Abstract

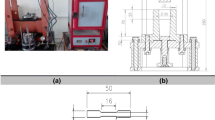

This paper reports a research in which an attempt was made to prepare AC2A aluminium alloy castings of a non symmetrical component through squeeze casting process. The primary objective was to investigate the influence of process parameters on mechanical properties of the castings. Experiments were conducted based on orthogonal array suggested in Taguchi’s offline quality control concept. The experimental results showed that squeeze pressure, die preheating temperature and compression holding time were the parameters making significant improvement in mechanical properties. The optimal squeeze casting condition was found and mathematical models were also developed for the process.

Similar content being viewed by others

References

T. M. Yue and G. A. Chadwick, Squeeze casting of light alloys and their composites, J. Mater. Process. Technol., 58 (1996) 302–307.

T. M. Yue, Squeeze casting of high strength aluminium wrought alloy AA7010, J. Mater. Process. Technol., 66 (1997) 179–185.

S. W. Kim, G. Durrant, J. H. Lee and B. Cantor, The microstructure of squeeze cast and gravity die cast 7050 wrought Al alloy, J. Mater. Synth. Process, 6(2) (1998) 75–87.

M. R. Ghomashchi and A. Vikhrov, Squeeze casting: an overview, J. Mater. Process. Technol., 101 (2000) 1–9.

M. S. Yong and A. J. Clegg, Process optimization for a squeeze cast magnesium alloy, J. Mater. Process. Technol., 145 (2004) 134–141.

P. Vijian and V. P. Arunachalam, Experimental study of squeeze casting of gunmetal, J. Mater. Process. Technol., 170 (2005) 32–36.

P. Vijian and V. P. Arunachalam, Optimization of squeeze cast parameters of LM6 aluminium alloy for surface roughness using Taguchi method, J. Mater. Process. Technol., 18 (2006) 161–166.

A. Maleki, B. Niroumand and A. Shafyei, Effects of squeeze casting parameters on density, macrostructure and hardness of LM13 alloy, Mater. Sci. Eng. A428 (2006) 135–140.

P. Vijian and V. P. Arunachalam, Modelling and multi objective optimization of LM24 aluminium alloy squeeze cast process parameters using genetic algorithm, J. Mater. Process. Technol. 186 (2007) 82–86.

P. Vijian and V. P. Arunachalam, Optimization of squeeze casting process parameters using Taguchi analysis, Int. J. Adv. Manuf. Technol. 30 (2006) 1122–1127.

M. T. Abou El-khair, Microstructure characterization and tensile properties of squeeze cast AlSiMg alloys, Mater. Lett. 59 (2005) 894–900.

ZHANG Ming, ZHANG Wei-wen, ZHAO Hai-dong, ZHANG Da-tong and LI Yuan-yuan, Effect of pressure on microstructures and mechanical properties of Al-Cu-based alloy prepared by squeeze casting, Trans. Nonferrous Met. Soc. China, 17 (2007) 496–501.

C. H. Fan, Z. H. Chen, W. Q. He, J. H. Chen and D. Chen, Effects of the casting temperature on microstructure and mechanical properties of the squeeze cast Al-Zn-Mg-Cu alloy, J. Alloys and compounds, 504 (2010) L42–L45.

K. Sukumaran, K. K. Ravikumar, S. G. K Pillai, T. P. D Rajan, M. Ravi, R. M. Pillai and B. C. Pai, Studies on squeeze casting of Al 2124 alloy and 2124-10% SiCp metal matrix composite, Mater. Sci. Eng. A 490 (2008) 235–241.

N. Belavendram, Quality by design, Prentice Hall, Singapore (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Dae-Eun Kim Editor Mohammad Abdul Aziz

P. Senthil received his B.E degree in Mechanical Engineering and M.E degree in Production Engineering from Bharathiar University, India in 1998 and 2002 respectively. He is currently an Assistant Professor at the Department of Mechanical Engineering, Coimbatore Institute of Engineering and Technology, Coimbatore, India.

K. S. Amirthagadeswaran received his B.E degree in Mechanical Engineering from Madras University, India in 1980 and M.E degree in Production Engineering from Bharathiar University, India in 1988. He then received his Ph.D degree from Bharathiar University, Coimbatore, India in 2007. He is currently a Professor at the Department of Mechanical Engineering, Government College of Technology, Coimbatore, India. His publications are over 25 in different journals and conferences. His current research interests include Scheduling, Cellular Manufacturing Systems, Non-traditional Optimization Algorithms, Robotics, Squeeze Casting and Electro Discharge Machining.

Rights and permissions

About this article

Cite this article

Senthil, P., Amirthagadeswaran, K.S. Optimization of squeeze casting parameters for non symmetrical AC2A aluminium alloy castings through Taguchi method. J Mech Sci Technol 26, 1141–1147 (2012). https://doi.org/10.1007/s12206-012-0215-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-012-0215-z