Abstract

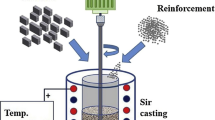

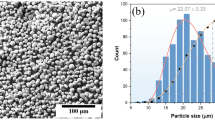

Metal matrix composites (MMCs) based on aluminium (Al) are being employed extensively in the aerospace and automotive industries due to their remarkable strength-to-weight ratio. When reinforced with silicon carbide (SiC) particles, Al-based MMCs exhibit advantageous properties. With the addition of SiC, the density of the MMCs rises. SiC particle has a positive effect on the base matrix because it improves its mechanical characteristics, such as hardness and tensile strength. This investigation summarizes the comprehensive evaluation of the physical, mechanical, and tribology characteristics of the Al 6063 alloy with SiC particles of different particle sizes and weight percentages (wt.%) simultaneously. The stir casting process is used to manufacture Al 6063-based MMCs. From the microstructural investigation, it is seen that the distribution of SiC particles is uniform following successful fabrication. Al-6063 alloy and its composites underwent experimental examination to determine their ultimate tensile strength, compressive strength, microhardness, and wear behaviour. Hardness and toughness measurements show that mechanical qualities raise to a particular wt.% and then these fall with an increase of the same because of the development of larger and more numerous pores and clustering. The wear patterns of the composites have been tested with a pin-on-disc wear testing machine. Wear test using a load of 20 N and a sliding time of 25 min is performed on every fabricated MMCs. The MMCs with 9 wt.% of 25 µm size SiC particle has the lowest coefficient of friction and wear rate. The wear behaviour of the MMCs is also assessed by studying the images of a scanning electron microscope.

Similar content being viewed by others

Data availability

The authors confirm that all data are included within the manuscript.

References

Sekar S, Palanisamy SK, Ravichandran M, Balan AV (2017) Processing of aluminium metal matrix composites-a review. J Manuf Eng 12:130–141

Arunachalam R, Krishnan PK, Muraliraja R (2019) A review on the production of metal matrix composites through stir casting- Furnace design, properties, challenges, and research opportunities. J Manuf Process 42:213–245. https://doi.org/10.1016/j.jmapro.2019.04.017

Bains PS, Sidhu SS, Payal HS (2016) Fabrication and machining of metal matrix composites: a review. Mater Manuf Process 31:553–573. https://doi.org/10.1080/10426914.2015.1025976

Amitesh, Kale VC (2015) Aluminium based metal matrix composites for aerospace application: a literature review. IOSR J Mech Civil Eng (IOSR-JMCE) 12:31–36. https://doi.org/10.9790/1684-12653136

Saravanan C, Subramanian K, Ananda KV, Sankara NR (2015) Effect of particulate reinforced aluminium metal matrix composite – a review. Mechanics Mech Eng 19:23–30

Prabu SB, Karunamoorthy L, Kathiresan S, Mohan B (2006) Influence of stirring speed and stirring time on the distribution of particles in cast metal matrix composite. J Mater Process Tech 171:268–273. https://doi.org/10.1016/j.jmatprotec.2005.06.071

Samal P, Vundavilli PR, Meher A, Mahapatra MM (2020) Recent progress in aluminum metal matrix composites: a review on processing, mechanical and wear properties. J Manuf Process 59:131–152. https://doi.org/10.1016/j.jmapro.2020.09.010

Garg P, Jamwal A, Kumar D, Sadasivuni KK, Hussain MC, Gupta P (2019) Advance research progresses in aluminium matrix composites: manufacturing & applications. J Mater Res Tech 8:4924–4939. https://doi.org/10.1016/j.jmrt.2019.06.028

Dey D, Bhowmik A, Biswas A (2022) Effect of SiC content on mechanical and tribological properties of Al2024-SiC composites. Silicon 14:1–11. https://doi.org/10.1007/s12633-020-00757-y

Patel SK, Kuriachen B, Kumar N, Nateriya R (2018) The slurry abrasive wear behavior and microstructural analysis of A2024-SiC-ZrSiO4 metal matrix composite. Ceram Int 44:6426–6432. https://doi.org/10.1016/j.ceramint.2018.01.037

Rana RS, Rajesh P, Das S (2013) Tribological behavior of AA 5083/Micron and Nano SiC composites fabricated by ultrasonic-assisted stir casting process. Int J Sci Res Pub 9:2250–3153

Dey D, Ajay Biswas (2021) Comparative study of physical, mechanical and tribological properties of Al2024 alloy and SiC-TiB2 composites. Silicon 13(6):1895–1906. https://doi.org/10.1007/s12633-020-00560-9

