Abstract

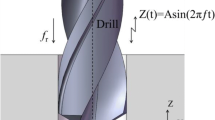

In the present study, passive infrared thermography and embedded K-type thermocouple were employed to investigate the tool and workpiece temperature during drilling of Al–5%SiC composite. The dry drilling experiments were performed based on the Taguchi’s L9 method with the mixed orthogonal array. The cutting factors in the range of 600–1200 rpm speeds, 0.07–0.17 mm/rev feed rates, and 90°–135° point angle tools were used for the drilling tests. The temperature line profile was used to explain the various stages of drilling mechanisms. The measured tool and workpiece temperature were correlated with the cutting parameters. A preliminary numerical model was used to simulate the workpiece temperature, and the simulation results were compared with the experimental value. The effect of cutting parameters on the tool temperature and surface roughness was studied by analysis of variance (ANOVA). The ANOVA result shows that the point angle and cutting speed were the significant factors to the tool temperature, while the feed rate was the most influential parameter for the surface roughness. The tool damage was measured and compared with the cutting tool temperature for different point angles. Additionally, the tool damage, workpiece damage, and chip formation were evaluated by using a scanning electron microscope.

Similar content being viewed by others

References

Prasad, S.V.; Asthana, R.: Aluminum metal−matrix composites for automotive applications tribological considerations. Tribol. Lett. 17, 445–453 (2004)

Fridlymander, J.N.: Metal Matrix Composites, 3rd edn. Chapman and Hall, Oxford (1995)

Taherzadeh Mousavian, R.; Khosroshahi, R.; Yazdani, S.; Brabazon, D.; Boostani, A.F.: Fabrication of aluminum matrix composites reinforced with nano- to micrometer-sized SiC particles. Mater. Des. 89, 58–70 (2016)

Coelho, R.T.; Yamada, S.; Aspinwall, D.K.; Wise, M.L.H.: The application of polycrystalline diamond (PCD) tool materials when drilling and reaming aluminium based alloys including MMC. Int. J. Mach. Tool. Manuf. 35(5), 761–774 (1995)

Ozcelik, B.; Bagci, E.: Experimental and numerical studies on the determination of twist drill temperature in dry drilling—a new approach. Mater. Des. 27(10), 920–927 (2006)

Ramulu, M.; Rao, P.N.; Kao, H.: Drilling of (Al2O3) p/6061 metal matrix composites. J. Mater. Process. Technol. 124, 244–254 (2002)

Patne, H.S.; Kumar, A.; Karagadde, S.; Joshi, S.S.: Modeling of temperature distribution in drilling of titanium. Int. J. Mech. Sci. 133, 598–610 (2017)

Rajmohan, T.; Palanikumar, K.; Davim, P.: Analysis of surface integrity in drilling metal matrix and hybrid metal matrix composites. J. Mater. Sci. Technol. 28, 761–768 (2012)

Mekid, S.: Introduction to Precision Machine Design and Error Assessment, pp. 1–355. CRC Press, Boca Raton (2008)

Sivasakthivel, P.S.; Sundhakaran, R.: Optimization of machining parameters on temperature rise in end milling of Al 6063 using response surface methodology and genetic algorithm. Int. J. Adv. Manuf. Technol. 67, 2313–2323 (2013)

Taskensen, A.; Kutukde, K.: Analysis and optimization of drilling parameters for tool wear and hole dimensional accuracy in B4C reinforced Al-alloy. Trans. Nonferrous Met. Soc. China 23, 2524–2536 (2013)

El-Gallab, M.; Sklad, M.: Machining of Al/SiC particulate metal-matrix composites: part I: tool performance. J. Mater. Proces. Technol. 83, 151–158 (1998)

Riaz Ahamed, A.; Asokan, P.; Aravindan, S.; Prakash, M.K.: Drilling of hybrid Al–5%SiCp–5%B4Cp metal matrix composites. Int. J. Adv. Manuf. Technol. 49, 871–877 (2010)

Maldauge, X.P.V.: Theory and Practice of Infrared Technology for Nondestructive Testing, 1st edn. Wiley Interscience, New York (2001)

Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T.: Infrared thermography for condition monitoring—a review. Infrared Phys. Technol. 60, 35–55 (2013)

Saez-de-Buruaga, M.; Spler, D.; Aristimuno, P.X.; Esnaola, J.A.; Arrazola, P.J.: Determining tool/chip temperatures from thermography measurements in metal cutting. Appl. Therm. Eng. 145, 305–314 (2018)

Mekid, S.: Spatial thermal map** using thermal infrared camera and wireless sensors for error compensation via open architecture controllers. Proc. Inst. Mech. Eng. I 224(7), 789–798 (2010)

Prasad, B.S.; Prabha, K.A.; Kumar, P.V.S.G.: Condition monitoring of turning process using infrared thermography technique—an experimental approach. Infrared Phys. Technol. 81, 137–147 (2017)

