Abstract

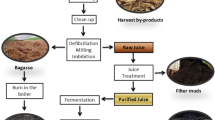

The worldwide expansion in energy and resource use has resulted in a number of unsustainable innovations, necessitating the development of resource sustainability and a reduction in energy usage. Valorization of industrial waste is centred on reducing the amount of pollutants in the environment as well as increasing the revenue generated by industries. Sugarcane processing generates large amount of by-products, namely cane trash, bagasse, molasses and press mud which can be valorized into various value-added products. In this paper, the authors reviewed the variety of applications of sugar industry by-products that has been physically and chemically transformed. It also observed that the technology for producing power from the by-products has advanced, while the manufacture of value-added chemicals has not. The key technological challenges in this area are downstream separation and purification. The difficulties in putting these waste valorization methods in place are also discussed. The amount of investigation and implementation of various solutions varies a lot. In order to translate research findings into commercial products, both business participation and government encouragement are essential. Economic and technological constraints must be recognized for effective commercialization. Some interesting areas were also highlighted which can become the basis for further investigations and could act as guidance for further research in this domain.

Similar content being viewed by others

References

Abba, M., B.B. Nyakuma, Z. Ibrahim, J.B. Ali, S.I.A. Razak, and R. Salihu. 2020. Physicochemical, morphological, and microstructural characterisation of bacterial nanocellulose from Gluconacetobacter xylinus BCZM. Journal of Natural Fibers. https://doi.org/10.1080/15440478.2020.1857896.

Acharya, S.K., P. Mishra, and S.K. Mehar. 2011. Effect of surface treatment on the mechanical properties of bagasse fiber reinforced polymer composite. BioResources 6 (3): 3155–3165.

Adeniyi, A.G., J.O. Ighalo, and A. Abdulsalam. 2019. Modelling of integrated processes for the recovery of the energetic content of sugarcane bagasse. Biofuels, Bioproducts & Biorefining 13 (4): 1057–1067. https://doi.org/10.1002/bbb.1998.

Adeniyi, A.G., J.O. Ighalo, D.V. Onifade, and S.A. Adeoye. 2020a. Modeling the valorization of poultry litter via thermochemical processing. Biofuels, Bioproducts and Biorefining 14 (2): 242–248.

Adeniyi, A.G., D.V. Onifade, S.A. Abdulkareem, M.K. Amosa, and J.O. Ighalo. 2020b. Valorization of plantain stalk and polystyrene wastes for composite development. Journal of Polymers and the Environment 28 (10): 2644–2651.

Adeniyi, A.G., S.A. Abdulkareem, J.O. Ighalo, D.V. Onifade, and S.K. Sanusi. 2020c. Thermochemical co-conversion of sugarcane bagasse-LDPE hybrid waste into biochar. Arabian Journal for Science and Engineering. https://doi.org/10.1007/s13369-020-05119-9.

Adeniyi, A.G., J.O. Ighalo, and C.A. Adeyanju. 2021. Materials-to-product potentials for sustainable development in Nigeria. International Journal of Sustainable Engineering 14 (4): 664–671. https://doi.org/10.1080/19397038.2021.1896591.

Adeniyi, A.G., S.A. Abdulkareem, M.K. Amosa, M.T. Abdulkareem, and J.O. Ighalo. 2022. Mechanical Crystallographic and microstructural analysis of polymer composites developed from iron filings and polystyrene wastes. Mechanics of Advanced Composite Structures. https://doi.org/10.22075/MACS.2022.20943.1282.

Afiomah, C.S., and K.O. Iwuozor. 2020. Nutritional and phytochemical properties of beta vulgaris Linnaeus (Chenopodiaceae)–A review. Nigerian Journal of Pharmaceutical and Applied Science Research 9 (4): 38–44.

Ajala, E., J. Ighalo, M. Ajala, A. Adeniyi, and A. Ayanshola. 2021. Sugarcane bagasse: A biomass sufficiently applied for improving global energy, environment and economic sustainability. Bioresources and Bioprocessing 8 (1): 1–25.

Akbar, A., and I. Ali. 2017. Value-added by-products from sugar processing industries. Food Processing By-Products and their Utilization. https://doi.org/10.1002/9781118432921.ch21.

Akbar, N.M. 2006. Study on effluents from selected sugar mills in Pakistan: Potential environmental, health, and economic consequences of an excessive pollution load. Sustainable Development Policy Institute. 1-41.

Akhabue, C., K.S. Otoikhian, D. Bello, A.G. Adeniyi, and J.O. Ighalo. 2019. Effect of dilute acid pre-treatment on the functional complexes and surface morphology of wood sawdust for bioethanol production. In: 18th annual International Materials Congress for the Materials Society of Nigeria (MSN), University of Ilorin, Nigeria, 2019. pp 318–322.

Alavéz-Ramírez, R., P. Montes-Garcia, J. Martínez-Reyes, D.C. Altamirano-Juárez, and Y. Gochi-Ponce. 2012. The use of sugarcane bagasse ash and lime to improve the durability and mechanical properties of compacted soil blocks. Construction and Building Materials 34: 296–305.

Alomá, I., M. Martín-Lara, I. Rodríguez, G. Blázquez, and M. Calero. 2012. Removal of nickel (II) ions from aqueous solutions by biosorption on sugarcane bagasse. Journal of the Taiwan Institute of Chemical Engineers 43 (2): 275–281.

Alomá, I.D.L.C., I. Rodriguez, M. Calero, and G. Blazquez. 2014. Biosorption of Cr6+ from aqueous solution by sugarcane bagasse. Desalination and Water Treatment 52 (31–33): 5912–5922.

Alves de Oliveira, R., C.E. Vaz Rossell, B.H. Lunelli, P.O. Schichi, J. Venus, and R.M. Filho. 2018. Different strategies to improve lactic acid productivity based on microorganism physiology and optimum operating conditions. Industrial & Engineering Chemistry Research 57 (31): 10118–10125.

Amin, N.-U. 2011. Use of bagasse ash in concrete and its impact on the strength and chloride resistivity. Journal of Materials in Civil Engineering 23 (5): 717–720.

Anggono, J., Á.E. Farkas, A. Bartos, J. Móczó, H. Purwaningsih, and B. Pukánszky. 2019. Deformation and failure of sugarcane bagasse reinforced pp. European Polymer Journal 112: 153–160.

Ansari, K.B., and V.G. Gaikar. 2014. Pressmud as an alternate resource for hydrocarbons and chemicals by thermal pyrolysis. Industrial & Engineering Chemistry Research 53 (5): 1878–1889.

Asikin, Y., M. Takahashi, T. Mishima, M. Mizu, K. Takara, and K. Wada. 2013. Antioxidant activity of sugarcane molasses against 2, 2′-azobis (2-amidinopropane) dihydrochloride-induced peroxyl radicals. Food Chemistry 141 (1): 466–472.

Asikin, Y., M. Takahashi, M. Mizu, K. Takara, H. Oku, and K. Wada. 2016. DNA damage protection against free radicals of two antioxidant neolignan glucosides from sugarcane molasses. Journal of the Science of Food and Agriculture 96 (4): 1209–1215.

Assefa, D., and A. Nurfeta. 2013. Effects of molasses level in a concentrate mixture on performances of crossbred heifer calves fed a basal diet of maize stover. Journal of Cell and Animal Biology 7 (1): 1–8.

Bahurudeen, A., and M. Santhanam. 2015. Influence of different processing methods on the pozzolanic performance of sugarcane bagasse ash. Cement and Concrete Composites 56: 32–45.

Bahurudeen, A., K. Wani, M.A. Basit, and M. Santhanam. 2016. Assesment of pozzolanic performance of sugarcane bagasse ash. Journal of Materials in Civil Engineering 28 (2): 04015095.

Balakrishnan, M., and V. Batra. 2011. Valorization of solid waste in sugar factories with possible applications in India: A review. Journal of Environmental Management 92 (11): 2886–2891.

