Abstract

This work focused on the valorization of tar derived from rice husk pyrolysis as a precursor of matrices for the encapsulation of active principles. In this regard, the development of novel films based on alginate and eugenol-loaded tar microparticles with suitable mechanical properties and antibacterial activity was studied. Tar microparticles loaded with eugenol were incorporated into sodium alginate films and the effect on the mechanical, thermal and humidity resistance properties were determined, as well as the antimicrobial activity. Films with different crosslinking degrees were also prepared using CaCl2, and the eugenol controlled release profiles were evaluated. Crosslinked films exhibited improved mechanical and humidity resistance properties, as well as a lower release rate of eugenol in water. The antimicrobial studies showed that eugenol-loaded films present a higher antimicrobial activity against Staphylococcus aureus. Alginate/eugenol-loaded tar microparticles composites showed an enhancement of antibacterial properties and suitable physical characteristics to be used in active packaging applications.

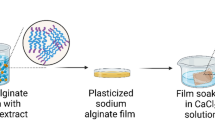

Graphical Abstract

Similar content being viewed by others

Data Availability

Not applicable.

Code Availability

Not applicable.

References

Wicochea-Rodríguez, J.D., Chalier, P., Ruiz, T., Gastaldi, E.: Active food packaging based on biopolymers and aroma compounds: how to design and control the release. Front. Chem. 7, 398 (2019). https://doi.org/10.3389/fchem.2019.00398

Barboza, J.N., da Silva Maia Bezerra Filho, C., Silva, R.O., Medeiros, J.V.R., de Sousa, D.P.: An overview on the anti-inflammatory potential and antioxidant profile of eugenol. Oxid. Med. Cell. Longev. (2018). https://doi.org/10.1155/2018/3957262

Cheng, J., Wang, H., Kang, S., **a, L., Jiang, S., Chen, M., Jiang, S.: An active packaging film based on yam starch with eugenol and its application for pork preservation. Food Hydrocoll. 96, 546–554 (2019). https://doi.org/10.1016/j.foodhyd.2019.06.007

Talón, E., Vargas, M., Chiralt, A., González-Martínez, C.: Eugenol incorporation into thermoprocessed starch films using different encapsulating materials. Food Packag. Shelf Life 21, 100326 (2019). https://doi.org/10.1016/j.fpsl.2019.100326

Goñi, M.L., Gañán, N.A., Strumia, M.C., Martini, R.E.: Eugenol-loaded LLDPE films with antioxidant activity by supercritical carbon dioxide impregnation. J. Supercrit. Fluids 111, 28–35 (2016). https://doi.org/10.1016/j.supflu.2016.01.012

Melendez-Rodriguez, B., Figueroa-Lopez, K.J., Bernardos, A., Martínez-Máñez, R., Cabedo, L., Torres-Giner, S., Lagaron, J.M.: Electrospun antimicrobial films of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) containing eugenol essential oil encapsulated in mesoporous silica nanoparticles. Nanomaterials 9, 227 (2019). https://doi.org/10.3390/nano9020227

Purwanti, N., Zehn, A.S., Pusfitasari, D., Khalid, N., Febrianto, Y., Sutrisno, S., Mardjan, A., Kobayashi, I., Zehn, S.: Emulsion stability of clove oil in chitosan and sodium alginate matrix. Int. J. Food Prop. (2018). https://doi.org/10.1080/10942912.2018.1454946

Dammak, I., do Sobral, P.J.A.: Active gelatin films incorporated with eugenol nanoemulsions: effect of emulsifier type on films properties. Int. J. Food Sci. Technol. 54, 2725–2735 (2019). https://doi.org/10.1111/ijfs.14183

Rodrigues do Amaral, P.H., Lopes Andrade, P., Costa de Conto, L.: Microencapsulation and its uses in food science and technology: a review (2019). https://doi.org/10.5772/intechopen.81997

Wang, S., Wang, Y., Cai, Q., Wang, X., **, H., Luo, Z.: Multi-step separation of monophenols and pyrolytic lignins from the water-insoluble phase of bio-oil. Sep. Purif. Technol. 122, 248–255 (2014). https://doi.org/10.1016/j.seppur.2013.11.017

Mullen, C.A., Boateng, A.A.: Characterization of water insoluble solids isolated from various biomass fast pyrolysis oils. J. Anal. Appl. Pyrolysis 90(2), 197–203 (2011)

Zhang, X., Chen, Q., Zhang, Q., Wang, C., Ma, L., Xu, Y.: Conversion of pyrolytic lignin to aromatic hydrocarbons by hydrocracking over pristine MoO3 catalyst. J. Anal. Appl. Pyrolysis 135, 60–66 (2018). https://doi.org/10.1016/j.jaap.2018.09.020

Wang, C., Li, M., Fang, Y.: Upgrading of pyrolytic lignin into hexamethylbenzene with high purity: demonstration of the “all-to-one” biochemical production strategy in thermo-chemical conversion. Green Chem. 21, 1000–1005 (2019). https://doi.org/10.1039/c8gc03788d

Zhang, L., Zhang, S., Hu, X., Gholizadeh, M.: Progress in application of the pyrolytic lignin from pyrolysis of biomass. Chem. Eng. J. (2021). https://doi.org/10.1016/j.cej.2021.129560

Garcia-Perez, M., Chaala, A., Pakdel, H., Kretschmer, D., Roy, C.: Characterization of bio-oils in chemical families. Biomass Bioenergy 31(4), 222–242 (2007)

