Abstract

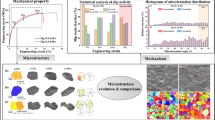

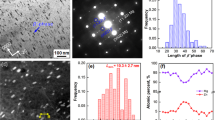

Noteworthy ductility Mg-8Gd-4Y-1Nd-0.5Si (wt.%) alloy with a strong non-basal texture was developed by 12 passes of multi-directional forging (MDF) combine with extrusion. The slip trace analysis indicated that deformation mechanism after 3 passes of MDF and extrusion were basal < a > , pyramidal < a > and pyramidal < c + a > slips. The intensity of non-basal texture increased from 5.37 to 8.03 with the MDF passes increased from 3 to 12, which means grain orientation tends to be more consistent and makes the basal < a > slips easy to pass through grain boundaries to accommodate ductility. With more basal < a > slips crossing the grain boundaries, dislocation interaction in grain interior caused stress accumulation, exceeding the critical shear stress (CRSS) of slips with low schmidt factor (SF), and multiple slips appeared. The activation of slip cross grain boundary and multiple slip improved the elongation from 14.7% to 25.6% of MDFs-extruded Mg-8Gd-4Y-1Nd-0.5Si alloy.

Graphical abstract

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

V.M. Miller, T.D. Berman, I.J. Beyerlein, J.W. Jones, T.M. Pollock, Mater. Sci. Eng. A 675, 345 (2016). https://doi.org/10.1016/j.msea.2016.08.063

W. Cheng, Y. Liu, Y. Zhang, S. Meng, S. Arthanari, H. Wang, L. Wang, Met. Mater. Int. 27, 4510 (2021). https://doi.org/10.1007/s12540-020-00703-y

C. Tang, K. Wu, W. Liu, D. Feng, G. Zuo, W. Liang, Y. Yang, X. Chen, Q. Li, X. Liu, Met. Mater. Int. 27, 1438 (2021). https://doi.org/10.1007/s12540-019-00558-y

B.Y. Liu, F. Liu, N. Yang, X.B. Zhai, L. Zhang, Y. Yang, B. Li, J. Li, E. Ma, J.F. Nie, Z.W. Shan, Science 365, 73 (2019). https://doi.org/10.1126/science.aaw2843

Z. Wu, W.A. Curtin, Nature 526, 62 (2015). https://doi.org/10.1038/nature15364

S.H. Jeong, Y.J. Kim, K.H. Kong, T.H. Cho, Y.K. Kim, H.K. Lim, W.T. Kim, D.H. Kim, Met. Mater. Int. 24, 391 (2018). https://doi.org/10.1007/s12540-018-0027-5

W. Cheng, M. Wang, Z. Que, C. Xu, J. Zhang, W. Liang, B. You, S. Park, J. Central South Univ. 20, 2643 (2013). https://doi.org/10.1007/s11771-013-1779-1

R. Zheng, J.-P. Du, S. Gao, H. Somekawa, S. Ogata, N. Tsuji, Acta Mater. 198, 35 (2020). https://doi.org/10.1016/j.actamat.2020.07.055

J. Koike, T. Kobayashi, T. Mukai, H. Watanabe, M. Suzuki, K. Maruyama, K. Higashi, Acta Mater. 51, 2055 (2003). https://doi.org/10.1016/S1359-6454(03)00005-3

C. Tang, W. Liu, Y. Chen, X. Liu, Y. Deng, J. Mater. Eng. Perform. 26, 383 (2017). https://doi.org/10.1007/s11665-016-2422-8

J. Zhao, J. Fu, B. Jiang, A. Tang, H. Sheng, T. Yang, G. Huang, D. Zhang, F. Pan, Met. Mater. Int. 27, 1403 (2021). https://doi.org/10.1007/s12540-019-00528-4

M.G. Jiang, C. Xu, H. Yan, G.H. Fan, T. Nakata, C.S. Lao, R.S. Chen, S. Kamado, E.H. Han, B.H. Lu, Acta Mater. 157, 53 (2018). https://doi.org/10.1016/j.actamat.2018.07.014

Z.R. Zeng, Y.M. Zhu, S.W. Xu, M.Z. Bian, C.H.J. Davies, N. Birbilis, J.F. Nie, Acta Mater. 105, 479 (2016). https://doi.org/10.1016/j.actamat.2015.12.045

N. **a, C. Wang, Y. Gao, Z. Hua, C. Ma, C. Du, H. Zhang, H. Zhang, M. Li, M. Zha, H. Wang, Mater. Sci. Eng. A 813, 141128 (2021). https://doi.org/10.1016/j.msea.2021.141128

