Abstract

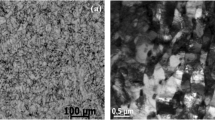

Fusion reactor components undergo asymmetric cyclic loading,that leads to a progressive increase in plastic strain and causes deterioration in life of engineering components. This investigation deals with fatigue behavior of modified 9Cr–1Mo steel at room temperature and presents the effect of mean stress (σm), stress amplitude (σa) and stress rate (\(\dot{\sigma }\)) on fatigue life, deformation and fracture behavior under asymmetric cyclic loading. A series of fatigue tests were conducted under asymmetric stress-controlled loading with different combinations of σm (190–210 MPa), σa (400–420 MPa) and \(\dot{\sigma }\) (50–450 MPa/s). The plastic strain increased with increase in σm and σa and the fatigue life was reduced, whereas increase in \(\dot{\sigma }\) reduced the accumulated plastic strain and the cyclic life was increased. The deformation behavior and microstructural changes under the influence of the three parameters (σm, σa and \(\dot{\sigma }\)) were examined by tranmission electron microscope (TEM). With increase in the three parameters (σm, σa, \(\dot{\sigma }\)), the lath martensitic structure changed to subgrain structure along with dislocation cells and forest dislocations. Scanning electron microscopy revealed unique features of fractured specimens, with progressive reduction in diameter towards the fracture-end, fatigue striations on the tapered circumferential surface and dimples on the fracture surface.

Graphic Abstract

Similar content being viewed by others

References

V.T. Paul, S. Saroja, M. Vijayalakshmi, J. Nucl. Mater. (2008). https://doi.org/10.1016/j.jnucmat.2008.06.033

V. Shankar, M. Valsan, K.B.S. Rao, R. Kannan, S.L. Mannan, S.D. Pathak, Mater. Sci. Eng., A (2006). https://doi.org/10.1016/j.msea.2006.07.146

A. Nagesha, R. Kannan, G.V.S. Sastry, R. Sandhya, V. Singh, K.B.S. Rao, M.D. Mathew, Mater. Sci. Eng., A (2012). https://doi.org/10.1016/j.msea.2012.06.021

B. Das, A. Singh, Fusion Eng. Des. (2019). https://doi.org/10.1016/j.fusengdes.2018.11.007

M. Atkins, Am. Soc. Met. 1980, 260 (1980).

T. Shrestha, S.F. Alsagabi, I. Charit, G.P. Potirniche, M.V. Glazoff, Metals (2015). https://doi.org/10.3390/met5010131

M. Yoshino, Y. Mishima, Y. Toda, H. Kushima, K. Sawada, K. Kimura, Mater. High Temp. (2008). https://doi.org/10.3184/096034008X356349

P. Verma, N.S. Srinivas, S.R. Singh, V. Singh, Mater. Sci. Eng., A (2016). https://doi.org/10.1016/j.msea.2015.11.060

K.S. Chandravathi, K. Laha, K. Bhanu Sankara Rao, S.L. Mannan, Mater. Sci. Technol. (2001). https://doi.org/10.1179/026708301101510212

B.K. Choudhary, Mater. Sci. Eng., A (2013). https://doi.org/10.1016/j.msea.2012.11.104

S.K. Paul, S. Sivaprasad, S. Dhar, S. Tarafder, Int. J. Pres. Ves. Pip. (2010). https://doi.org/10.1016/j.ijpvp.2010.07.008

S.K. Paul, S. Sivaprasad, S. Dhar, S. Tarafder, J. Nucl. Mater. (2010). https://doi.org/10.1016/j.jnucmat.2010.03.014

S. Sivaprasad, S.K. Paul, S.K. Gupta, V. Bhasin, N. Narasaiah, S. Tarafder, Int. J. Pres. Ves. Pip. (2010). https://doi.org/10.1016/j.ijpvp.2010.06.002

S. Sreenivasan, S.K. Mishra, K. Dutta, Mater. Sci. Eng., A (2017). https://doi.org/10.1016/j.msea.2017.05.048

R.S. Rajpurohit, N.S. Srinivas, S.R. Singh, V. Singh, Trans. Ind. Inst. Met. (2018). https://doi.org/10.1007/s12666-017-1251-2

G. Kang, Q. Gao, L. Cai, Y. Sun, Nucl. Eng. Des. (2002). https://doi.org/10.1016/S0029-5493(02)00062-6

K.K. Ray, K. Dutta, S. Sivaprasad, S. Tarafder, Proc. Eng. (2010). https://doi.org/10.1016/j.proeng.2010.03.194

C. Gaudin, X. Feaugas, Acta Mater. (2004). https://doi.org/10.1016/j.actamat.2004.03.011

S. Vishnuvardhan, G. Raghava, P. Gandhi, M. Saravanan, S. Goyal, P. Arora, S.K. Gupta, V. Bhasin, Int. J. Pres. Ves. Pip. (2013). https://doi.org/10.1016/j.ijpvp.2013.03.005

S.C. Kulkarni, Y.M. Desai, T. Kant, G.R. Reddy, Y. Parulekar, K.K. Vaze, Int. J. Pres. Ves. Pip. (2003). https://doi.org/10.1016/S0308-0161(03)00029-2

