Abstract

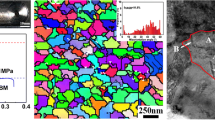

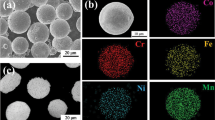

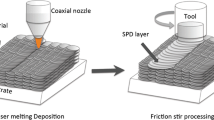

An equiatomic CoCrFeMnNi high entropy alloy (HEA) coating layer was prepared via a cold spray (CS) process. In order to control the microstructure and nano-indentation properties of the CS HEA, heat treatments were employed. CS HEA coating layer showed a heterogeneous microstructure where ultra-fine grains were formed at the particle interfaces, while coarse grains were formed inside the particles. Furthermore, deformation twins (DTs) were also formed inside the particles due to severe plastic deformation (SPD) in each particle generated during the CS deposition. For the 550 °C heat treatment (HT), fine Cr-rich precipitates were additionally formed at the grain boundary and particle boundary. By contrast, recrystallization occurred during 850 °C HT, while the size of the Cr-rich precipitate increased. The nano-indentation hardness of the CS HEA coating layer was 10.9 GPa, which was ~ 3 times higher than that of the conventional cast HEA. The superior hardness of the CS HEA might has been enabled due to the combination of the high dislocation density, DTs, and ultra-fine grains. Based on the results above, the strategy to control the microstructure and mechanical properties through HT of the equiatomic CoCrFeMnNi HEA coating layer prepared via the CS process has been discussed.

Graphic Abstract

Similar content being viewed by others

References

D.B. Miracle, O.N. Senkov, Acta Mater. 122, 448 (2017)

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Mater. Sci. Eng. A 375, 213 (2004)

J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tsau, S.-Y. Chang, Adv. Eng. Mater. 6, 299 (2004)

B. Cantor, Entropy 16, 4749 (2014)

Y.-K. Kim, Y.-A. Joo, H.S. Kim, K.-A. Lee, Intermetallics 98, 45 (2018)

Y.-K. Kim, G.-S. Ham, H.S. Kim, K.-A. Lee, Intermetallics 111, 106486 (2019)

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, R.O. Ritcie, Science 345, 1153 (2014)

Y. Lu, X. Gao, L. Jiang, Z. Chen, T. Wang, J. Jie, H. Kang, Y. Zhang, S. Guo, H. Ruan, Y. Zhao, Z. Cao, T. Li, Acta Mater. 124, 143 (2017)

M. Kang, J.W. Won, K.R. Lim, S.H. Park, S.M. Seo, Y.S. Na, Korean J. Met. Mater. 55, 732 (2017)

E. Colombini, R. Rosa, L. Trombi, M. Zadra, A. Casagrande, P. Veronesi, Mater. Chem. Phys. 210, 78 (2018)

M.L. Brocq, P.-A. Goujon, J. Monnier, B. Villeroy, L. Perrire, R. Pirs, G. Garchin, J. Alloys Compd. 780, 856 (2019)

Y.-K. Kim, J. Choe, K.-A. Lee, J. Alloys Compd. 805, 680 (2019)

Q. Ye, K. Feng, Z. Li, F. Lu, R. Li, J. Huang, Y. Wu, Appl. Surf. Sci. 396, 1420 (2017)

M.Z. Ghomsheh, G. Khatibi, B. Weiss, M. Lederer, S. Schwarz, A.S. -T, M.A. Tikhonovsky, E.D. Tabachnikova, E. Schafler, Mater. Sci. Eng. A 777, 139034 (2020)

W.-L. Hsu, H. Murakami, J.-W. Yeh, A.-C. Yeh, K. Shimoda, Surf. Coat. Technol. 316, 71 (2017)

L. Chen, K. Bobzin, Z. Zhou, L. Zhao, M. Öte, T. Königstein, Z. Tan, D. He, Surf. Coat. Technol. 358, 215 (2019)

J.-K. **ao, H. Tan, Y.-Q. Wu, J. Chen, C. Zhang, Surf. Coat. Technol. 385, 125430 (2020)

F. Chang, B. Cai, C. Zhang, B. Huang, S. Li, P. Dai, Surf. Coat. Technol. 359, 132 (2019)

C. Lee, J. Kim, J. Therm. Spray Technol. 24, 592 (2015)

H.-J. Kim, C.-H. Lee, S.-Y. Hwang, Surf. Coat. Technol. 191, 335 (2005)

A.P. Alkhimov, A.N. Papyrin, V.F. Kosarev, N.I. Nesterovich, M.M. Shushpanov, Gas-dynamic spraying method for applying a coating, U.S. Patent 5,302,414, 12 Apr 1994

S. Yin, W. Li, B. Song, X. Yan, M. Kuang, Y. Xu, K. Wen, R. Lupoi, J. Mater. Sci. Technol. 35, 1003 (2019)

R. Partovi-Nia, S. Ramamurthy, D. Zagidulin, J. Chen, R. Jacklin, P. Keech, D. Shoesmith, Corrosion 71, 1237 (2015)

Y. Zhang, N. Brodusch, S. Descartes, R. Chromik, R. Gauvin, Microsc. Microanal. 20, 1499 (2014)

G. Bae, K. Kang, C. Lee, Mater. Lett. 89, 320 (2012)

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, A. Kostka, D. Raabe, Acta Mater. 94, 124 (2015)

