Abstract

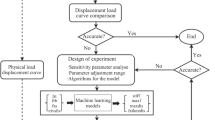

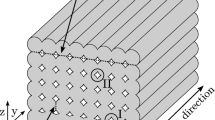

With the rising interest in lightweight construction, the usage of high strength steel has increased remarkably during the last years. Unfortunately, there is manufacturing problem: high strength steel has a higher occurrence rate of cracks than mild steel. The Gurson-Tvergaard-Needleman (GTN) model is used to precisely predict the occurrence of cracks in roll forming. The flow stress and the GTN material parameters are identified using a load-displacement curve obtained from tensile test. In detail, the material parameters that have to be determined were selected and based on this 3-level orthogonal array is made. The coefficients of the objective function are derived using the response surface method with the orthogonal array based on the simulation results. The material parameters are obtained by minimizing the objective function and determined by comparing the simulation and test results. The reliability of the material parameters determined by the tensile test increased through cross-validation using the bending test. The roll forming simulation with the determined parameters is fulfilled, and the experiments are performed to determine the occurrence of micro-cracks according to bending angles. Micro-cracks are quantified by comparing the void volume fraction (f) from the GTN model, and the micro-cracks on the surface are measured using a scanning-electron-microscope.

Similar content being viewed by others

References

Y. X. Li, Z. Q. Lin, A. Q. Jiang, and G. L. Chen, Mater. Design 24, 177 (2003).

K. Sweeney and U. Grunewald, J. Mater. Process Technol. 132, 9 (2003).

M. Lindgren, J. Mater. Process Techol. 191, 44 (2007).

M. Lindgren, J. Mater Process Technol. 186, 77 (2007).

P. Groche, P. Beiter, and M. Henkelmann, Prod. Eng. Res. Devel. 2, 401 (2008).

H. Ona, J. Mater. Process Technol. 153, 247 (2004).

M. Merklein and M. Geiger, J. Mater. Process Technol. 125, 532 (2002).

A. L. Gurson, J. Eng. Mater. Technol. 99, 2 (1977).

V. Tvergaard, Int. J. Fract. 17, 389 (1981).

V. Tvergaard, Int. J. Fract. 18, 237 (1982).

V. Tvergaard and A. Needleman, Acta Metall. 32, 157 (1984).

L. **a, C.F. Shih, and J.W. Hutchinson, J. Mech. Phys. Solids 43, 389 (1995).

W. Schmitt, D.Z. Sun, and J.G. Blauel, Nucl. Eng. Des. 174, 237 (1997).

T. S. Srivatsan, M. Al-Hajri, C. Smith, and M. Petraroli, Mater. Sci. Eng. a-Struct. 346, 91 (2003).

E.-Y. Kim, H. S. Yang, S. H. Han, J. H. Kwak, and S.-H. Choi, Met. Mater. Int. 18, 573 (2012).

M. He, F.G. Li, and Z.G. Wang, Chinese J. Aeronaut. 24, 378 (2011).

M. Springmann and M. Kuna, Comp. Mater. Sci. 33, 500 (2005).

J. Wang, N. Kim, and H. Lee, Met. Mater. Int. 18, 303 (2012).

I.-K. Kim, J.-Y. Song, O.-K. Hwan, and S. I. Hong, Korean J. Met. Mater. 50, 345 (2012).

J. C. Simo and T. J. R. Hughes, Computational Inelasticity, p.120, Springer, New York (1998).

C. C. Chu and A. Needleman, J. Eng. Mater. Technol. 102, 249 (1980).

N. Aravas, Int. J. Numer Meth. Eng. 24, 1395 (1987).

J. E. Dennis and R. B. Schnabel, Numerical Methods for Unconstrained Optimization and Nonlinear Equations, p.86, Prentice-Hall, Englewood Cliffs, N.J. (1983).

J. C. Simo and T. A. Laursen, Comput. Struct. 42, 97 (1992).

S. Hong, S. Lee, and N. Kim, J. Mater. Process Tech. 113, 774 (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cha, Wg., Kim, N. Quantification of micro-cracks on the bending surface of roll formed products using the GTN model. Met. Mater. Int. 20, 841–850 (2014). https://doi.org/10.1007/s12540-014-5008-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-014-5008-8