Barros, S. 2021. Sugar Annual. Sao Paulo ATO. https://apps.fas.usda.gov/newgainapi/api/Report/DownloadReportByFileName?fileName=Sugar%20Annual_Sao%20Paulo%20ATO_Brazil_04-15-2021.pdf. Accessed 12 Dec 2021.

Baurhoo, B., and A. Mustafa. 2014. Effects of molasses supplementation on performance of lactating cows fed high-alfalfa silage diets. Journal of Dairy Science 97 (2): 1072–1076.

Bento, H.B., A.K. Carvalho, C.E. Reis, and H.F. De Castro. 2020. Single cell oil production and modification for fuel and food applications: Assessing the potential of sugarcane molasses as culture medium for filamentous fungus. Industrial Crops and Products 145: 112141.

Bezerra, T.L., and A.J. Ragauskas. 2016. A review of sugarcane bagasse for second-generation bioethanol and biopower production. Biofuels, Bioproducts and Biorefining 10 (5): 634–647.

Bhatnagar, A., K.K. Kesari, and N. Shurpali. 2016. Multidisciplinary approaches to handling wastes in sugar industries. Water, Air, & Soil Pollution 227 (1): 1–30.

Bhatti, Z.A., M.-U.-H. Rajput, G. Maitlo, Z.A. Solangi, and G.S. Shaikh. 2019. Impact of storage time, rain and quality of molasses in the production of bioethanol. Mehran University Research Journal of Engineering & Technology 38 (4): 1021–1032.

Boviatsi, E., A. Papadaki, M.N. Efthymiou, G.J.E. Nychas, S. Papanikolaou, J.A. da Silva, D.M. Freire, and A. Koutinas. 2020. Valorisation of sugarcane molasses for the production of microbial lipids via fermentation of two Rhodosporidium strains for enzymatic synthesis of polyol esters. Journal of Chemical Technology & Biotechnology 95 (2): 402–407.

Candido, R., G. Godoy, and A.R. Gonçalves. 2017. Characterization and application of cellulose acetate synthesized from sugarcane bagasse. Carbohydrate Polymers 167: 280–289.

Canilha, L., V.T. Santos, G.J. Rocha, J.B. Almeida e Silva, M. Giulietti, S.S. Silva, M.G. Felipe, A. Ferraz, A.M. Milagres, and W. Carvalho. 2011. A study on the pretreatment of a sugarcane bagasse sample with dilute sulfuric acid. Journal of Industrial Microbiology and Biotechnology 38 (9): 1467–1475.

Casu, R.E., A. Selivanova, and J.M. Perroux. 2012. High-throughput assessment of transgene copy number in sugarcane using real-time quantitative PCR. Plant Cell Reports 31 (1): 167–177.

Chaisu, K., A.L. Charles, Y.-K. Guu, T.-B. Yen, and C.-H. Chiu. 2014. Optimization lactic acid production from molasses renewable raw material through response surface methodology with Lactobacillus casei M-15. APCBEE Procedia 8: 194–198.

Chan, S., S. Kanchanatawee, and K. Jantama. 2012. Production of succinic acid from sucrose and sugarcane molasses by metabolically engineered Escherichia coli. Bioresource Technology 103 (1): 329–336.

Chandel, A.K., S.S. da Silva, W. Carvalho, and O.V. Singh. 2012. Sugarcane bagasse and leaves: Foreseeable biomass of biofuel and bio-products. Journal of Chemical Technology & Biotechnology 87 (1): 11–20.

Chauhan, J.S., and J.P.N. Rai. 2012. Reuse of distillery wastewater with designed dose and pattern for sugarcane irrigation. CLEAN–Soil, Air, Water 40 (8): 838–843.

Cheng, Y., Y. Yu, C. Wang, Z. Zhu, and M. Huang. 2021. Inhibitory effect of sugarcane (Saccharum officinarum L.) molasses extract on the formation of heterocyclic amines in deep-fried chicken wings. Food Control 119: 107490.

Corrales, R.C.N.R., F.M.T. Mendes, C.C. Perrone, C. Sant’Anna, W. de Souza, Y. Abud, E.P.P. da Silva Bon, and V. Ferreira-Leitão. 2012. Structural evaluation of sugar cane bagasse steam pretreated in the presence of CO2 and SO2. Biotechnology for Biofuels 5 (1): 1–8.

Cueva-Orjuela, J.C., A. Hormaza-Anaguano, and A. Merino-Restrepo. 2017. Sugarcane bagasse and its potential use for the textile effluent treatment. Dyna 84 (203): 291–297.

da Silva, L.G., R. Ruggiero, M. de Patrícia, R.B. Gontijo, B.R. Pinto, E.C. Lima, T.H. Fernandes, and T. Calvete. 2011. Adsorption of Brilliant Red 2BE dye from water solutions by a chemically modified sugarcane bagasse lignin. Chemical Engineering Journal 168 (2): 620–628.

Dantas, G.A., L.F. Legey, and A. Mazzone. 2013. Energy from sugarcane bagasse in Brazil: An assessment of the productivity and cost of different technological routes. Renewable and Sustainable Energy Reviews 21: 356–364.

De Albuquerque Wanderley, M.C., C. Martín, G.J. de Moraes Rocha, and E.R. Gouveia. 2013. Increase in ethanol production from sugarcane bagasse based on combined pretreatments and fed-batch enzymatic hydrolysis. Bioresource Technology 128: 448–453.

De Moraes Rocha, G.J., V.M. Nascimento, A.R. Goncalves, V.F.N. Silva, and C. Martín. 2015. Influence of mixed sugarcane bagasse samples evaluated by elemental and physical–chemical composition. Industrial Crops and Products 64: 52–58.

de Oliveira, F.B., J. Bras, M.T.B. Pimenta, A.A. da Silva Curvelo, and M.N. Belgacem. 2016a. Production of cellulose nanocrystals from sugarcane bagasse fibers and pith. Industrial Crops and Products 93: 48–57.

de Oliveira Lino, F.S., T.O. Basso, and M.O.A. Sommer. 2018. A synthetic medium to simulate sugarcane molasses. Biotechnology for Biofuels 11 (1): 1–12.

de Souza, C.J., D.A. Costa, M.Q. Rodrigues, A.F. dos Santos, M.R. Lopes, A.B. Abrantes, P. dos Santos Costa, W.B. Silveira, F.M. Passos, and L.G. Fietto. 2012. The influence of presaccharification, fermentation temperature and yeast strain on ethanol production from sugarcane bagasse. Bioresource Technology 109: 63–69.

Demoz, Y., A. Assefa, and K. Endale. 2018. Effect of feeding urea-molasses treated TEFF straw on milk yield and composition of cross bred dairy cows. Online Journal of Animal and Feed Research 8 (6): 175–179.

Déportes, I., J.-L. Benoit-Guyod, and D. Zmirou. 1995. Hazard to man and the environment posed by the use of urban waste compost: A review. Science of the Total Environment 172 (2–3): 197–222.

Deseo, M.A., A. Elkins, S. Rochfort, and B. Kitchen. 2020. Antioxidant activity and polyphenol composition of sugarcane molasses extract. Food Chemistry 314: 126180.

Dias, M.O., T.L. Junqueira, O. Cavalett, M.P. Cunha, C.D. Jesus, C.E. Rossell, R. Maciel Filho, and A. Bonomi. 2012. Integrated versus stand-alone second generation ethanol production from sugarcane bagasse and trash. Bioresource Technology 103 (1): 152–161.

Ding, W., X. Dong, I.M. Ime, B. Gao, and L.Q. Ma. 2014. Pyrolytic temperatures impact lead sorption mechanisms by bagasse biochars. Chemosphere 105: 68–74.

Dos Santos, V.C., J.V. De Souza, C.R. Tarley, J. Caetano, and D.C. Dragunski. 2011. Copper ions adsorption from aqueous medium using the biosorbent sugarcane bagasse in natura and chemically modified. Water, Air & Soil Pollution 216 (1): 351–359.

Duga, N.D.F., P.E.A. Imperial, A.N. Soriano, and A.D. Nieva. 2016. Packed bed biosorption of lead and copper ions using sugarcane bagasse. ASEAN Journal of Chemical Engineering 16 (1): 23–37.