D. Wei, X. Li, J. Jiang, W. Heng, Y. Koizumi, W.-M. Choi, B.-J. Lee, H.S. Kim, H. K, A. Chiba, Scr. Mater. 165, 39 (2019)

D. Wei, X. Li, S. Schönecker, J. Jiang, W.-M. Choi, B.-J. Lee, H.S. Kim, A. Chiba, H. Kato, Acta Mater. 181, 318 (2019)

T.-H. Lee, E. Shin, C.-S. Oh, H.-Y. Ha, S.-J. Kim, Acta Mater. 58, 3173 (2010)

J. Lu, L. Hultman, E. Holmström, K.H. Antonsson, M. Grehk, W. Li, L. Vitos, A. Golpayegani, Acta Mater. 111, 39 (2016)

G. Laplanche, A. Kostka, O.M. Horst, G. Eggeler, E.P. George, Acta Mater. 118, 152 (2016)

S.F. Liu, Y. Wu, H.T. Wang, J.Y. He, J.B. Liu, C.X. Chen, X.J. Liu, H. Wang, Z.P. Lu, Intermetallics 93, 269 (2018)

F. Otto, A. Dlouhý, Ch Somsen, H. Bei, G. Eggler, E.P. George, Acta Mater. 61, 5743 (2013)

G. Laplanche, S. Berglund, C. Reinhart, A. Kostka, F. Fox, E.P. George, Acta Mater. 161, 338 (2018)

M.-H. Tsai, K.-C. Chang, J.-H. Li, R.-C. Tsai, A.-H. Cheng, Mater. Res. Lett. 4, 90 (2016)

M.-H. Tsai, K.-Y. Tsai, C.-W. Tsai, C. Lee, C.-C. Juan, J.-W. Yeh, Mater. Res. Lett. 1, 207 (2013)

F. Otto, A. Dlouhý, K.G. Pradeep, M. Kuběnová, D. Raabe, G. Eggeler, E.P. George, Acta Mater. 112, 40 (2016)

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan, A. Hohenwarter, Acta Mater. 96, 258 (2015)

H. Shahmir, J. He, Z. Lu, M. Kawasaki, T.G. Langdon, Mater. Sci. Eng. A 676, 294 (2016)

Y.H. Jo, W.M. Choi, D.G. Kim, A. Zargaran, K. Lee, H. Sung, S.S. Sohn, H.S. Kim, B.J. Lee, S. Lee, Mater. Sci. Eng. A 743, 665 (2019)

Y.H. Jo, W.-M. Choi, S.S. Sohn, H.S. Kim, B.-J. Lee, S. Lee, Mater. Sci. Eng. A 724, 403 (2018)

Y.-K. Kim, K.-S. Kim, H.-J. Kim, C.-H. Park, K.-A. Lee, J. Therm. Spray Technol. 26, 1498 (2017)

A. Piglione, B. Dovgyy, C. Liu, C.M. Gourlay, P.A. Hooper, M.S. Pham, Mater. Lett. 224, 22 (2018)

E. Abbasi, K. Dehghani, Mater. Sci. Eng. A 753, 224 (2019)

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan, A. Hohenwarter, Mechanical properties. Acta Mater. 96, 258 (2015)

S. Huang, W. Li, S. Lu, F. Tian, J. Shen, E. Holmström, L. Vitos, Scr. Mater. 108, 44 (2015)

P.-L. Sun, Y.H. Zhao, J.C. Cooley, M.E. Kassner, Z. Horita, T.G. Langdon, E.J. Lavernia, Y.T. Zhu, Mater. Sci. Eng. A 525, 83 (2009)

W.C. Oliver, G.M. Pharr, Mat. Res. 19, 3 (2004)

C. Sha, Z. Zhou, Z. **e, P. Munroe, Surf. Coat. Technol. 385, 125435 (2020)

A. Leyland, A. Mattews, Wear 246, 1 (2000)

M. Roy, L. Whiteside, J. Xu, B. Katerberg, Acta Biomater. 6, 1619 (2010)

A. Miserez, J.C. Weaver, P.J. Thurner, J. Aizenberg, Y. Dauphin, P. Fratzl, D.E. Morse, F.W. Zok, Adv. Funct. Mater. 18, 1241 (2008)

Acknowledgements

This study was supported by Korea Institute for Advancement of Technology (KIAT) grant funded by the Korea Government (MOTIE) (P0002007, The Competency Development Program for Industry Specialist). It was also supported by National Research Foundation of Korea (NRF) grant funded by the Korea government (MEST) (No. 2019R1A2C1008904).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ahn, JE., Kim, YK., Yoon, SH. et al. Tuning the Microstructure and Mechanical Properties of Cold Sprayed Equiatomic CoCrFeMnNi High-Entropy Alloy Coating Layer. Met. Mater. Int. 27, 2406–2415 (2021). https://doi.org/10.1007/s12540-020-00886-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00886-4