Abstract

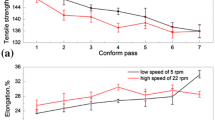

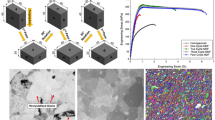

A continuously cast Al–Mg–Si–Cu alloy was processed by repetitive continuous extrusion forming (R-Conform) and the corresponding deformation behaviors, microstructural evolution and mechanical properties were investigated systematically by combining uniaxial compression deformation, finite element simulation, microstructural observation and mechanical test. The results showed that the grain size of Al–Mg–Si–Cu alloy bar was gradually refined and became more uniform after R-Conform processing with the increase of pass as a result of continuous dynamic recrystallization. The evolution of microstructure was related to the complex thermomechanical conditions of temperature, shear rate and the distribution of accumulated strain during R-Conform process. Then the improvement of properties was obtained by the refined grains after R-Conform processing. Further, the dense and fine precipitates formed after solution treatment and aging led to optimized mechanical properties with tensile strength approximate 400 MPa and elongation about 17.8%.

Graphical Abstract

Similar content being viewed by others

References

J. Hirsch, Trans. Nonferrous Met. Soc. China 24, 8 (2014)

L. Ding, Z. Jia, J. Nie, Y. Weng, L. Cao, H. Chen, X. Wu, Q. Liu, Acta Mater. 145, 437 (2018)

J. Man, L. **g, S.G. Jie, J. Alloy Compd. 437, 146 (2007)

Q. **ao, H. Liu, D. Yi, D. Yin, Y. Chen, Y. Zhang, B. Wang, J. Alloy Compd. 695, 1005 (2017)

K. Liu, X.G. Chen, Mater. Des. 84, 340 (2015)

Y. Xu, H. Nagaumi, Y. Han, G. Zhang, T. Zhai, Metall. Mater. Trans. A 48, 1 (2017)

L. Lodgaard, N. Ryum, Mater. Sci. Eng. A 283, 144 (2000)

X. Ji, H. Zhang, S. Luo, F. Jiang, D. Fu, Mater. Sci. Eng. A 649, 128 (2016)

H. Cai, J. Hu, F. Jiang, D. Fu, J. Teng, H. Zhang, Mater. Sci. Eng. A 753, 192 (2019)

R. Lu, S. Zheng, J. Teng, J. Hu, D. Fu, J. Chen, G. Zhao, F. Jiang, H. Zhang, J. Mater. Sci. Technol. 80, 150 (2021)

X. Zhang, H. Zhang, X. Kong, D. Fu, Trans. Nonferrous Met. Soc. China 25, 1763 (2015)

N. Zhao, C. Ban, Met. Mater. Int. 28, 2513 (2022)

R.Z. Valiev, I.V. Alexandrov, Nanostruct. Mater. 45, 35 (1999)

Y. Saito, H. Utsunomiya, N. Tsuji, T. Sakai, Acta Mater. 47, 579 (1999)

S. Samiei, G. Dini, M. Ebrahimian-Hosseinabadi, Met. Mater. Int. (2022). https://doi.org/10.1007/s12540-022-01202-y

K. Edalati, Z. Horita, Mater. Sci. Eng. A 652, 325 (2016)

T.G. Langdon, Mater. Sci. Eng. A 462, 3 (2007)

P.N. Rao, D. Singh, R. Jayaganthan, Mater. Des. 56, 97 (2014)

G.J. Raab, R.Z. Valiev, T.C. Lowe, Y.T. Zhu, Mater. Sci. Eng. A 382, 30 (2004)

W. Huo, L. Hou, C. Hua, L. Zhuang, J. Zhang, Mater. Sci. Eng. A 618, 244 (2014)

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, J.J. Jonas, Prog Mater. Sci. 60, 130 (2014)

X. Kong, H. Zhang, X. Ji, Mater. Sci. Eng. A 612, 131 (2014)

J. Hu, J. Teng, X. Ji, D. Fu, W. Zhang, H. Zhang, Mater. Sci. Eng. A 695, 35 (2017)

J. Hu, W. Zhang, D. Fu, J. Teng, H. Zhang, J. Mater. Res. Technol. 8, 5950 (2019)

R. Lu, L. Zhang, S. Zheng, D. Fu, J. Teng, J. Chen, G. Zhao, F. Jiang, H. Zhang, Int. J. Miner Metall. Mater. 29, 11 (2022)