El-Gendy, N.S., H.R. Madian, and S.S.A. Amr. 2013. Design and optimization of a process for sugarcane molasses fermentation by Saccharomyces cerevisiae using response surface methodology. International Journal of Microbiology 2013: 1–9.

Ellis, T.P., A.G. Wright, P.M. Clifton, and L.L. Ilag. 2016. Postprandial insulin and glucose levels are reduced in healthy subjects when a standardised breakfast meal is supplemented with a filtered sugarcane molasses concentrate. European Journal of Nutrition 55 (8): 2365–2376.

Emenike, E.C., A.G. Adeniyi, P.E. Omuku, K.C. Okwu, and K.O. Iwuozor. 2022. Recent Advances in Nano-adsorbents for the sequestration of Copper from Water. Journal of Water Process Engineering 47: 102715.

Emenike, E.C., K.O. Iwuozor, and S.U. Anidiobi. 2021. Heavy metal pollution in aquaculture: sources, impacts and mitigation techniques. Biological Trace Element Research. https://doi.org/10.1007/s12011-021-03037-x.

Esparza, I., N. Jiménez-Moreno, F. Bimbela, C. Ancín-Azpilicueta, and L.M. Gandía. 2020. Fruit and vegetable waste management: Conventional and emerging approaches. Journal of Environmental Management 265: 110510.

Fadel, M., A.A. Keera, F.E. Mouafi, and T. Kahil. 2013. High level ethanol from sugar cane molasses by a new thermotolerant Saccharomyces cerevisiae strain in industrial scale. Biotechnology Research International. https://doi.org/10.1155/2013/253286.

Faria, K., R. Gurgel, and J. Holanda. 2012. Recycling of sugarcane bagasse ash waste in the production of clay bricks. Journal of Environmental Management 101: 7–12.

Farooq, U., F.M. Anjum, T. Zahoor, M.A. Sajjad-Ur-Rahman, A.A. Randhawa, and K. Akram. 2012. Optimization of lactic acid production from cheap raw material: Sugarcane molasses. Pakistan Journal of Botany 44 (1): 333–338.

Fatoye, E., and M. Onigbinde. 2020. Dye adsorption with sugarcane bagasse and corn cob. SAU Science-Tech Journal 5 (1): 182–193.

Feng, Y.-H., T.-Y. Cheng, W.-G. Yang, P.-T. Ma, H.-Z. He, X.-C. Yin, and X.-X. Yu. 2018. Characteristics and environmentally friendly extraction of cellulose nanofibrils from sugarcane bagasse. Industrial Crops and Products 111: 285–291.

Ferreira, F., M. Mariano, S. Rabelo, R. Gouveia, and L. Lona. 2018. Isolation and surface modification of cellulose nanocrystals from sugarcane bagasse waste: From a micro-to a nano-scale view. Applied Surface Science 436: 1113–1122.

Franitza, L., M. Granvogl, and P. Schieberle. 2016. Influence of the production process on the key aroma compounds of rum: From molasses to the spirit. Journal of Agricultural and Food Chemistry 64 (47): 9041–9053.

Franitza, L., L. Nicolotti, M. Granvogl, and P. Schieberle. 2018. Differentiation of rums produced from sugar cane juice (rhum agricole) from rums manufactured from sugar cane molasses by a metabolomics approach. Journal of Agricultural and Food Chemistry 66 (11): 3038–3045.

Frías, M., E. Villar, and H. Savastano. 2011. Brazilian sugar cane bagasse ashes from the cogeneration industry as active pozzolans for cement manufacture. Cement and Concrete Composites 33 (4): 490–496.

Furlan, F.F., R. Tonon Filho, F.H. Pinto, C.B. Costa, A.J. Cruz, R.L. Giordano, and R.C. Giordano. 2013. Bioelectricity versus bioethanol from sugarcane bagasse: Is it worth being flexible? Biotechnology for Biofuels 6 (1): 1–12.

Gangavati, P., M. Safi, A. Singh, B. Prasad, and I. Mishra. 2005. Pyrolysis and thermal oxidation kinetics of sugar mill press mud. Thermochimica Acta 428 (1–2): 63–70.

Gasmalla, M., R. Yang, M. Nikoo, and S. Man. 2012. Production of ethanol from Sudanese sugar cane molasses and evaluation of its quality. Journal of Food Processing & Technology 3 (7): 163–165.

George, P.A.O., J.J.C. Eras, A.S. Gutierrez, L. Hens, and C. Vandecasteele. 2010. Residue from sugarcane juice filtration (filter cake): Energy use at the sugar factory. Waste and Biomass Valorization 1 (4): 407–413.

Gharib-Bibalan, S. 2018. High Value-added products recovery from sugar processing by-products and residuals by green technologies: Opportunities, challenges, and prospects. Food Engineering Reviews 10 (2): 95–111.

Ghorbani, F., H. Younesi, A.E. Sari, and G. Najafpour. 2011. Cane molasses fermentation for continuous ethanol production in an immobilized cells reactor by Saccharomyces cerevisiae. Renewable Energy 36 (2): 503–509.

Gil, M.P., A.M.C. Moya, and E.R. Domínguez. 2013. Life cycle assessment of the cogeneration processes in the Cuban sugar industry. Journal of Cleaner Production 41: 222–231.

Gopinath, A., A. Bahurudeen, S. Appari, and P. Nanthagopalan. 2018. A circular framework for the valorisation of sugar industry wastes: Review on the industrial symbiosis between sugar, construction and energy industries. Journal of Cleaner Production 203: 89–108.

Gupta, R., J. Ladha, J. Bains, and J. Singh. 2008. Evaluation of press mud cake as a source of nitrogen and phosphorus for rice–wheat crop** system in the Indo-Gangetic plains of India. Biology and Fertility of Soils 44 (5): 755–762.

Gupta, N., S. Tripathi, and C. Balomajumder. 2011. Characterization of pressmud: A sugar industry waste. Fuel 90 (1): 389–394.

Gupta, A., S. Vidyarthi, and N. Sankararamakrishnan. 2015. Concurrent removal of As (III) and As (V) using green low cost functionalized biosorbent–Saccharum officinarum bagasse. Journal of Environmental Chemical Engineering 3 (1): 113–121.

Gutiérrez-Rivera, B., B. Ortiz-Muñiz, J. Gómez-Rodríguez, A. Cárdenas-Cágal, J.M.D. González, and M.G. Aguilar-Uscanga. 2015. Bioethanol production from hydrolyzed sugarcane bagasse supplemented with molasses “B” in a mixed yeast culture. Renewable Energy 74: 399–405.

Hamouda, H.I., H.N. Nassar, H.R. Madian, S.S.A. Amr, and N.S. El-Gendy. 2015. Response surface optimization of bioethanol production from sugarcane molasses by Pichia veronae strain HSC-22. Biotechnology Research International 2015: 1–10.

Hamzeh, Y., A. Ashori, Z. Khorasani, A. Abdulkhani, and A. Abyaz. 2013. Pre-extraction of hemicelluloses from bagasse fibers: Effects of dry-strength additives on paper properties. Industrial Crops and Products 43: 365–371.

Hans, M., S. Garg, V.O. Pellegrini, J.G. Filgueiras, E.R. de Azevedo, F.E. Guimaraes, A.K. Chandel, I. Polikarpov, B.S. Chadha, and S. Kumar. 2021. Liquid ammonia pretreatment optimization for improved release of fermentable sugars from sugarcane bagasse. Journal of Cleaner Production 281: 123922.

Hemmasi, A.H., A. Samariha, A. Tabei, M. Nemati, and A. Khakifirooz. 2011. Study of morphological and chemical composition of fibers from Iranian sugarcane bagasse. American-Eurasian Journal of Agriculture Environmental Sciences 11 (4): 478–481.

Hinojosa-Nogueira, D., S. Pérez-Burillo, J.Á. Rufián-Henares, and S.P. de la Cueva. 2020. Characterization of rums sold in Spain through their absorption spectra, furans, phenolic compounds and total antioxidant capacity. Food chemistry 323: 126829.

