Abstract

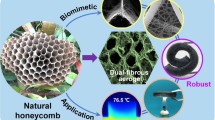

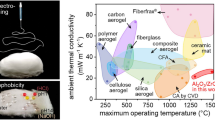

Ceramic membranes are attractive for thermal management applications due to its lightweight and ultralow thermal conductivity, while it is indispensable to address the long-standing obstacle of its poor mechanical stability and degradation under thermal shock. In this work, a series of the organic polymer template-modulated yttria doped zirconia (YDZ) nanofibrous membranes with lightweight, superior mechanical and thermal stability are developed through a cost-effective, scalable sol-gel electrospinning and subsequent calcination method. The YDZ membranes demonstrate excellent flexibility and foldability, which can be attributed to the tetragonal phase and small crystallite size of the YDZ fibers due to the presence of yttria. Besides, the fibrous size, grain size, mechanical and thermal stability of YDZ nanofibrous membranes could be tailored by varying the species and molecular weight of polymer template. The remarkable performances are obtained through the poly(vinyl pyrrolidone) (PVP) template YDZ nanofibrous membranes, featuring the superior tensile strength up to ∼ 4.82 MPa, excellent flexibility with bending rigidity ∼ 26 mN, robust thermal stability up to 1,200 °C, ultra-low thermal conductivity of 0.008–0.023 W·m−1·K−1 (25–1,000 °C), and excellent flame retardancy with tolerance of flame up to 1,000 °C. The remarkable properties can be attributed to the smaller fibrous size, and higher grain size resulting from PVP template. This robust material system is ideal for thermal superinsulation with a wide range of uses from energy saving building applications to spacecraft.

Similar content being viewed by others

References

Xu, X.; Zhang, Q. Q.; Hao, M. L.; Hu, Y.; Lin, Z. Y.; Peng, L. L.; Wang, T.; Ren, X. X.; Wang, C.; Zhao, Z. P. et al. Double-negative-index ceramic aerogels for thermal superinsulation. Science 2019, 363, 723–727.

Shin, S.; Wang, Q. Y.; Luo, J.; Chen, R. K. Advanced materials for high-temperature thermal transport. Adv. Funct. Mater. 2020, 30, 1904815.

Cui, Y.; Qin, Z. H.; Wu, H.; Li, M.; Hu, Y. J. Flexible thermal interface based on self-assembled boron arsenide for high-performance thermal management. Nat. Commun. 2021, 12, 1284.

Jia, C.; Li, L.; Liu, Y.; Fang, B.; Ding, H.; Song, J. N.; Liu, Y. B.; **ang, K. J.; Lin, S.; Li, Z. W. et al. Highly compressible and anisotropic lamellar ceramic sponges with superior thermal insulation and acoustic absorption performances. Nat. Commun. 2020, 11, 3732.

Xu, X.; Fu, S. B.; Guo, J. R.; Li, H.; Huang, Y.; Duan, X. F. Elastic ceramic aerogels for thermal superinsulation under extreme conditions. Mater. Today 2021, 42, 162–177.

Zhang, B. J.; Tong, Z. W.; Yu, H. J.; Xu, H.; Chen, Z. W.; Li, X. L.; Ji, H. M. Flexible and high-temperature resistant ZrO2/SiC-based nanofiber membranes for high temperature thermal insulation. J. Alloys Compd. 2021, 872, 159618.

Mao, X.; Bai, Y.; Yu, J. Y.; Ding, B. Flexible and highly temperature resistant polynanocrystalline zirconia nanofibrous membranes designed for air filtration. J. Am. Ceram. Soc. 2016, 99, 2760–2768.

Sumirat, I.; Ando, Y.; Shimamura, S. Theoretical consideration of the effect of porosity on thermal conductivity of porous materials. J. Porous. Mater. 2006, 13, 439–443.

Zhang, K.; Yang, Z.; Mao, X.; Chen, X. L.; Li, H. H.; Wang, Y. Y. Multifunctional textiles/metal-organic frameworks composites for efficient ultraviolet radiation blocking and noise reduction. ACS Appl. Mater. Interfaces 2020, 12, 55316–55323.

Zhang, K.; Huo, Q.; Zhou, Y. Y.; Wang, H. H.; Li, G. P.; Wang Y. W.; Wang Y. Y. Textiles/metal-organic frameworks composites as flexible air filters for efficient particulate matter removal. ACS Appl. Mater. Interfaces 2019, 11, 17368–17374.

Xu, H. J.; **ng, Z. B.; Wang, F. Q.; Cheng, Z. M. Review on heat conduction, heat convection, thermal radiation and phase change heat transfer of nanofluids in porous media: Fundamentals and applications. Chem. Eng. Sci. 2019, 195, 462–483.

Russell, H. W. Principles of heat flow in porous insulators. J. Am. Ceram. Soc. 1935, 18, 1–5.

Mao, X.; Si, Y.; Chen, Y. C.; Yang, L. P.; Zhao, F.; Ding, B.; Yu, J. Y. Silica nanofibrous membranes with robust flexibility and thermal stability for high-efficiency fine particulate filtration. RSC Adv. 2012, 2, 12216–12223.

Yang, L. P.; Raza, A.; Si, Y.; Mao, X.; Shang, Y. W.; Ding, B.; Yu, J. Y.; Al-Deyab, S. S. Synthesis of superhydrophobic silica nanofibrous membranes with robust thermal stability and flexibility via in situ polymerization. Nanoscale 2012, 4, 6581–6587.

