Abstract

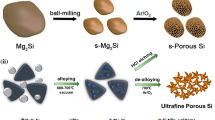

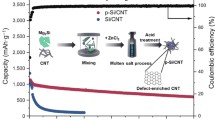

Nanoporous silicon is a promising anode material for high energy density batteries due to its high cycling stability and high tap density compared to other nanostructured anode materials. However, the high cost of synthesis and low yield of nanoporous silicon limit its practical application. Here, we develop a scalable, low-cost top-down process of controlled oxidation of Mg2Si in the air, followed by HCl removal of MgO to generate nanoporous silicon without the use of HF. By controlling the synthesis conditions, the oxygen content, grain size and yield of the porous silicon are simultaneously optimized from commercial standpoints. In situ environmental transmission electron microscopy reveals the reaction mechanism; the Mg2Si microparticle reacts with O2 to form MgO and Si, while preventing SiO2 formation. Owing to the low oxygen content and microscale secondary structure, the nanoporous silicon delivers a higher initial reversible capacity and initial Coulombic efficiency compared to commercial Si nanoparticles (3,033 mAh/g vs. 2,418 mAh/g, 84.3% vs. 73.1%). Synthesis is highly scalable, and a yield of 90.4% is achieved for the porous Si nanostructure with the capability to make an excess of 10 g per batch. Our synthetic nanoporous silicon is promising for practical applications in next generation lithium-ion batteries.

Similar content being viewed by others

References

Aricò, A. S.; Bruce, P.; Scrosati, B.; Tarascon, J. M.; van Schalkwijk, W. Nanostructured materials for advanced energy conversion and storage devices. Nat. Mater. 2005, 4, 366–377.

Armand, M.; Tarascon, J. M. Building better batteries. Nature2008, 451, 652–657.

Liu, Y. Y.; Zhou, G. M.; Liu, K.; Cui. Y. Design of complex nano-materials for energy storage: Past success and future opportunity. Acc. Chem. Res. 2017, 50, 2895–2905.

Sun, Y. M.; Liu, N.; Cui. Y. Promises and challenges of nano-materials for lithium-based rechargeable batteries. Nat. Energy2016, 1, 16071.

Pomerantseva, E.; Bonaccorso, F.; Feng, X. L.; Cui, Y.; Gogotsi, Y. Energy storage: The future enabled by nanomaterials. Science2019, 366, eaan8285.

Chan, C. K.; Peng, H. L.; McIlwrath, K.; Zhang, X. F.; Huggins, R. A.; Cui, Y. High-performance lithium battery anodes using silicon nanowires. Nat. Nanotechnol. 2008, 3, 31–35.

Yang, S. F.; Zavalij, P. Y.; Whittingham. M. S. Anodes for lithium batteries: Tin revisited. Electrochem. Commun. 2003, 5, 587590.

Zheng, G. Y.; Lee, S. W.; Liang, Z.; Lee, H. W.; Yan, K.; Yao, H. B.; Wang, H. T.; Li, W. Y.; Chu, S.; Cui, Y. Interconnected hollow carbon nanospheres for stable lithium metal anodes. Nat. Nanotechnol. 2014, 9, 618–623.

Bruce, P. G.; Freunberger, S. A.; Hardwick, L. J.; Tarascon, J. M. Li-O2 and Li-S batteries with high energy storage. Nat. Mater. 2012, 11, 19–29.

Dunn, B.; Kamath, H.; Tarascon, J. M. Electrical energy storage for the grid: A battery of choices. Science2011, 334, 928–935.

Wang, J. Y.; Tang, H. J.; Zhang, L. J.; Ren, H.; Yu, R. B.; **, Q.; Qi, J.; Mao, D.; Yang, M.; Wang, Y. et al. Multi-shelled metal oxides prepared via an anion-adsorption mechanism for lithium-ion batteries. Nat. Energy2016, 1, 15050.

Wu, H.; Cui. Y. Designing nanostructured Si anodes for high energy lithium ion batteries. Nano Today2012, 7, 414–429.

Wang, J. Y.; Cui, Y.; Wang. D. Design of hollow nanostructures for energy storage, conversion and production. Adv. Mater. 2019, 31, 1801993.

Li, Y. Z.; Yan, K.; Lee, H. W.; Lu, Z. D.; Liu, N.; Cui, Y. Growth of conformal graphene cages on micrometre-sized silicon particles as stable battery anodes. Nat. Energy2016, 1, 15029.