Hofsetz, K., and M.A. Silva. 2012. Brazilian sugarcane bagasse: Energy and non-energy consumption. Biomass and Bioenergy 46: 564–573.

Ighalo, J.O., and A.G. Adeniyi. 2020a. A perspective on environmental sustainability in the cement industry. Waste Disposal and Sustainable Energy 2 (3): 161–164. https://doi.org/10.1007/s42768-020-00043-y.

Ighalo, J.O., and A.G. Adeniyi. 2020b. Statistical modelling and optimisation of the biosorption of Cd(II) and Pb(II) onto dead biomass of pseudomonas aeruginosa. Chemical Product and Process Modelling 16 (1): 20190139. https://doi.org/10.1515/cppm-2019-0139.

Ighalo, J.O., C.A. Igwegbe, C.O. Aniagor, and S.N. Oba. 2021. A review of methods for the removal of penicillins from water. Journal of Water Process Engineering 39: 101886. https://doi.org/10.1016/j.jwpe.2020.101886.

Igwegbe, C.A., I.A. Obiora-Okafo, K.O. Iwuozor, S. Ghosh, S.B. Kurniawan, S. Rangabhashiyam, R. Kanaoujiya, and J.O. Ighalo. 2022. Treatment technologies for bakers’ yeast production wastewater. Environmental Science and Pollution Research 29 (8): 11004–11026.

Inaba, T., D. Watanabe, Y. Yoshiyama, K. Tanaka, J. Ogawa, H. Takagi, H. Shimoi, and J. Shima. 2013. An organic acid-tolerant HAA1-overexpression mutant of an industrial bioethanol strain of Saccharomyces cerevisiae and its application to the production of bioethanol from sugarcane molasses. AMB Express 3 (1): 1–7.

Inyang, M., B. Gao, W. Ding, P. Pullammanappallil, A.R. Zimmerman, and X. Cao. 2011. Enhanced lead sorption by biochar derived from anaerobically digested sugarcane bagasse. Separation Science and Technology 46 (12): 1950–1956.

Iwuozor, K.O. 2018. Removal of heavy metals from their solution using polystyrene adsorbent (foil take-away disposable plates). International Journal of Environmental Chemistry 2 (2): 10. https://doi.org/10.11648/j/ijec.20180202.11.

Iwuozor, K.O. 2019a. Prospects and challenges of using coagulation-flocculation method in the treatment of effluents. Advanced Journal of Chemistry-Section A 2 (2): 105–127.

Iwuozor, K.O. 2019b. Qualitative and quantitative determination of anti-nutritional factors of five wine samples. Advanced Journal of Chemistry-Section A 2 (2): 136–146.

Iwuozor, K.O., and E.E. Gold. 2018. Physico-chemical parameters of industrial effluents from a brewery industry in Imo state, Nigeria. Advanced Journal of Chemistry-Section A 1 (2): 66–78.

Iwuozor, K.O., L.A. Ogunfowora, and I.P. Oyekunle. 2021a. Review on sugarcane-mediated nanoparticle synthesis: A green approach. SugarTech 23: 12. https://doi.org/10.1007/s12355-021-01038-7.

Iwuozor, K.O., J.O. Ighalo, L.A. Ogunfowora, A.G. Adeniyi, and C.A. Igwegbe. 2021. An empirical literature analysis of adsorbent performance for methylene blue uptake from aqueous media. Journal of Environmental Chemical Engineering 9: 105658.

Iwuozor, K.O., I.P. Oyekunle, I.O. Oladunjoye, E.M. Ibitogbe, and T.S. Olorunfemi. 2021c. A review on the mitigation of heavy metals from aqueous solution using sugarcane bagasse. SugarTech. https://doi.org/10.1007/s12355-021-01051-w.

Iwuozor, K.O., J.O. Ighalo, L.A. Ogunfowora, A.G. Adeniyi, and C.A. Igwegbe. 2021d. An empirical literature analysis of adsorbent performance for methylene blue uptake from aqueous media. Journal of Environmental Chemical Engineering 9 (4): 105658. https://doi.org/10.1016/j.jece.2021.105658.

Iwuozor, K.O., E.C. Emenike, C.O. Aniagor, F.U. Iwuchukwu, E.M. Ibitogbe, B.T. Okikiola, P.E. Omuku, and A.G. Adeniyi. 2022. Removal of pollutants from aqueous media using cow dung-based adsorbents. Current Research in Green and Sustainable Chemistry 5: 103300. https://doi.org/10.1016/j.crgsc.2022.100300.

Iwuozor, K.O., V.U. Anyanwu, B.O. Olaniyi, P.S. Mbamalu, and A.G. Adeniyi. 2022a. Adulteration of sugar: A growing global menace. Sugar Tech. https://doi.org/10.1007/s12355-022-01122-6.

Jaimes, J.B., B. Da Silva, J.J. Figueroa, B. Lunelli, R. Maciel Filho, M.W. Maciel, A. Morita, and P. 2014. Coutinho Hybrid route to produce acrylic acid from sugarcane molasses. In: Iconbm: International Conference on Biomass, Pts, 2014.

Jain, R., and P. Venkatasubramanian. 2017. Sugarcane molasses–a potential dietary supplement in the management of iron deficiency anemia. Journal of Dietary Supplements 14 (5): 589–598.

Jamil, M., M. Qasim, and M.S. Zia. 2008. Utilization of pressmud as organic amendment to improve physico-chemical characteristics of calcareous soil under two legume crops. Journal of the Chemical Society of Pakistan 3 (1): 145–150.

Jamir, L., V. Kumar, J. Kaur, S. Kumar, and H. Singh. 2021. Composition, valorization and therapeutical potential of molasses: A critical review. Environmental Technology Reviews 10 (1): 131–142.

Jamsawang, P., H. Poorahong, N. Yoobanpot, S. Songpiriyakij, and P. Jongpradist. 2017. Improvement of soft clay with cement and bagasse ash waste. Construction and Building Materials 154: 61–71.

Jayawickrama, D.R., P.B. Weerasinghe, D.D. Jayasena, and D.C. Mudannayake. 2013. Effects of supplementation of urea-molasses multinutrient block (UMMB) on the performance of dairy cows fed good quality forage based diets with rice straw as a night feeding. Korean Journal of Agricultural Science 40 (2): 123–129.

Ji, J., X. Yang, M. Flavel, Z.P.-I. Shields, and B. Kitchen. 2019. Antioxidant and anti-diabetic functions of a polyphenol-rich sugarcane extract. Journal of the American College of Nutrition 38 (8): 670–680.

Ji, J., M. Flavel, X. Yang, O.C. Chen, L. Downey, C. Stough, and B. Kitchen. 2020. A polyphenol rich sugarcane extract as a modulator for inflammation and neurological disorders. Pharma Nutrition 12: 100187.

Ji, J., X. Yang, M. Flavel, Z.P. Shields, J. Neoh, M.-L. Bowen, and B. Kitchen. 2020b. Age-deterring and skin care function of a polyphenol rich sugarcane concentrate. Cosmetics 7 (2): 30.

Ji, X.-J., H. Huang, Z.-K. Nie, L. Qu, Q. Xu, and G.T. Tsao. 2011. Fuels and chemicals from hemicellulose sugars. Biotechnology in China III: biofuels and bioenergy 128: 199–224. https://doi.org/10.1007/10_2011_124.

José, C., A.G. Lino, J.L. Colodette, C.F. Lima, A. Gutiérrez, Á.T. Martínez, F. Lu, J. Ralph, and J. Rencoret. 2015. Differences in the chemical structure of the lignins from sugarcane bagasse and straw. Biomass and Bioenergy 81: 322–338.

Karp, S.G., A.L. Woiciechowski, V.T. Soccol, and C.R. Soccol. 2013. Pretreatment strategies for delignification of sugarcane bagasse: A review. Brazilian Archives of Biology and Technology 56 (4): 679–689.