Sorrentino, L.; Turchetta, S.; Bellini, C.: In process monitoring of cutting temperature during the drilling of FRP laminate. Compos. Struct. 168, 549–561 (2017)

Le Coz, G.; Jrad, M.; Laheurte, P.; Dudzinski, D.: Analysis of local cutting-edge geometry on temperature distribution and surface integrity when dry drilling of aeronautical alloys. Int. J. Adv. Manuf. Technol. 93(5–8), 2037–2044 (2017)

Giasin, K.; Ayvar-Soberanis, S.: Evaluation of workpiece temperature during drilling of glare fiber metal laminates using infrared techniques: effect of cutting parameters, fiber orientation and spray mist application. J. Mater. 9, 622 (2016)

Yashiro, T.; Ogawa, T.; Sasahara, H.: Temperature measurement of the cutting tool and machined surface layer in the milling of CFRP. Int. J. Mach. Tool. Manuf. 70, 63–69 (2013)

Arrazola, P.J.; Arriolaa, I.; Davies, M.A.; Cookec, A.L.; Duttererc, B.S.: The effect of machinability on thermal fields in orthogonal cutting of AISI 4140 steel. CIRP Ann. 57, 65–68 (2008)

Cuesta, M.; Aristimuño, P.; Garay, A.; Arrazola, P.J.: Heat transferred to the workpiece based on temperature measurements by IR technique in dry and lubricated drilling of Inconel 718. Appl. Therm. Eng. 104, 309–318 (2016)

Cakiroglu, R.; Acir, A.: Optimization of cutting parameters on drill bit temperature in drilling by Taguchi method. Measurement 46, 3525–3531 (2013)

Bagci, E.; Ozcelik, B.: Analysis of temperature changes on the twist drill under different drilling conditions based on Taguchi method during dry drilling of Al7075-T651. Int. J. Adv. Manuf. Technol. 29, 629–636 (2006)

Venkatesh, G.; Chakradhar, D.: Influence of thermally assisted machining parameters on the machinability of Inconel 718 superalloy. Silicon 9(6), 867–877 (2017)

Inegbenebor, A.O.; Bolu, C.A.; Babalola, P.O.; Inegbenebor, A.I.; Fayomi, O.S.I.: aluminum silicon carbide particulate metal matrix composite development via stir casting processing. Silicon 10(2), 343–347 (2016)

Park, S.H.: Robust Design and Analysis for Quality Engineering. Chapman & Hall, London (1996)

Choudhury, M.R.; Srinivas, M.S.; Debnathe, K.: Experimental investigation on drilling lignocellulosic fiber reinforced composite laminates. J. Manuf. Pros. 34, 51–61 (2018)

Sorrentino, L.; Bellini, C.: Validation of a methodology for cure process optimization of thick composite laminates. Poly Plast. Technol. Eng. 54, 1803–1811 (2015)

Samy, G.S.; Thirumalai Kumaran, S.: Measurement and analysis of temperature, thrust force and surface roughness in the drilling of AA (6351)-B4C composites. Measurement 103, 1–9 (2017)

Yanming, Q.; Zehua, Z.: Tool wear and its mechanism for cutting SiC particle-reinforced aluminium matrix composites. J. Mat. Process. Technol. 100, 194–199 (2000)

Kurt, M.; Bagci, E.; Kaynak, Y.: Application of Taguchi methods in the optimization of cutting parameters for surface finish and hole diameter accuracy in dry drilling processes. Int. J. Adv. Manuf. Technol. 40, 458–469 (2009)

Karabulut, S.; Gokmen, U.; Cinici, H.: Study on the mechanical and drilling properties of AA7039 composites reinforced with Al2O3/B4C/SiC particles. Compos. Part. B. Eng. 93, 43–55 (2016)

Zitoune, R.; Krishnaraj, V.; Almabouacif, B.S.; Collombet, F.; Sima, M.; Jolin, A.: Influence of machining parameters and new nano-coated tool on drilling performance of CFRP/aluminum sandwich. Compos. Part. B 43, 1480–1488 (2012)

Singh, S.: Effect of modified drill point geometry on drilling quality characteristics of metal matrix composite (MMCs). Int. J. Mech. Sci. 30(6), 2691–2698 (2016)

Acknowledgements

Authors are thankful to Dr. A. K Bhaduri, Director, Indira Gandhi Centre for Atomic Research (IGCAR), Kalpakkam and Dr. G. Amarendra, Director, Metallurgy and Materials Group, IGCAR, for constant support. Authors are thankful to Dr. S. Murugan, Head, RIMMD, IGCAR for hel** to carry out the drilling experiments. Authors also thank Dr. Amirthapandian, MSG, IGCAR for hel** to carry out the SEM studies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thirukkumaran, K., Menaka, M., Mukhopadhyay, C.K. et al. A Study on Temperature Rise, Tool Wear, and Surface Roughness During Drilling of Al–5%SiC Composite. Arab J Sci Eng 45, 5407–5419 (2020). https://doi.org/10.1007/s13369-020-04427-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04427-4