Wang, J. Y.; Liao, L.; Li, Y. Z.; Zhao, J.; Shi, F. F.; Yan, K.; Pei, A.; Chen, G. X.; Li, G. D.; Lu, Z. Y. et al. Shell-protective secondary silicon nanostructures as pressure-resistant high-volumetric-capacity anodes for lithium-ion batteries. Nano Lett. 2018, 18, 7060–7065.

Wang, J. Y.; Liao, L.; Lee, H. R.; Shi, F. F.; Huang, W.; Zhao, J.; Pei, A.; Tang, J.; Zheng, X. L.; Chen, W. et al. Surface-engineered mesoporous silicon microparticles as high-Coulombic-efficiency anodes for lithium-ion batteries. Nano Energy2019, 61, 404–410.

Huang, W.; Wang, J.; Braun, M. R.; Zhang, Z.; Li, Y.; Boyle, D. T.; Mclntyre, P. C.; Cui, Y. Dynamic structure and chemistry of the silicon solid-electrolyte interphase visualized by cryogenic electron microscopy. Matter2019, 1, 1232–1245.

Li, Y. Z.; Huang, W.; Li, Y. B.; Pei, A.; Boyle, D. T.; Cui, Y. Correlating structure and function of battery interphases at atomic resolution using Cryoelectron microscopy. Joule2018, 2, 2167–2177.

Huang, W.; Boyle, D. T.; Li, Y. Z.; Li, Y. B.; Pei, A.; Chen, H.; Cui, Y. Nanostructural and electrochemical evolution of the solid-electrolyte interphase on CuO nanowires revealed by cryogenic-electron microscopy and impedance spectroscopy. ACS Nano2019, 13, 737–744.

Li, Y. Z.; Li, Y. B.; Cui, Y. Catalyst: How Cryo-EM shapes the development of next-generation batteries. Chem2018, 4, 2250–2256.

Liu, N.; Wu, H.; McDowell, M. T.; Yao, Y.; Wang, C. M.; Cui, Y. A yolk-shell design for stabilized and scalable Li-ion battery alloy anodes. Nano Lett. 2012, 12, 3315–3321.

Zhou, Y. L.; Jiang, X. L.; Chen, L.; Yue, J.; Xu, H. Y.; Yang, J.; Qian, Y. T. Novel mesoporous silicon nanorod as an anode material for lithium ion batteries. Electrochim. Acta2014, 127, 252–258.

Soleimani-Amiri, S.; Tali, S. A. S.; Azimi, S.; Sanaee, Z.; Mohajerzadeh, S. Highly featured amorphous silicon nanorod arrays for high-performance lithium-ion batteries. Appl. Phys. Lett. 2014, 105, 193903.

Cui, L. F.; Ruo, R.; Chan, C. K.; Peng, H. L.; Cui, Y. Crystalline-amorphous core-shell silicon nanowires for high capacity and high current battery electrodes. Nano Lett. 2009, 9, 491–495.

**ao, Y.; Hao, D.; Chen, H. X.; Gong, Z. L.; Yang, Y. Economical synthesis and promotion of the electrochemical performance of silicon nanowires as anode material in Li-ion batteries. ACS Appl. Mater. Interfaces2013, 5, 1681–1687.

Park, M. H.; Kim, M. G.; Joo, J.; Kim, K.; Kim, J.; Ahn, S.; Cui, Y.; Choi, J. Silicon nanotube battery anodes. Nano Lett. 2009, 9, 3844–3847.

Wu, H.; Chan, G.; Choi, J. W.; Ryu, I.; Yao, Y.; McDowell, M. T.; Lee, S. W.; Jackson, A.; Yang, Y.; Hu, L. B. et al. Stable cycling of double-walled Si nanotube battery anodes through solid-electrolyte interphase control. Nat. Nanotechnol. 2012, 7, 310–315.

Ryu, J.; Hong, D.; Choi, S.; Park, S. Synthesis of ultrathin Si nanosheets from natural clays for lithium-ion battery anodes. ACS Nano2016, 10, 2843–2851.

Kim, W. S.; Hwa, Y.; Shin, J. H.; Yang, M.; Sohn, H. J.; Hong, S. H. Scalable synthesis of silicon nanosheets from sand as an anode for Li-ion batteries. Nanoscale2014, 6, 4297–4302.