Kawade, U., V. Rathi, and V.D. Girge. 2013. Effect of use of bagasse ash on strength of concrete. International Journal of Innovative Research in Science, Engineering and Technology 2 (7): 2997–3000.

Kebede, G., A. Guteta, and F. Dereje. 2018. Characterization of dairy farms, farmers’ training and on-farm evaluation of urea-treated straw and urea-molasses-block (UMB) feeding on performances of lactating crossbred cows in Ada District of East Shoa Zone, Ethiopia. World Journal of Agricultural Sciences 14 (3): 81–88.

Keshavanath, P., and B. Gangadhara. 2006. Evaluation of sugarcane by-product pressmud as a manure in carp culture. Bioresource Technology 97 (4): 628–634.

Khatiwada, D., S. Leduc, S. Silveira, and I. McCallum. 2016. Optimizing ethanol and bioelectricity production in sugarcane biorefineries in Brazil. Renewable Energy 85: 371–386.

Khoja, A.H., E. Ali, K. Zafar, A.A. Ansari, A. Nawar, and M. Qayyum. 2015. Comparative study of bioethanol production from sugarcane molasses by using Zymomonas mobilis and Saccharomyces cerevisiae. African Journal of Biotechnology 14 (31): 2455–2462.

Khoja, A.H., S.M. Yahya, A. Nawar, A.A. Ansari, and M. Qayyum. 2018. Fermentation of sugarcane molasses using Zymomonas mobilis for enhanced bioethanol production. Journal of Advanced Research in Applied Sciences and Engineering Technology 11 (1): 31–38.

Khoramzadeh, E., B. Nasernejad, and R. Halladj. 2013. Mercury biosorption from aqueous solutions by sugarcane bagasse. Journal of the Taiwan Institute of Chemical Engineers 44 (2): 266–269.

Kiani, A., N. Yosefi, and A. Azarfar. 2013. Feeding urea-molasses blocks reduced milk urea nitrogen in Iranian rural dairy cows. Magnesium 1 (1.5): 1.5.

Komesu, A., J.A.R. de Oliveira, L.H. da Silva Martins, M.R.W. Maciel, and R. Maciel Filho. 2017. Lactic acid production to purification: A review. BioResources 12 (2): 4364–4383.

Krishnan, C., L.D.C. Sousa, M. **, L. Chang, B.E. Dale, and V. Balan. 2010. Alkali-based AFEX pretreatment for the conversion of sugarcane bagasse and cane leaf residues to ethanol. Biotechnology and Bioengineering 107 (3): 441–450.

Kumar, S. 1996. Biogas from press mud. Bio Energy News 1 (2): 15–17.

Kumar, V., and A. Chopra. 2016. Effects of sugarcane pressmud on agronomical characteristics of hybrid cultivar of eggplant (Solanum melongena L.) under field conditions. International Journal of Recycling of Organic Waste in Agriculture 5 (2): 149–162.

Kumar, R., D. Verma, B.L. Singh, and U. Kumar. 2010. Composting of sugar-cane waste by-products through treatment with microorganisms and subsequent vermicomposting. Bioresource Technology 101 (17): 6707–6711.

Kumar, A., Y.S. Negi, V. Choudhary, and N.K. Bhardwaj. 2014. Characterization of cellulose nanocrystals produced by acid-hydrolysis from sugarcane bagasse as agro-waste. Journal of Materials Physics and Chemistry 2 (1): 1–8.

Lawania, P., and B. Khadda. 2017. Efficacy of urea molasses minerals block on milk production and reproductive performance of Zebu cattle under field condition. Journal of Krishi Vigyan 6 (1): 83–87.

Li, J., X. Wei, Q. Wang, J. Chen, G. Chang, L. Kong, J. Su, and Y. Liu. 2012. Homogeneous isolation of nanocellulose from sugarcane bagasse by high pressure homogenization. Carbohydrate Polymers 90 (4): 1609–1613.

Lois-Correa, J. 2012. Depithers for efficient preparation of sugar cane bagasse fibers in pulp and paper industry. Ingeniería, Investigación y Tecnología 13 (4): 417–424.

López-Gómez, J.P., M. Alexandri, R. Schneider, and J. Venus. 2019. A review on the current developments in continuous lactic acid fermentations and case studies utilising inexpensive raw materials. Process Biochemistry 79: 1–10.

Lu, Y., Y.-C. Lu, H.-Q. Hu, F.-J. **e, X.-Y. Wei, and X. Fan. 2017. Structural characterization of lignin and its degradation products with spectroscopic methods. Journal of Spectroscopy 2017: 8951658. https://doi.org/10.1155/2017/8951658.

Madurwar, M.V., S.A. Mandavgane, and R.V. Ralegaonkar. 2014. Use of sugarcane bagasse ash as brick material. Current Science. https://doi.org/10.18520/CS/V107/I6/1044-1051.

Mahala, A., A. Mokhtar, E. Amasiab, and B. AttaElmnan. 2013. Sugarcane tops as animal feed. International Research Journal of Agricultural Science and Soil Science 3 (4): 147–151.

Maiti, B., A. Rathore, S. Srivastava, M. Shekhawat, and P. Srivastava. 2011. Optimization of process parameters for ethanol production from sugar cane molasses by Zymomonas mobilis using response surface methodology and genetic algorithm. Applied Microbiology and Biotechnology 90 (1): 385–395.

Mandal, A., and D. Chakrabarty. 2011. Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydrate Polymers 86 (3): 1291–1299.

Mangwanda, T., J.B. Johnson, J.S. Mani, S. Jackson, S. Chandra, T. McKeown, S. White, and M. Naiker. 2021. Processes, challenges and optimisation of rum production from molasses—A contemporary review. Fermentation 7 (1): 21.

Marlin, L., I. Perada, J. Garciga, E. Barrera, and O. Romero. 2020. Energetic, economic and environmental assessment for the anaerobic digestion of pretreated and codigested press mud. Waste Management 102: 249–259.

Martel, C.A., E. Titgemeyer, L. Mamedova, and B. Bradford. 2011. Dietary molasses increases ruminal pH and enhances ruminal biohydrogenation during milk fat depression. Journal of Dairy Science 94 (8): 3995–4004.

Maryana, R., D. Ma’rifatun, A. Wheni, K. Satriyo, and W.A. Rizal. 2014. Alkaline pretreatment on sugarcane bagasse for bioethanol production. Energy Procedia 47: 250–254.

Mashoko, L., C. Mbohwa, and V. Thomas. 2013. Life cycle inventory of electricity cogeneration from bagasse in the South African sugar industry. Journal of Cleaner Production 39: 42–49.

Maurya, D.P., A. Singla, and S. Negi. 2015. An overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. 3 Biotech 5 (5): 597–609.

Mayzuhroh, A., S. Arindhani, and C. Caroenchai. 2016. Studies on bioethanol production of commercial baker’s and alcohol yeast under aerated culture using sugarcane molasses as the media. Agriculture and Agricultural Science Procedia 9: 493–499.

Medeiros, A., M. de Matos, A. de Pinho Monteiro, J. de Carvalho, and C. Soccol (2017) Cachaça and rum. In: Current Developments in Biotechnology and Bioengineering. pp. 451–468. https://doi.org/10.1016/B978-0-444-63666-9.00016-9.

Meghana, M., and Y. Shastri. 2020. Sustainable valorization of sugar industry waste: status, opportunities, and challenges. Bioresource technology 303: 122929.

Meko, B., and J.O. Ighalo. 2021a. Utilization of cordia africana wood sawdust ash as partial cement replacement in C 25 concrete. Cleaner Materials 1: 100012. https://doi.org/10.1016/j.clema.2021.100012.

Meko, B., and J.O. Ighalo. 2021b. Utilization of waste paper ash as supplementary cementitious material in C-25 concrete: Evaluation of fresh and hardened properties. Cogent Engineering 8 (1): 1938366. https://doi.org/10.1080/23311916.2021.1938366.

Mengistu, G., and W. Hassen. 2017. Review on: Supplementary feeding of urea molasses multi-nutrient blocks to ruminant animals for improving productivity. IJVSAH 2: 43–49.