W.B. Hutchinson, M.R. Barnett, Scripta Mater. 63, 737 (2010). https://doi.org/10.1016/j.scriptamat.2010.05.047

T. Zhang, H. Cui, X. Cui, E. Zhao, Y. Pan, R. Feng, Q. Jia, J. Zhao, J. Alloy. Compd. 784, 1130 (2019). https://doi.org/10.1016/j.jallcom.2019.01.110

Q. Wang, Y. Shen, B. Jiang, A. Tang, J. Song, Z. Jiang, T. Yang, G. Huang, F. Pan, Mater. Sci. Eng. A 735, 131 (2018). https://doi.org/10.1016/j.msea.2018.08.035

S. Sandlöbes, M. Friák, S. Zaefferer, A. Dick, S. Yi, D. Letzig, Z. Pei, L.F. Zhu, J. Neugebauer, D. Raabe, Acta Mater. 60, 3011 (2012). https://doi.org/10.1016/j.actamat.2012.02.006

G. Chen, Y. Zhang, W. **a, D. Chen, J. Central South Univ. 22, 4112 (2015). https://doi.org/10.1007/s11771-015-2957-0

C. Wang, H. Zhang, H. Wang, G. Liu, Q. Jiang, Scripta Mater. 69, 445 (2013). https://doi.org/10.1016/j.scriptamat.2013.05.026

L. Guan, Y. Deng, A. Luo, X. Guo, C. Tang, Mater. Sci. Eng. A 804, 140736 (2021). https://doi.org/10.1016/j.msea.2021.140736

M.G. Jiang, H. Yan, R.S. Chen, Mater. Design 87, 891 (2015). https://doi.org/10.1016/j.matdes.2015.08.052

C. Cui, J. He, W. Wang, W. Chen, W. Zhang, J. Alloy. Compd. 909, 164795 (2022). https://doi.org/10.1016/j.jallcom.2022.164795

M.G. Jiang, H. Yan, R.S. Chen, Mater. Sci. Eng. A 621, 204 (2015). https://doi.org/10.1016/j.msea.2014.10.075

Z. Wu, R. Ahmad, B. Yin, S. Sandlobes, W.A. Curtin, Science 359, 447 (2018). https://doi.org/10.1126/science.aap8716

S. Shalvi, Science 365, 29 (2019). https://doi.org/10.1126/science.aax5034

H. Wu, T. Wang, R. Wu, L. Hou, J. Zhang, X. Li, M. Zhang, J. Manuf. Process. 46, 139 (2019). https://doi.org/10.1016/j.jmapro.2019.09.004

P. Mehrotra, T.M. Lillo, S.R. Agnew, Ductility enhancement of a heat-treatable magnesium alloy. Scripta Mater. 55(10), 855–858 (2006). https://doi.org/10.1016/j.scriptamat.2006.08.005

X. Chen, L. **ao, Y. Liu, M. Xu, T. Xu, B. Gao, Z. Hu, H. Zhou, Vacuum 179, 109568 (2020). https://doi.org/10.1016/j.vacuum.2020.109568

X. **a, Q. Chen, Z. Zhao, M. Ma, X. Li, K. Zhang, J. Alloy. Compd. 623, 62 (2015). https://doi.org/10.1016/j.jallcom.2014.10.084

M.G. Jiang, H. Yan, R.S. Chen, J. Alloy. Compd. 650, 399 (2015). https://doi.org/10.1016/j.jallcom.2015.07.281

Z. Zhang, L. Yuan, D. Shan, B. Guo, Mater. Sci. Eng. A 827, 142036 (2021). https://doi.org/10.1016/j.msea.2021.142036

J. Shen, L. Zhang, L. Hu, W. Liu, A. Fang, Z. Yao, Y. Ning, L. Ren, Y. Sun, J. Alloy. Compd. 873, 159604 (2021). https://doi.org/10.1016/j.jallcom.2021.159604

Y. Zhou, Q. Luo, B. Jiang, Q. Li, F. Pan, Scripta Mater. 208, 114345 (2022). https://doi.org/10.1016/j.scriptamat.2021.114345

C. He, S. Bai, B. Jiang, L. Liu, Q. Wang, M. Yuan, Z. Dong, W. He, G. Huang, D. Zhang, F. Pan, J. Mater. Res. Technol. 20, 343 (2022). https://doi.org/10.1016/j.jmrt.2022.07.034

J. Xu, W. Liu, B. Jiang, H. Yang, X. Li, Y. Kang, N. Zhou, W. Zhang, K. Zheng, F. Pan, J. Market. Res. 18, 3143 (2022). https://doi.org/10.1016/j.jmrt.2022.03.165

