Abstract

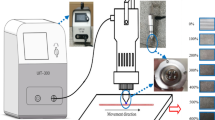

Ultra-low carbon (ULC) steels, containing a carbon content ~ 0.055 wt%, have been used in several applications in the form of thin foils. However, there are limited studies on the effects of foil thickness (t) to grain size (d) ratio and foil condition on the tensile response and formability of thin ULC steel foils. In the present work, the tensile and forming behaviours of ULC steel foils of thickness about 400 µm were evaluated in both annealed and prestrained (by cold reduction to 2–7%) conditions as a function of t/d ratio and followed by detailed texture evolution analysis. Vacuum annealing was used to achieve varying t/d ratios in the specimens. Additionally, thin ULC steel foils of 100 μm thickness in annealed condition were also used for examining the thickness effect. Microstructural analysis was performed using the electron backscattered diffraction technique. Microformability was assessed by a miniaturised Nakazima test setup with specimen geometries designed to produce three different strain paths. The annealed foils displayed a typical yield-point phenomenon, but the total yield-point elongation decreased with decreasing thickness and grain size. The foils exhibited typical Hall–Petch strengthening, cold work hardening, and forming limit curves; however, there were substantial reductions in both tensile strength and ductility, and consequently, the forming strains, with decreasing the t/d ratio. The tensile response and formability of the foils were adversely affected by both thinning and prestraining. The texture studies revealed the formation of a γ-fibre i.e., < 111 >||normal direction, and its intensity varied significantly with the t/d ratio and mode of strain path.

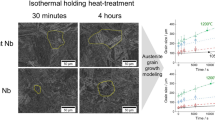

Graphical Abstract

Similar content being viewed by others

References

D.T. Llewellyn, R.C. Hudd, Steels: Metallurgy and Applications (Butterworth-Heinemann, Oxford, 1998)

C. Capdevila, C. Garcia-Mateo, F.G. Caballero, C. Garcia de Andres, Neural network analysis of the influence of processing on strength and ductility of automotive low carbon sheet steels. Comp. Mater. Sci. 38, 192–201 (2006). https://doi.org/10.1016/j.commatsci.2006.02.005

P. Antoine, S. Vandeputte, J.B. Vogt, Effect of microstructure on strain-hardening behaviour of a Ti-IF steel grade. ISIJ Int. 45, 399–404 (2005). https://doi.org/10.2355/isi**ternational.45.399

P. Antoine, S. Vandeputte, J.B. Vogt, Empirical model predicting the value of the strain-hardening exponent of a Ti-IF steel grade. Mater. Sci. Eng. A 433, 55–63 (2006). https://doi.org/10.1016/j.msea.2006.06.030

C. Capdevila, J.P. Ferrer, F.G. Caballero, C. Garcia de Andres, Influence of processing parameters on the recrystallized microstructure of extra-low-carbon steels. Metall. Mater. Trans. A 37, 2059–2068 (2006). https://doi.org/10.1007/bf02586126

G.E. Dieter, D. Bacon, Mechanical Metallurgy (McGraw-Hill, New York, 1976)

W.F. Hosford, Mechanical Behavior of Materials (Cambridge University Press, Cambridge, 2010). https://doi.org/10.1017/s0001924000088126

G. Simons, Ch. Weippert, J. Dual, J. Villain, Size effects in tensile testing of thin cold rolled and annealed Cu foils. Mater. Sci. Eng. A 416, 290–299 (2006). https://doi.org/10.1016/j.msea.2005.10.060

M. Klein, A. Hadrboletz, B. Weiss, G. Khatibi, The ‘size effect’ on the stress–strain, fatigue and fracture properties of thin metallic foils. Mater. Sci. Eng. A 319, 924–928 (2001). https://doi.org/10.1016/s0921-5093(01)01043-7

J. Kim, R. Golle, H. Hoffmann, Investigation of size effects of very thin aluminum and copper sheets using aero-bulge test. Mater. Sci. Eng. A 527, 7220–7224 (2010). https://doi.org/10.1016/j.msea.2010.07.076

M.W. Fu, W.L. Chan, A review on the state-of-the-art microforming technologies. Int. J. Adv. Manuf. Technol. 67, 2411–2437 (2013). https://doi.org/10.1007/s00170-012-4661-7

J. Sahu, S. Chakrabarty, R. Raghavan, S. Mishra, Investigations of size effect on formability and microstructure evolution in SS304 thin foils. J. Strain Anal. 53(7), 517–528 (2018). https://doi.org/10.1177/0309324718792443

E. Hoggan, R. Scott, M.R. Barnett, P.D. Hodgson, Mechanical properties of tension levelled and skin passed steels. J. Mater. Proc. Technol. 125, 155–163 (2002). https://doi.org/10.1016/s0924-0136(02)00368-0

C.H. Chen, R.S. Lee, J.T. Gau, Size effect and forming-limit strain prediction for microscale sheet metal forming of stainless steel 304. J. Strain Anal. Eng. Design 45, 283–299 (2010). https://doi.org/10.1243/03093247jsa585

J.S.H. Lake, Control of discontinuous yielding by temper rolling. J. Mech. Work. Technol. 12, 35–66 (1985). https://doi.org/10.1016/0378-3804(85)90041-5

J.-R. Kim, A. Eun-Yeong, H. Das, J. Yong-Ha, H. Sung-Tae, M. Miles, L. Kwang-**, Effect of tool geometry and process parameters on mechanical properties of friction stir spot welded dissimilar aluminum alloys. Int. J. Prec. Eng. Manuf. 18, 445–452 (2017). https://doi.org/10.1007/s12541-017-0053-0