Mesa, L., E. González, C. Cara, M. González, E. Castro, and S.I. Mussatto. 2011. The effect of organosolv pretreatment variables on enzymatic hydrolysis of sugarcane bagasse. Chemical Engineering Journal 168 (3): 1157–1162.

Mohan, N. 2021. An insight to sugar manufacture. Kanpur: Kratika Printers.

Moisés, M.P., C.T.P. da Silva, J.G. Meneguin, E.M. Girotto, and E. Radovanovic. 2013. Synthesis of zeolite NaA from sugarcane bagasse ash. Materials Letters 108: 243–246.

Monteiro, S.N., V.S. Candido, F.O. Braga, L.T. Bolzan, R.P. Weber, and J.W. Drelich. 2016. Sugarcane bagasse waste in composites for multilayered armor. European Polymer Journal 78: 173–185.

Moretti, J.P., S. Nunes, and A. Sales. 2018. Self-compacting concrete incorporating sugarcane bagasse ash. Construction and Building Materials 172: 635–649.

Moro, M.K., R.S.S. Teixeira, A.S.A. da Silva, M.D. Fujimoto, P.A. Melo, A.R. Secchi, and E.P. da Silva Bon. 2017. Continuous pretreatment of sugarcane biomass using a twin-screw extruder. Industrial Crops and Products 97: 509–517.

Muhammad, D., and R. Khattak. 2009. Growth and nutrient concentrations of maize in press mud treated saline-sodic soils. Soil and Environment 28 (2): 145–155.

Mulye, S. (2019) The effect of distillation conditions and molasses concentration on the volatile compounds of unaged rum. Auckland University of Technology.

Nakanishi, S.C., L.B. Soares, L.E. Biazi, V.M. Nascimento, A.C. Costa, G.J.M. Rocha, and J.L. Ienczak. 2017. Fermentation strategy for second generation ethanol production from sugarcane bagasse hydrolyzate by Spathaspora passalidarum and Scheffersomyces stipitis. Biotechnology and Bioengineering 114 (10): 2211–2221.

Nimbalkar, P., M. Khedkar, S. Gaikwad, P. Chavan, and S. Bankar. 2017. Mew insight into sugarcane industry waste utilization (press mud) for cleaner biobutanol production by using C. acetobutylicum NRRL B-527. Applied Biochemistry and Biotechnology 183 (2): 1008–1025.

Noreen, S., and H.N. Bhatti. 2014. Fitting of equilibrium and kinetic data for the removal of Novacron Orange P-2R by sugarcane bagasse. Journal of Industrial and Engineering Chemistry 20 (4): 1684–1692.

Novo, L.P., J. Bras, M.N. Belgacem, and A. da Aprigio Silva Curvelo. 2018. Pulp and paper from sugarcane: Properties of rind and core fractions. Journal of Renewable Materials 6 (2): 160–168.

Ofuyatan, M.O., A.G. Adeniyi, and J.O. Ighalo. 2021. Evaluation of fresh and hardened properties of blended silica fume self-compacting concrete (SCC). Research on Engineering Structures and Materials 7 (2): 211–223.

Ofuyatan, M.O., B.O. Agbawhe, D.O. Omole, C.A. Igwegbe, and J.O. Ighalo. 2022. RSM and ANN modelling of the mechanical properties of self-compacting concrete with silica fume and plastic waste as partial constituent replacement. Cleaner Materials. https://doi.org/10.1016/j.clema.2022.100065.

Ogunlalu, O., I.P. Oyekunle, K.O. Iwuozor, A.D. Aderibigbe, and E.C. Emenike. 2021. Trends in the mitigation of heavy metal ions from aqueous solutions using unmodified and chemically-modified agricultural waste adsorbents. Current Research in Green and Sustainable Chemistry 4: 18. https://doi.org/10.1016/j.crgsc.2021.100188.

Oliveira, R., R. Maciel Filho, and C.V. Rossel. 2016b. High lactic acid production from molasses and hydrolysed sugarcane bagasse. Chemical Engineering Transactions 50: 307–312.

Osman, O.A., N.M. Elkhair, and K.A. Abdoun. 2020. Effects of dietary supplementation with different concentration of molasses on growth performance, blood metabolites and rumen fermentation indices of Nubian goats. BMC Veterinary Research 16 (1): 1–12.

Palmonari, A., D. Cavallini, C. Sniffen, L. Fernandes, P. Holder, L. Fagioli, I. Fusaro, G. Biagi, A. Formigoni, and L. Mammi. 2020. Characterization of molasses chemical composition. Journal of Dairy Science 103 (7): 6244–6249.

Panyakaew, S., and S. Fotios. 2011. New thermal insulation boards made from coconut husk and bagasse. Energy and Buildings 43 (7): 1732–1739.

Partha, N., and V. Sivasubramanian. 2006. Recovery of chemicals from pressmud-a sugar industry waste. Indian Chemical Engineer 48 (3): 160–163.

Peng, Y., and S. Wu. 2011. Fast pyrolysis characteristics of sugarcane bagasse hemicellulose. Cellulose Chemistry and Technology 45 (9): 605.

Phukan, A., and R. Boruah. 1999. Extraction and evaluation of microcrystalline wax from press mud waste of the sugar industry. Separation and Purification Technology 17 (3): 189–194.

Pinilla, L., R. Torres, and C. Ortiz. 2011. Bioethanol production in batch mode by a native strain of Zymomonas mobilis. World Journal of Microbiology and Biotechnology 27 (11): 2521–2528.

Pino, J.A., and E. Roncal. 2016. Validation of a HS-SPME-GC method for determining higher fatty esters and oak lactones in white rums. Food Analytical Methods 9 (7): 1958–1962.

Pino, J.A., S. Tolle, R. Gök, and P. Winterhalter. 2012. Characterisation of odour-active compounds in aged rum. Food Chemistry 132 (3): 1436–1441.

Plermjai, K., K. Boonyarattanakalin, W. Mekprasart, S. Pavasupree, W. Phoohinkong, and W. Pecharapa. 2018. Extraction and characterization of nanocellulose from sugarcane bagasse by ball-milling-assisted acid hydrolysis. In: AIP Conference Proceedings, 2018. vol 1. AIP Publishing LLC, p 020005.

Prakash, M., and N. Karmegam. 2010. Vermistabilization of pressmud using Perionyx ceylanensis Mich. Bioresource Technology 101 (21): 8464–8468.

Prakash, M.D., L. Stojanovska, J. Feehan, K. Nurgali, E.L. Donald, M. Plebanski, M. Flavel, B. Kitchen, and V. Apostolopoulos. 2021. Anti-cancer effects of polyphenol-rich sugarcane extract. PLoS ONE 16 (3): e0247492. https://doi.org/10.1371/journal.pone.0247492.

Purnomo, C.W., C. Salim, and H. Hinode. 2012. Synthesis of pure Na–X and Na–A zeolite from bagasse fly ash. Microporous and Mesoporous Materials 162: 6–13.

Quirk, R., V. Zwieten, S. Kimber, A. Downie, S. Morris, and J. Rust. 2012. Utilization of biochar in sugarcane and sugar-industry management. Sugar Tech 14 (4): 321–326.

Rabelo, S., H. Carrere, R. Maciel Filho, and A. Costa. 2011. Production of bioethanol, methane and heat from sugarcane bagasse in a biorefinery concept. Bioresource Technology 102 (17): 7887–7895.

Radwan, N., K.H. Mo, C.C. Onn, C.G. Ng, and T.-C. Ling. 2021. Waste press mud in enhancing the performance if glass powder unblended cement. Construction and Building Materials 313: 125469.

Raharja, R., U. Murdiyatmo, A. Sutrisno, and A. Wardani. 2019. Bioethanol production from sugarcane molasses by instant dry yeast. In: IOP Conference Series: Earth and Environmental Science, 2019. vol 1. IOP Publishing, p 012076.

