Abstract

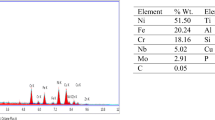

Estimation of machining time and accuracy plays a pivotal role in exemplifying the efficacy of the wire electric discharge machining (WEDM) process. The comprehensive insight on the influence of servo feed rate under different control modes (proportional control mode, constant feed mode, and constant voltage mode) on the machining time (MT), corner error (CE), and radius of the concave profile (RUC) of a convex–concave-based geometrical profile was discussed in the present research venture. Moreover, the influence of other process variables such as dielectric water pressure (WP), wire tension (WT), and servo voltage (SV) on the responses was also included in the present research. A face-centered central composite design strategy was employed to plan the experiments. The ANOVA test analyzed that SV and SF are the influential parameters for all the responses. Unlike the MT and RUC, the dielectric water pressure (WP) and wire tension (WT) were also found to influence the CE from the ANOVA analysis. Contour plots were exhibited to reveal the interaction effect between servo feed rate and servo voltage on the responses. Finally, the desirability function with the Nelder–Mead simplex algorithm was exploited to optimize the three responses simultaneously. The optimal settings determined by the proposed approach were as follows: WP = 15 kg/cm2, WT = 12 N, SV = 60 V, and SF = 2150 mm/min. FESEM micrographs and images from non-contact optical profilometry were showcased for different servo settings to demonstrate the role of servo parameters on the machined surfaces.

Similar content being viewed by others

References

Dekeyser, W. L.: Geometrical accuracy of wire-EDM. Proc. of ISEM-9, 226–232 (1989)

Dauw, D.F.; Beltrami, I.: High-precision wire-EDM by online wire positioning control. CIRP Ann. 43, 193–197 (1994)

Hsue, W.J.; Liao, Y.S.; Lu, S.S.: Fundamental geometry analysis of wire electrical discharge machining in corner cutting. Int. J. Mach. Tools Manuf. 39, 651–667 (1999)

Lin, C.T.; Chung, I.F.; Huang, S.Y.: Improvement of machining accuracy by fuzzy logic at corner parts for wire-EDM. Fuzzy Sets Syst. 122(3), 499–511 (2001)

Puri, A.B.; Bhattacharyya, B.: An analysis and optimisation of the geometrical inaccuracy due to wire lag phenomenon in WEDM. Int. J. Mach. Tools Manuf. 43, 151–159 (2003)

Sarkar, S.; Sekh, M.; Mitra, S.; Bhattacharyya, B.: A novel method of determination of wire lag for enhanced profile accuracy in WEDM. Precis. Eng. 35, 339–347 (2011)

Selvakumar, G.; Sarkar, S.; Mitra, S.: Experimental investigation on die corner accuracy for wire electrical discharge machining of Monel 400 alloy. Proc Inst Mech Eng B J Eng Manuf. 226, 1694–1704 (2012)

Selvakumar, G.; Jiju, K.B.; Sarkar, S.; Mitra, S.: Enhancing die corner accuracy through trim cut in WEDM. Int. J. Adv. Manuf. 83, 791–803 (2016)

Kumar, A.; Kumar, V.; Kumar, J.: Multi-response optimization of process parameters based on response surface methodology for pure titanium using WEDM process. Int. J. Adv. Manuf. 68, 2645–2668 (2013)

Sonawane, S.A.; Kulkarni, M.L.: Multi-feature optimization of WEDM for Ti-6Al-4V by applying a hybrid approach of utility theory integrated with the principal component analysis. Int J Mater Form Mach Processes (IJMFMP) 5, 32–51 (2018)

AbyarFirouzabadi, H.; Parvizian, J.; Abdullah, A.: Improving accuracy of curved corners in wire EDM successive cutting. Int. J. Adv. Manuf. 76, 447–459 (2015)

Yan, M.T.; Huang, P.H.: Accuracy improvement of wire-EDM by real-time wire tension control. Int. J. Mach. Tools Manuf. 44, 807–814 (2004)

Sanchez, J.A.; López de Lacalle, L.N.; Lamikiz, A.: A computer-aided system for the optimization of the accuracy of the wire electro-discharge machining process. Int. J. Comput. Integr. Manuf. 17(5), 413–420 (2004)

Sanchez, J.A.; Rodil, J.L.; Herrero, A.; De Lacalle, L.L.; Lamikiz, A.: On the influence of cutting speed limitation on the accuracy of wire-EDM corner-cutting. J. Mater. Process. Technol. 182, 574–579 (2007)

Werner, A.: Method for enhanced accuracy in machining curvilinear profiles on wire-cut electrical discharge machines. Precis. Eng. 44, 75–80 (2016)

Conde, A.; Sanchez, J.A.; Plaza, S.; Ramos, J.M.: On the influence of wire-lag on the WEDM of low-radius free-form geometries. Procedia CIRP. 42, 274–279 (2016)