Zhang, X., Zhu, J., Wu, C., Wu, Q., Liu, K., Jiang, K.: Preparation and properties of wood tar-based rejuvenated asphalt. Materials (Basel) (2020). https://doi.org/10.3390/ma13051123

Tian, X., Zhang, L., Li, H., Zhang, X., Wang, Q., **, L., Cao, Q.: Preparation of bio-oil-based polymer microspheres for adsorption Cu2+ and its adsorption behaviors. J. Dispers. Sci. Technol. (2020). https://doi.org/10.1080/01932691.2020.1727344

Liakos, I., Rizzello, L., Scurr, D.J., Pompa, P.P., Bayer, I.S., Athanassiou, A.: All-natural composite wound dressing films of essential oils encapsulated in sodium alginate with antimicrobial properties. Int. J. Pharm. 463, 137–145 (2014). https://doi.org/10.1016/j.ijpharm.2013.10.046

Aadil, K.R., Prajapati, D., Jha, H.: Improvement of physcio-chemical and functional properties of alginate film by Acacia lignin. Food Packag. Shelf Life 10, 25–33 (2017). https://doi.org/10.1016/j.fpsl.2016.09.002

Mauriello, G., Ercolini, D., La Storia, A., Casaburi, A., Villani, F.: Development of polythene films for food packaging activated with an antilisterial bacteriocin from Lactobacillus curvatus 32Y. J. Appl. Microbiol. 97, 314–322 (2004). https://doi.org/10.1111/j.1365-2672.2004.02299.x

Prauchner, M.J., Pasa, V.M.D., Otani, C., Otani, S.: Characterization and thermal polymerization of Eucalyptus tar pitches. Energy Fuels 15, 449–454 (2001). https://doi.org/10.1021/ef000196o

Simões, M.G., Coimbra, P.A., Carreira, S., Figueiredo, M.M., Gil, M.H., Simões, P.N., Simões, M.G.: Eugenol-loaded microspheres incorporated into textile substrates. Cellulose 27, 4109–4121 (2020). https://doi.org/10.1007/s10570-020-03010-2

Michelin, M., Marques, A.M., Pastrana, L.M., Teixeira, J.A., Cerqueira, M.A.: Carboxymethyl cellulose-based films: effect of organosolv lignin incorporation on physicochemical and antioxidant properties. J. Food Eng. 285, 110107 (2020). https://doi.org/10.1016/j.jfoodeng.2020.110107

**ao, C., Weng, L., Zhang, L.: Improvement of physical properties of crosslinked alginate and carboxymethyl konjac glucomannan blend films. J. Appl. Polym. Sci. 84, 2554–2560 (2002). https://doi.org/10.1002/app.10582

Tavares, L.B., Ito, N.M., Salvadori, M.C., dos Santos, D.J., Rosa, D.S.: PBAT/kraft lignin blend in flexible laminated food packaging: peeling resistance and thermal degradability. Polym. Test. 67, 169–176 (2018). https://doi.org/10.1016/j.polymertesting.2018.03.004

Campos-Vallette, M.M., Chandía, N.P., Clavijo, E., Leal, D., Matsuhiro, B., Osorio-Román, I.O., Román, R., Torres, S.: Characterization of sodium alginate and its block fractions by surface-enhanced Raman spectroscopy. J. Raman Spectrosc. (2010). https://doi.org/10.1002/jrs.2517

Teno, J., González-Gaitano, G., González-Benito, J.: Poly(ethylene-co-vinyl acetate) films prepared by solution blow spinning: surface characterization and its relation with E. coli adhesion. Polym. Test. 60, 140–148 (2017). https://doi.org/10.1016/j.polymertesting.2017.03.020

Piletti, R., Bugiereck, A.M., Pereira, A.T., Gussati, E., Dal Magro, J., Mello, J.M.M., Dalcanton, F., Ternus, R.Z., Soares, C., Riella, H.G., Fiori, M.A.: Microencapsulation of eugenol molecules by β-cyclodextrine as a thermal protection method of antibacterial action. Mater. Sci. Eng. C 75, 259–271 (2017). https://doi.org/10.1016/j.msec.2017.02.075

Acknowledgements

The authors are grateful to the Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET), Universidad Nacional del Litoral (U.N.L.), Universidad Tecnológica Nacional (U.T.N.), and Agencia Nacional de Promoción Científica y Tecnológica (ANPCyT) for the financial support.

Funding

This work was supported by the Grant N° PIP2011 848 and PUE N° 2920160100007 (CONICET), Grant N° PICT2011 1254 and PICT 1208/2016 (National Agency for Scientific and Technological Promotion (ANPCyT)) and Grant N° CAI+D2011 419 and CAID 50420150100068LI (Universidad Nacional del Litoral).

Author information

Authors and Affiliations

Contributions

MET: investigation, formal analysis, data curation, conceptualization, writing—original draft. CB: investigation, formal analysis, data curation, conceptualization, writing—original draft. PS: investigation, formal analysis, writing—original draft. MB: investigation, formal analysis, writing—original draft. US: visualization, conceptualization, writing—review & editing, project administration, funding acquisition. DE: visualization, conceptualization, supervision, writing—review & editing, resources, project administration, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

All authors have read and agreed to the published version of the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Taverna, M.E., Busatto, C.A., Saires, P.J. et al. Bio-composite Films Based on Alginate and Rice Husk Tar Microparticles Loaded with Eugenol for Active Packaging. Waste Biomass Valor 13, 3061–3070 (2022). https://doi.org/10.1007/s12649-022-01679-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01679-z