Bhushan KR, Kumar S, Das S (2013) Fabrication and characterization of 7075 Al alloy reinforced with SiC particulates. Int J Adv Manuf Tech 65:611–624. https://doi.org/10.1007/s00170-012-4200-6

Singh J, Jawalkar CS, Belokar RM (2010) Analysis of mechanical properties of AMC fabricated by vacuum stir casting process. Silicon 12:2433–2443. https://doi.org/10.1007/s12633-019-00338-8

Kumar GBV, Rao CSP, Selvaraj N (2012) Studies on mechanical and dry sliding wear of Al6061-SiC composites. Compo Part B 43:1185–1191. https://doi.org/10.1016/j.compositesb.2011.08.046

Balasubramanian I, Maheswaran R (2015) Effect of inclusion of SiC particulates on the mechanical resistance behaviour of stir-cast AA6063/SiC composites. Mater Design 65:511–520. https://doi.org/10.1016/j.matdes.2014.09.067

Shamim FA, Dvivedi A, Kumar P (2021) On near-dry wire ECDM of Al6063/SiC/10 MMC. Mater Manuf Process 36:122–134. https://doi.org/10.1080/10426914.2020.1802044

Shamim FA, Dvivedi A, Kumar P (2022) Fabrication and characterization of Al6063/SiC composites using electromagnetic stir casting process. Proc IMechE Part E: J Procss Mech Eng 236(1):187–193. https://doi.org/10.1177/09544089211045796

Kamrani S, Riedel R, Seyed Reihani SM, Kleebe HJ (2010) Effect of reinforcement volume fraction on the mechanical properties of Alg -SiC nanocomposites produced by mechanical alloying and consolidation. J Com Mater 44:313–326. https://doi.org/10.1177/0021998309347570

Fenghong CC, Zhenyu C, Muthuramalingam W, Anbuchezhiyan TG (2019) Effects of silicon carbide and tungsten carbide in aluminium metal matrix composites. Silicon 11:2625–2632. https://doi.org/10.1007/s12633-018-0051-6

Straffelini G, Pellizzari M, Molinari A (2004) Influence of load and temperature on the dry sliding behaviour of Al-based metal-matrix-composites against friction material. Wear 256:754–763. https://doi.org/10.1016/S0043-1648(03)00529-5

Singh N, Belokar RM, Walia RS (2022) A critical review on advanced reinforcements and base materials on hybrid metal matrix composites. Silicon 14:335–358. https://doi.org/10.1007/s12633-020-00853-z

Reddy PV, Kumar GS, Krishnudu DM, Rao HR (2020) Mechanical and wear performances of aluminium-based metal matrix composites: a review. J Bio Tribo-Corro 6:1–16. https://doi.org/10.1007/s40735-020-00379-2

Suresha S, Sridhara BK (2012) Friction characteristics of aluminium silicon carbide graphite hybrid composites. Mater Design 34:576–583. https://doi.org/10.1016/j.matdes.2011.05.010

Zhao Y, Yu T, Guan C, Sun J, Tan X (2019) Microstructure and friction coefficient of ceramic (TiC, TiN and B4C) reinforced Ni-based coating by laser cladding. Ceram Int 45:20824–20836. https://doi.org/10.1016/j.ceramint.2019.07.070

Sharma VK, Kumar V, Joshi R S (2019) Experimental investigation on effect of RE oxides addition on tribological and mechanical properties of Al-6063 based hybrid composites. Mater Res Exp IOP 6. https://doi.org/10.1088/2053-1591/ab2504

Shorowordi KM, Laoui T, Haseeb A, Celis JP, Froyen L (2003) Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: a comparative study. J Mater Process Tech 142:738–743

Acknowledgements

The authors are thankful to the Department of Mechanical Engineering, NIT Silchar, CIF NIT Silchar, Raghavendra Spectro Metallurgical laboratory Hyderabad, CIC Tripura University for providing the necessary resources to conduct the experiment.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Pallab Sarmah conceptualized the work, conducted experiments, compiled the data, written the draft manuscript, and prepared all the figures and tables. Promod Kumar Patowari supervised the work and edited the final manuscript. Both authors analyzed the results and reviewed the manuscript.

Corresponding author

Ethics declarations

Ethics approval

The results/data/figures in this manuscript have not been published elsewhere, nor they are under consideration by another publisher.

Consent to participate

All authors have agreed to participate in this research work.

Consent for publication

All authors have given consent for the publication of the manuscript in its current form.

Competing interests

The authors have no competing interests to declare that are relevant to the content reported in this paper.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sarmah, P., Patowari, P.K. Mechanical and Tribological Analysis of the Fabricated Al 6063-based MMCs with SiC Reinforcement Particles. Silicon 15, 2781–2796 (2023). https://doi.org/10.1007/s12633-022-02175-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-022-02175-8