 53:41–79. https://doi.org/10.1016/j.pecs.2015.10.002

Sanchez-Jimnez PE, Perejn A, Criado JM, Dinez MJ, Prez-Maqueda LA (2010) Kinetic model for thermal dehydrochlorination of poly(vinyl chloride). Polymer 51(17):3998–4007. https://doi.org/10.1016/j.polymer.2010.06.020

Miranda R, Yang J, Roy C, Vasile C (1999) Vacuum pyrolysis of PVC I. Kinetic study. Polym Degrad Stab 64(1):127–144. https://doi.org/10.1016/S0141-3910(98)00186-4

Bhargava A, van Hees P, Andersson B (2016) Pyrolysis modeling of PVC and PMMA using a distributed reactivity model. Polym Degrad Stab 129:199–211. https://doi.org/10.1016/j.polymdegradstab.2016.04.016

Miranda R, Yang J, Roy C, Vasile C (2001) Vacuum pyrolysis of commingled plastics containing PVC I. Kinetic study. Polym Degrad Stab 72(3):469–491. https://doi.org/10.1016/S0141-3910(01)00048-9

Seshadri V, Westmoreland PR (2014) Role of pericyclic reactions in the pyrolysis of cellulose and hemicellulose. In: Role of pericyclic reactions in the pyrolysis of cellulose and hemicellulose, San Francisco, CA, vol Paper ENFL-133.

Seshadri V, Westmoreland PR (2012) Concerted reactions and mechanism of glucose pyrolysis and implications for cellulose kinetics. J Phys Chem A 116(49):11,997–12,013. https://doi.org/10.1021/jp3085099

Bar-Gadda R (1980) The kinetics of xylan pyrolysis. Thermochim Acta 42(2):153–163. https://doi.org/10.1016/0040-6031(80)87099-7

Tran KQ, Bach QV, Trinh TT, Seisenbaeva G (2014) Non-isothermal pyrolysis of torrefied stump – a comparative kinetic evaluation. Appl Energy 136:759–766. https://doi.org/10.1016/j.apenergy.2014.08.026

Li Z, Zhao W, Meng B, Liu C, Zhu Q, Zhao G (2008) Kinetic study of corn straw pyrolysis: comparison of two different three-pseudocomponent models. Bioresour Technol 99(16):7616–7622. https://doi.org/10.1016/j.biortech.2008.02.003

Staggs JEJ (2002) Modelling random scission of linear polymers. Polym Degrad Stab 76(1):37–44. https://doi.org/10.1016/S0141-3910(01)00263-4

Samuelsson LN, Moriana R, Babler MU, Ek M, Engvall K (2015) Model-free rate expression for thermal decomposition processes: the case of microcrystalline cellulose pyrolysis. Fuel 143:438–447. https://doi.org/10.1016/j.fuel.2014.11.079

Brown ME (1998) Handbook of thermal analysis and calorimetry: Principles and practice, vol 1. Elsevier, Amsterdam

Acknowledgments

The authors gratefully thank our colleagues at RAPSODEE research centre for technical help.

Funding

The study was financially supported by Suez Environnement (France) and IMT Mines Albi.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ephraim, A., Pozzobon, V., Lebonnois, D. et al. Pyrolysis of wood and PVC mixtures: thermal behaviour and kinetic modelling. Biomass Conv. Bioref. 13, 8669–8683 (2023). https://doi.org/10.1007/s13399-020-00952-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00952-2