J. Zhao, B. Jiang, J. Xu, W. He, G. Huang, F. Pan, Mater. Sci. Eng. A 839, 142867 (2022). https://doi.org/10.1016/j.msea.2022.142867

M. Li, Y. Huang, Y. Liu, X. Wang, Z. Wang, Mater. Sci. Eng. A 832, 142479 (2022). https://doi.org/10.1016/j.msea.2021.142479

J. Xu, B. Jiang, Y. Kang, J. Zhao, W. Zhang, K. Zheng, F. Pan, J. Mater. Sci. Technol. 113, 48 (2022). https://doi.org/10.1016/j.jmst.2021.09.023

C. Tang, X. Wang, W. Liu, D. Feng, K. Wu, C. Zhang, G. Miao, W. Liang, J. Li, X. Liu, Q. Li, Mater. Sci. Eng. A 759, 172 (2019). https://doi.org/10.1016/j.msea.2019.05.010

C. Tang, J. Chen, X. Ma, W. Liu, H. **e, M. Li, X. Liu, Mater. Charact. 189, 111952 (2022). https://doi.org/10.1016/j.matchar.2022.111952

Y. Ma, C. Liu, S. Jiang, Y. Wan, Z. Chen, Mater. Charact. 189, 111969 (2022). https://doi.org/10.1016/j.matchar.2022.111969

C. He, M. Yuan, B. Jiang, S. Bai, B. Lei, X. Qian, G. Huang, D. Zhang, F. Pan, Mater. Sci. Eng. A 836, 142699 (2022). https://doi.org/10.1016/j.msea.2022.142699

S. Lee, M. Kim, Y. Chae, H. Guim, J. Singh, S. Choi, J. Alloy. Compd. 897, 163238 (2022). https://doi.org/10.1016/j.jallcom.2021.163238

L. Tang, C. Liu, Z. Chen, D. Ji, H. **ao, Mater. Design 50, 587 (2013). https://doi.org/10.1016/j.matdes.2013.03.054

K.B. Nie, K.K. Deng, X.J. Wang, F.J. Xu, K. Wu, M.Y. Zheng, Mater. Sci. Eng. A 624, 157 (2015). https://doi.org/10.1016/j.msea.2014.11.076

L.L. Chang, Y.N. Wang, X. Zhao, M. Qi, Mater. Charact. 60, 991 (2009). https://doi.org/10.1016/j.matchar.2009.04.001

Y. Guo, T.B. Britton, A.J. Wilkinson, Acta Mater. 76, 1 (2014). https://doi.org/10.1016/j.actamat.2014.05.015

J.L. Li, D. Wu, R.S. Chen, E.H. Han, Acta Mater. 159, 31 (2018). https://doi.org/10.1016/j.actamat.2018.08.013

J. Kacher, B.P. Eftink, B. Cui, I.M. Robertson, Curr. Opin. Solid State Mater. Sci. 18, 227 (2014). https://doi.org/10.1016/j.cossms.2014.05.004

B. Zhou, Y. Li, L. Wang, H. Jia, X. Zeng, Acta Mater. 227, 117662 (2022). https://doi.org/10.1016/j.actamat.2022.117662

T.R. Bieler, P. Eisenlohr, C. Zhang, H.J. Phukan, M.A. Crimp, Curr. Opin. Solid State Mater. Sci. 18, 212 (2014). https://doi.org/10.1016/j.cossms.2014.05.003

B. Anthony, B. Leu, I.J. Beyerlein, V.M. Miller, Acta Mater. 219, 117225 (2021). https://doi.org/10.1016/j.actamat.2021.117225

Y. Takayama, J.A. Szpunar, Mater. Trans. 45, 2316 (2004)

Acknowledgements

The authors gratefully acknowledge National key R & D projects (Project No. 2021YFB3501002) and the Equipment Advance Study Project (Project No. 41422010705). Laboratory stability support funding was obtained from the National Key Laboratory of Science and Technology on High-Strength Structural Materials, Central South University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

All authors have read and approve this version of the article, and due care has been taken to ensure the integrity of the work. The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. This paper is our original unpublished work and it has not been submitted to any other journal for reviews.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuan, M., Zhang, J., Deng, Y. et al. Mechanism of Ductility Enhancement of the Mg-8Gd-4Y-1Nd-0.5Si Alloy by Multi-Directional Forging Process before Extrusion. Met. Mater. Int. 29, 1323–1333 (2023). https://doi.org/10.1007/s12540-022-01310-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01310-9