Liu, N.; Lu, Z. D.; Zhao, J.; McDowell, M. T.; Lee, H. W.; Zhao, W. T.; Cui, Y. A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat. Nanotechnol. 2014, 9, 187–192.

Yi, R.; Dai, F.; Gordin, M. L.; Chen, S. R.; Wang, D. H. Micro-sized Si-C composite with interconnected nanoscale building blocks as high-performance anodes for practical application in lithium-ion batteries. Adv. Energy Mater. 2013, 3, 295–300.

Kim, H.; Han, B.; Choo, J.; Cho. J. Three-dimensional porous silicon particles for use in high-performance lithium secondary batteries. Angew. Chem., Int. Ed. 2008, 47, 10151.

Ren, W. F.; Wang, Y. H.; Zhang, Z. L.; Tan, Q. Q.; Zhong, Z. Y.; Su, F. B. Carbon-coated porous silicon composites as high performance Li-ion battery anode materials: Can the production process be cheaper and greener. J. Mater. Chem. A2016, 4, 552–560.

Liu, N.; Huo, K. F.; McDowell, M. T.; Zhao, J.; Cui. Y. Rice husks as a sustainable source of nanostructured silicon for high performance Li-ion battery anodes. Sci. Rep. 2013, 3, 1919.

Liang, J. W.; Wei, D. H.; Lin, N.; Zhu, Y. C.; Li, X. N.; Zhang, J. J.; Fan, L.; Qian, Y. T. Low temperature chemical reduction of fusional sodium metasilicate nonahydrate into a honeycomb porous silicon nanostructure. Chem. Commun. 2014, 50, 6856–6859.

Ge, M. Y.; Lu, Y. H.; Ercius, P.; Rong, J. P.; Fang, X.; Mecklenburg, M.; Zhou, C. W. Large-scale fabrication, 3D tomography, and lithium-ion battery application of porous silicon. Nano Lett. 2014, 14, 261–268.

Liang, J. W.; Li, X. N.; Hou, Z. G.; Guo, C.; Zhu, Y. C.; Qian, Y. T. Nanoporous silicon prepared through air-oxidation demagnesiation of Mg2Si and properties of its lithium ion batteries. Chem. Commun. 2015, 51, 7230–7233.

Chen, M.; Li, B.; Liu, X. J.; Zhou, L.; Yao, L.; Zai, J. T.; Qian, X. F.; Yu, X. B. Boron-doped porous Si anode materials with high initial Coulombic efficiency and long cycling stability. J. Mater. Chem. A2018, 6, 3022–3027.

Chen, W.; Fan, Z. L.; Dhanabalan, A.; Chen, C. H.; Wang, C. L. Mesoporous silicon anodes prepared by Magnesiothermic reduction for lithium ion batteries. J. Electrochem. Soc. 2011, 158, A1055–A1059.

Chun, J. Y.; An, S.; Lee, J. Highly mesoporous silicon derived from waste iron slag for high performance lithium ion battery anodes. J. Mater. Chem. A2015, 3, 21899–21906.

Ruffo, R.; Hong, S. S.; Chan, C. K.; Huggins, R. A.; Cui. Y. Impedance analysis of silicon nanowire lithium ion battery anodes. J. Phys. Chem. C2009, 113, 11390–11398.

Gauthier, M.; Mazouzi, D.; Reyter, D.; Lestriez, B.; Moreau, P.; Guyomard, D.; Roue, L. A low-cost and high performance ball-milled Si-based negative electrode for high-energy Li-ion batteries. Energy Environ. Sci. 2013, 6, 2145–2155.

Lin, D. C.; Lu, Z. D.; Hsu, P. C.; Lee, H. R.; Liu, N.; Zhao, J.; Wang, H. T.; Liu, C.; Cui, Y. A high tap density secondary silicon particle anode fabricated by scalable mechanical pressing for lithium-ion batteries. Energy Environ. Sci. 2015, 8, 2371–2376.

Acknowledgements

This work was supported by Samsung SDI. Part of this work was performed at the Stanford Nano Shared Facilities (SNSF) and Stanford Nanofabrication Facility (SNF).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Huang, W., Kim, Y.S. et al. Scalable synthesis of nanoporous silicon microparticles for highly cyclable lithium-ion batteries. Nano Res. 13, 1558–1563 (2020). https://doi.org/10.1007/s12274-020-2770-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-020-2770-4