Rahiman, F., and E.J. Pool. 2016. The effect of sugar cane molasses on the immune and male reproductive systems using in vitro and in vivo methods. Iranian Journal of Basic Medical Sciences 19 (10): 1125.

Raimondi, I., V. Rodrigues, J. Lima, J. Marques, and L. Vaz. 2020. The potential use of pressmud as reactive material for Cd 2+ removal: Adsorption equilibrium, kinetics, desorption, and bioaccessibility. Water, Air, & Soil Pollution 231 (7): 1–20.

Rainey, T.J., and G. Covey. 2016. Pulp and paper production from sugarcane bagasse. Sugarcane-Based Biofuels and Bioproducts 2017: 259–280.

Ram, D., M. Ram, and R. Singh. 2006. Optimization of water and nitrogen application to menthol mint (Mentha arvensis L.) through sugarcane trash mulch in a sandy loam soil of semi-arid subtropical climate. Bioresource Technology 97 (7): 886–893.

Rasche, L., and R.S. Del Diego. 2020. Pros and cons of sugarcane straw recovery in São Paulo. BioEnergy Research 13 (1): 147–156.

Rasmey, A.-H.M., H.H. Hassan, O.A. Abdulwahid, and A.A. Aboseidah. 2018. Enhancing bioethanol production from sugarcane molasses by Saccharomyces cerevisiae Y17. Egyptian Journal of Botany 58 (3): 547–561.

Rasul, G., A. Appuhn, T. Müller, and R.G. Joergensen. 2006. Salinity-induced changes in the microbial use of sugarcane filter cake added to soil. Applied Soil Ecology 31 (1–2): 1–10.

Rezende, C.A., M.A. De Lima, P. Maziero, E.R. deAzevedo, W. Garcia, and I. Polikarpov. 2011. Chemical and morphological characterization of sugarcane bagasse submitted to a delignification process for enhanced enzymatic digestibility. Biotechnology for Biofuels 4 (1): 1–19.

Rocha, G.D.M., A.R. Gonçalves, B. Oliveira, E. Olivares, and C. Rossell. 2012. Steam explosion pretreatment reproduction and alkaline delignification reactions performed on a pilot scale with sugarcane bagasse for bioethanol production. Industrial Crops and Products 35 (1): 274–279.

Rodrigues, C., L. Vandenberghe, A. Woiciechowski, J. de Oliveira, L. Letti, and C. Soccol. 2017. Production and application of lactic acid. In: Current Developments in Biotechnology and Bioengineering. pp 543–556. https://doi.org/10.1016/B978-0-444-63662-1.00024-5.

Romero, E., J. Scandaliaris, P. Digonzelli, L. Alonso, F. Leggio-Neme, J. Giardina, S. Casen, J. Tonatto, and J. Fernández de Ullivarri. 2007. Sugarcane potential trash estimation: Variety and cane yield effect. Proceedings - International Society of Sugar Cane Technology 2007: 421–425.

Rubcumintara, T. 2015. Adsorptive recovery of Au (III) from aqueous solution using modified bagasse biosorbent. International Journal of Chemical Engineering and Applications 6 (2): 95.

Sadaf, S., H.N. Bhatti, S. Ali, and K.-U. Rehman. 2014. Removal of Indosol Turquoise FBL dye from aqueous solution by bagasse, a low cost agricultural waste: Batch and column study. Desalination and Water Treatment 52 (1–3): 184–198.

Saleh-e-in, M.M., S. Yeasmin, B.K. Paul, M. Ahsan, M.Z. Rahman, and S.K. Roy. 2012. Chemical studies on press mud: A sugar industries waste in Bangladesh. Sugar Tech 14 (2): 109–118.

Salvador-Loreto, I., C.M. Arriaga-Jordán, J.G. Estrada-Flores, F. Vicente-Mainar, A. García-Martínez, and B. Albarrán-Portillo. 2016. Molasses supplementation for dual-purpose cows during the dry season in subtropical Mexico. Tropical Animal Health and Production 48 (3): 643–648.

Sampaio, I.L., T.F. Cardoso, N.R. Souza, M.D. Watanabe, D.J. Carvalho, A. Bonomi, and T.L. Junqueira. 2019. Electricity production from sugarcane straw recovered through bale system: Assessment of retrofit projects. BioEnergy Research 12 (4): 865–877.

Sarker, T.C., S.M.G.G. Azam, and G. Bonanomi. 2017. Recent advances in sugarcane industry solid by-products valorization. Waste and Biomass Valorization 8 (2): 241–266.

Sella Kapu, N., and H.L. Trajano. 2014. Review of hemicellulose hydrolysis in softwoods and bamboo. Biofuels, Bioproducts and Biorefining 8 (6): 857–870.

Shafiqa-Atikah, M., M. Nor-Khaizura, N. Mahyudin, F. Abas, J. Nur-Syifa, and Y. Ummul-Izzatul. 2020. Evaluation of phenolic constituent, antioxidant and antibacterial activities of sugarcane molasses towards foodborne pathogens. Food Research 4 (2): 40–47.

Shaik, O., J. Kavitha, M.H. Varma, and N. Chittibabu. 2020. Biosorption of eosin yellow dye from aqueous solution using sugarcane bagasse: Equillibrium, kinetics and thermodynamics. Materials Today: Proceedings 26: 842–849.

Shankaranand, V., and B. Lonsane. 1993. Sugarcane-pressmud as a novel substrate for production of citric acid by solid-state fermentation. World Journal of Microbiology and Biotechnology 9 (3): 377–380.

Sheikh, G., A. Ganai, F. Sheikh, S.A. Bhat, D. Masood, S. Mir, I. Ahmad, and M.A. Bhat. 2017. Effect of feeding urea molasses treated rice straw along with fibrolytic enzymes on the performance of Corriedale Sheep. Journal of Entomology and Zoology Studies 5 (6): 2626–2630.

Singh, R., A. Dhawan, and P. Saxena. 1999. Potential of press mud - a sugar factory byproduct - in supplemantary diets and its impact on fish growth. Bioresource Technology 67 (1): 61–64.

Singh, P., A. Suman, P. Tiwari, N. Arya, A. Gaur, and A. Shrivastava. 2008. Biological pretreatment of sugarcane trash for its conversion to fermentable sugars. World Journal of Microbiology and Biotechnology 24 (5): 667–673.

Singh, S.S., D.R. Salem, and R.K. Sani. 2021. Spectroscopy, microscopy, and other techniques for characterization of bacterial nanocellulose and comparison with plant-derived nanocellulose. In: Microbial and Natural Macromolecules. Pp 419–454. https://doi.org/10.1016/B978-0-12-820084-1.00018-1.

Siverson, A., C. Vargas-Rodriguez, and B. Bradford. 2014. Effects of molasses products on productivity and milk fatty acid profile of cows fed diets high in dried distillers grains with solubles. Journal of Dairy Science 97 (6): 3860–3865.

Sofla, M.R.K., R. Brown, T. Tsuzuki, and T. Rainey. 2016. A comparison of cellulose nanocrystals and cellulose nanofibres extracted from bagasse using acid and ball milling methods. Advances in Natural Sciences: Nanoscience and Nanotechnology 7 (3): 035004.

Somna, R., C. Jaturapitakkul, P. Rattanachu, and W. Chalee. 2012. Effect of ground bagasse ash on mechanical and durability properties of recycled aggregate concrete. Materials & Design 1980–2015 (36): 597–603.

Souza, A., S. Teixeira, G. Santos, F. Costa, and E. Longo. 2011. Reuse of sugarcane bagasse ash (SCBA) to produce ceramic materials. Journal of Environmental Management 92 (10): 2774–2780.

Srivastava, A.K., A.D. Tripathi, A. Jha, A. Poonia, and N. Sharma. 2015. Production, optimization and characterization of lactic acid by Lactobacillus delbrueckii NCIM 2025 from utilizing agro-industrial byproduct (cane molasses). Journal of Food Science and Technology 52 (6): 3571–3578.