Han, W. D.; Cui, F. H.; Si, Y.; Mao, X.; Ding, B.; Kim, H. Self-assembly of perovskite crystals anchored Al2O3-La2O3 nanofibrous membranes with robust flexibility and luminescence. Small 2018, 14, 1801963.

Reddy, K. M.; Guo, J. J.; Shinoda, Y.; Fujita, T.; Hirata, A.; Singh, J. P.; McCauley, J. W.; Chen, M. W. Enhanced mechanical properties of nanocrystalline boron carbide by nanoporosity and interface phases. Nat. Commun. 2012, 3, 1052.

Yan, J. H.; Han, Y. H.; **a, S. H.; Wang, X.; Zhang, Y. Y.; Yu, J. Y.; Ding, B. Polymer template synthesis of flexible BaTiO3 crystal nanofibers. Adv. Funct. Mater. 2019, 29, 1907919.

Gao, Y.; **ang, H. F.; Wang, X. X.; Yan, K.; Liu, Q.; Li, X.; Liu, R. Q.; Yu, M.; Long, Y. Z. A portable solution blow spinning device for minimally invasive surgery hemostasis. Chem. Eng. J. 2020, 387, 124052.

Ellison, C. J.; Phatak, A.; Giles, D. W.; Macosko, C. W.; Bates, F. S. Melt blown nanofibers: Fiber diameter distributions and onset of fiber breakup. Polymer 2007, 48, 3306–3316.

Jang, S. Y.; Seshadri, V.; Khil, M. S.; Kumar, A.; Marquez, M.; Mather, P. T.; Sotzing, G. A. Welded electrochromic conductive polymer nanofibers by electrostatic spinning. Adv. Mater. 2005, 17, 2177–2180.

Guo, F.; Servi, A.; Liu, A. D.; Gleason, K. K.; Rutledge, G. C. Desalination by membrane distillation using electrospun polyamide fiber membranes with surface fluorination by chemical vapor deposition. ACS Appl. Mater. Interfaces 2015, 7, 8225–8232.

Liu, X. F.; Lai, Y. K.; Huang, J. Y.; Al-Deyab, S. S.; Zhang, K. Q. Hierarchical SiO2@Bi2O3 core/shell electrospun fibers for infrared stealth camouflage. J. Mater. Chem. C 2015, 3, 345–351.

Wu, H.; Hu, L. B.; Carney, T.; Ruan, Z. C.; Kong, D. S.; Yu, Z. F.; Yao, Y.; Cha, J. J.; Zhu, J.; Fan, S. H. Low reflectivity and high flexibility of tin-doped indium oxide nanofiber transparent electrodes. J. Am. Chem. Soc. 2011, 133, 27–29.

Li, Z. L.; Joshi, M. K.; Chen, J. X.; Zhang, Z. M.; Li, Z. Q.; Fang, X. S. Mechanically compatible UV photodetectors based on electrospun free-standing Y3+-doped TiO2 nanofibrous membranes with enhanced flexibility. Adv. Funct. Mater. 2020, 30, 2005291.

Song, J.; Wu, X. H.; Zhang, M.; Liu, C.; Yu, J. Y.; Sun, G.; Si, Y.; Ding, B. Highly flexible, core-shell heterostructured, and visible-light-driven titania-based nanofibrous membranes for antibiotic removal and E. coil inactivation. Chem. Eng. J. 2020, 379, 122269.

Wang, Y.; Li, J.; Sun, J. Y.; Wang, Y. B.; Zhao, X. Electrospun flexible self-standing Cu-Al2O3 fibrous membranes as Fenton catalysts for bisphenol A degradation. J. Mater. Chem. A 2017, 5, 19151–19158.

Witz, G.; Shklover, V.; Steurer, W.; Bachegowda, S.; Bossmann, H. P. Phase evolution in yttria-stabilized zirconia thermal barrier coatings studied by rietveld refinement of X-ray powder diffraction patterns. J. Am. Ceram. Soc. 2007, 90, 2935–2940.

Mao, X.; Shan, H. R.; Song, J.; Bai, Y.; Yu, J. Y.; Ding, B. Brittle-flexible-brittle transition in nanocrystalline zirconia nanofibrous membranes. CrystEngComm 2016, 18, 1139–1146.

Patterson, A. L. The Scherrer formula for X-ray particle size determination. Phys. Rev. 1939, 56, 978–982.

Song, J.; Wang, X. Q.; Yan, J. H.; Yu, J. Y.; Sun, G.; Ding, B. Soft Zr-doped TiO2 nanofibrous membranes with enhanced photocatalytic activity for water purification. Sci. Rep. 2017, 7, 1636.

Acknowledgement

This work was supported by the National Natural Science Foundation of China (Program No. 21971207), Natural Science Basic Research Plan in Shaanxi Province of China (Program No. 2019JQ-856), Scientific Research Program Funded by Shaanxi Provincial Education Department (Program No. 18JK0356), Outstanding Young Talents of Shaanxi Universities (2019), Graduate Scientific Innovation Fund for **’an Polytechnic University (Program No. chx2021003).

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Supplementary material, approximately 20.9 MB.

Supplementary material, approximately 1.19 MB.

Supplementary material, approximately 7.72 MB.

Rights and permissions

About this article

Cite this article

Mao, X., Zhao, L., Zhang, K. et al. Highly flexible ceramic nanofibrous membranes for superior thermal insulation and fire retardancy. Nano Res. 15, 2592–2598 (2022). https://doi.org/10.1007/s12274-021-3799-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-021-3799-8