Abstract

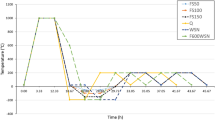

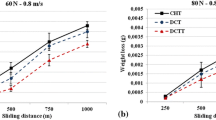

The present research paper focuses on optimisation of wear test parameters for different deep cryogenic treated AISI M2 tool steel material. Commercially available, AISI M2 tool steel material is machined as per ASTM G99-05 standards and was subjected to deep cryogenic treatment for the different holding time of 12, 24 and 36 h, followed by tempering for 2 h at \(150\,^{\circ }\hbox {C}\). The specimens were tested for their wear resistance using a pin-on-disc wear testing setup adopting Taguchi‘s design of experiments approach. The control variables selected were deep cryogenic treatment holding time, the speed of the rotating disc and load applied to the specimen pin. The wear test was conducted as per trials generated by Taguchi‘s \(\hbox {L}_{27}\) orthogonal array, and the results are analysed using signal-to-noise ratio and analysis of variance. The results show that the cryogenic holding time has majorly affected the wear resistance followed by the load on the pin and disc speed. It is also observed that 24 h holding time for deep cryogenic treatment yields better wear resistance compared to 12 and 36 h. Microstructure and X-ray diffraction analysis of the cryogenically treated specimens reveals the conversion of retained austenite into martensite and the formation of fine carbides in the martensite lattice after deep cryogenic treatment process which are responsible for the increase in wear resistance. Also, the worn surface analysis shows that the adhesion wear, oxidation wear and abrasion wear are the predominant wear mechanisms observed under different testing conditions.

Similar content being viewed by others

References

Sindi, C.T.; Najafabadi, M.A.; Salehi, M.: Investigation of surface damages during sheet metal forming using acoustic emission. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 227(3), 286–296 (2013)

Ebner, R.; Leitner, H.; Jeglitsch, F.; Caliskanoglu, D.: Methods of property oriented tool steel design. In: Proceeding of 5th International Conference on Tooling, Leoben, Sept. 29th to October 1st (pp. 3–24) (1999, October)

Podgornik, B.; Leskovšek, V.: Microstructure and origin of hot-work tool steel fracture toughness deviation. Metall. Mater. Trans. A 44(13), 5694–5702 (2013)

Billur, E.; Altan, T.: Challenges in forming advanced high strength steels. In: Proceedings of New Developments in Sheet Metal Forming, pp. 285–304 (2012)

Leskovšek, V.; Podgornik, B.: Vacuum heat treatment, deep cryogenic treatment and simultaneous pulse plasma nitriding and tempering of P/M S390MC steel. Mater. Sci. Eng. A 531, 119–129 (2012)

Surberg, C.H.; Stratton, P.; Lingenhöle, K.: The effect of some heat treatment parameters on the dimensional stability of AISI D2. Cryogenics 48(1–2), 42–47 (2008)

Li, S.; Deng, L.; Wu, X.: The mechanism investigation of deep cryogenic treatment on high alloy martensitic steel by low frequency internal friction. Cryogenics 50(8), 433–438 (2010)

Das, D.; Sarkar, R.; Dutta, A.K.; Ray, K.K.: Influence of sub-zero treatments on fracture toughness of AISI D2 steel. Mater. Sci. Eng. A 528(2), 589–603 (2010)

Thornton, R.; Slatter, T.; Ghadbeigi, H.: Effects of deep cryogenic treatment on the dry sliding wear performance of ferrous alloys. Wear 305(1–2), 177–191 (2013)

Podgornik, B.; Majdic, F.; Leskovsek, V.; Vizintin, J.: Improving tribological properties of tool steels through combination of deep-cryogenic treatment and plasma nitriding. Wear 288, 88–93 (2012)

Amini, K.; Akhbarizadeh, A.; Javadpour, S.: Investigating the effect of quench environment and deep cryogenic treatment on the wear behavior of AZ91. Mater. Des. 1980–2015(54), 154–160 (2014)

Li, S.; Min, N.; Li, J.; Wu, X.: Internal friction measurements of phase transformations during the process of deep cryogenic treatment of a tool steel. Cryogenics 57, 1–5 (2013)

Li, S.; Min, N.; Li, J.; Wu, X.; Li, C.; Tang, L.: Experimental verification of segregation of carbon and precipitation of carbides due to deep cryogenic treatment for tool steel by internal friction method. Mater. Sci. Eng. A 575, 51–60 (2013)

Carlson, E.: Cold treating and cryogenic treatment of steel. ASM Int. ASM Handb. 4, 203–206 (1991)

Jia-shan, G.E.; **an-guo, Y.A.N.; Hong, G.U.O.; Haizhen, Z.; **awei, D.: Stochastic characteristics analysis on mechanical properties of W6Mo5Cr4V2 high-speed steel. Heat Treat. Met. 1, 052 (2015)

Leskovšek, V.; Kalin, M.; Vižintin, J.: Influence of deep-cryogenic treatment on wear resistance of vacuum heat-treated HSS. Vacuum 80(6), 507–518 (2006)

Lal, D.M.; Renganarayanan, S.; Kalanidhi, A.: Cryogenic treatment to augment wear resistance of tool and die steels. Cryogenics 41(3), 149–155 (2001)

Collins, D.N.: Deep cryogenic treatment of a D2 cold work tool steel. Heat Treat. Met. 3, 71–74 (1997)

Molinari, A.; Pellizzari, M.; Gialanella, S.; Straffelini, G.; Stiasny, K.H.: Effect of deep cryogenic treatment on the mechanical properties of tool steels. J. Mater. Process. Technol. 118(1–3), 350–355 (2001)

Yan, X.G.; Li, D.Y.: Effects of the sub-zero treatment condition on microstructure, mechanical behavior and wear resistance of W9Mo3Cr4V high speed steel. Wear 302(1–2), 854–862 (2013)

Stratton, P.F.: Optimising nano-carbide precipitation in tool steels. Mater. Sci. Eng. A 449, 809–812 (2007)

Candane, D.; Alagumurthi, N.; Palaniradja, K.: Effect of cryogenic treatment on microstructure and wear characteristics of AISI M35 HSS. Int. J. Mater. Sci. Appl. 2(2), 56–65 (2013)

Thornton, P.A.: Fundamentals of Engineering Materials, p. 144. Prentice-Hall, Upper Saddle River (1985)

Akincioğlu, S.; Gökkaya, H.; Uygur, İ.: A review of cryogenic treatment on cutting tools. Int. J. Adv. Manuf. Technol. 78(9–12), 1609–1627 (2015)

Bongale, A.; Kumar, S.; Sachit, T.S.; Jadhav, P.: Wear rate optimization of Al/SiCnp/E-glass fibre hybrid metal matrix composites using Taguchi method and genetic algorithm and development of wear model using artificial neural networks. Mater. Res. Express 5, 035005 (2018)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, S., Nagraj, M., Bongale, A. et al. Deep Cryogenic Treatment of AISI M2 Tool Steel and Optimisation of Its Wear Characteristics Using Taguchi‘s Approach. Arab J Sci Eng 43, 4917–4929 (2018). https://doi.org/10.1007/s13369-018-3242-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-018-3242-y