Chen, Z.; Zhang, Y.; Zhang, G.; Li, W.: Modeling and reducing workpiece corner error due to wire deflection in WEDM rough corner-cutting. J Manuf Process. 36, 557–564 (2018)

Chen, Z.; Huang, Y.; Zhang, Z.; Li, H.; Yi Ming, W.; Zhang, G.: An analysis and optimization of the geometrical inaccuracy in WEDM rough corner cutting. Int. J. Adv. Manuf. 74, 917–929 (2014)

Abyar, H.; Abdullah, A.; Akbarzadeh, A.: Analyzing wire deflection errors of WEDM process on small arced corners. J Manuf Process. 36, 216–223 (2018)

Kirwin, R.M.; Moller, J.C.; Jahan, M.P.: Modification and adaptation of wire lag model based on surface feed for improving accuracy in wire EDM of Ti-6Al-4V alloy. Int. J. Adv. Manuf. 117, 2909–2920 (2021)

Chakraborty, S.; Bose, D.: Improvement of die corner inaccuracy of inconel 718 alloy using entropy based GRA in WEDM process. Adv Eng Forum. 20, 29–41 (2017)

Bisaria, H.; Shandilya, P.: Processing of curved profiles on Ni-rich Nickel–titanium shape memory alloy by WEDM. Mater. Manuf. Process. 34, 1333–1341 (2019)

Naveed, R.; Mufti, N.A.; Mughal, M.P.; Saleem, M.Q.; Ahmed, N.: Machining of curved profiles on tungsten carbide-cobalt composite using wire electric discharge process. Int. J. Adv. Manuf. 93, 1367–1378 (2017)

Selvakumar, G.; ThiruppathiKuttalingam, K.G.; Ram Prakash, S.: Investigation on machining and surface characteristics of AA5083 for cryogenic applications by adopting trim cut in WEDM. J. Braz. Soc. Mech. Sci. Eng. 40, 1–8 (2018)

Yan, H.; Bakadiasa, K.D.; Chen, Z.; Yan, Z.; Zhou, H.; Han, F.: Attainment of high corner accuracy for thin-walled sharp-corner part by WEDM based on magnetic field-assisted method and parameter optimization. Int. J. Adv. Manuf. 106, 4845–4857 (2020)

Mandal, K.; Sarkar, S.; Mitra, S.; Bose, D.: Parametric analysis and GRA approach in WEDM of Al 7075 alloy. Mater. Today: Proc. 26, 660–664 (2020)

Saha, S.; Maity, S.R.; Dey, S.; Dutta, S.: Modeling and combined application of MOEA/D and TOPSIS to optimize WEDM performances of A286 superalloy. Soft Comput. 25, 14697–14713 (2021)

Mustafa, A.H.; Hashmi, M.S.; Yilbas, B.S.; Sunar, M.: Investigation into thermal stresses in gas turbine transition-piece: Influence of material properties on stress levels. J. Mater. Process. Tech. 201, 369–373 (2008)

Rao, M.N.: High performance stainless steels for critical engineering applications. Trans. Indian Inst. Met. 63, 321–330 (2010)

Derringer, G.; Suich, R.: Simultaneous optimization of several response variables. J. Qual. Technol. 12, 214–219 (1980)

Mobin, M.; Mousavi, S.M.; Komaki, M.; Tavana, M.: A hybrid desirability function approach for tuning parameters in evolutionary optimization algorithms. Measurement 114, 417–427 (2018)

Chabbi, A.; Yallese, M.A.; Meddour, I.; Nouioua, M.; Mabrouki, T.; Girardin, F.: Predictive modeling and multi-response optimization of technological parameters in turning of Polyoxymethylene polymer (POM C) using RSM and desirability function. Measurement 95, 99–115 (2017)

Chen, Z.; Wu, L.; Lin, P.; Wu, Y.; Cheng, S.: Parameters identification of photovoltaic models using hybrid adaptive Nelder-Mead simplex algorithm based on eagle strategy. Appl. Energy. 182, 47–57 (2016)

Brabender, S.; Kallis, K.T.; Keller, L.O.; Poloczek, R.R.; Fiedler, H.L.: Optimization of reactive ion etching processes using desirability. Microelectron. Eng. 87, 1413–1415 (2010)

Acknowledgements

This study acknowledges the Govt. of India, Ministry of Human Resource and Development for providing scholarship during the research period.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

About this article

Cite this article

Saha, S., Maity, S.R. & Dey, S. Machinability Study of A286 Superalloy for Complex Profile Generation Through Wire Electric Discharge Machining. Arab J Sci Eng 48, 3241–3253 (2023). https://doi.org/10.1007/s13369-022-07028-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-07028-5