Abstract

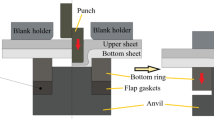

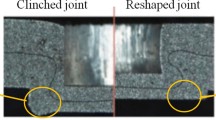

This article describes the joining of thin metal sheets by a single stroke clinching process. Elastic-plastic and rigid-plastic finite element analysis were applied by employing Coulomb friction and constant shear friction in order to investigate the behavior of the clinch joint formation process. Four process variables, such as die diameter, die depth, groove width, and groove corner radius were selected to investigate the parametric effect on the clinch joint. The strength of clinch joints were evaluated by examining the separation strengths, such as peel strength and tensile shear strength, respectively. A failure diagram was constructed that summarizes the analysis results. The simulation results showed that die diameter and depth were the most decisive parameters for controlling the quality of the clinch joint, while the bottom’s thickness was the most important evaluation parameter to determine the separation strengths.

Similar content being viewed by others

References

J. Varis, J. Mater. Process. Technol. 174, 277 (2006).

TOX-Pressotechnik GmbH, Overview of TOX clinching Tech. http://www.tox-de.com (2005).

J. P. Varis, J. Mater. Process. Technol. 132, 242 (2003).

ATTEXOR Inc., What is Clinching, http://www.attexorinc.com (2005).

N. Nong, O. Keju, and Z. Yu, J. Mater. Process. Technol. 137, 59 (2003).

M. Carboni, S. Bereetta, and M. Monno, Eng. Fract. Mech. 73, 179 (2006).

R. F. Pedreschi, and B. P. Sinha, Constr. Build. Mater. 22, 921 (2007).

C.-S. Chung, B.-S. Cha, and H.-K. Kim, Mater. Manufact. Process 16, 387 (2001).

V. Hamel and J. M. Roelandt, Comput. Struct. 77, 185 (2000).

J. Gardstam, Licentiate thesis, p. 5–15, Royal Institute of Technology, Sweden (2006).

P. Hrycaj, S. Cescotto, and J. Oudin, J. Eng. Comput. 8, 291 (1991).

D. H. Jang and B. B Hwang, Mater. Sci. Forum 475, 3255 (2005).

V. R. Jayasekara, J. H. Noh, B. B. Hwang, K. C. Ham, and D. H. Jang, Trans. of Mater. Process. 16, 603 (2007).

M. Oudjene and L. Ben-Ayed, J. Eng. Struct. 30, 1782 (2008).

P. F. Zheng, L. C. Chan, and T. C. Lee, J. Finite Elem. Anal. Des. 42, 189 (2005).

SFTC, DEFROM-2D Ver. 8.0 Users Manual, Scientific Forming Technologies Corporation Inc., USA (2004).

J. Sarkar, T. R. G. Kutty, and K. T. Conlon, J. Mater. Sci. Eng. A 316, 52 (2001).

H. Nordberg, Fatigue Properties of Stainless Steel Lap Joints, http://www.sae.org (2005).

A. A. de Paula, M. T. P. Aguilar, and A. E. M. Pertence, J. Mater. Process. Technol. 182, 352 (2007).

S.-S Park, S.-M. Lee, Y.-J. Cho, J. Kor. Inst. Met. & Mater. 46, 672 (2008).

SFTC, DEFROM-3D Ver. 5.0 Users Manual, Scientific Forming Technologies Corporation Inc., USA (2004).

Y. Tan, O. Hahn, and F. Du, ISIJ Int. 45, 723 (2005).

J. P. Varis and J. Lepisto, Thin-Walled Struct. 41, 691 (2003).

Adam Cort BNP Media, In a Clinch, http://www.assemblymag.com (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jayasekara, V., Min, K.H., Noh, J.H. et al. Rigid-plastic and elastic-plastic finite element analysis on the clinching joint process of thin metal sheets. Met. Mater. Int. 16, 339–347 (2010). https://doi.org/10.1007/s12540-010-0427-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-010-0427-7