St-Pierre, P., G. Pilon, V. Dumais, C. Dion, M.-J. Dubois, P. Dubé, Y. Desjardins, and A. Marette. 2014. Comparative analysis of maple syrup to other natural sweeteners and evaluation of their metabolic responses in healthy rats. Journal of Functional Foods 11: 460–471.

Sun, Y., Z. Xu, Y. Zheng, J. Zhou, and Z. **u. 2019. Efficient production of lactic acid from sugarcane molasses by a newly microbial consortium CEE-DL15. Process Biochemistry 81: 132–138.

Tayade, A.S., P. Geetha, S. Anusha, R. Dhanapal, and K. Hari. 2017. Effect of green cane trash blanketing and microbial consortia application on soil compaction and productivity of mechanically harvested sugarcane ratoon crops. Journal of Sugarcane Research 7 (2): 112–120.

Trivedi, S., and S. Shah. 2014. The effect of cane molasses on cow milk productivity. International Journal of Current and Engineering Technology 4: 4157–4161.

Ullah, I., R. Nadeem, M. Iqbal, and Q. Manzoor. 2013. Biosorption of chromium onto native and immobilized sugarcane bagasse waste biomass. Ecological Engineering 60: 99–107.

Umenweke, G., J.O. Ighalo, M. Anusi, B. Itabana, and L. Ekeh. 2021. Selected thermo-chemical biorefining: Evaluation of the current trends and progressions. European Journal of Sustainable Development Research 5 (2): em0154.

Valli, V., A.M. Gómez-Caravaca, M. Di Nunzio, F. Danesi, M.F. Caboni, and A. Bordoni. 2012. Sugar cane and sugar beet molasses, antioxidant-rich alternatives to refined sugar. Journal of Agricultural and Food Chemistry 60 (51): 12508–12515.

Velmurugan, R., and K. Muthukumar. 2011. Utilization of sugarcane bagasse for bioethanol production: Sono-assisted acid hydrolysis approach. Bioresource Technology 102 (14): 7119–7123.

Vera, L.M., D. Bermejo, M.F. Uguña, N. Garcia, M. Flores, and E. González. 2019. Fixed bed column modeling of lead (II) and cadmium (II) ions biosorption on sugarcane bagasse. Environmental Engineering Research 24 (1): 31–37.

Vidra, A., A.J. Tóth, and Á. Németh. 2017. Lactic acid production from cane molasses. Waste Treatment and Recovery 2 (1): 13–16.

Vikash, P.V., P.V. Mandade, and Y. Shastri. 2018. Assessment of bagasse and trash utilization for ethanol production: A case study in india. Environmental Progress & Sustainable Energy 37 (6): 2165–2174.

Wang, B.-S., L.-W. Chang, Z.-C. Kang, H.-L. Chu, H.-M. Tai, and M.-H. Huang. 2011. Inhibitory effects of molasses on mutation and nitric oxide production. Food Chemistry 126 (3): 1102–1107.

Williams, I.O., E.O. Onyenweaku, and I.J. Atangwho. 2016. Nutritional and antimicrobial evaluation of Saccharum officinarum consumed in Calabar, Nigeria. African Journal of Biotechnology 15 (33): 1789–1795.

Windsor, P., S. Nampanya, L. Olmo, S. Khounsy, P. Phengsavanh, and R. Bush. 2020. Provision of urea–molasses blocks to improve smallholder cattle weight gain during the late dry season in tropical develo** countries: Studies from Lao PDR. Animal Production Science 61 (5): 503–513.

Wright, A.G., T.P. Ellis, and L.L. Ilag. 2014. Filtered molasses concentrate from sugar cane: Natural functional ingredient effective in lowering the glycaemic index and insulin response of high carbohydrate foods. Plant Foods for Human Nutrition 69 (4): 310–316.

Wu, R., D. Chen, S. Cao, Z. Lu, J. Huang, Q. Lu, Y. Chen, X. Chen, N. Guan, and Y. Wei. 2020. Enhanced ethanol production from sugarcane molasses by industrially engineered Saccharomyces cerevisiae via replacement of the PHO4 gene. RSC Advances 10 (4): 2267–2276.

Xavier, S., and B. Lonsane. 1994. Sugar-cane pressmud as a novel and inexpensive substrate for production of lactic acid in a solid-state fermentation system. Applied Microbiology and Biotechnology 41 (3): 291–295.

Xu, Q., T. Ji, S.-J. Gao, Z. Yang, and N. Wu. 2019. Characteristics and applications of sugar cane bagasse ash waste in cementitious materials. Materials 12 (1): 39.

Yadav, R., S. Prasad, R. Singh, and V. Srivastava. 1994. Recycling sugarcane trash to conserve soil organic carbon for sustaining yields of successive ratoon crops in sugarcane. Bioresource Technology 49 (3): 231–235.

Yahaya, A., Y.S. Shu’aib, D.B. Danladi, and R.A. Idris. 2019. Phytochemical screening of helathy and sugarcane chlorotic streak virus-infected leaves of Saccharum officinarum. FUW Trends in Science & Technology Journal 4 (3): 920–923.

Yu, Q., X. Zhuang, S. Lv, M. He, Y. Zhang, Z. Yuan, W. Qi, Q. Wang, W. Wang, and X. Tan. 2013. Liquid hot water pretreatment of sugarcane bagasse and its comparison with chemical pretreatment methods for the sugar recovery and structural changes. Bioresource Technology 129: 592–598.

Yu, P., X.-B. Xu, and S.-J. Yu. 2017. Inhibitory effect of sugarcane molasses extract on the formation of Nε-(carboxymethyl) lysine and Nε-(carboxyethyl) lysine. Food Chemistry 221: 1145–1150.

Zanatta, E.R., T.O. Reinehr, J.A. Awadallak, S.J. Kleinübing, J.B.O. dos Santos, R.A. Bariccatti, P.A. Arroyo, and E.A. da Silva. 2016. Kinetic studies of thermal decomposition of sugarcane bagasse and cassava bagasse. Journal of Thermal Analysis and Calorimetry 125 (1): 437–445.

Zentou, H., Z.Z. Abidin, M. Zouanti, and D. Greetham. 2017. Effect of operating conditions on molasses fermentation for bioethanol production. International Journal of Applied Engineering Research 12 (15): 5202–5506.

Zhang, Z., L. Moghaddam, I.M. O’Hara, and W.O. Doherty. 2011. Congo Red adsorption by ball-milled sugarcane bagasse. Chemical Engineering Journal 178: 122–128.

Zhang, Z., I.M. O’Hara, G.A. Kent, and W.O. Doherty. 2013. Comparative study on adsorption of two cationic dyes by milled sugarcane bagasse. Industrial Crops and Products 42: 41–49.

Zhang, H., C. Qin, S. Nie, and S. Wang. 2018. Effects of D-hot pretreatment on micro-distribution of residual lignin in sugarcane bagasse pulp and fiber properties. Cellulose 25 (8): 4423–4435.

Zhou, X., W. Li, R. Mabon, and L.J. Broadbelt. 2017. A critical review on hemicellulose pyrolysis. Energy Technology 5 (1): 52–79.

Zhul-quarnain, A., K.O. Iwuozor, I. Modupe, E. Gold, and E.E. Chidubem. 2018. Adsorption of malachite green dye using orange peel. Journal of Biomaterials 2 (2): 10. https://doi.org/10.11648/j.jb.20180202.12.

Funding

There was no external funding for the study.

Author information

Authors and Affiliations

Contributions

KOI contributed to conceptualization; data curation; methodology; investigation; writing—original draft; writing—review and editing; supervision; validation; and project administration. ECE was involved in data curation; methodology; investigation; writing—review and editing; and validation. JOI contributed to data curation; methodology; investigation; writing—review and editing; and validation. SE, PEO and AGA were involved in writing—review and editing, and validation.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest.

Human or Animal Rights

This article does not contain any studies involving human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Iwuozor, K.O., Emenike, E.C., Ighalo, J.O. et al. Valorization of Sugar Industry’s By-products: A Perspective. Sugar Tech 24, 1052–1078 (2022). https://doi.org/10.1007/s12355-022-01143-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-022-01143-1