J.S. Ibrahim, R.T. Mathew, M.J.N.V. Prasad, K. Narasimhan, Processing and specimen thickness to grain size (t/d) ratio effects on tensile behaviour and microformability of copper foils. Met. Mater. Int. 28, 2340–2355 (2022). https://doi.org/10.1007/s12540-021-01145-w

R. Abbaschian, L. Abbaschian, R.E. Reed-Hill, Physical Metallurgy Principles, 4th edn. (Cengage Learning, USA, 2009)

W.G. Johnston, J.J. Gilman, Dislocation velocities, dislocation densities, and plastic flow in lithium fluoride crystals. J. App. Phys. 30, 129–144 (1959). https://doi.org/10.1063/1.1735121

E.O. Hall, The deformation and ageing of mild steel: III discussion of results. Proc. Phys. Soc. Sect. B 64, 747 (1951). https://doi.org/10.1088/0370-1301/64/9/303

N.J. Petch, The cleavage strength of polycrystals. J. Iron Steel Inst. 174, 25–28 (1953)

S. Takaki, K. Kawasaki, Y. Kimura, Mechanical properties of ultra-fine grained steels. J. Mater. Proc. Technol. 117, 359–363 (2001). https://doi.org/10.1016/s0924-0136(01)00797-x

K. Takeda, N. Nakada, T. Tsuchiyama, S. Takaki, Effect of interstitial elements on Hall–Petch coefficient of ferritic iron. ISIJ Int. 48, 1122–1125 (2008). https://doi.org/10.2355/isi**ternational.48.1122

L.L. Yang, T. Nakagaito, Y. Funakawa, K. Kojima, change in yield strength of Nb-bearing ultra-low carbon steels by temper-rolling. Mater. Sci. Forum 941, 230–235 (2018). https://doi.org/10.4028/www.scientific.net/msf.941.230

A.D. Rollett, U.F. Kocks, A review of the stages of work hardening. Solid State Phen. 35-36, 1–18 (1993). https://doi.org/10.4028/www.scientific.net/ssp.35-36.1

Y. Akiniwa, T. Suzuki, K. Tanaka, Evaluation of deformation behavior in Cu thin film under tensile and fatigue loading by X-ray method. Mater. Sci. Forum 524, 807–812 (2006). https://doi.org/10.4028/www.scientific.net/msf.524-525.807

C. Shen, Z. Zhu, D. Zhu, J. Ren, Copper deposits with high tensile strength and elongation electroformed in an ultra-low-concentration sulfate bath without additives. J Mater Eng Perf 26, 987–992 (2017). https://doi.org/10.1007/s11665-016-2494-5

S. Fujiwara, K. Abiko, Ductility of ultra high purity copper. Le J. de Phys. IV 5, C7-295 (1995). https://doi.org/10.1051/jp4:1995735

M. Shakeri, A. Sadough, B.M. Dariani, Effect of pre-straining and grain size on the limit strains in sheet metal forming. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 214, 821–827 (2000). https://doi.org/10.1243/0954405001517892

W.L. Chan, M.F. Fu, J. Lu, J.G. Liu, Modeling of grain size effect on micro deformation behavior in micro-forming of pure copper. Mater. Sci. Eng. A 527, 6638–6648 (2010). https://doi.org/10.1016/j.msea.2010.07.009

L.F. Peng, Z.T. Xu, M.F. Fu, X.M. Lai, Forming limit of sheet metals in meso-scale plastic forming by using different failure criteria. Int. J. Mech. Sci. 120, 190–203 (2017). https://doi.org/10.1016/j.ijmecsci.2016.11.021

B. Meng, Y.Y. Zhang, C. Cheng, J.Q. Han, M. Wan, Effect of plastic anisotropy on microscale ductile fracture and microformability of stainless steel foil. Int. J. Mech. Sci. 148, 620–635 (2018). https://doi.org/10.1016/j.ijmecsci.2018.09.027

P. Van Houtte, L. Delannay, I. Samajdar, Quantitative prediction of cold rolling textures in low-carbon steel by means of the LAMEL model. Text. Stress Microstruct. 31, 109–149 (1999). https://doi.org/10.1155/2008/173083

I. Samajdar, B. Verlinden, P. Van Houtte, Developments in macro and micro texture during plane strain channel die compression of IF steel. ISIJ Int. 38, 759–765 (1998). https://doi.org/10.2355/isi**ternational.38.759

S.K. Yerra, H.V. Vankudre, P.P. Date, I. Samajdar, Effect of strain path and the magnitude of prestrain on the formability of a low carbon steel: on the textural and microtextural developments. J. Eng. Mater. Technol. 126, 53–61 (2004). https://doi.org/10.1007/s10749-019-01047-3

M.A. Meyers, K.K. Chawla, Mechanical Behavior of Materials (Cambridge University Press, Cambridge, 2008). https://doi.org/10.1017/cbo9780511810947

Acknowledgements

The authors are grateful to M/s Theis Precision Steel India Private Limited for providing us ULC steel sheets and foils for the present study. The authors would like to thank the OIM-Texture lab, IIT Bombay for giving access to the EBSD and XRD texture facilities. The authors acknowledge the FIST-UTM (Mechanical characterization) lab for providing the UTM for conducting the tensile and forming experiments. The authors are thankful to Prof. Pradeep Dixit, Department of Mechanical Engineering, IIT Bombay for facilitating to use the Olympus DSX100 opto-digital microscope.

Funding

No funding is received for the present study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ibrahim, J.S., Prasad, M.J.N.V., Sarkar, P. et al. Effects of Foil Thickness to Grain Size (t/d) Ratio and Prestraining on Tensile Response, Microformability and Crystallographic Texture of Ultra-Low Carbon Steel Thin Foils. Met. Mater. Int. 30, 348–359 (2024). https://doi.org/10.1007/s12540-023-01520-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01520-9