Z. Shen, Z. Lin, P. Shi, J. Zhu, T. Zheng, B. Ding, Y. Guo, Y. Zhong, J. Mater. Sci. Technol. 110, 187 (2022)

M. Vaseghi, H.S. Kim, Mater. Des. 36, 735 (2012)

F. Kabirian, A. Khan, A. Pandey, Int. J. Plast. 55, 232 (2014)

R.C. Picu, Acta Mater. 52, 3447 (2004)

Y. Zhu, J. Fan, Z. Li, Y. Luo, Y. Niu, Mater. Today Commun. 30, 103060 (2022)

I. Nikulin, A. Kipelova, S. Malopheyev, R. Kaibyshev, Acta Mater. 60, 487 (2012)

A. Chaudhuri, A. Sarkar, S. Suwas, Int. J. Refract. Met. Hard Mater. 73, 168 (2018)

A. Chaudhuri, A.N. Behera, A. Sarkar, R. Kapoor, R.K. Ray, S. Suwas, Acta Mater. 164, 153 (2019)

G.W. Zhang, H. Nagaumi, Y. Han, Y. Xu, C.M. Parish, T.G. Zhai, Mater. Sci. Forum 877, 172 (2016)

C.L. Liu, X. Wang, N.C. Parson, W.J. Poole, Mater. Sci. Eng. A 802, 140605 (2021)

B. Dutta, E. Valdes, C.M. Sellars, Acta Metall. Mater. 40, 653 (1992)

B. Dutta, C.M. Sellars, Mater. Sci. Tech. 3, 197 (1987)

E. Nes, and et al, Acta Metall. 33, 11 (1985)

H. Nagaumi, J. Qin, C. Yu, X. Wang, L. Wang, Trans. Nonferrous Met. Soc. China 32, 1805 (2022)

K. Huang, K. Zhang, K. Marthinsen, R.E. Logé, Acta Mater. 141, 360 (2017)

X. Wang, M. Guo, C. Ma, J. Chen, J. Zhang, L. Zhuang, Int. J. Miner Metall. Mater. 25, 957 (2018)

Y. Weng, Z. Jia, L. Ding, J. Liao, P. Zhang, Y. Xu, Q. Liu, Trans. Nonferrous Met. Soc. China 32, 436 (2022)

R. Lapovok, L. Tóth, M. Winkler, S. Semiatin, J. Mater. Res. 24, 459 (2011)

Y. Wang, L. Zhang, B. Guo, K. Li, S. Ni, Y. Du, M. Song, Mater. Res. Express 5, 106521 (2018)

M. Guo, J. Zhu, Y. Zhang, G. Li, T. Lin, J. Zhang, L. Zhuang, Mater. Charact. 132, 248 (2017)

X. Wang, M. Guo, Y. Zhang, H. **ng, Y. Li, J. Luo, J. Zhang, L. Zhuang, J. Alloy Compd. 657, 906 (2016)

J. Jiang, M. Liu, Y. Liu, K. Tang, Z. Wang, Y. Li, Y. Yu, P. Skaret, H. Roven, Mater. Sci. Forum 877, 437 (2016)

G. Xue, G. Zhong, S. Lin, H.-T. Li, X. Gui, L. Zhang, MATEC Web Conf. 326, 03003 (2020)

R. Singh, A. Singh, N. Prasad, Mater. Sci. Eng. A 277, 114 (2000)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (52074114, 51904099), Key Technologies R&D in Strategic Emerging Industries and Transformation in High-tech Achievements Program of Hunan Province (2022GK4048), Graduate Training and Innovation Practice Base of Hunan Province and State Key Laboratory of Materials Processing and Die & Mould Technology, Huazhong University of Science and Technology.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, L., Lu, R., Tang, J. et al. Microstructural Evolution and Mechanical Properties of a Continuously Cast Al–Mg–Si–Cu Alloy Processed by Repetitive Continuous Extrusion Forming. Met. Mater. Int. 29, 2028–2039 (2023). https://doi.org/10.1007/s12540-022-01353-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01353-y