P.S. De, A. Kundu, P.C. Chakraborti, Mater. Des. (2014). https://doi.org/10.1016/j.matdes.2013.12.029

S.K. Paul, S. Sivaprasad, S. Dhar, S. Tarafder, J. Mater. Sci. (2012). https://doi.org/10.1007/s10853-012-6334-1

S.K. Paul, S. Sivaprasad, S. Dhar, S. Tarafder, Mater. Sci. Eng., A (2011). https://doi.org/10.1016/j.msea.2011.06.009

U. Sánchez-Santana, C. Rubio-González, G. Mesmacque, A. Amrouche, Int. J. Fatigue (2009). https://doi.org/10.1016/j.ijfatigue.2009.02.031

K. Dutta, K.K. Ray, Mater. Sci. Eng., A (2012). https://doi.org/10.1016/j.msea.2012.01.024

R. Kreethi, P. Verma, K. Dutta, Trans. Ind. Inst. Met. (2015). https://doi.org/10.1007/s12666-014-0449-9

C.B. Lim, K.S. Kim, J.B. Seong, Int. J. Fatigue (2009). https://doi.org/10.1016/j.ijfatigue.2008.04.008

Y.C. Lin, Z.H. Liu, X.M. Chen, J. Chen, Mater. Sci. Eng., A (2013). https://doi.org/10.1016/j.msea.2013.03.004

Y.C. Lin, X.M. Chen, G. Chen, J. Alloys Compd. (2011). https://doi.org/10.1016/j.jallcom.2011.03.129

H. Cheng, G. Chen, Z. Zhang, X. Chen, J. Nucl. Mater. (2015). https://doi.org/10.1016/j.jnucmat.2014.12.028

M. Wen, H. Li, D. Yu, G. Chen, X. Chen, Mater. Des. (2013). https://doi.org/10.1016/j.matdes.2012.10.049

R.S. Rajpurohit, N.S. Srinivas, S.R. Singh, V. Singh, Int. J. Pres. Ves. Pip. (2018). https://doi.org/10.1016/j.ijpvp.2017.11.012

J. Zhu, X. Chen, F. Xue, W. Yu, Int. J. Fatigue (2012). https://doi.org/10.1016/j.ijfatigue.2011.04.008

G. Tao, Z. **a, Polym. Test. (2007). https://doi.org/10.1016/j.polymertesting.2006.12.010

A. Sarkar, A. Nagesha, P. Parameswaran, R. Sandhya, M.D. Mathew, Mater. Sci. Eng., A (2013). https://doi.org/10.1016/j.msea.2012.11.115

G. Kang, Q. Gao, X. Yang, Mech. Mater. (2002). https://doi.org/10.1016/S0167-6636(01)00099-0

G. Kang, Q. Gao, X. Yang, Int. J. Nonlinear Mech. (2004). https://doi.org/10.1016/S0020-7462(03)00060-X

F. Yoshida, J. Kondo, Y. Kikuchi, Trans. Jpn. Soc. Mech. Eng. (Ser. A) 54, 1151–1157 (1988)

N. Ohno, J. Soc. Mater. Sci. Jpn. (1997). https://doi.org/10.2472/jsms.46.3Appendix_1

J.L. Chaboche, Int. J. Plast (1991). https://doi.org/10.1016/0749-6419(91)90050-9

Y. Jiang, P. Kurath, Int. J. Plast (1996). https://doi.org/10.1016/S0749-6419(96)00013-7

G. Kang, Y. Li, Q. Gao, Mech. Mater. (2005). https://doi.org/10.1016/j.mechmat.2005.01.006

G. Kang, Y. Dong, H. Wang, Y. Liu, X. Cheng, Mater. Sci. Eng., A (2010). https://doi.org/10.1016/j.msea.2010.06.020

G. Kang, Y. Dong, Y. Liu, H. Jiang, Mater. Charact. (2014). https://doi.org/10.1016/j.matchar.2014.02.014

R. Kreethi, A.K. Mondal, K. Dutta, Mater. Sci. Eng., A (2017). https://doi.org/10.1016/j.msea.2016.10.019

D. Melisova, B. Weiss, R. Stickler, Scr. Mater. (1997). https://doi.org/10.1016/S1359-6462(96)00478-2

P. Verma, G.S. Rao, P. Chellapandi, G.S. Mahobia, K. Chattopadhyay, N.S. Srinivas, V. Singh, Mater. Sci. Eng., A (2015). https://doi.org/10.1016/j.msea.2014.10.011

R.S. Rajpurohit, G.S. Rao, K. Chattopadhyay, N.S. Srinivas, V. Singh, J. Nucl. Mater. (2016). https://doi.org/10.1016/j.jnucmat.2016.05.014

W.B. Jones, C.R. Hills, D.H. Polonis, Metall. Trans. A (1991). https://doi.org/10.1007/BF0266-1098

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mishra, P., Rajpurohit, R.S., Srinivas, N.C.S. et al. Ratcheting Fatigue Behavior of Modified 9Cr–1Mo Steel at Room Temperature. Met. Mater. Int. 27, 4922–4936 (2021). https://doi.org/10.1007/s12540-020-00811-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00811-9